Patents

Literature

57results about How to "Combine tightly and evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

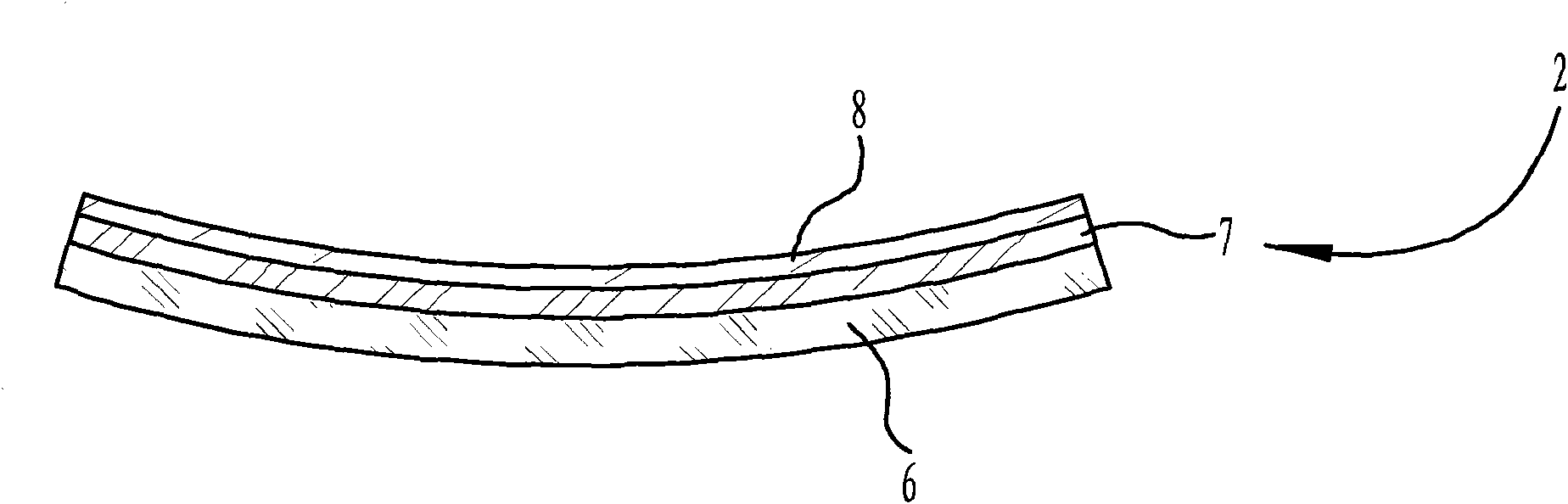

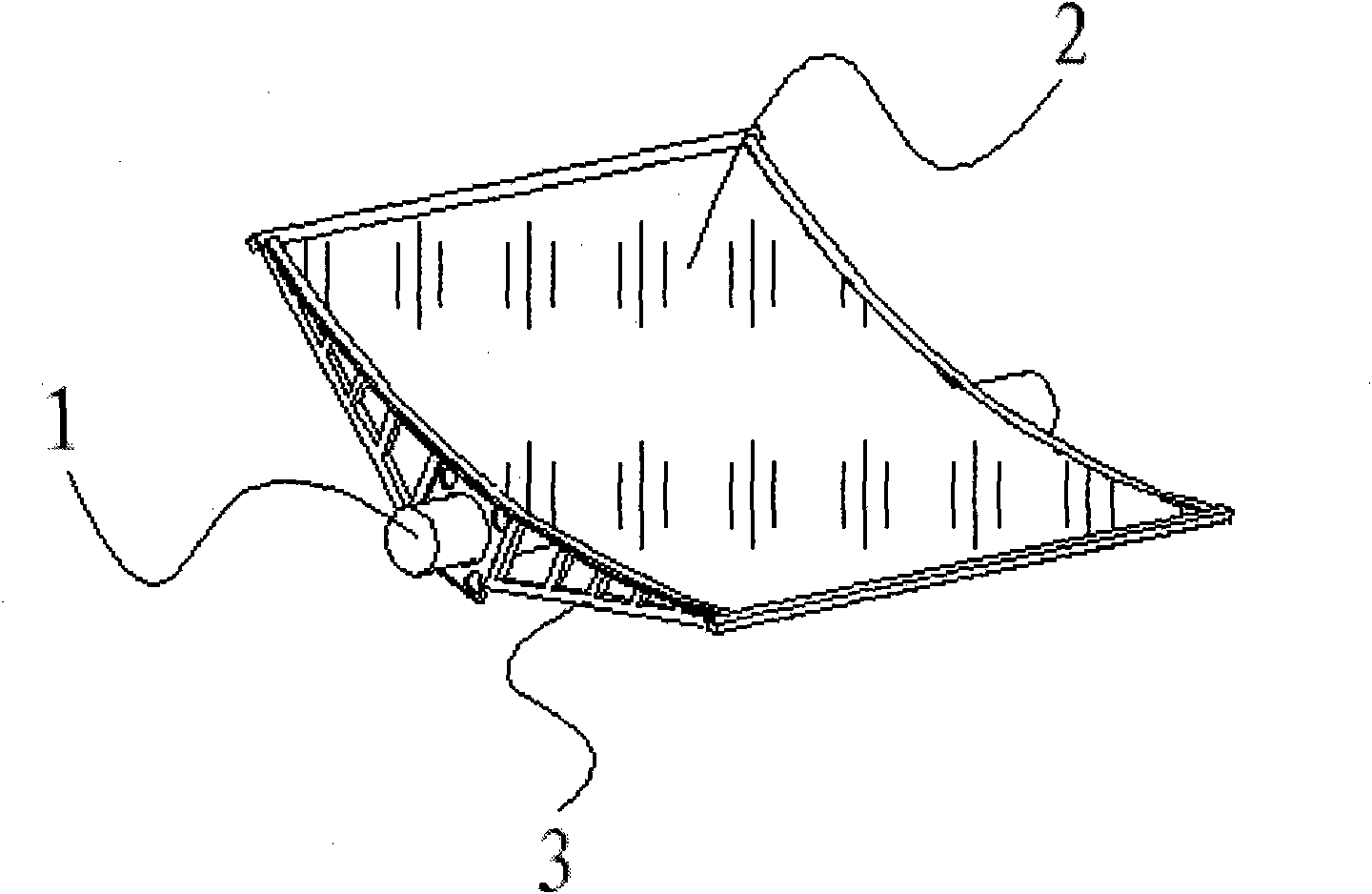

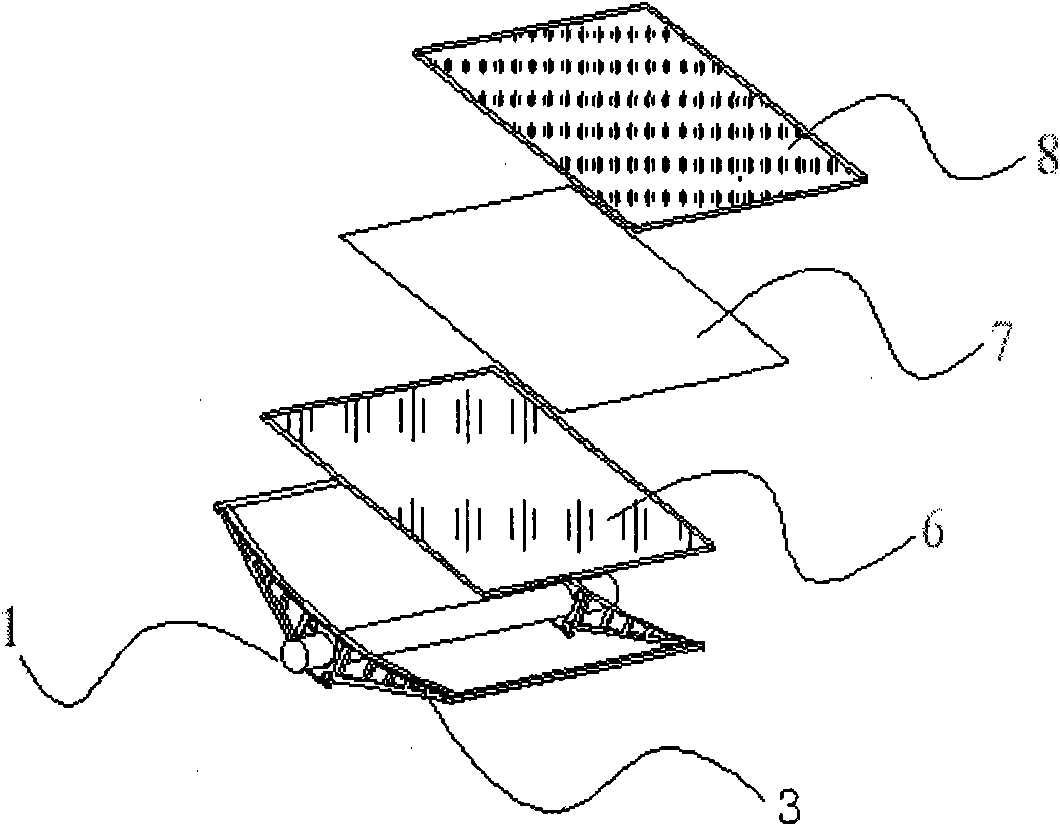

Curved mirror reflector and production method thereof

ActiveCN102759765AStable structureCombine tightly and evenlyMirrorsLayered productsOptoelectronicsFlat glass

The invention provides a curved mirror reflector (2), which comprises a flat glass structure (6), a middle bonding layer (7) and a flat glass mirror (8), wherein the flat glass structure (6) and the flat glass mirror (8) are processed by non-edging and / or non-tempered common glass; the middle bonding layer (7) is located between the flat glass structure (6) and the flat glass mirror (8), and is bent and deformed under support of a mould through a mechanical manner, and the bent and deformed flat glass structure (6), the middle bonding layer (7) and the flat glass mirror (8) are solidified and bonded to a composite curved surface structure through a heating and / or normal-temperature solidification manner. The curved mirror reflector (2), provided by the invention, can be widely applied in all kinds of fields of solar thermal collection and focus and solar thermal power generation.

