Installation method for rotary kiln for large-sized cement production line

An installation method and technology of rotary kiln, which can be applied to rotary drum furnaces, furnace types, furnaces, etc., can solve problems such as large site requirements, complex structure, and difficulty in on-site stacking, so as to reduce construction area, save installation time, and benefit The effect of overall management and deployment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] A method for installing a rotary kiln for a large cement production line, comprising the following steps:

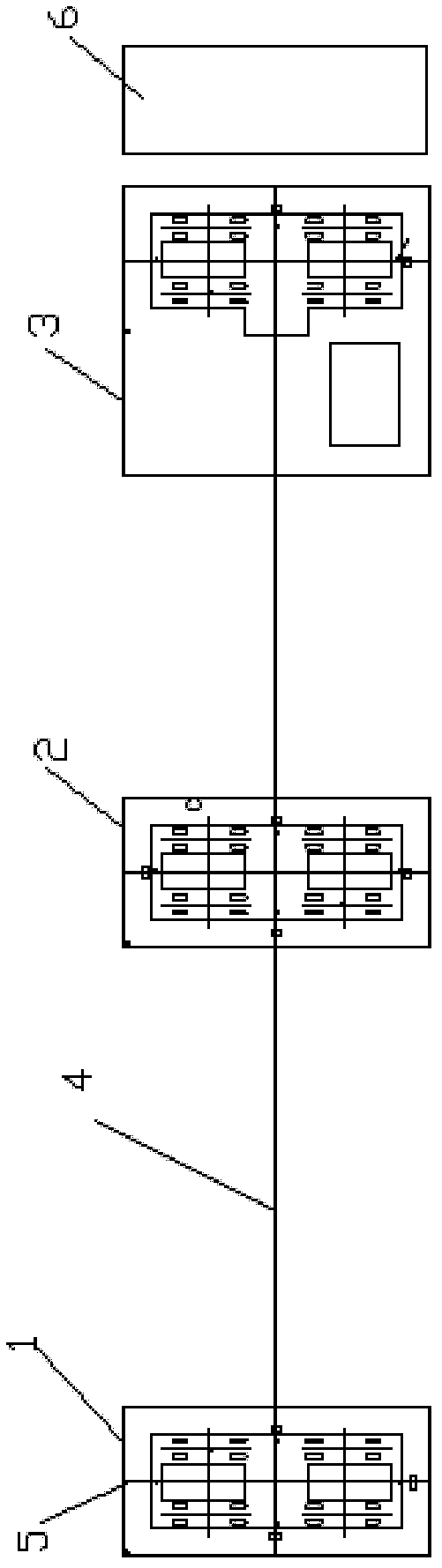

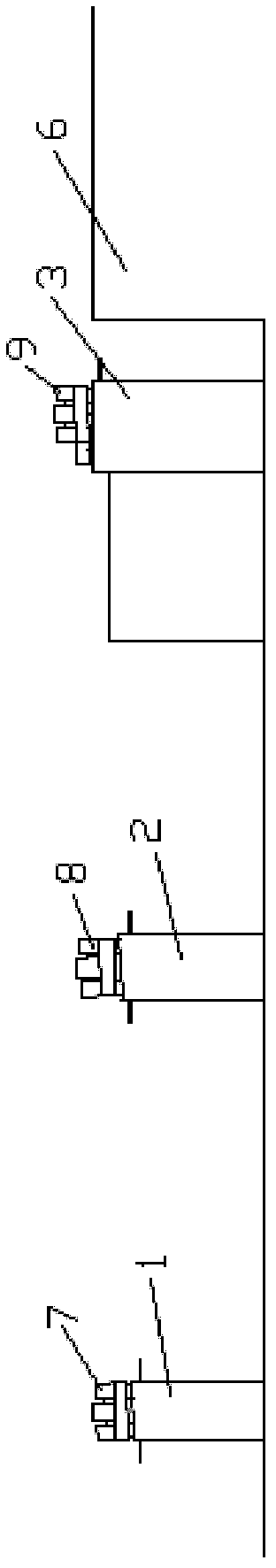

[0054] ①Foundation preparation and marking: Mark the rotary kiln shell divided into eight sections to be installed in sequence for future use, and then set the installation support points along the same straight line at the head, middle and tail of the rotary kiln at the site to be installed as the first kiln pier 1 , the second kiln pier 2 and the third kiln pier 3, that is, the first kiln pier corresponds to the eighth cylinder, the second kiln pier corresponds to the fifth cylinder, the third kiln pier corresponds to the second cylinder and the outside of the third kiln pier The kiln tail frame foundation 6 corresponds to the first shell; then the central axis 4 of the three kiln piers and the transverse centerline 5 of each kiln pier perpendicular to the central axis are marked (as figure 1 shown);

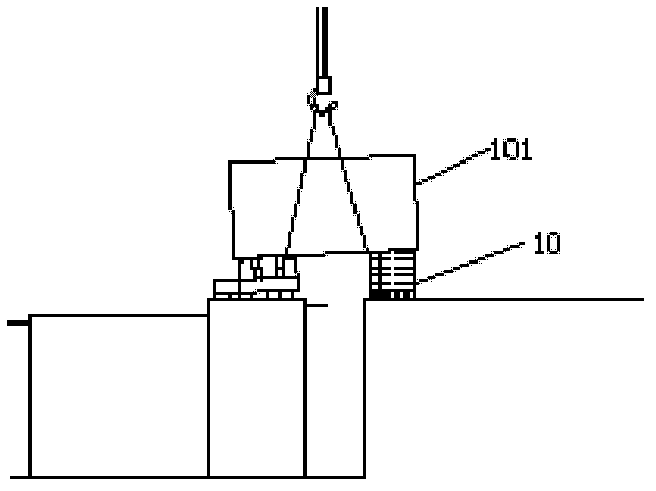

[0055] ② Hoisting of support roller groups: hoist the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com