Method for producing methane as clean energy source by utilizing catering organic waste

An organic waste, clean energy technology, applied in waste fuel, biological sludge treatment, fermentation and other directions, to achieve the effect of less heat supply, thorough sterilization, and large biological gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

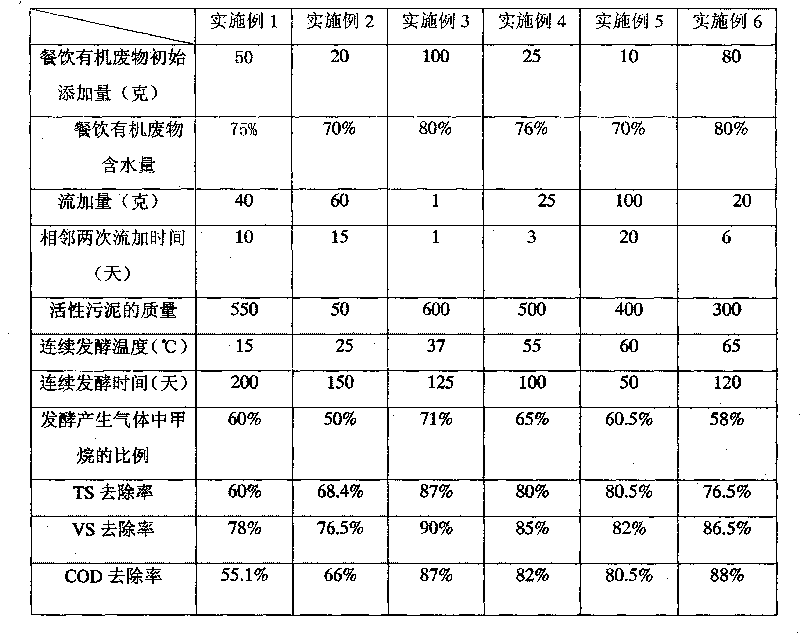

Embodiment 1

[0041] The reaction was carried out using a 1 L reactor. Take 50 grams of starch-based catering organic waste with a water content of 75%, add 550 grams of the above-mentioned domesticated activated sludge, add water to 800 mL, control the temperature at 15 degrees Celsius, and carry out fermentation. The reaction is carried out continuously, and the anaerobic state is strictly controlled throughout the process to facilitate the growth of anaerobic microorganisms. Raw materials were added by flow addition, and 40 grams of starch-based catering organic waste was added every 10 days. Continuous fermentation for 200 days, the average daily gas production during the fermentation process was 400mL, the methane content in the produced gas was 60%, the removal rate of TS was 60%, the removal rate of VS was 78%, and the removal rate of COD was 55.1%.

[0042] The invention directly mixes domesticated sludge with raw materials and water during anaerobic fermentation for the preparatio...

Embodiment 2

[0044] Embodiment 2: utilize 1L reactor to carry out reaction. Take 20 grams of cellulose-based catering organic waste with a water content of 70%, add 50 grams of domesticated activated sludge, add water to 800 mL, control the temperature at 20 degrees Celsius, and carry out fermentation. The reaction is carried out continuously, and the anaerobic state is strictly controlled throughout the process to facilitate the growth of anaerobic microorganisms. Raw materials were added by flow addition method, and 25 grams of cellulose-based catering organic waste was added every 15 days. Continuous fermentation for 150 days, the average daily gas production during the fermentation process was 500mL, the methane content in the produced gas was 65%, the removal rate of TS was 68.4%, the removal rate of VS was 76%, and the removal rate of COD was 66%.

Embodiment 3

[0045] Embodiment 3: use 1L reactor to carry out reaction. Take 100 grams of catering organic waste mainly composed of oil, with a water content of 80%, add 600 grams of domesticated activated sludge, add water to 800ml, control the temperature at 37 degrees Celsius, and carry out fermentation. The reaction is carried out continuously, and the anaerobic state is strictly controlled throughout the process to facilitate the growth of anaerobic microorganisms. Raw materials were added by flow addition, and 1 gram of catering organic waste, mainly oil, was added every other day. Continuous fermentation for 125 days, the average daily gas production during the fermentation process was 750mL, the methane content in the produced gas was 71%, the removal rate of TS was 87%, the removal rate of VS was 90%, and the removal rate of COD was 87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com