Owner:BEIJING TERASOLAR PHOTOTHERMAL TECH CO LTD

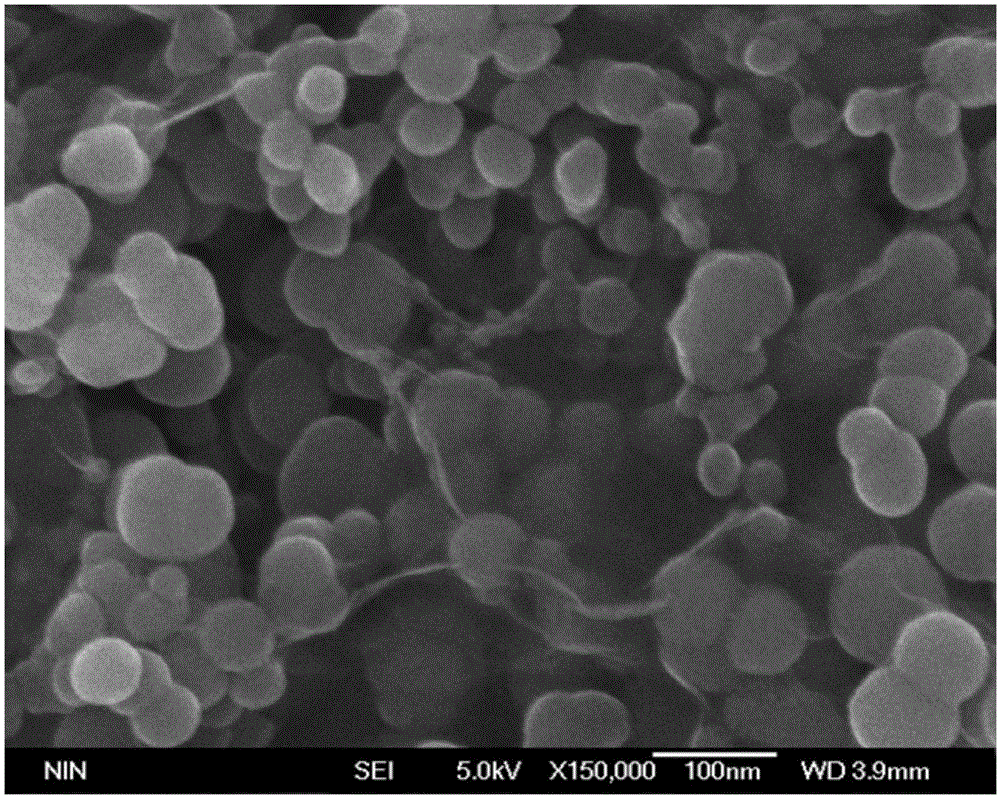

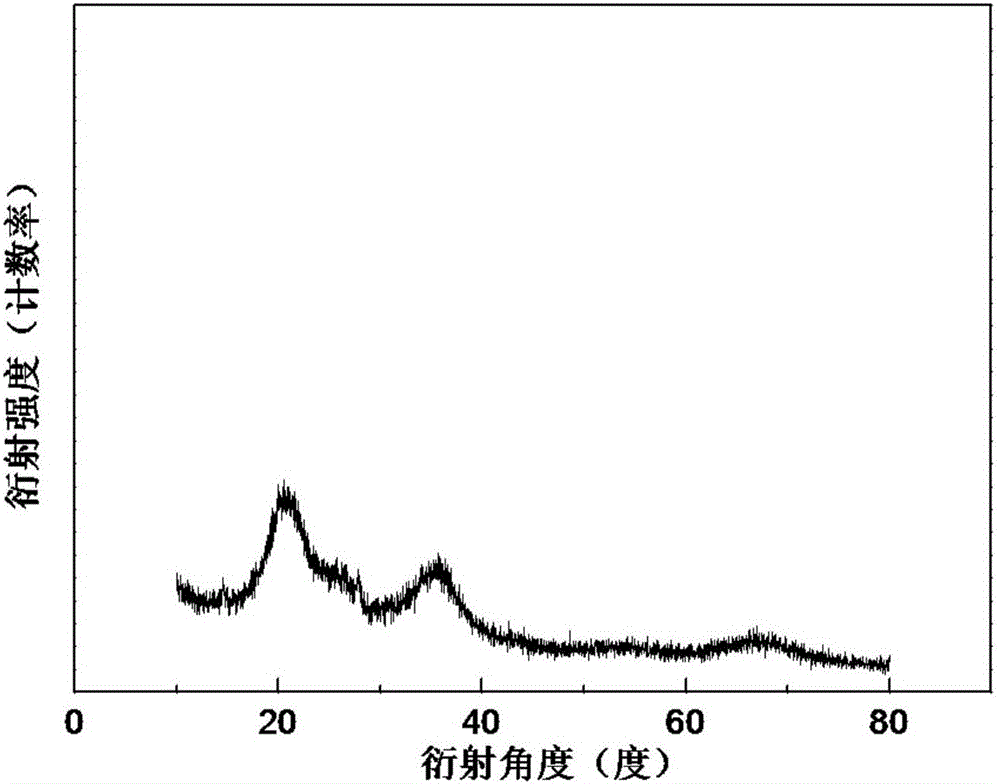

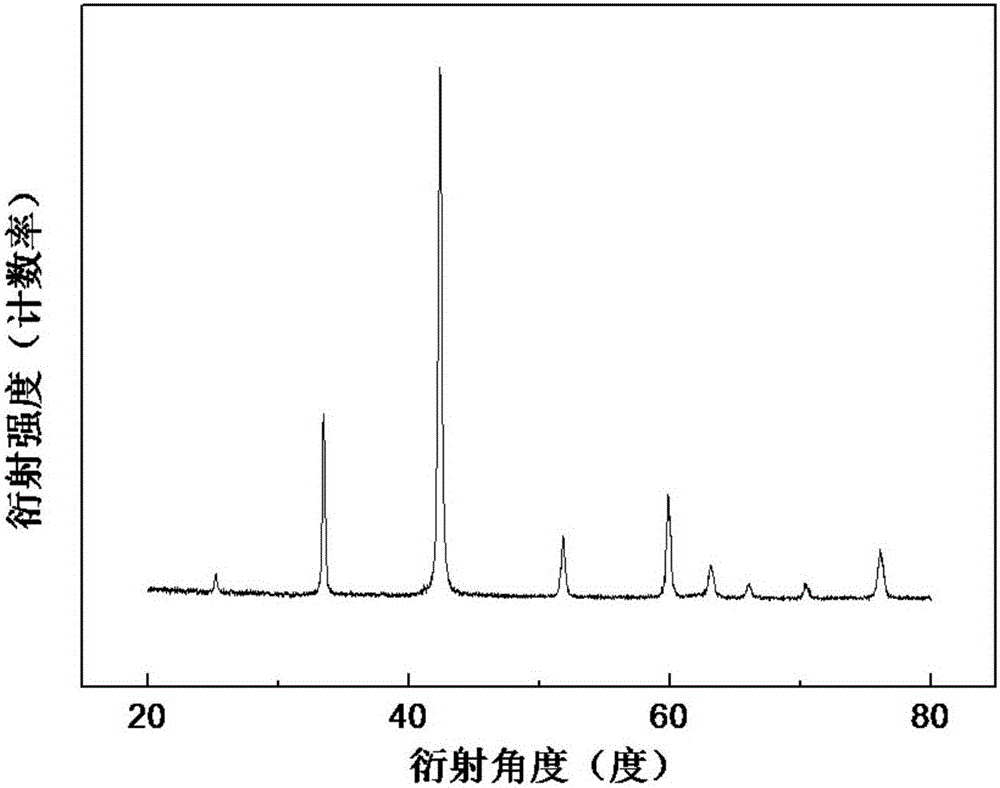

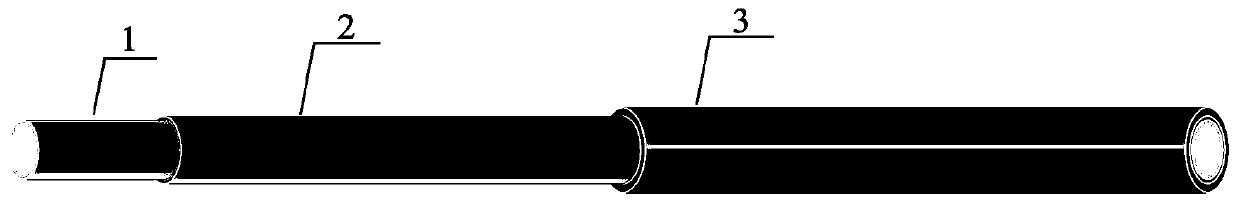

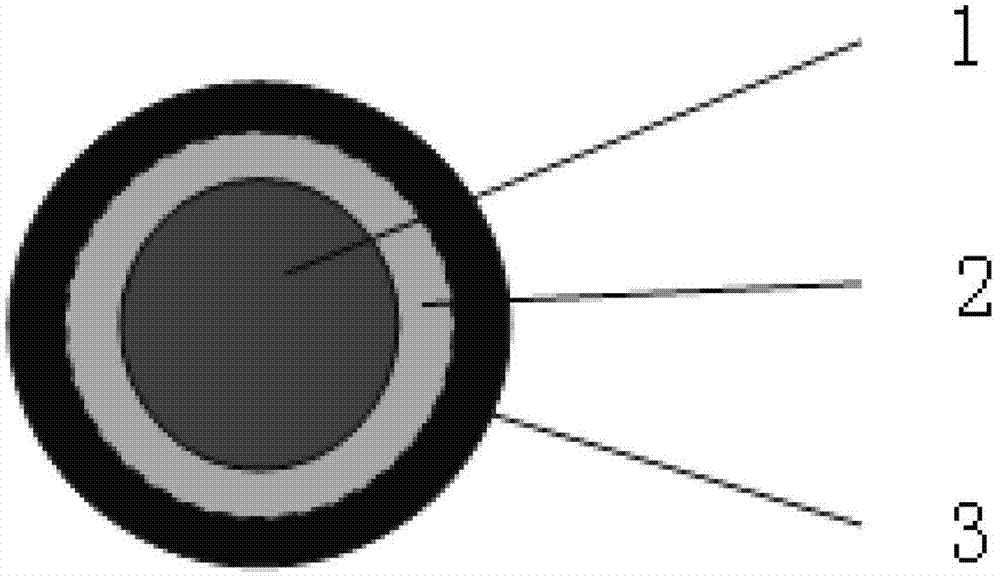

Method for preparing magnesium diboride superconducting wire with graphene coated boron powder

