Energy-saving, environment-friendly, broken-bridge and heat-insulating aluminum alloy doors and windows

A technology for energy saving, environmental protection, and heat insulation by breaking bridges. It is applied to windows/doors, parallel glass structures, building components, etc. It can solve problems such as easy formation of convection, poor sealing performance of doors and windows, and water leakage, and achieve overall aesthetic and sound insulation effects. good, waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

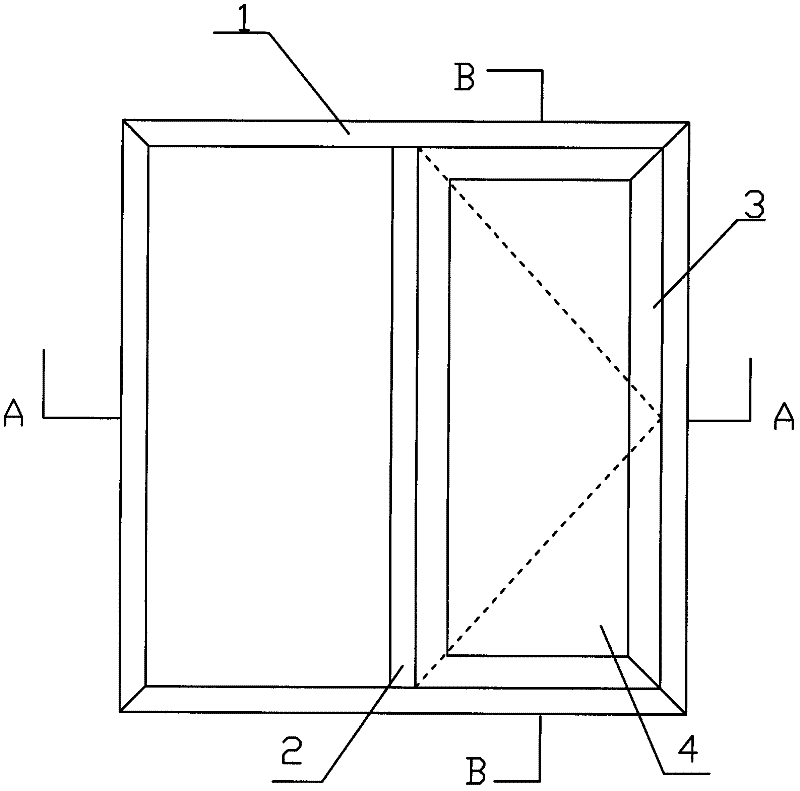

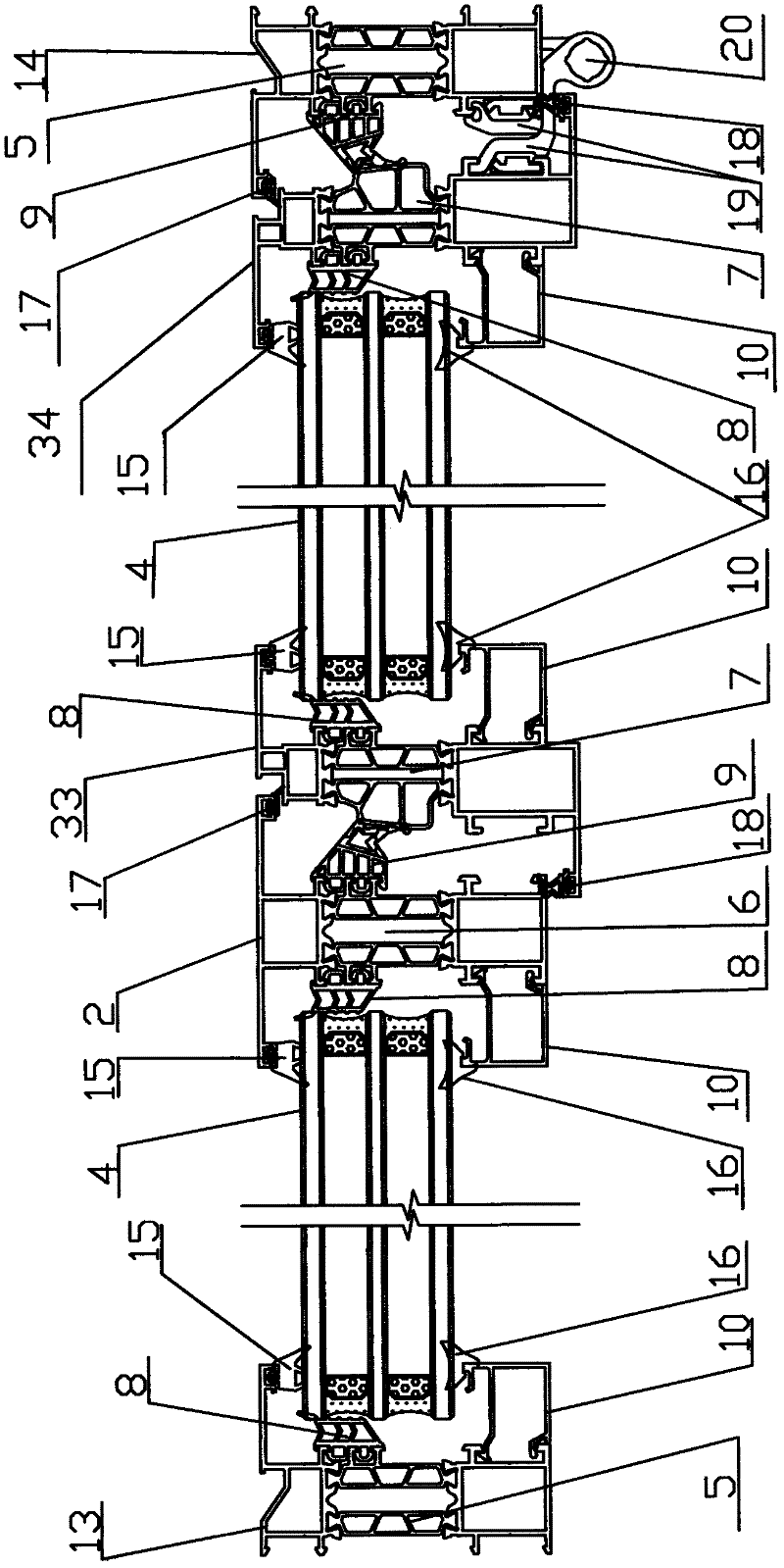

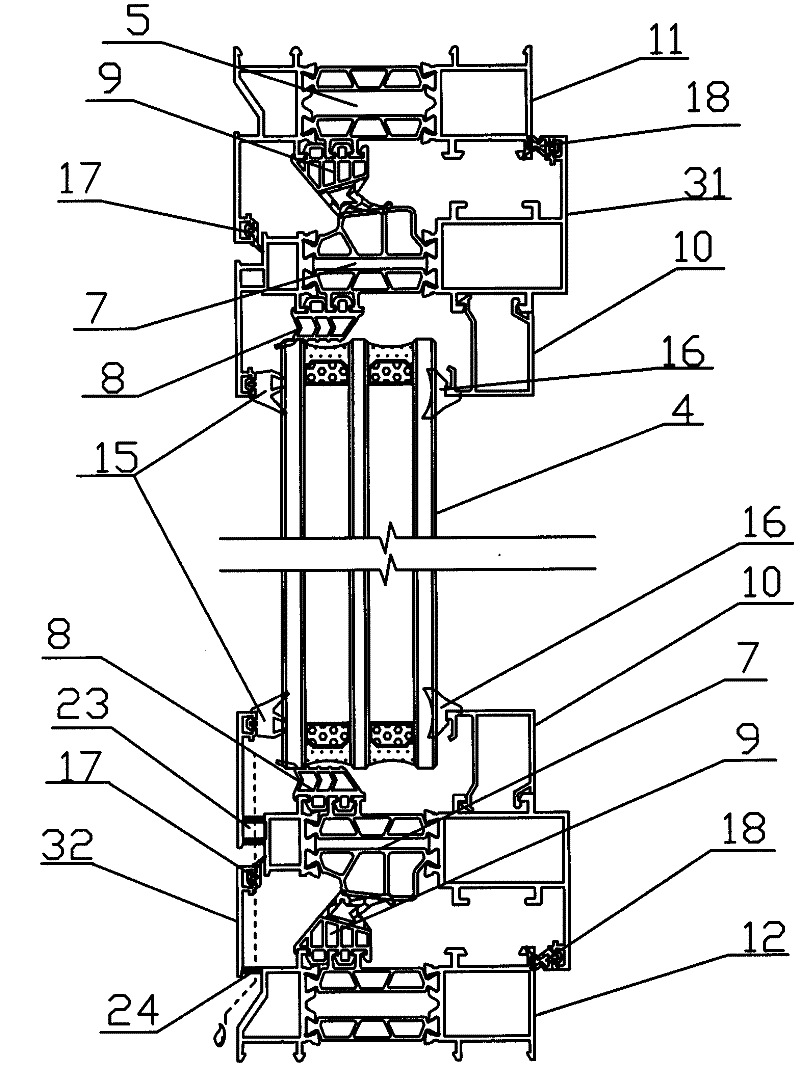

[0014] Such as figure 1 , figure 2 , image 3 and Figure 4 Shown, present embodiment is made up of a fixed fan and an opening fan. It includes a frame 1, a stile 2, a fan frame 3 and an insulating glass 4, and the insulating glass 4 is triple-glass double insulating glass. The insulating glass 4 is fixed between the upper frame 11, the lower frame 12, the left frame 13 and the middle stile 2 to form a fixed fan, and the insulating glass 4 is fixed on the upper fan frame 31, the lower fan frame 32, the left fan frame 33 and the right fan frame 34 An opening fan is formed between them. Open the right fan frame 34 of fan and its contacting right frame 14 is connected by hinge 19, and 20 is the axle of hinge 19. The upper frame 11, the lower frame 12, the left frame 13 and the right frame 14 of the frame 1, the middle stile 2, the upper sas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com