Underframe equipment hanging support capable of preventing falling and looseness as well as hanging structure

An underframe and equipment technology, applied in the underframe, railway car body parts, transportation and packaging, etc., can solve the problems of equipment without anti-off protection, potential safety hazards, and weakened ability to withstand longitudinal impact, so as to solve the problem of anti-off Loose and impact resistance problems, avoiding the fall of the bottom frame equipment, and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the drawings and specific preferred embodiments.

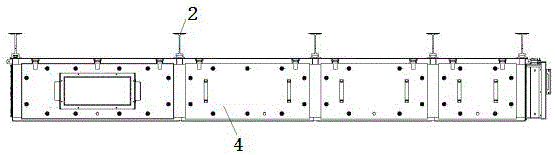

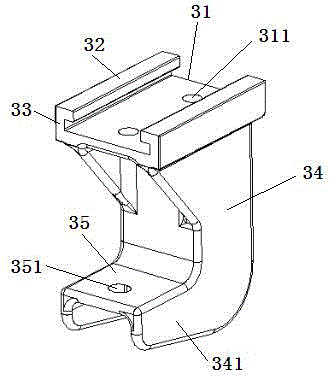

[0047] Such as Figure 2 to Figure 8 As shown, an underframe equipment suspension support capable of preventing detachment and loosening is hung on the underframe of a rail transit vehicle for installation of underframe equipment 4.

[0048] Such as Figure 4 with Figure 8 As shown, the underframe includes two underframe side beams 1 and a plurality of underframe beams 2, and the underframe beams are all fixed and arranged in parallel between the two underframe side beams.

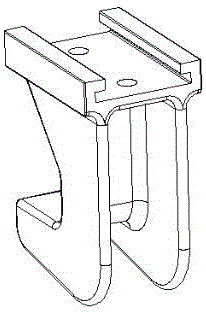

[0049] A suspension frame 21 is fixedly arranged at the bottom of each underframe beam, and each suspension frame includes a central chute 22, two C-shaped groove cutouts 23 and two C-shaped groove cutouts 24.

[0050] The central chute is arranged at the center line of the suspension frame and is parallel to the underframe beam.

[0051] Two C-shaped groove cuts are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com