ActiveCN105931750ACombine tightly and evenlyInhibition of contractionSuperconductors/hyperconductorsSuperconductor devicesRoom temperatureMagnesium diboride

The invention discloses a method for preparing a magnesium diboride superconducting wire with graphene coated boron powder. The method comprises the steps of: 1, adding the spherical nano boron powder to graphene oxide solution, filtering after stirring uniformly to obtain filter residue and carrying out vacuum drying on the filter residue to obtain mixed powder; 2, carrying out heat treatment on the mixed powder to obtain the graphene coated boron powder; 3, after mixing the graphene coated boron powder with magnesium powder, grinding to obtain tubing precursor powder; 4, putting the tubing precursor powder into an Nb / Cu composite tube which is processed by acid pickling to obtain a tubing complex; 5, processing the tubing complex into a single-core wire; 6, processing into a multi-core wire by employing a bundle-drawing technology; and 7, carrying out phase-forming heat treatment, and cooling to room temperature with a furnace to obtain the magnesium diboride superconducting wire. According to the method disclosed by the invention, through adding the spherical boron powder to the graphene oxide solution, the single-layer graphene coated boron powder is realized; after the heat treatment, the graphene has no agglomeration and can be combined with the boron powder tightly and uniformly; and the phenomena of graphene contraction and nonuniformity in the traditional method are inhibited.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

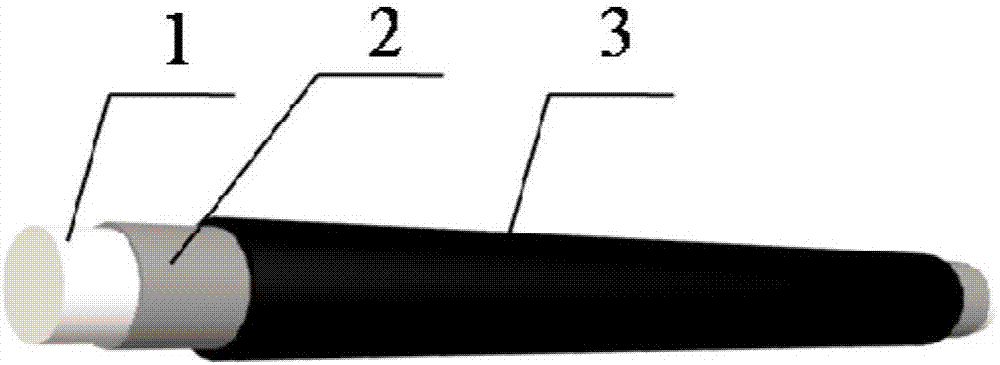

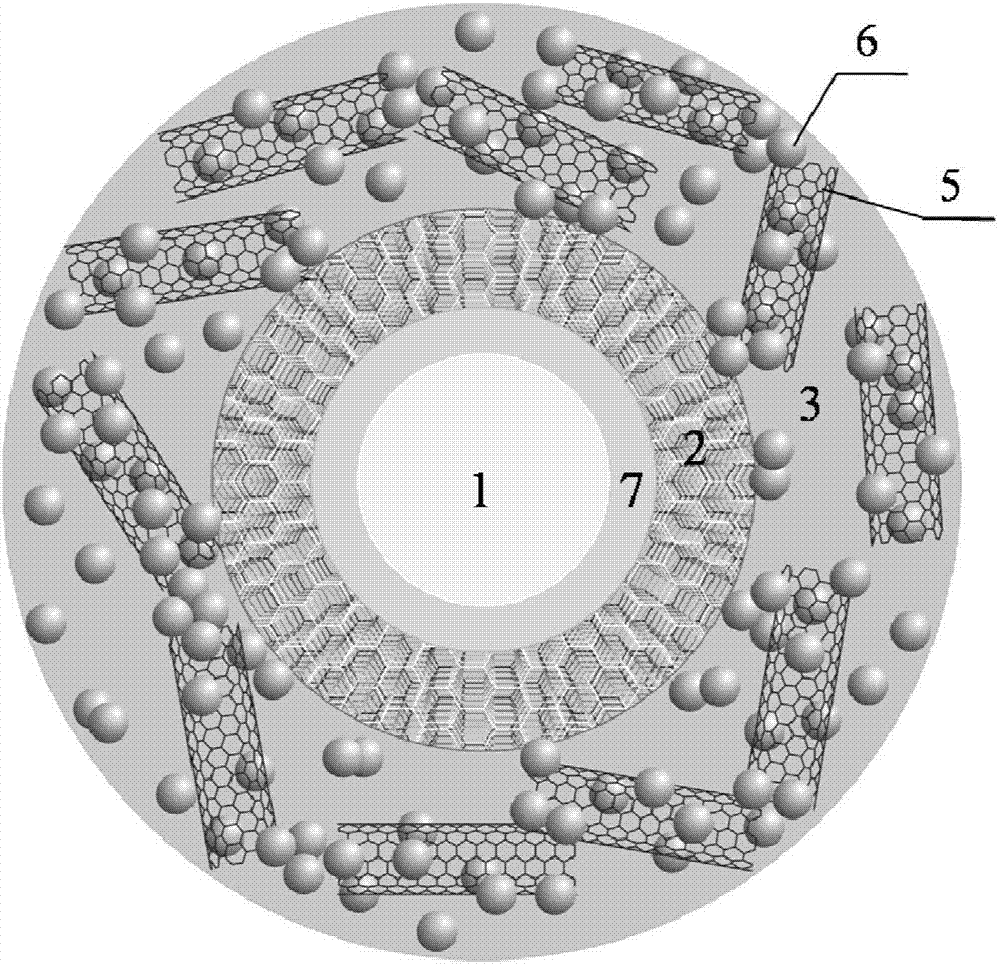

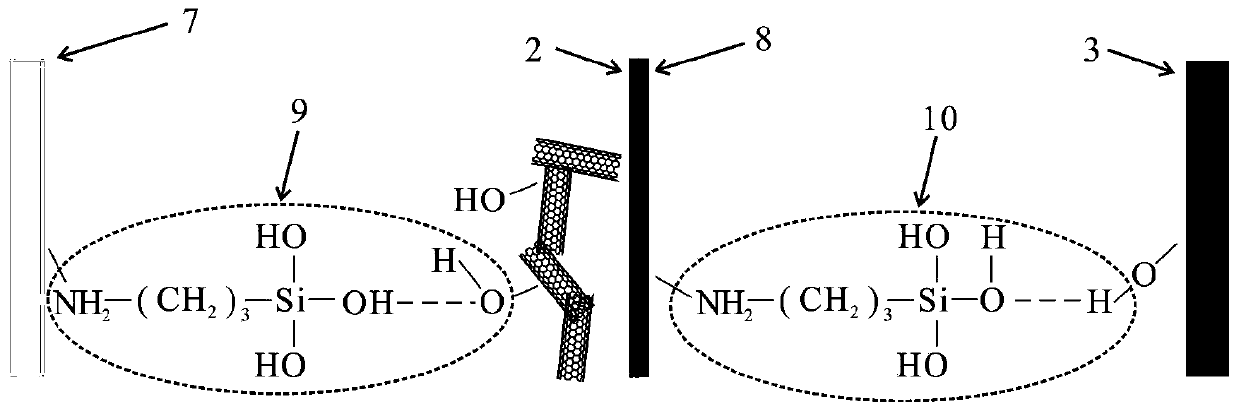

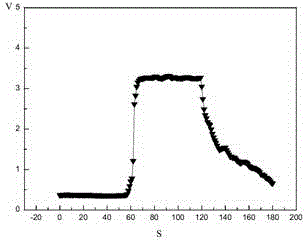

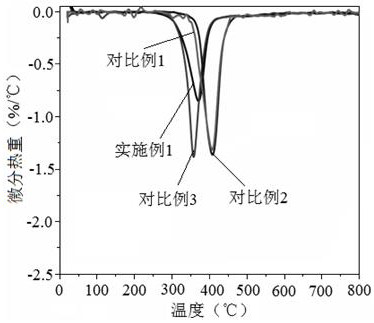

Stretchable strain sensor based on polyurethane fiber and preparation method of strain sensor

ActiveCN107881768ACombine tightly and evenlyImprove adhesionElectrical/magnetic solid deformation measurementGrip property fibresFiberCarbon nanotube

The invention discloses a stretchable strain sensor based on polyurethane fiber and a preparation method of the strain sensor. The polyurethane fiber is taken as a matrix, the surface of the matrix issequentially wrapped with an inner conductive structure adopting a graphene nanosheet layer and an outer conductive structure adopting a collaboratively conductive network layer of carbon black and single-walled carbon nanotubes. The strain sensor has good softness, stretching characteristic and large-scale integration characteristic and can serve as a wearable device compatible with skin.

Owner:HEFEI UNIV OF TECH

Touch screen electrode preparation method

InactiveCN101261560AEvenly combinedEven contactInput/output processes for data processingElectrical resistance and conductanceGas phase

A manufacturing method of an touch screen electrode comprises the following steps: a layer of metal film is formed on a resistance layer of a transparent conductive strip or a plate by physical vapor phase deposition; an anti-corrosion layer with an electrode pattern is formed on the metal film; the electrode pattern is formed by using alkaline metal etching liquid for etching the metal film; and a non-function area of the resistance layer is isolated with the electrode and a function area by etching. An electrode metal layer of the touch screen electrode which is manufactured by the method is formed under the physical vapor phase state, the electrode metal layer and the transparent resistance layer form the even and close combination, the contact is very even, and the contact resistance is extremely small; in addition, the formed metal resistance rate of the electrode is at the magnitude order of 10 Omega / cm, an ACP manufacturing procedure can be used for producing the large-size touch screen, the reduced contact resistance and the improved uniformity can enhance the electrical properties of the touch screen, and the production yield is improved.

