Method for constructing large pontoon-type decanter

A construction method and decanter technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of less use of large buoy type decanters and large buoy type decanters The construction method has no detailed and specific construction guidance, etc., to achieve the effect of small construction area, low cost and convenient demolition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

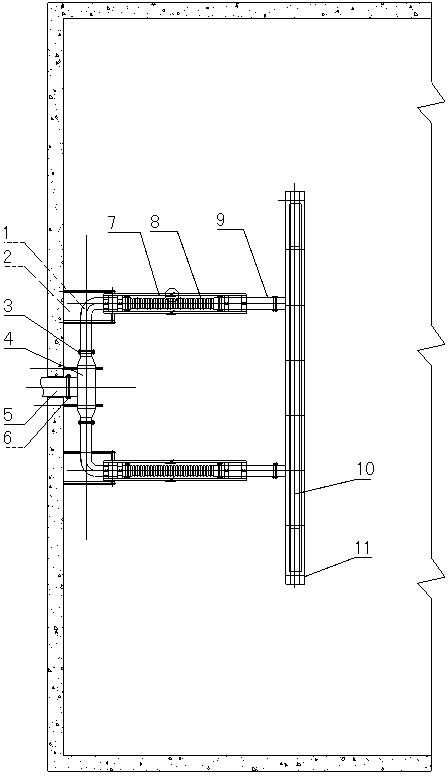

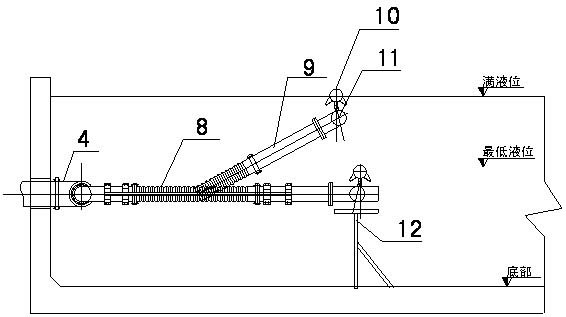

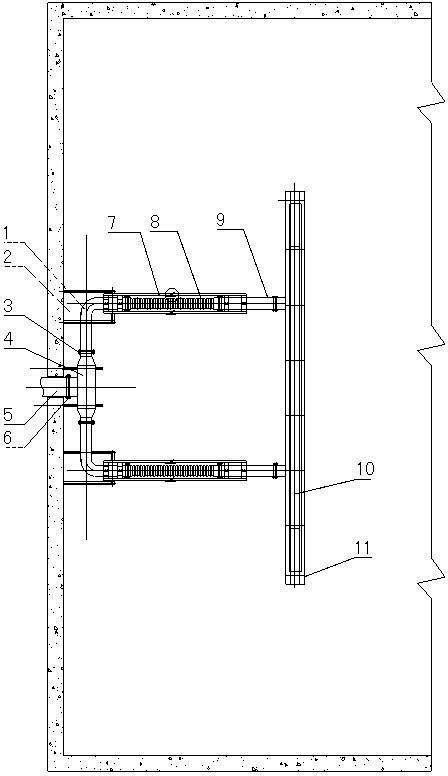

[0023] Below in conjunction with accompanying drawing, the present invention is described in detail.

[0024] like figure 1 , 2 Shown, a large buoy type decanter construction method, including the following steps:

[0025] 1. Material hoisting: allocate parts according to each sewage treatment tank, and transport the allocated parts to the site;

[0026] 2. Erection: Set up a decanter support 12 at the bottom of the sewage treatment tank, then set up a temporary support 2 equal to the decanter support 12 at the pool wall where the wall-through pipe 5 is provided, and decant the water The device 11 is placed on the decanter support 12, and the elbow 1 is placed on the support 2;

[0027] 3. Connect the wall pipe 5 to one end of the water inlet pipe 4 through the flange 6, connect the other end of the water inlet pipe 4 to one end of the elbow 1 through the connecting bolt 3, and connect one end 8 of the rubber hose 8 to the other end of the elbow 1 ; When installing the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com