A process for horizontal directional drill passing through and tampering casing for separating gravel

A technology of horizontal directional drilling and process method, which is applied in the directions of pipeline laying and maintenance, pipes/pipe joints/pipe fittings, machinery and equipment, etc., to achieve the effects of simple operation, fast pipe laying speed and small amount of earthwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

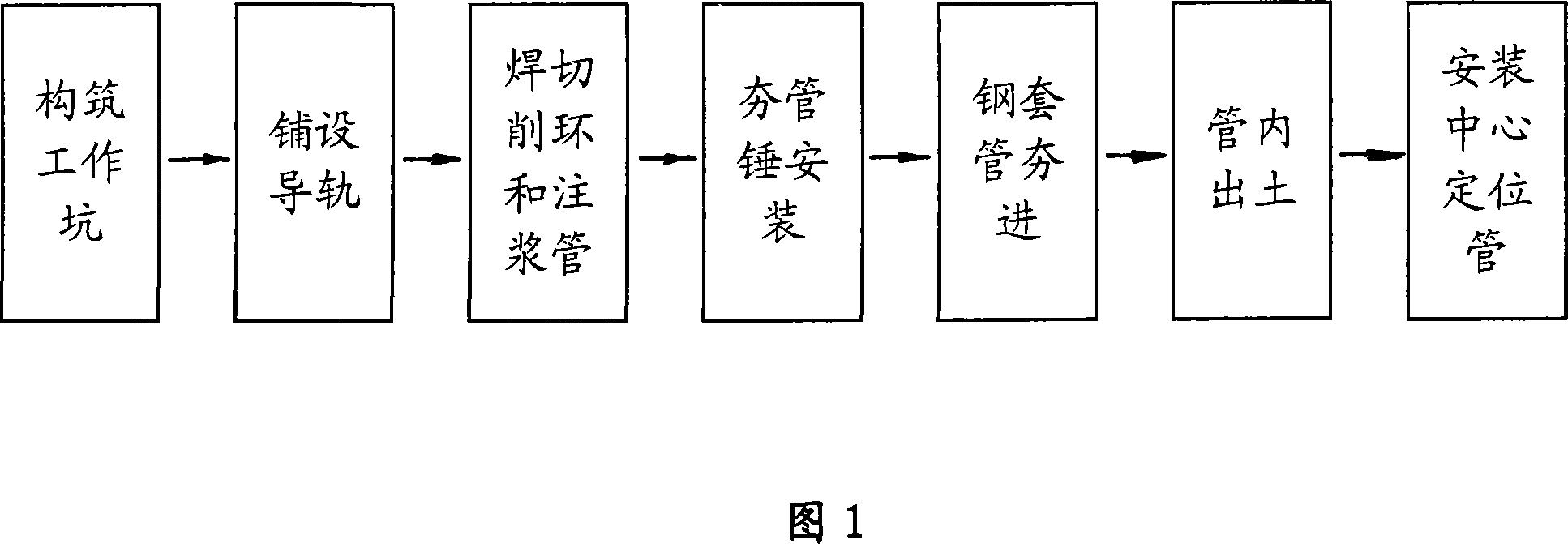

