A kind of anti-graffiti surface treatment liquid and preparation method thereof

A surface treatment liquid and anti-graffiti technology, applied in antifouling/underwater coatings, coatings, polyurea/polyurethane coatings, etc., can solve problems such as difficult cleaning, single surface feel, low production efficiency, etc., and achieve good weather resistance and durability, shortening of operation time, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

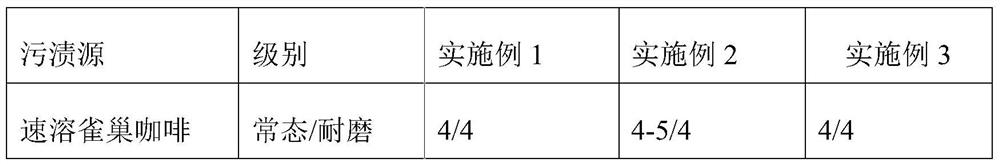

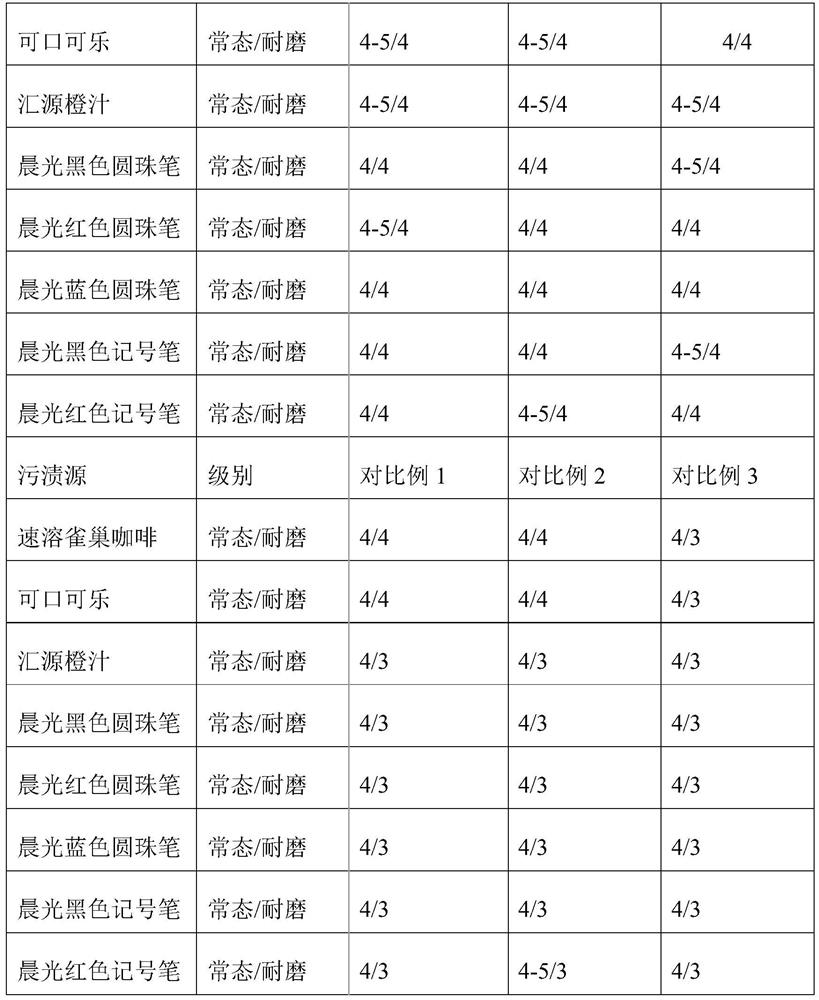

Embodiment 1

[0035] An anti-graffiti surface treatment liquid is prepared from the following components in parts by weight: 5 parts of polytetrafluoroethylene, 80 parts of water-based aliphatic polyurethane, 15 parts of water-based styrene-acrylic emulsion, and 15 parts of water-based chlorinated vinegar emulsion , 1 part of silane coupling agent, 5 parts of carbodiimide, 1 part of leveling agent, 1 part of defoamer, 1 part of thickener and 5 parts of polymethylmethacrylate urea resin.

[0036] The method for preparing the anti-graffiti surface treatment liquid comprises the following steps:

[0037] 1) The polytetrafluoroethylene powder is cleaned by vacuum plasma; the wetting angle after vacuum plasma treatment is 15.5°-25°;

[0038] 2) Mix the polytetrafluoroethylene powder treated in step 1) with a silane coupling agent, heat to 60°C, and react for 4 hours;

[0039] 3) adding water-based aliphatic polyurethane, water-based styrene-acrylic emulsion and water-based chloro-vinyl acetate ...

Embodiment 2

[0043] An anti-graffiti surface treatment liquid is prepared from the following components in parts by weight: 10 parts of polytetrafluoroethylene, 100 parts of water-based aliphatic polyurethane, 20 parts of water-based styrene-acrylic emulsion, and 20 parts of water-based chloro-vinyl acetate emulsion , 1.2 parts of silane coupling agent, 6 parts of carbodiimide, 1.2 parts of leveling agent, 1.2 parts of defoamer, 1.2 parts of thickener and 5 parts of polymethylmethacrylate urea resin.

[0044] The method for preparing the anti-graffiti surface treatment liquid comprises the following steps:

[0045] 1) The polytetrafluoroethylene powder is cleaned by vacuum plasma; the wetting angle after vacuum plasma treatment is 15.5°-25°;

[0046] 2) Mix the polytetrafluoroethylene powder treated in step 1) with a silane coupling agent, heat to 80°C, and react for 2 hours;

[0047] 3) adding water-based aliphatic polyurethane, water-based styrene-acrylic emulsion and water-based chloro...

Embodiment 3

[0051] An anti-graffiti surface treatment liquid is prepared from the following components in parts by weight: 15 parts of polytetrafluoroethylene, 120 parts of water-based aliphatic polyurethane, 25 parts of water-based styrene-acrylic emulsion, and 25 parts of water-based chlorinated vinegar emulsion , 1.5 parts of silane coupling agent, 6 parts of carbodiimide, 1.5 parts of leveling agent, 1.5 parts of defoamer, 1.5 parts of thickener and 5 parts of polymethyl methacrylate urea resin.

[0052] The method for preparing the anti-graffiti surface treatment liquid comprises the following steps:

[0053] 1) The polytetrafluoroethylene powder is cleaned by vacuum plasma; the wetting angle after vacuum plasma treatment is 15.5°-25°;

[0054] 2) Mix the polytetrafluoroethylene powder treated in step 1) with a silane coupling agent, heat to 100°C, and react for 0.5h;

[0055] 3) adding water-based aliphatic polyurethane, water-based styrene-acrylic emulsion and water-based chloro-v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com