Cold resistant polyvinyl chloride cable material and preparation method thereof

A polyvinyl chloride cable and polychlorotrifluoroethylene technology, which is applied in the field of polyvinyl chloride cable material and its preparation, can solve the problems of limited application, poor cold resistance and low temperature impact performance, and solve the problems of poor cold resistance and good impact resistance. , the effect of excellent cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

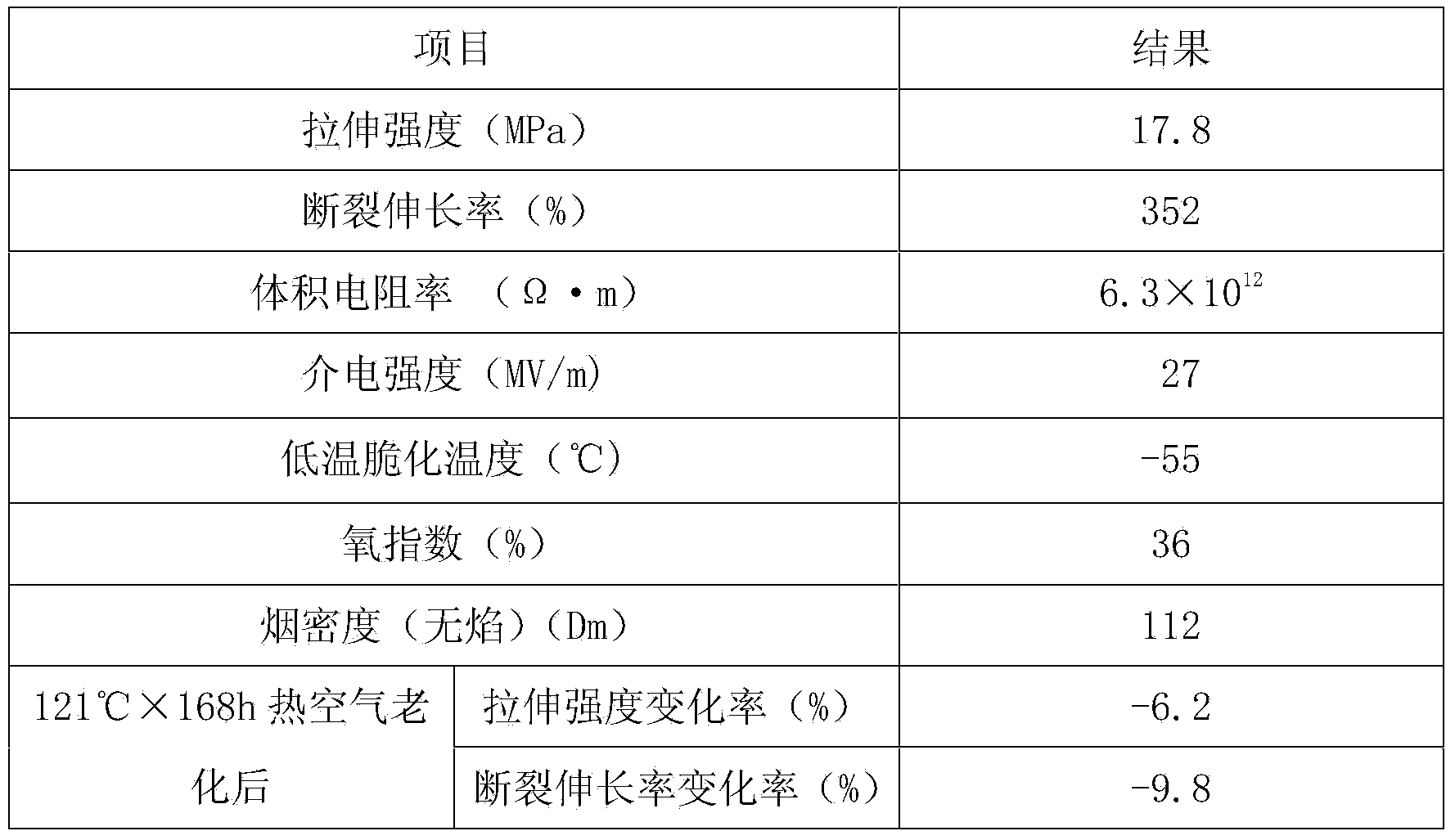

[0012] A kind of cold-resistant polyvinyl chloride cable material, made of the following raw materials in weight (kg): SG-3 type PVC resin 80, fluorosilicone rubber 20, polychlorotrifluoroethylene 10, dioctyl sebacate 20, o-phthalic acid Dibutyl Diformate 12, Tribasic Lead Sulfate 2, Dibasic Lead Phosphite 2, Bisphenol A 0.8, Nano Kaolin 8, Fumed Silica 12, Nano Potassium Feldspar Powder 10, Zinc Oxide 1.5, Stearic Acid Calcium 0.8, barium stearate 1.5, liquid paraffin 3, ammonium polyphosphate 14, barium metaborate 8, composite filler 5;

[0013] The preparation method of described composite filler is as follows: a. get the raw material of following weight (kg): bentonite 8, coal gangue 6, glass microsphere 4, jade powder 3, liquid coumarone resin 10, pentaerythritol stearate 1.5, N-2-(aminoethyl)-3-aminopropyltrimethoxysilane 2, nano-boron nitride 4, magnetic powder 2, antioxidant 10101; b, calcining bentonite and coal gangue at 550°C for 3h, crushing Finally, add appropria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com