Composite self-heat-insulation concrete hollow building block and production method thereof

A hollow block and concrete technology, which is applied in the field of concrete blocks, can solve problems such as unsatisfactory thermal insulation performance, and achieve good self-thermal insulation performance, improved earthquake resistance, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

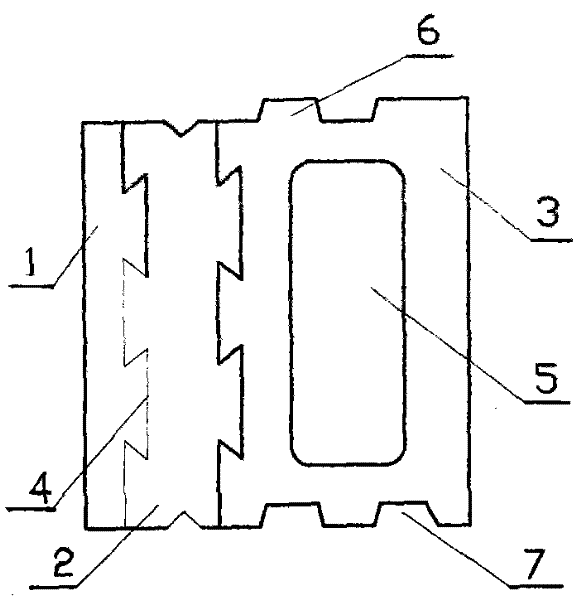

[0024] Example 1 as figure 1 The composite self-insulating concrete hollow block is composed of an inner part 1, an insulating part 2 and an outer part 3. The inner part 1 and the outer part 3 are made of fly ash as the main raw material, cement, water-quenched slag and water are added. The material of the heat preservation part 2 is polystyrene resin; the inner part 1 and the outer part 3 clamp the heat preservation part 2 through two pairs of dovetail grooves 4, so that the inner part 1, the heat preservation part 2 and the outer part 3 are tightly combined; The center of the outer part 3 has a rectangular opening 5 with rounded corners on the front; two protruding lock heads 6 and two recessed lock grooves 7 are respectively provided at both ends of the outer part 3 . A V-shaped groove is respectively arranged at both ends of the thermal insulation part 3 .

[0025] The external dimension of this block is 394mm * 194mm * 200mm. After inspection, its density is 765kg / m 3 ...

Embodiment 2

[0027] Embodiment 2 produces composite self-insulating concrete hollow block according to the following steps:

[0028] ①Put the expandable granules into the foaming cylinder and foam them with steam until the pressure reaches 1800kPa, and then pass the obtained granules into a foam block through a molding machine for later use;

[0029] ② fully mix fly ash, cement, water-quenched slag and water according to the mass ratio of 20:14:76:170, stir evenly, and prepare the obtained slurry for later use; Sorted raw ash; the cement is Portland cement labeled P.C32.5; the water-quenched slag is mainly calcium silicate and calcium aluminosilicate produced during blast furnace smelting pig iron. Molten material, material that is granulated by water quenching;

[0030] ③ Add the above-mentioned mixture into the molding machine, and form it through molding vibration, and the vibration acceleration is 15g; before the masonry is formed, insert the insulation layer with dovetail groove stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| shear load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com