Transparent-aerogel vacuum glass and manufacturing method thereof

A technology of vacuum glass and manufacturing method, applied in parallel glass structure, adhesive, climate change adaptation and other directions, can solve the problems of easy breakage, decreased thermal insulation performance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

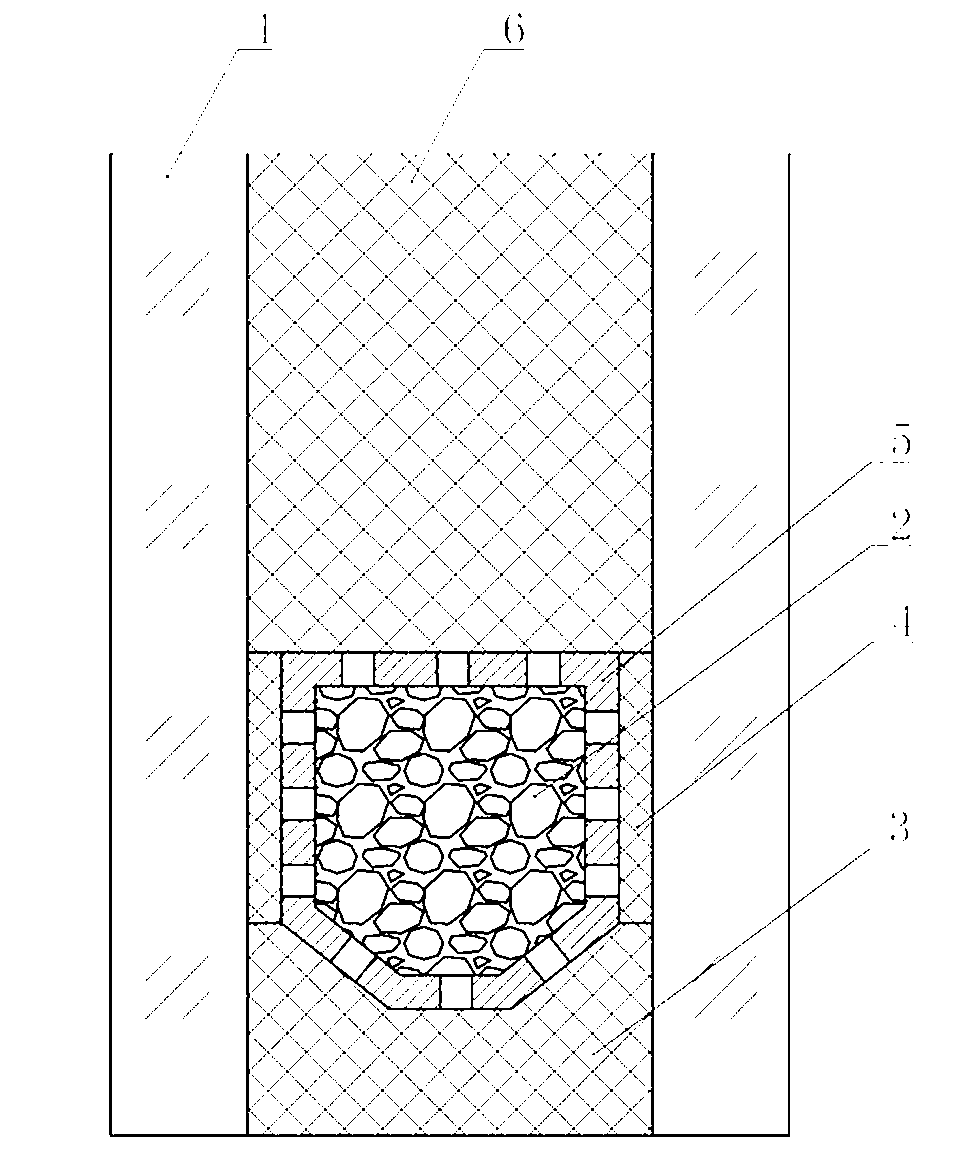

[0017] see figure 1 , a transparent airgel glass of the present invention, comprising a glass plate 1, a desiccant aluminum strip (composed of an aluminum groove spacer frame 5 and a desiccant 2 loaded into its cavity, which is the prior art) and a sealing rubber ring 3 , a desiccant aluminum strip is arranged in the periphery between the two glass plates 1, and the outer side of the desiccant aluminum strip is sealed with a sealing rubber ring 3, and a hollow interlayer is formed between the two glass plates 1, and a transparent interlayer is installed in the hollow interlayer. Airgel 6 and evacuated.

[0018] The manufacturing method of transparent airgel glass of the present invention comprises the following steps:

[0019] 1. Select two glass plates 1. The glass plates 1 include ordinary float glass, laminated glass and solar control glass. The distance between the two glass plates 1 is 5-20mm.

[0020] 2. Cut the transparent airgel 6 into a thickness suitable for fillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com