Swirl pool water stop curtain and construction method thereof

A water-stop curtain and construction method technology, which is applied in excavation, foundation structure engineering, sheet pile walls, etc., can solve the problems of waterproof and pressure difference, etc., and achieve the effect of reducing pile length, strengthening water-stop effect, and occupying less land for construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

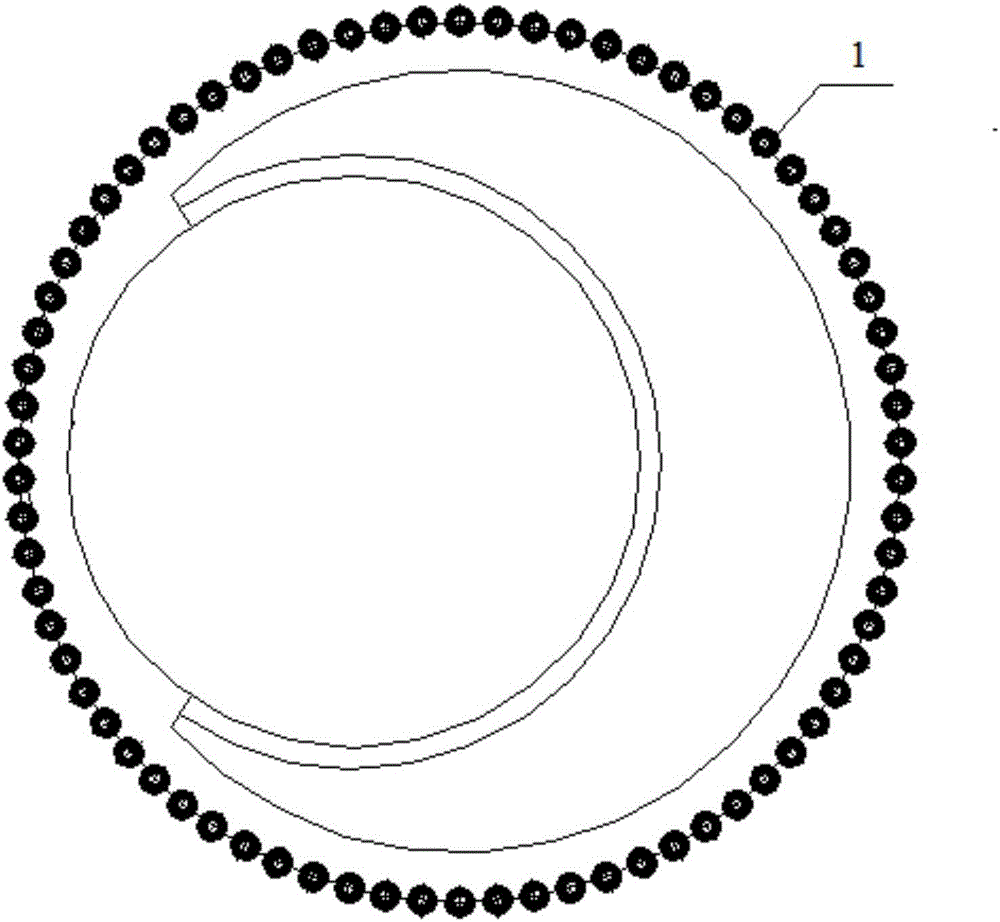

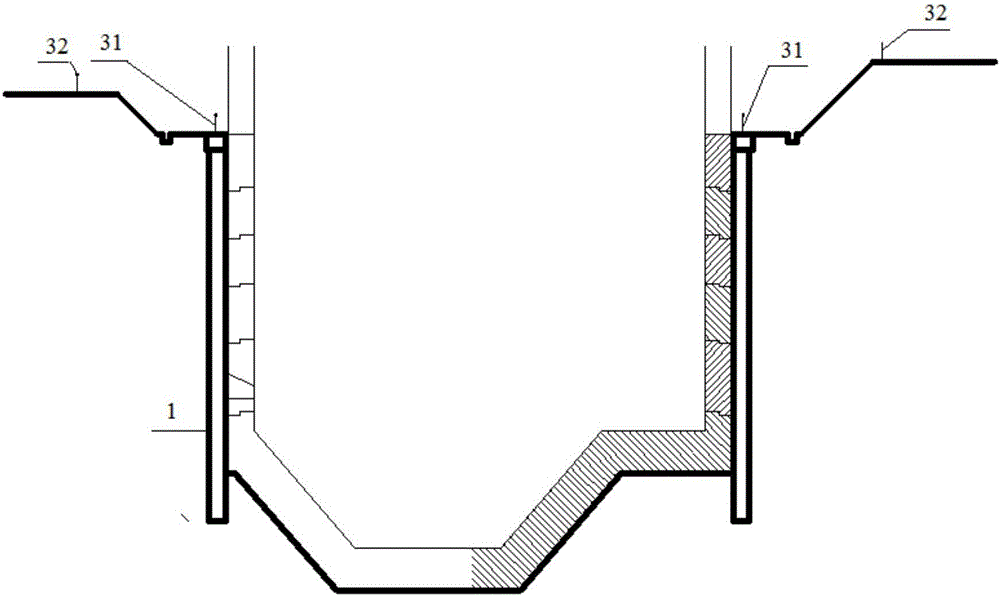

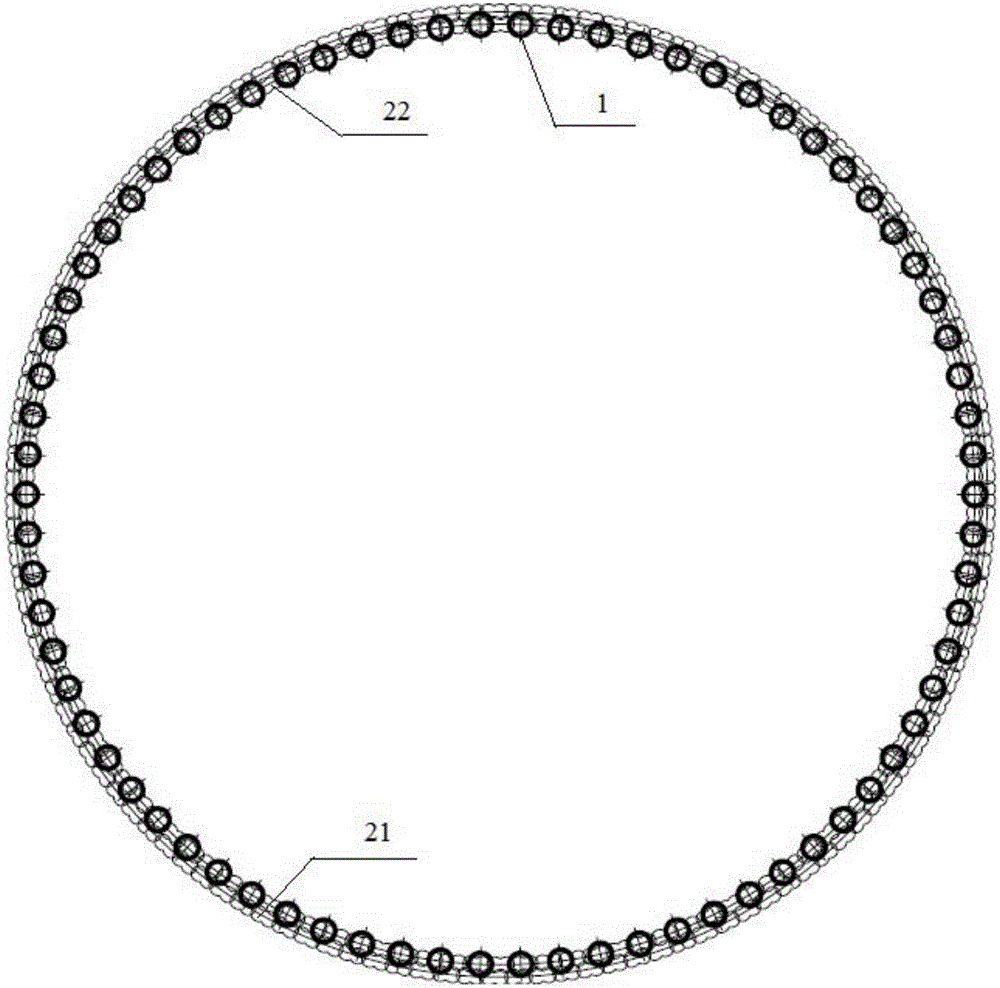

[0049] combine Figure 1-8 , a water-stop curtain for a swirl pool, comprising a swirl pool outer cylinder, support piles 1 and water-stop piles, a row of support piles 1 are arranged at equal intervals outside the swirl pool outer cylinder, and the support piles 1 Set water-stop piles on the outside, set water-stop piles between adjacent support piles 1, and overlap between two contacting water-stop piles. Using lap joint technology, according to the abundance of water in the soil, determine a reasonable lap length, so that the force of a ring of water-stop piles is balanced, there will be no weak links in force, and the water-stop piles are firm as a whole, so that the swirl pool

[0050] The number of water-stop piles is set to more than two rows, which is to strengthen the water-stop effect, and the water-stop piles can also play a role in resisting the lateral pressure of the soil. The water stop pile adopts high-pressure rotary grouting pile, which is affected by geolog...

Embodiment 2

[0063] This embodiment is the same as Embodiment 1, wherein the depth of the foundation pit is 3m, the slope is 1:1, and plain concrete is sprayed on the slope to protect the slope.

Embodiment 3

[0065] This embodiment is the same as Embodiment 1, wherein the depth of the foundation pit is 4m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com