Method for reinforcement construction of soft soil foundation by exchange-filling with foam lightweight soil

A foam lightweight soil and construction method technology, applied in roads, roads, buildings, etc., can solve the problems that plague the engineering field and cannot meet the requirements of the foundation bearing capacity of underground pipelines at the same time, so as to ensure safety and suppress uneven settlement and lateral movement, reducing the effect of additional stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The soft soil foundation reinforcement construction method provided by the present invention using foam light soil replacement will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

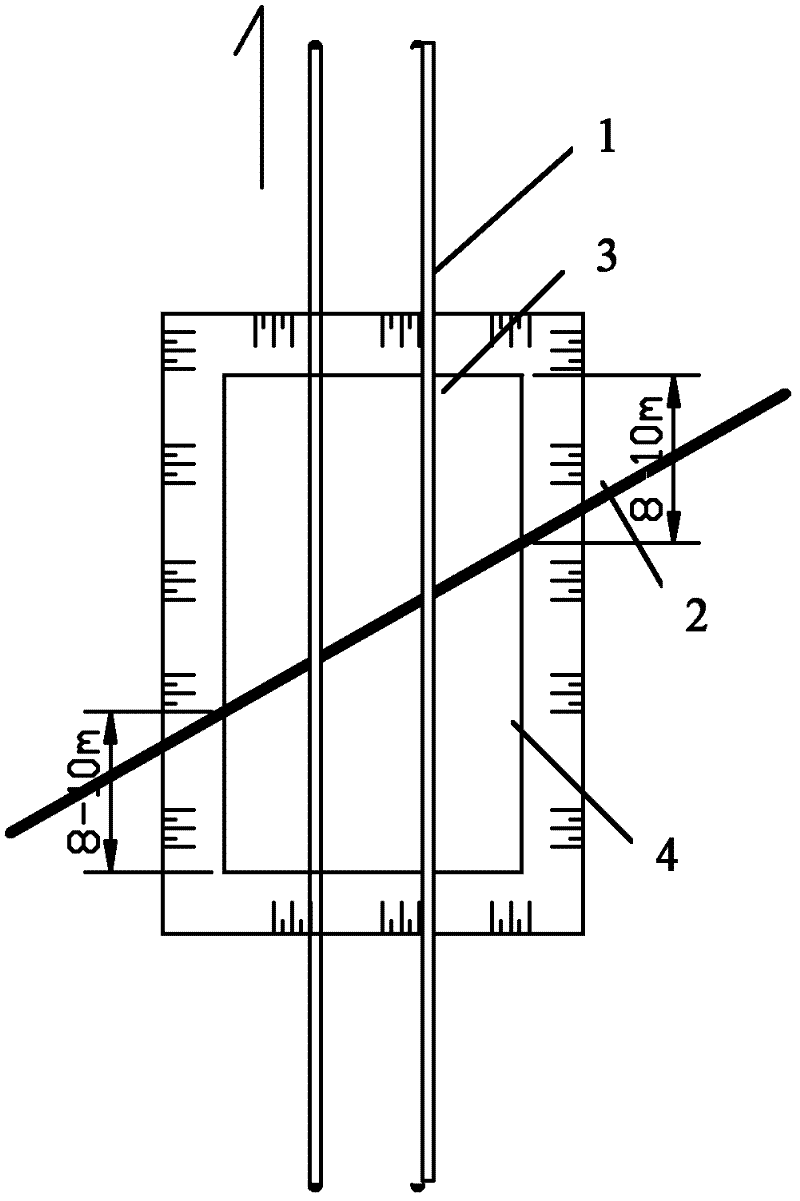

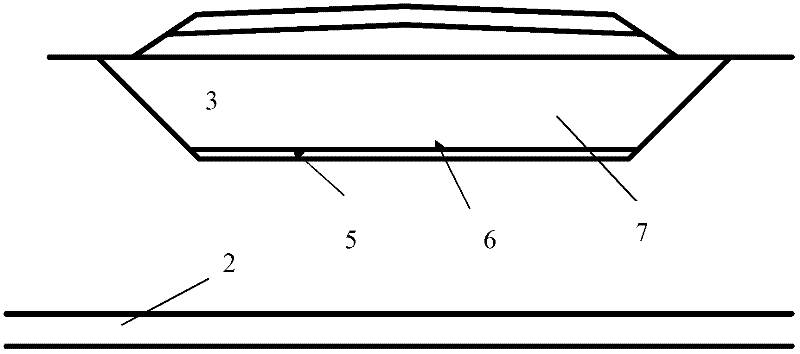