Owner:张树峰

Preparation method for graphene-coated niobium-aluminium superconductive wire material

InactiveCN106920597AUniform compositionImprove performanceSuperconductors/hyperconductorsSuperconductor devicesNiobiumAluminium powder

The invention discloses a preparation method for a graphene-coated niobium-aluminium superconductive wire material. According to the preparation method, aluminum powder is added to a graphene oxide solution to realize singe-layer graphene-coated aluminum powder; the graphene after being subjected to heat treatment is free of agglomeration and can be tightly and uniformly combined with aluminum powder; graphene is on the interface of the prepared graphene-coated aluminium powder, so that oxidization of the aluminum powder is avoided; by virtue of the preparation method, the conditions that a precursor is cracked easily at a high temperature and special requirement on heating equipment is required in the conventional rapid-heating and rapid-cooling processing also can be avoided; and the obtained superconductive wire material is uniform in ingredients and excellent in performance, so that the cost is effectively lowered and large-scale production can be facilitated.

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

Method for preparing alkaline sizing agent in cation rosin

InactiveCN101054784APrevent or delay permeabilityPrevent or slow the spreadWater-repelling agents additionCardboardFiber

A method for preparing basic glue blending agent in cation iron rosin includes steps of: using rosin and trimethylamine as main raw material, choosing an epoxy-containing monomer to react with the raw material to prepare the cation iron rosin ester, and after a certain condition, reacting to rosin emulsion. The invention can equally distribute a substance of low surface free energy on paper surface to form a liquid-proof film, the liquid-proof film can prevent or defer liquid permeation or diffusion to fiber, and make paper or cardboard with liquid (especially water and water solution) permeation and diffusion resistance.

Owner:SHAANXI UNIV OF SCI & TECH

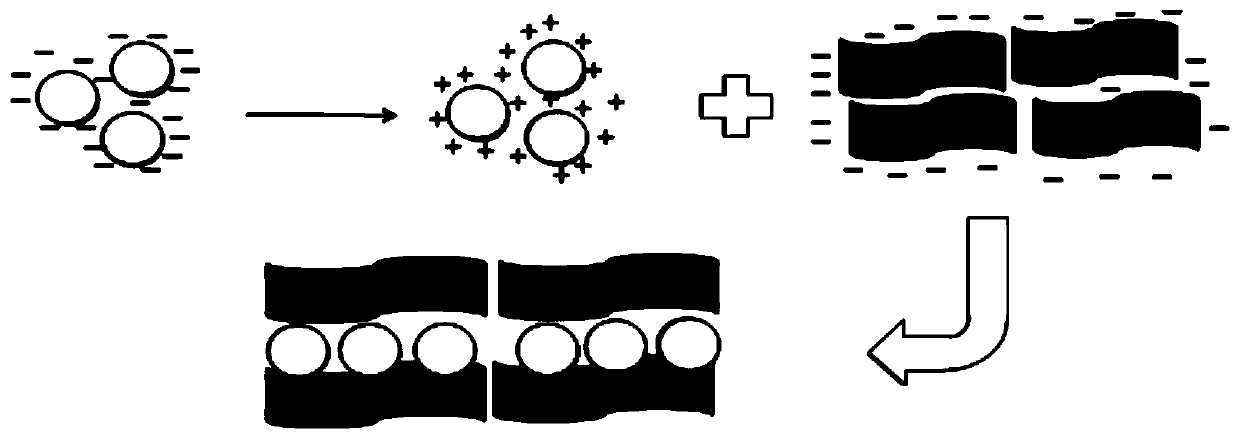

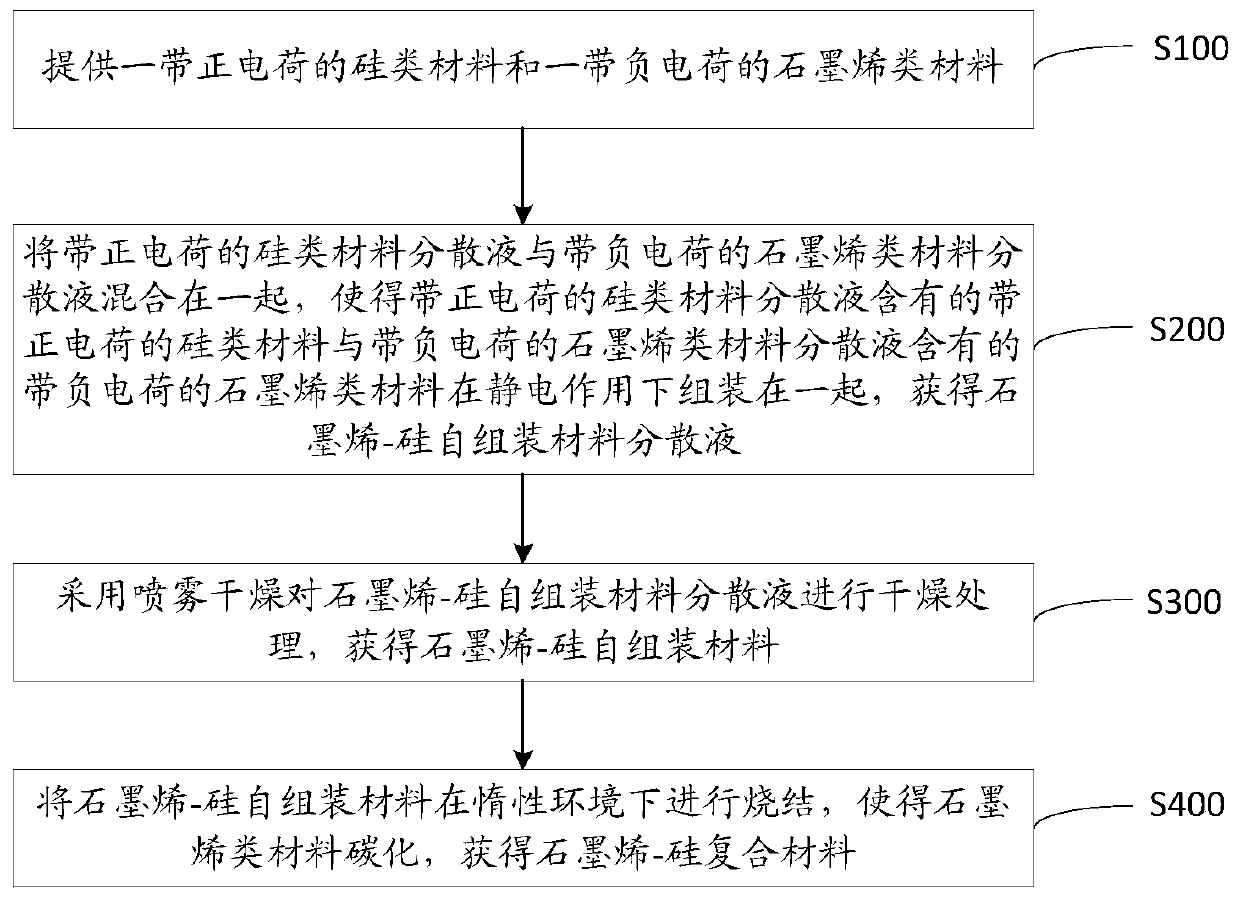

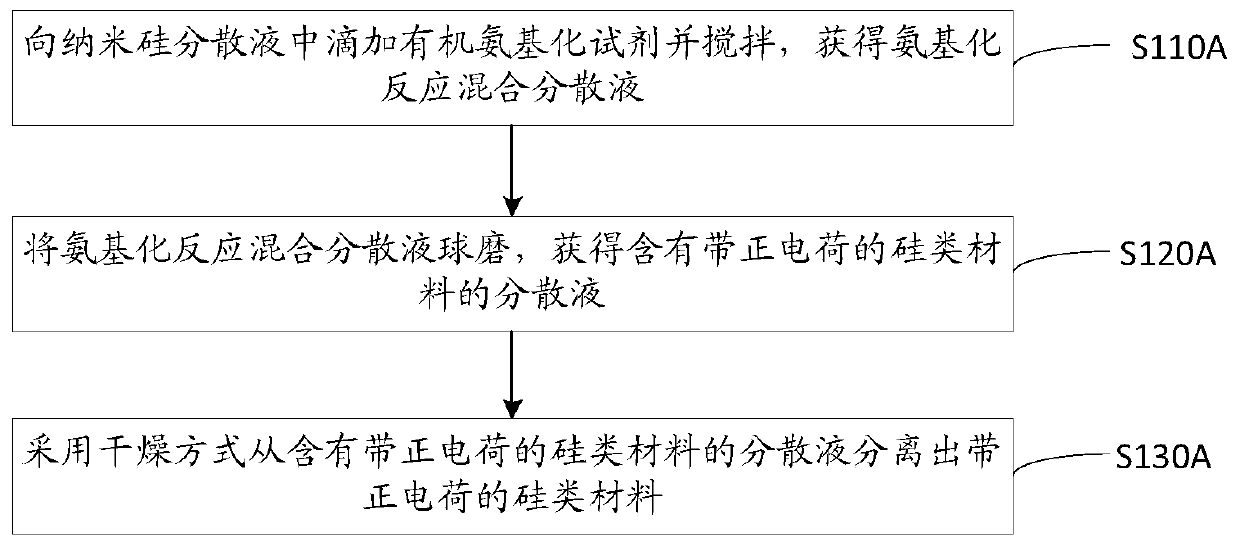

Graphene-silicon composite material, preparation method thereof, electrode material and battery

ActiveCN110112408AImprove structural strengthFast evaporationMaterial nanotechnologyNegative electrodesCvd grapheneStructural stability

The invention discloses a graphene-silicon composite material, a preparation method thereof, an electrode material and a battery and relates to the technical field of batteries so as to improve the structural stability of an electrode containing a silicon-based material, and therefore, the cycle performance of the battery is ensured. The preparation method of the graphene-silicon composite material comprises a step of mixing positively-charged silicon-based material dispersion liquid with a negatively-charged graphene-based material dispersion liquid such that a positively-charged silicon-based material and a negatively-charged graphene-based material are assembled together to obtain a graphene-silicon self-assembled material dispersion liquid, a step of drying the a graphene-silicon self-assembled material dispersion liquid by using spray drying to obtain a graphene-silicon self-assembled material, and a step of sintering the graphene-silicon self-assembled material in an inert environment to obtain the graphene-silicon composite material. The graphene-silicon composite material is prepared by the above preparation method. The graphene-silicon composite material provided by the invention is applied to the battery.

