High-strength low-heat-conductivity grade A noninflammable aerogel foam and preparation and application thereof

A technology with low thermal conductivity and high strength, which is applied in applications, other household appliances, and household appliances. It can solve problems such as changes in mechanical properties and thermal conductivity, moisture absorption of airgel materials, etc., and achieve material density reduction, strength improvement, and excellent performance. Environmental Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

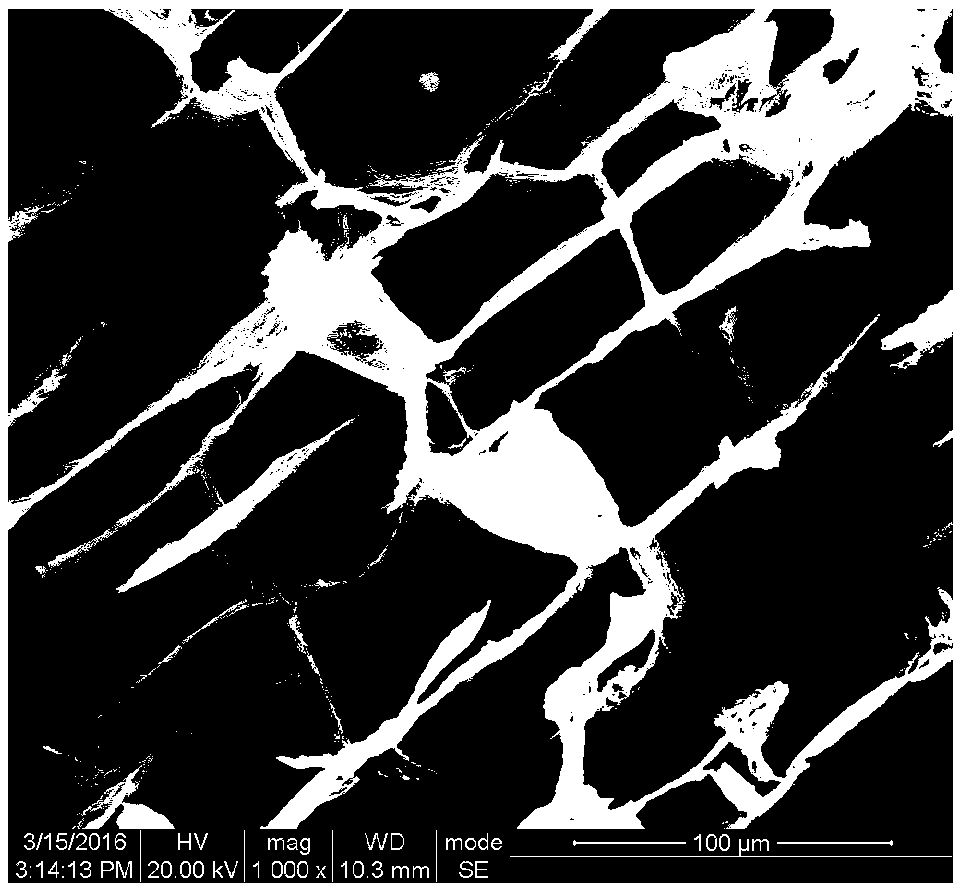

Image

Examples

Embodiment 1

[0053] Add 3 parts of montmorillonite to 100 parts of water, stir evenly and add 0.4 parts of modified cationic pullulan. After the dispersion is fully gelled, place it in an environment of -150 ~ -200 ° C to freeze until it is solid, and then in Fully dry in 0.1Pa atmospheric pressure environment, -50℃~25℃ environment for 72~168h. Subsequent surface modification was performed by chemical vapor deposition using trichloromethylsilane for 12 h.

[0054] Table 1 shows the performance test results of high charcoal-forming A-grade non-combustible gel materials.

Embodiment 2

[0056] Add 3 parts of montmorillonite to 100 parts of water, stir evenly and add 0.6 parts of modified cationic pullulan. After the dispersion is fully gelled, place it in the environment of -150 ~ -200 ° C to freeze until it is solid, and then in Fully dry in 0.1Pa atmospheric pressure environment, -50℃~25℃ environment for 72~168h. Subsequent surface modification was performed by chemical vapor deposition using trichloromethylsilane for 12 h.

[0057] Table 1 shows the performance test results of high charcoal-forming A-grade non-combustible gel materials.

Embodiment 3

[0059] Add 3 parts of montmorillonite to 100 parts of water, stir evenly and add 0.8 parts of modified cationic pullulan. After the dispersion is fully gelled, place it in an environment of -150 ~ -200 ° C to freeze until it is solid, and then in Fully dry in 0.1Pa atmospheric pressure environment, -50℃~25℃ environment for 72~168h. Subsequent surface modification was performed by chemical vapor deposition using trichloromethylsilane for 12 h.

[0060] Table 1 shows the performance test results of high charcoal-forming A-grade non-combustible gel materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com