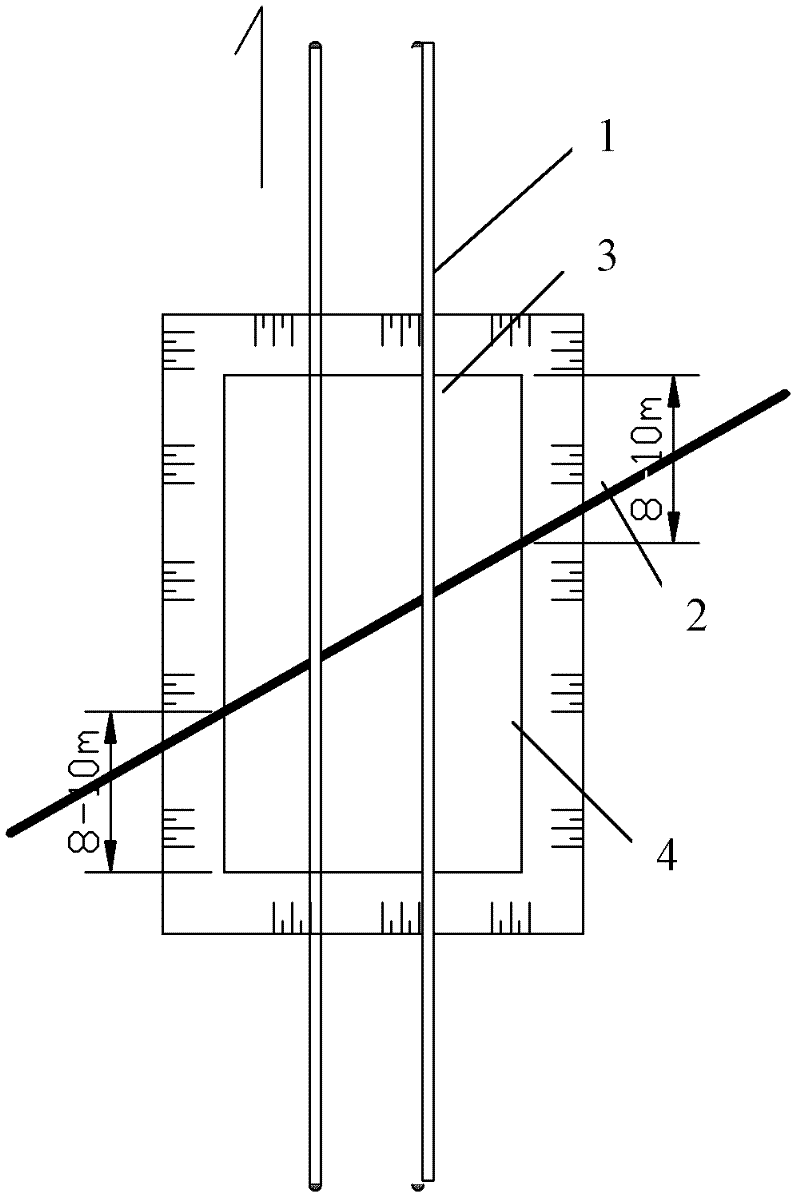

[0017] like figure 1 , figure 2 As shown, a new railway line 1 in the first section of the subgrade center mileage DK62+488.87 passes through a China Aviation Oil pipeline 2 with a diameter of Φ329.9mm and an angle of 60° with the new railway line 1. The pipeline 2 provided by the owner The approximate buried depth ranges from 7 to 12m. The filling height of the subgrade here is only 1m, and the original design base treatment is a 14m long two-way cement mixing pile. In order to ensure that the safety of the pipeline is not affected during the construction of the cement mixing pile, the position of the pipeline 2 must be accurately located before construction. Due to interference from surrounding high-voltage lines, the exact position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com