Owner:内蒙古信敏惠纳米科技有限公司

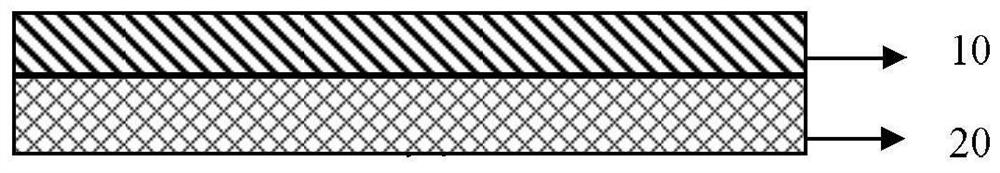

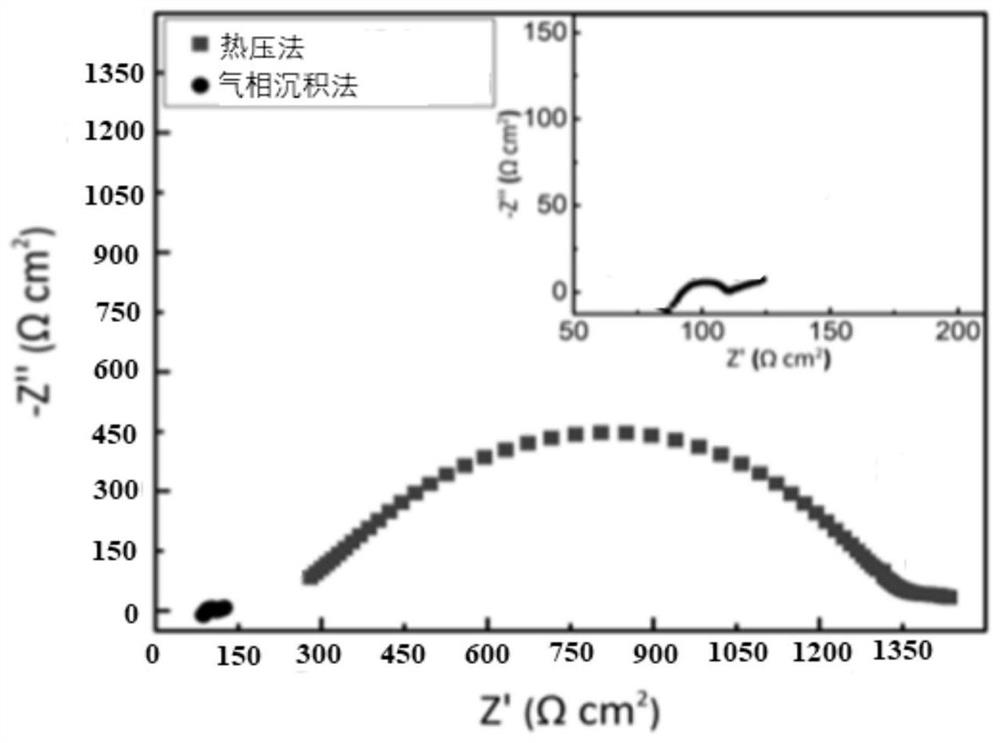

Solid electrolyte-lithium negative electrode complex, preparation method thereof, and all-solid-state lithium secondary battery

PendingCN112736277AControl thicknessControl UniformityFinal product manufactureLi-accumulatorsSolid state electrolyteMetallic lithium

The invention provides an integrated solid-state electrolyte-lithium negative electrode complex, a preparation method thereof, and an all-solid-state lithium secondary battery containing the integrated solid-state electrolyte lithium negative electrode complex. The complex is composed of: a polyphenylene sulfide solid electrolyte layer; a lithium layer vapor-deposited on one surface of the solid electrolyte layer; and optionally, a metal foil attached to the lithium layer as a current collector or tab. The complex can be directly used as an electrolyte and a negative electrode of the battery. On one hand, the thickness of the lithium layer is effectively controlled, on the other hand, the problem of interface contact between the solid electrolyte and the metal lithium negative electrode is effectively solved, the interface contact resistance is improved, and the specific capacity and the cycle life of the battery are improved.

