Cement concrete cored pile construction integrated type cored pile driver and construction method thereof

A technology of cement concrete and core pile machine, which is applied in the direction of sheet pile wall, soil protection, foundation structure engineering, etc. It can solve the problem of reduced bearing capacity of pile composite foundation, poor control of verticality of core pile, and influence on project quality, etc. To solve the problem, the bearing capacity and the rigidity of the pile body are improved, the construction process is easy to control, and the effect of improving the construction progress is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

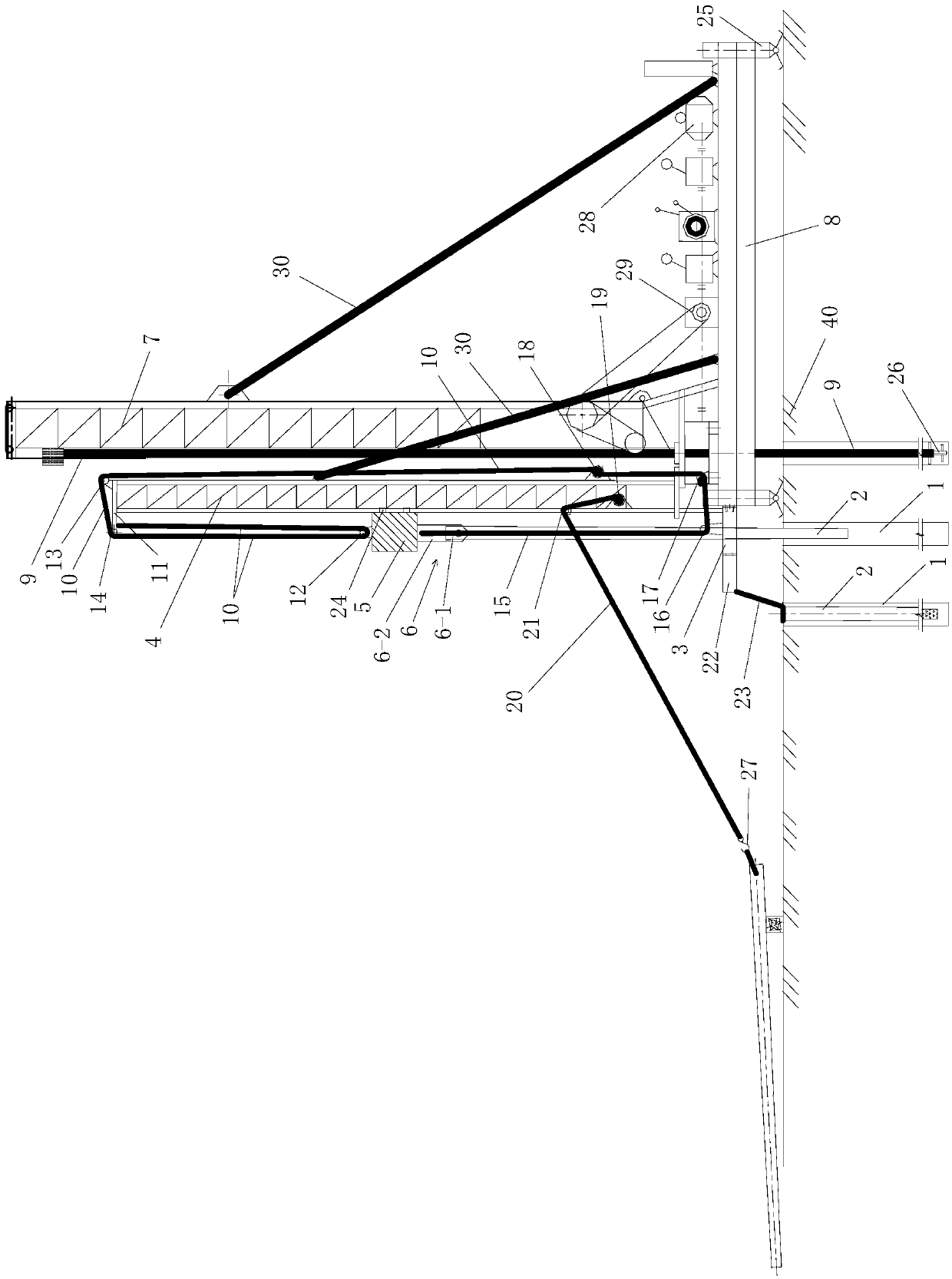

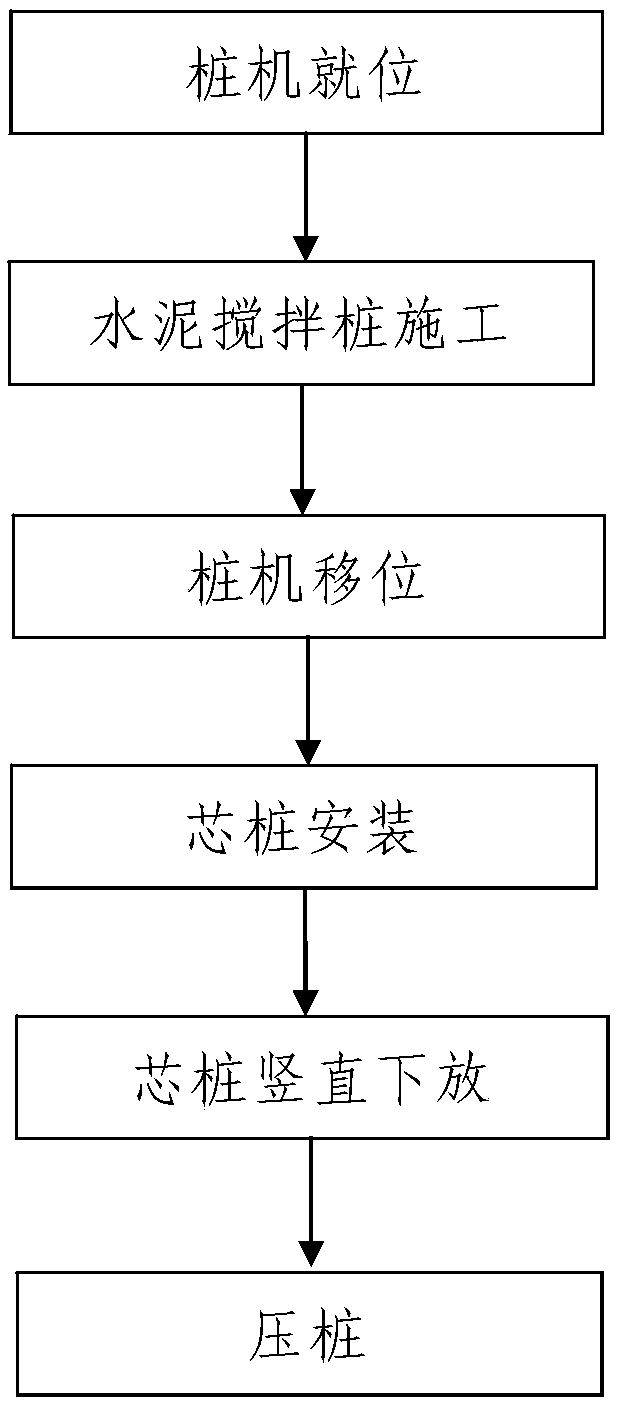

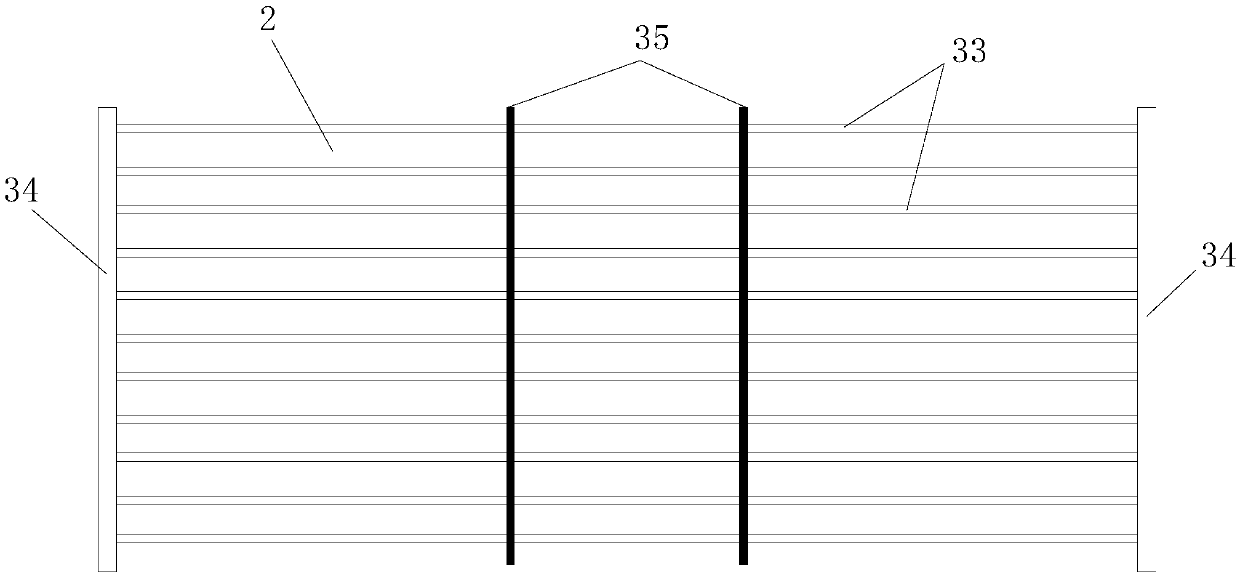

[0060] Such as figure 1 An integrated cored pile machine for the construction of cement concrete cored piles is shown, including a pile mixer for constructing the cement mixing pile 1 of the constructed cement concrete cored pile and pressing the core pile 2 into the cement mixing pile 1 Pile pressing equipment is carried out inside, and the pile pressing equipment is installed on the mixing pile machine; the cement concrete cored pile constructed is composed of a cement mixing pile 1 and a core pile 2 located in the middle of the inner side of the cement mixing pile 1, and the core pile 2 It is a reinforced concrete pile and it is arranged vertically with the cement mixing pile 1;

[0061] The pile-pressing equipment includes a pile-pressing platform 3, a vibratory hammer 5 that presses down the core pile 2 vertically and can move vertically up and down, a guide frame 4 that is installed on the pile-pressing platform 3 and guides the vibratory hammer 5, and Installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com