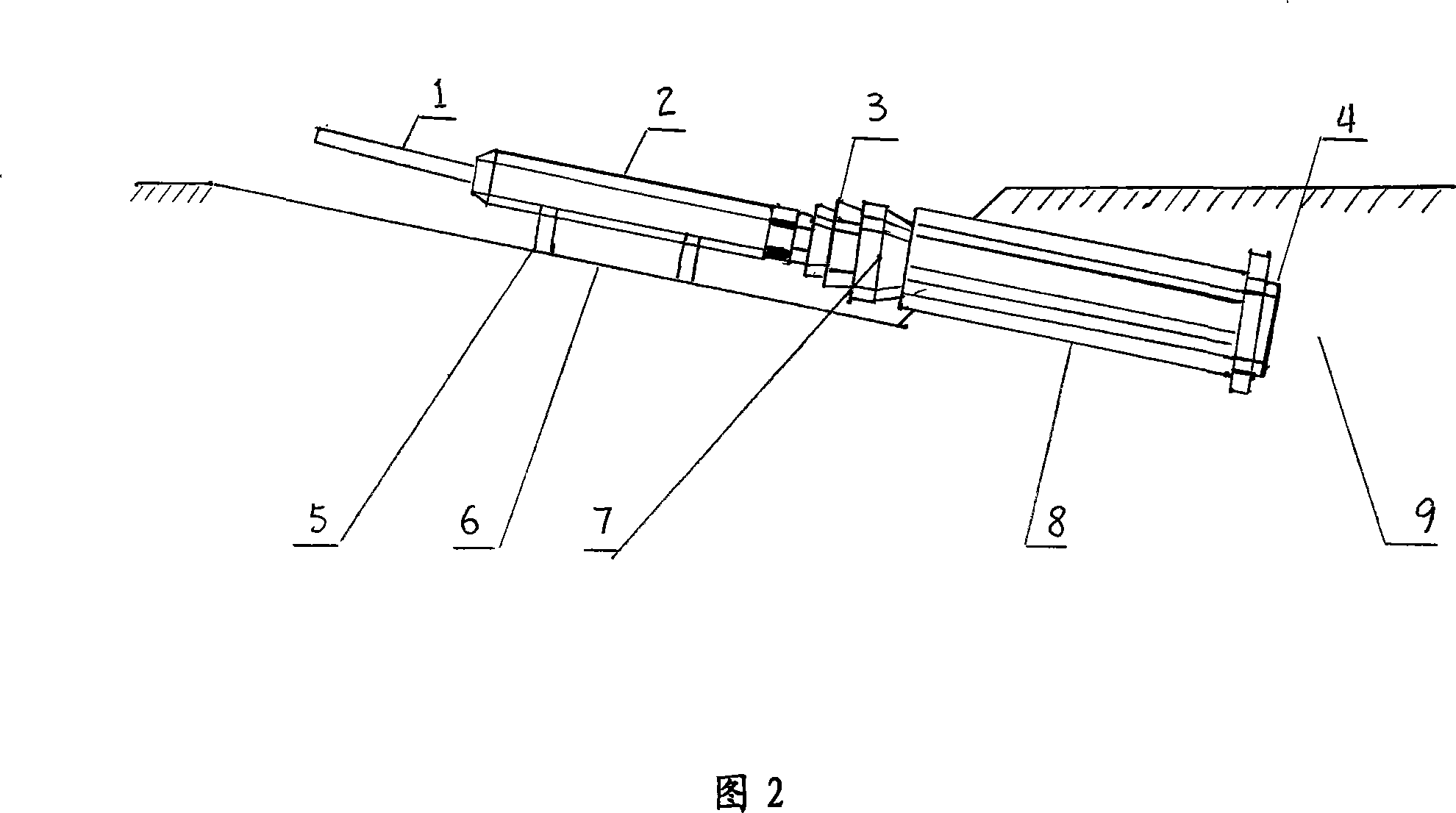

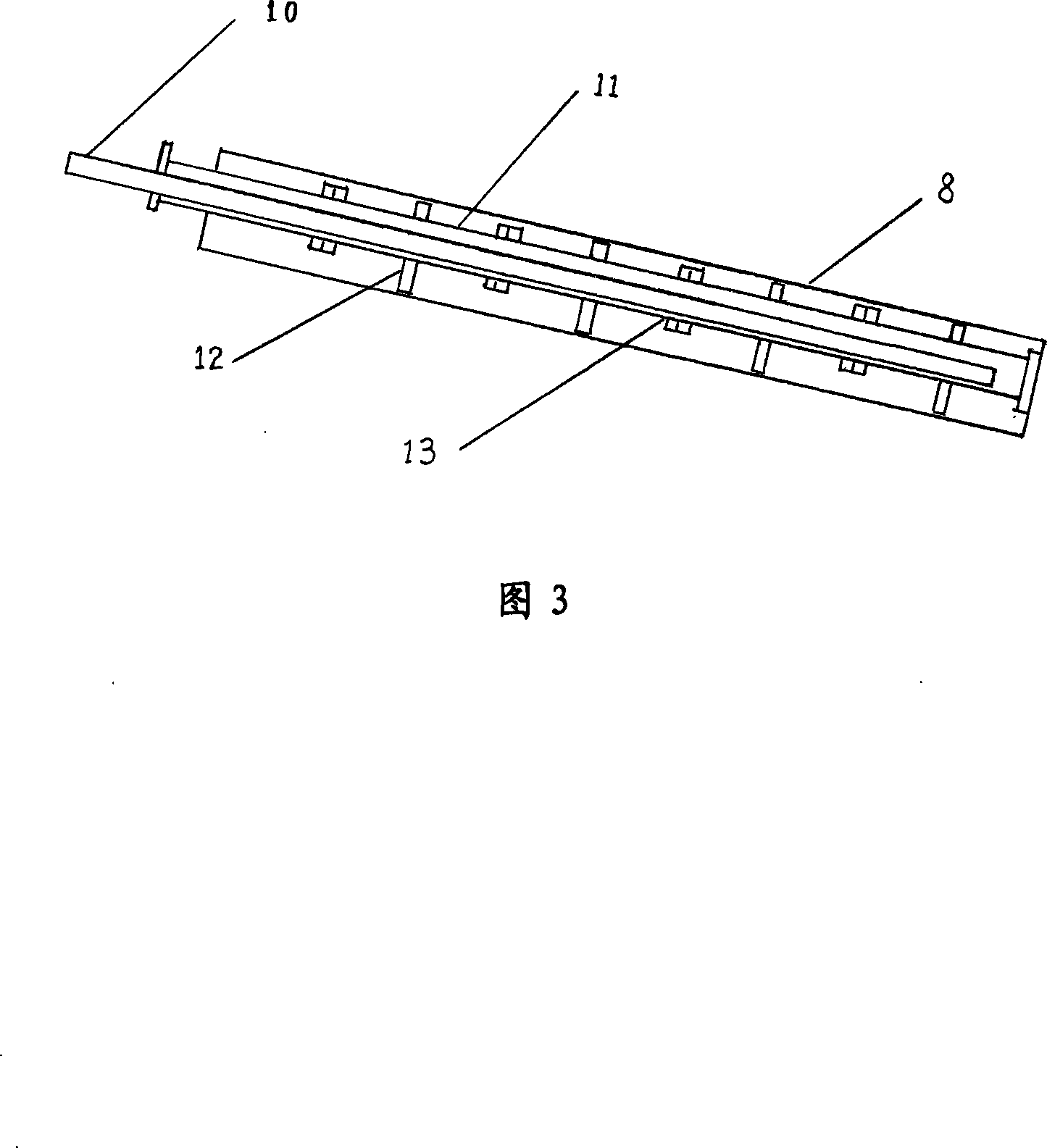

[0014] The casing construction method of horizontal directional drilling and ramming is a method (process) to solve the problem that horizontal directional drilling cannot pass through egg and gravel layers, and it is a kind of non-excavation technology. Fig. 1 shows the construction process flow chart of the present invention. A pipe rammer is a device that can ram into a hollow steel pipe, and its basic principle is powered by compressed air or hydraulic oil. First build the working pit, lay the guide rail, weld the cutting ring and the grouting pipe, install the pipe rammer, and then directly ram the steel casing to be laid into the ground along the design route. With the advancement of the steel casing, the cut soil (stone) enters the steel casing. After the steel casing reaches the target position, the soil core in the pipe is removed, the central posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com