Owner:CHINA ENERGY LITHIUM

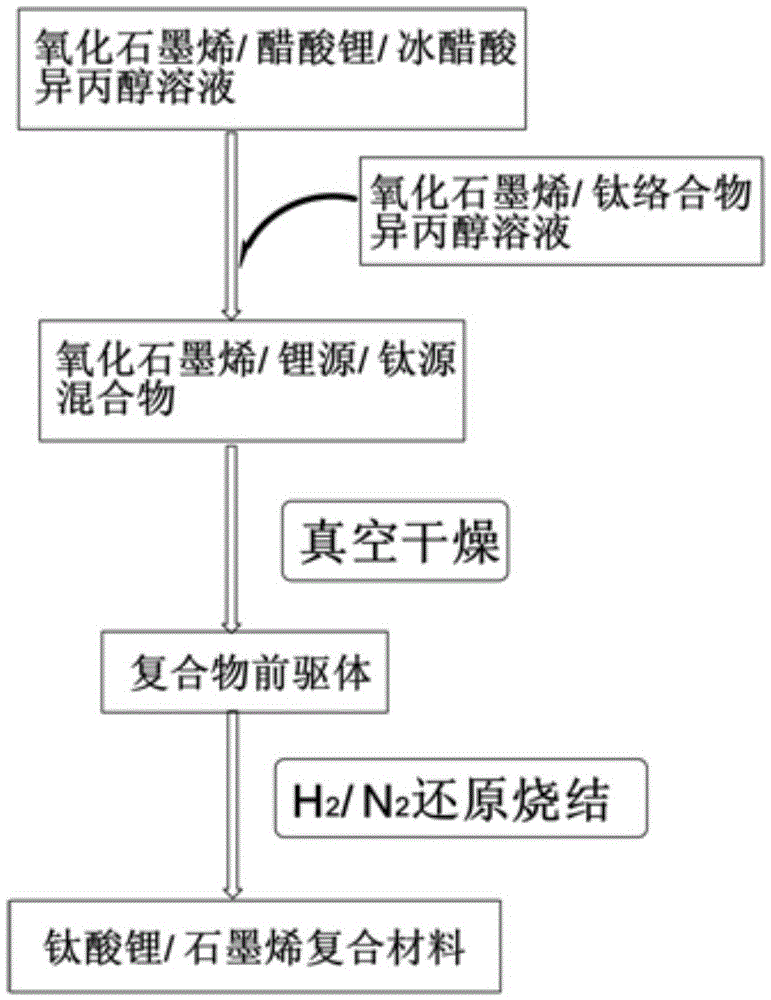

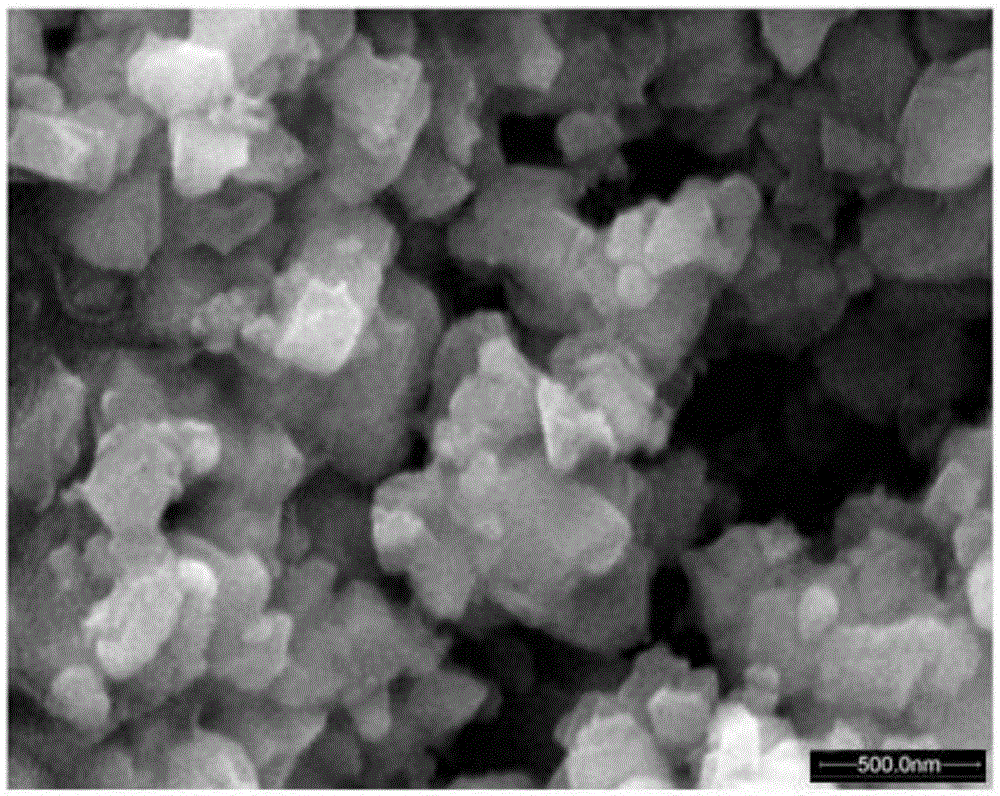

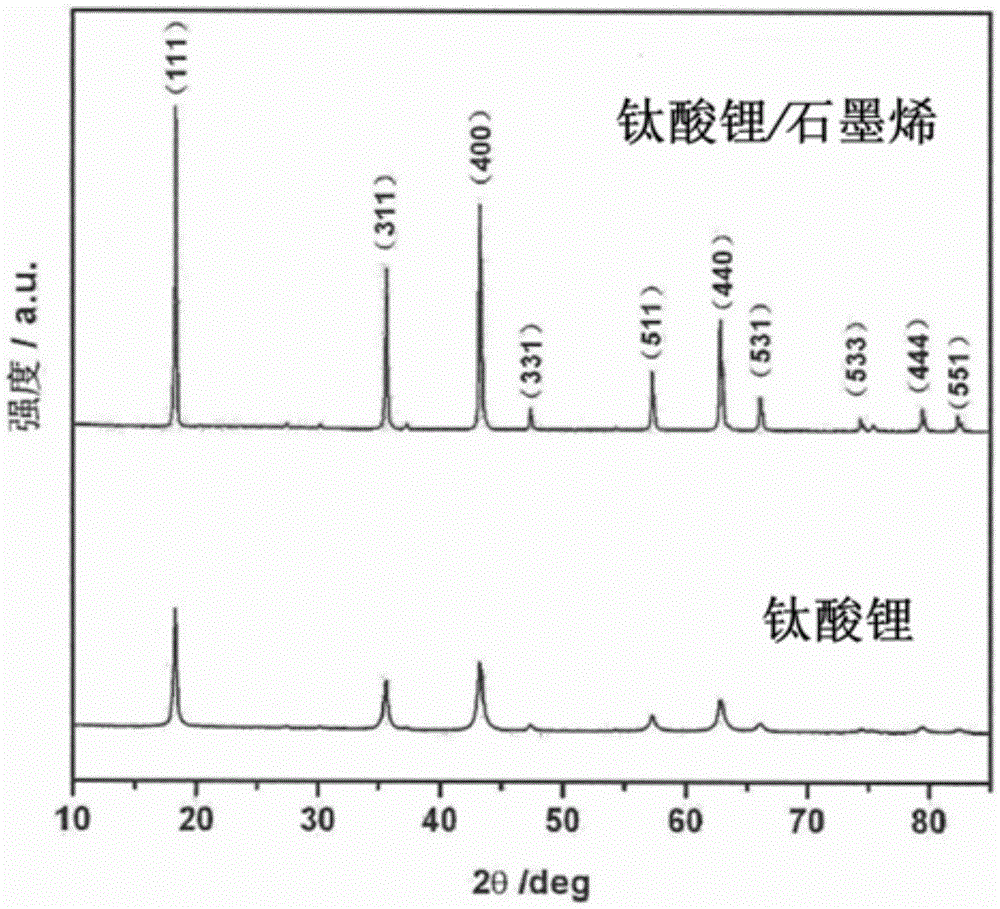

Preparation method of micro-nano dimensional graphene/lithium titanate composite negative electrode material

ActiveCN105590756AEvenly distributedShorten the diffusion distanceMaterial nanotechnologyHybrid capacitor electrodesMicro nanoMaterials science

The invention provides a preparation method of a micro-nano dimensional graphene / lithium titanate composite negative electrode material. The preparation method includes the steps of (1) preparation of a graphene oxide / lithium acetate / titanium complex / glacial acetic acid / isopropyl alcohol mixed solution; (2) synthesis of a graphene oxide / lithium titanate compound precursor; and (3) thermal recovery treatment of the graphene oxide / lithium titanate compound precursor. The particle distribution of the graphene / lithium titanate composite negative electrode material is between 200nm and 5mum. Because the size of the prepared graphene is between nanometer and a few of microns, the size is small, the lithium ion of the material has a small diffusion distance, and the micro-nano dimensional graphene / lithium titanate composite negative electrode material has the good electrochemical property. The 1C capacity of the material is larger than 170mAh / g, 10C capacity is larger than 120mAh / g, the energy density can reach 132 watt-hour / kg or more, and the power density reaches 6800 watt / kg or more.

Owner:山东信开源科技创新发展有限责任公司

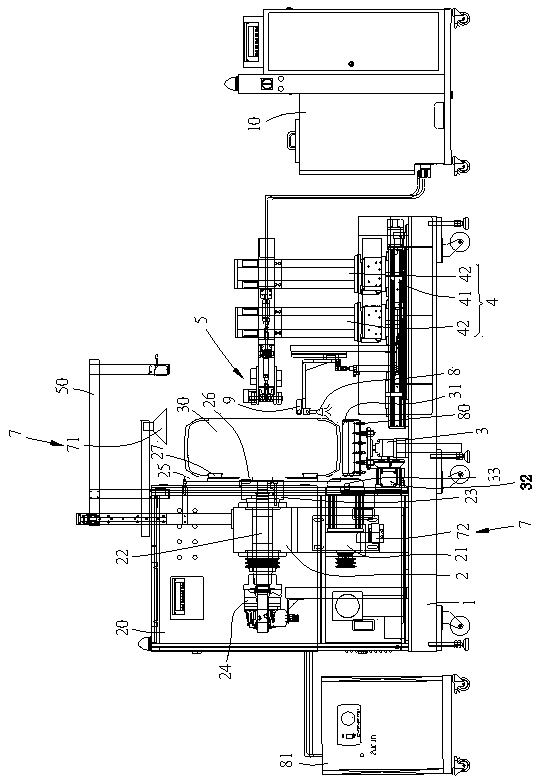

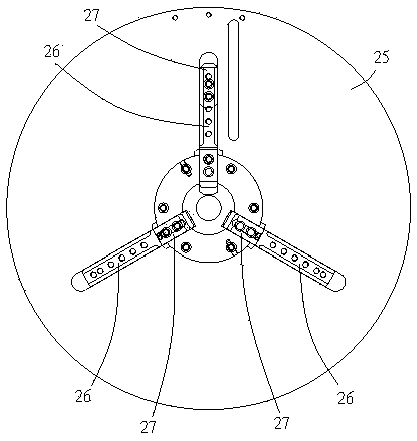

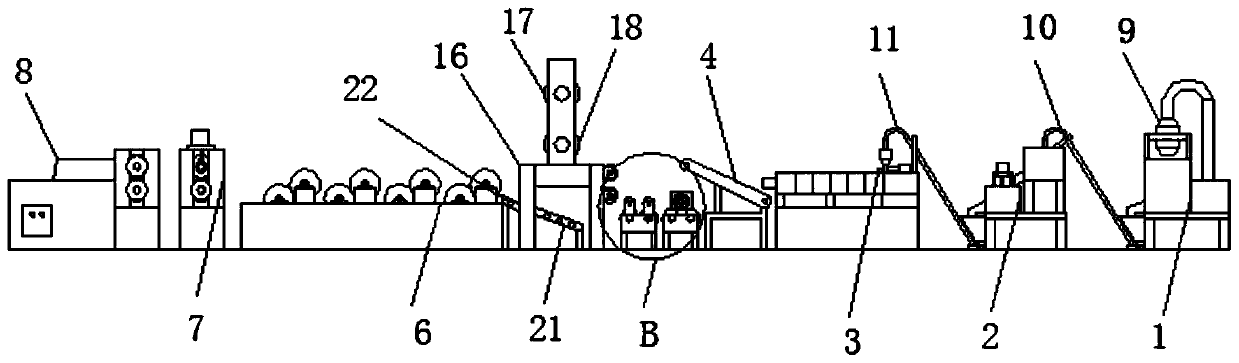

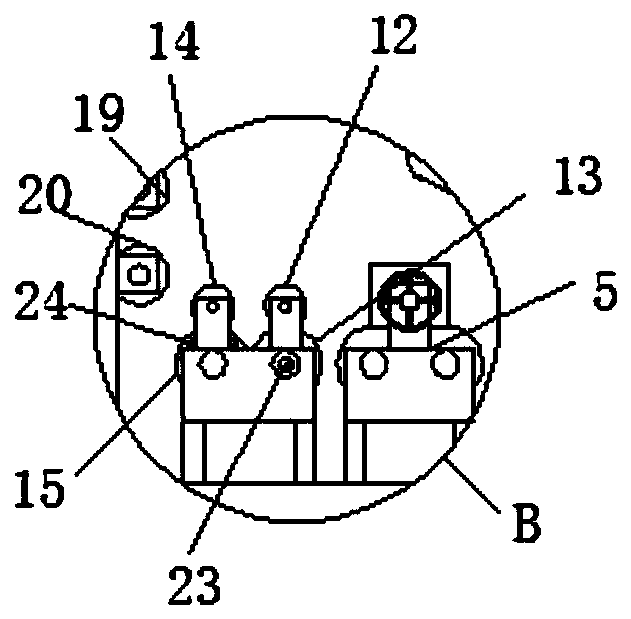

Anti-puncture and anti-explosion tire and spray-dripping method and spray-dripping equipment therefor

InactiveCN107649345AReduce rubber lossReduce the defective rate of finished productsRoad vehicle tyresSpraying apparatusSpray nozzleProduct defect

The present invention relates to an anti-puncture and anti-explosion tire and a spray-dripping method and spray-dripping equipment therefor. The spray-dripping device is used for spraying a puncture-resisting detonating plastic on a tire, and includes a digitized person. Machine system operating platform, a base, one side rotation fixing device, one / small wheel replaceable bottom supporting device, one displacement unit and one single and double parallel gun body assembly; digital human-machine system operation platform is used to control the whole device to operate; the lateral rotation fixing device and the large / small wheel replaceable bottom supporting device are used to support and drive the rotation of the tire; the displacement unit includes a first displacement module that can movealong the X axis and can move along the Y axis. A second displacement module; the single and double parallel gun body assembly includes a fixed-point nozzle or a multi-angle continuous reciprocatingnozzle; the single-double parallel gun body assembly is driven by a displacement unit and spray-penetrated to prevent the puncture and detonation of the tire; the technical solution can effectively reduce the plastic material loss and finished product defect rate.

