Protective glass for LED street lamp and manufacturing method of protective glass

A technology of LED street lamps and protective glass, which is applied in the field of LED lighting, can solve the problems of reduced tempering effect, high heat, dead lights, etc., and achieve the effect of solving impact resistance and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

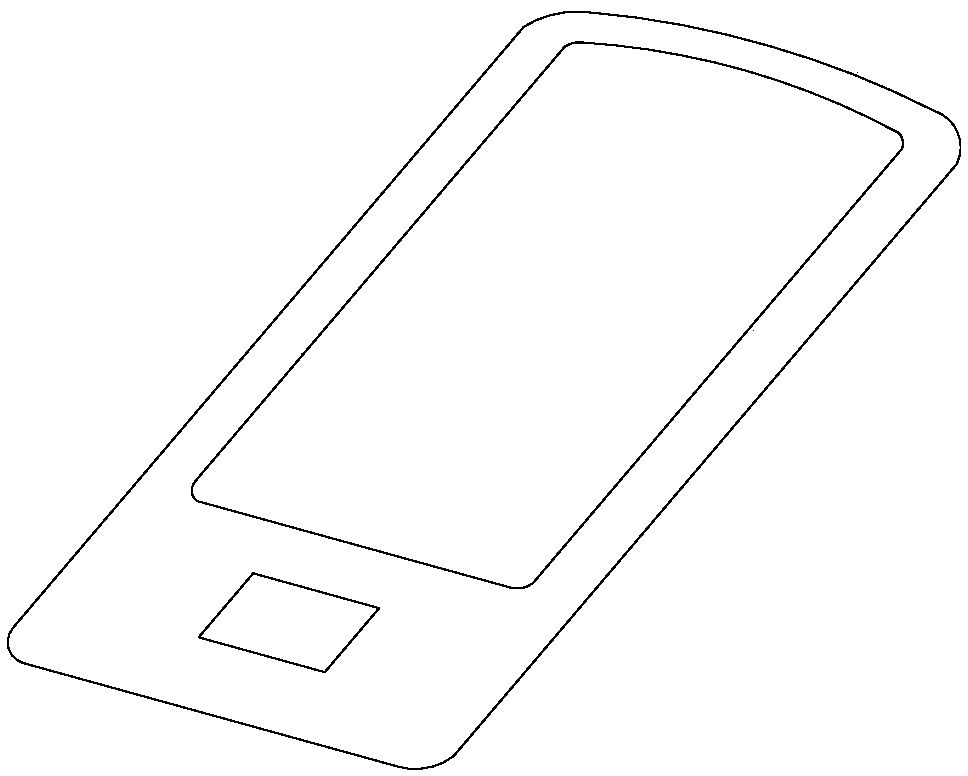

[0040] see Figure 1 to Figure 7 , a kind of manufacture method of protective glass of LED street lamp, the step following operation:

[0041] Process 1: Select glass: take a glass body with a thickness of 3mm (such as figure 1 ).

[0042] Process 2: Cutting the outline: use CNC water jet cutting to process the basic glass panel (such as figure 2 ).

[0043] Step 3: Grinding: Grinding the basic glass panel processed in Step 2, and wiping the surface with alcohol to ensure that it is free of impurities, clean, and has no corners or burrs on the edges.

[0044] Process 4: Cleaning: After the glass is polished, there will be water stains and glass residues attached to the glass, which should be cleaned manually, that is, with a hand-held brush with a water brush, and then rinsed with a glass cleaner.

[0045] Step 5: Dry the cleaned glass.

[0046] Process 6: Full tempering treatment: In order to improve the strength of the glass, compressive stress is formed on the glass s...

Embodiment 2

[0057] see Figure 1 to Figure 7 , a kind of manufacture method of protective glass of LED street lamp, the step following operation:

[0058] Operation 1: take a glass body with a thickness of 4mm (such as figure 1 ).

[0059] Process 2: CNC water jet cutting is used to process the basic glass panel (such as figure 2 ).

[0060] Step 3: Grind the basic glass panel processed in Step 2, and use alcohol to wipe the surface, free of impurities, clean, with no corners or burrs on the edges.

[0061] Process 4: After the glass is polished, there will be water stains and glass residues attached to the glass, which should be cleaned by hand, that is, with a hand-held brush and a water brush, and then rinsed with a small amount of ethanol.

[0062] Step 5: Dry the cleaned glass: place it in an oven for 30 minutes at 40°C.

[0063] Process 6: Full tempering treatment: In order to improve the strength of the glass, compressive stress is formed on the glass surface. When the glass ...

Embodiment 3

[0074] see Figure 1 to Figure 7 , a kind of manufacture method of protective glass of LED street lamp, the step following operation:

[0075] Operation 1: take a glass body with a thickness of 6mm (such as figure 1 ).

[0076] Process 2: CNC water jet cutting is used to process the basic glass panel (such as figure 2 ).

[0077] Step 3: Grind the basic glass panel processed in Step 2, and use alcohol to wipe the surface, free of impurities, clean, with no corners or burrs on the edges.

[0078] Process 4: After the glass is polished, there will be water stains and glass residues attached to the glass, machine cleaning, the machine is vertical, suitable for glass deep processing batch glass cleaning.

[0079] Step 5: Dry the cleaned glass: place it in an oven for drying at 100°C for 5 minutes.

[0080] Process 6: Full tempering treatment: In order to improve the strength of the glass, compressive stress is formed on the glass surface. When the glass is subjected to exter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com