Owner:黄鸿翔 +1

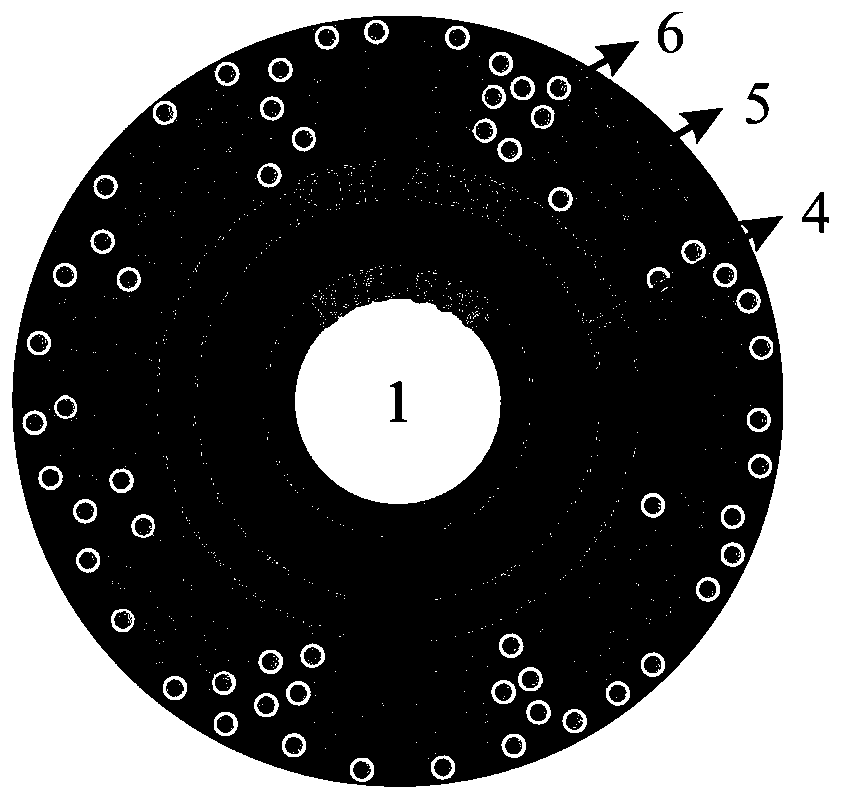

High-stretchable flexible strain sensor based on two-component polyurethane line and preparation method of sensor

ActiveCN110863352AImprove adhesionCombine tightly and evenlyFibre typesElectrical/magnetic solid deformation measurementPolymer scienceGraphite

The invention discloses a high-stretchable flexible strain sensor based on a two-component polyurethane line. The two-component polyurethane line serves as a base, the surface of the base is coated with an internal conducting layer (short hydroxyl carbon nanotube layer) after KH-550 modification, and the surface of the internal conducting layer is coated with an external conducting layer (hydroxylated graphene nanosheet / silver / silicon rubber cooperative conducting network layer) after KH-550 modification. The strain sensor has the advantages of high stretchability, high stability, high durability, rapid response characteristic and the like and can be used for electronic skin monitoring of human joint movement and gait detection.

Owner:HEFEI UNIV OF TECH

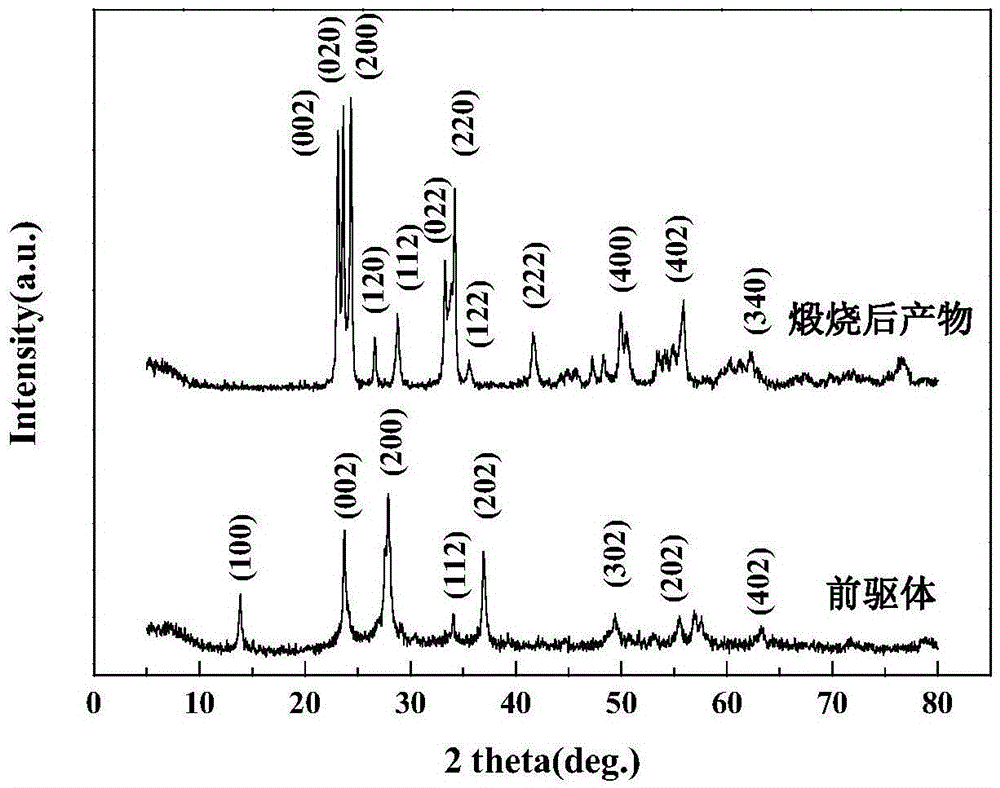

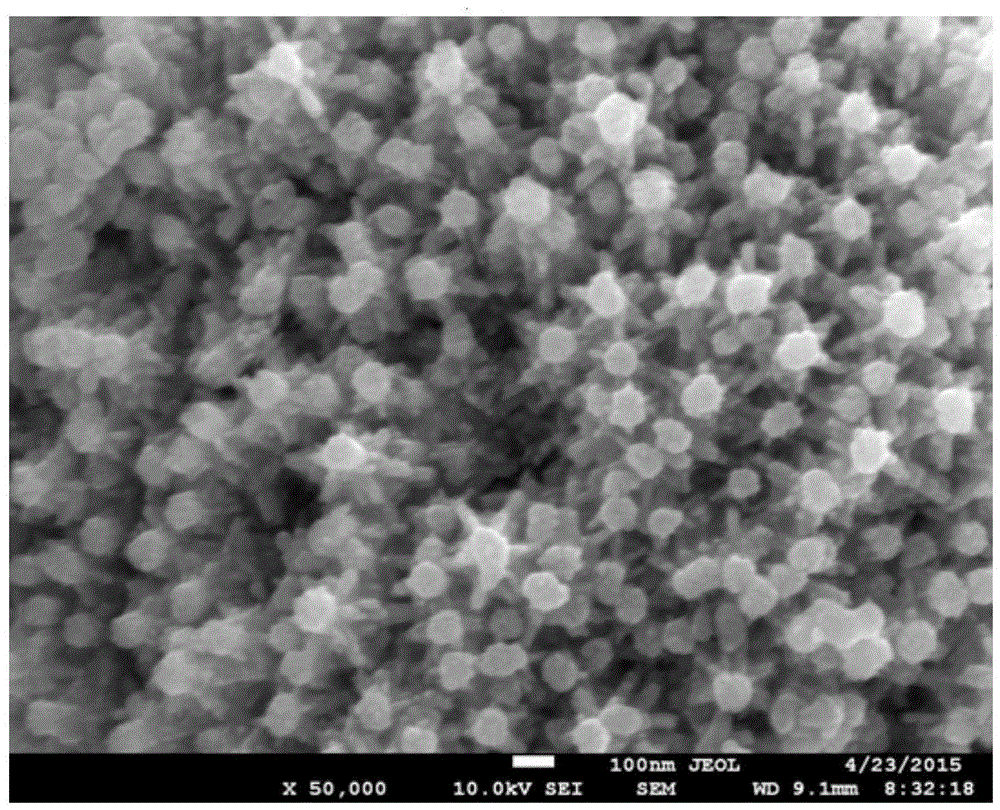

Nano-material and preparation method and application thereof

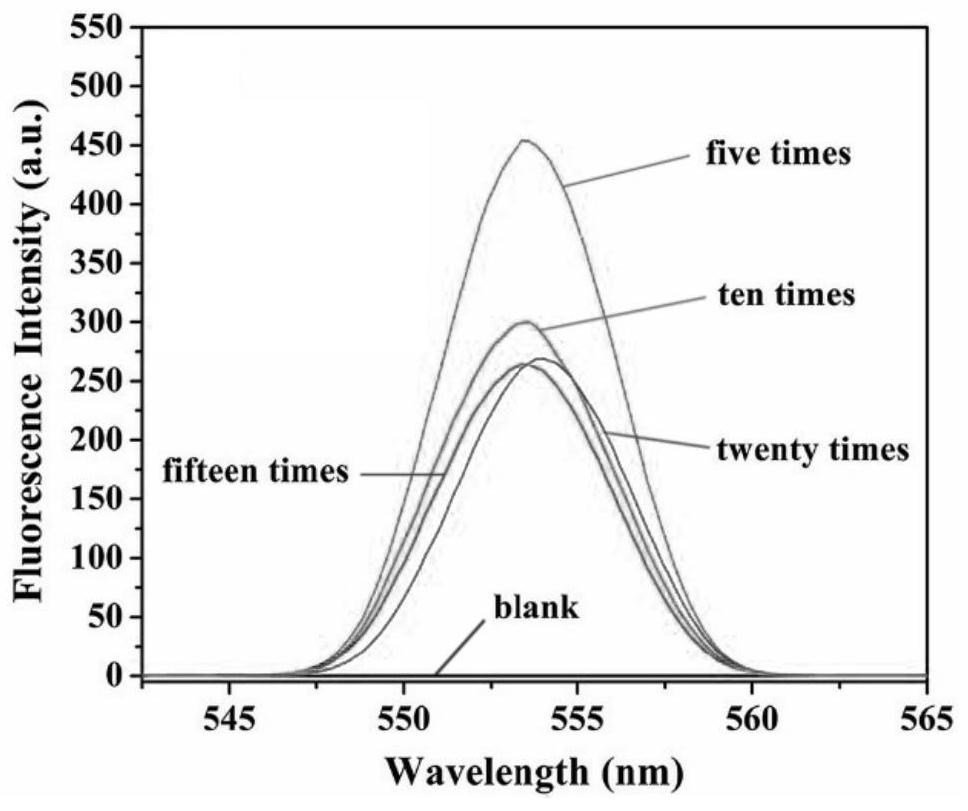

InactiveCN105668638AImprove gas sensing performanceUniform responseMaterial nanotechnologyTungsten oxides/hydroxidesMicrowaveWorking temperature

The invention relates to a nano-material and a preparation method and application thereof.The nano-material is a nano WO3 precursor and sintered product which presents excellent gas-sensitive performance to dimethylbenzene gas.The preparation method includes: dissolving tungsten hexachloride as a tungsten source in a glycol solvent, using ammonia water as a precipitation agent, and while stirring, and adopting microwave heating at 170-190 DEG C for reaction on a gas-liquid interface for 50-80 min to obtain a nano WO3 precursor which is gear-shaped; calcining the precursor in air at 450-550 DEG C for 2h to obtain a doughnut-shaped nano WO3 sintered product with a middle hole.Both the precursor and the sintered product present excellent gas-sensitive performance to dimethylbenzene gas.The preparation method has the advantages of quick reaction, energy conservation and cost reduction, and a dimethylbenzene gas sensor obtained has the advantages of low working temperature, high sensitivity, high selectivity and short response / restoration time.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

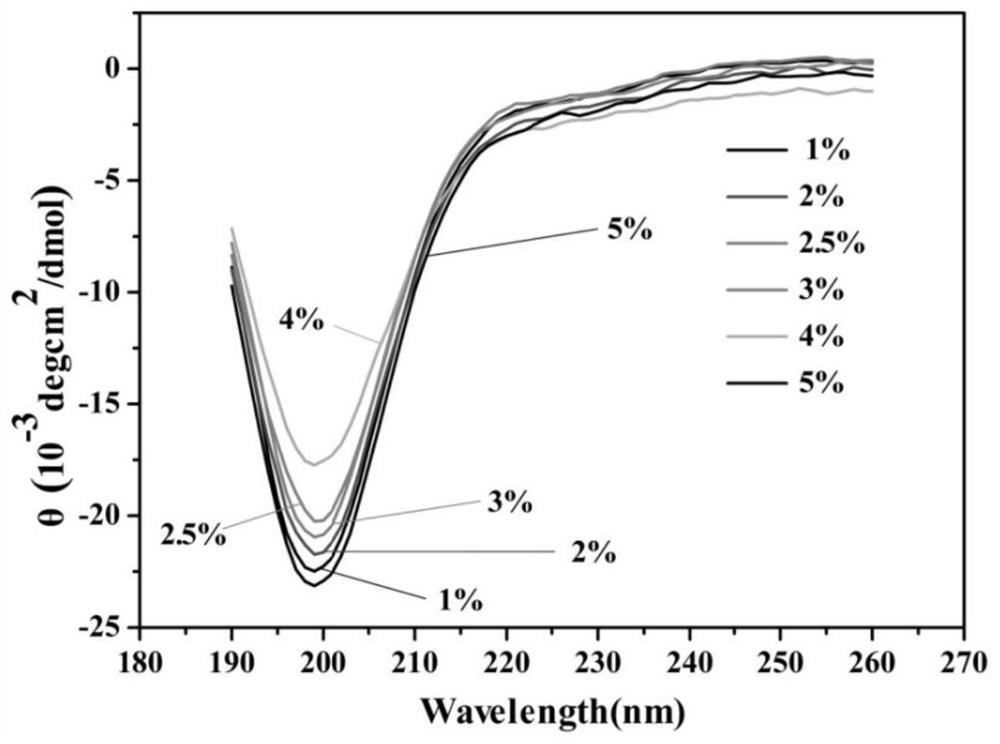

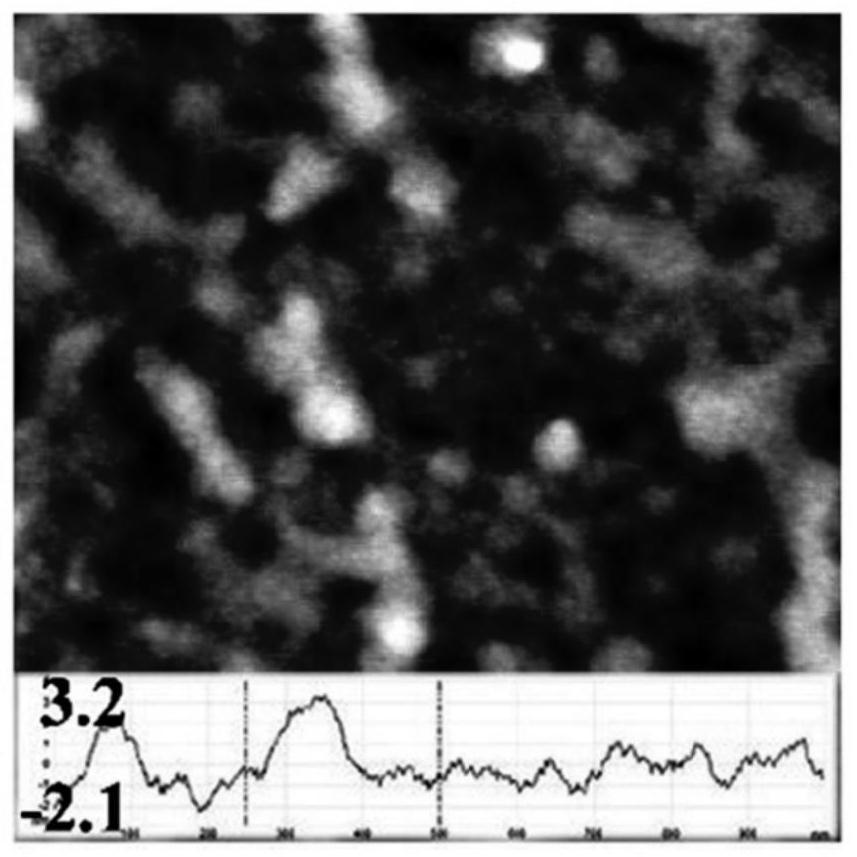

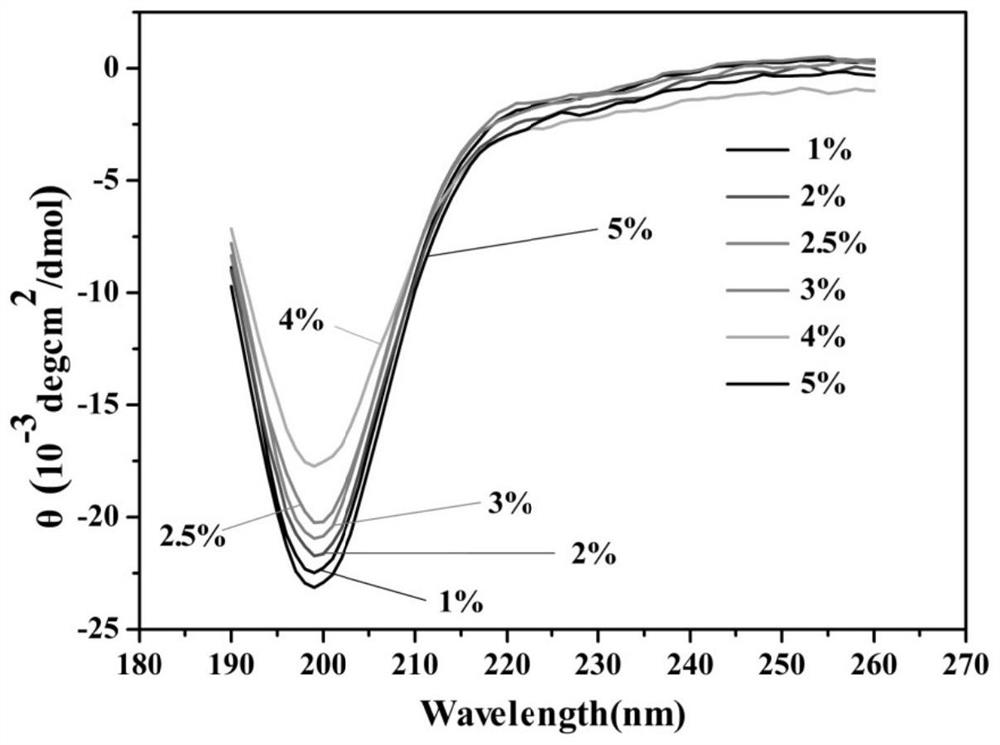

Polypeptide monolayer film with 7% of exposure quantity of primary amino groups as well as preparation method and application of polypeptide monolayer film

ActiveCN111671970AImprove stabilityGood adhesionTissue regenerationCoatingsThin membraneBiomedical engineering

The present invention provides a polypeptide monolayer film with 7% of exposure quantity of primary amino groups as well as a preparation method and application of the polypeptide monolayer film. Thepolypeptide is composed of a polypeptide molecule with the molecular weight of (1.48+ / -0.2)*105 g / mol, wherein the thickness of a monolayer film is 8.9+ / -0.1 nm, the primary amino group exposure of the surface of the film is 7.0+ / -0.2%, the Zeta potential of the polypeptide monolayer film is 0.76+ / -0.1 mV; and the contact angle of the film is 48+ / -1 DEG. The polypeptide monolayer film provided bythe present invention has good stability, may be applied as a coating material on the surface of an oral implant and may carry antibiotics and antibacterial drugs and stably release the antibiotics and the antibacterial drugs, the exposure quantity of the primary amino groups on the surface of the film is precisely controlled at 6.0+ / -0.3%, a local medicine carrying coating of the polypeptide monolayer film has the advantages such as little toxic and side effects to human bodies and strong antibacterial property, and the polypeptide monolayer film is uniform and tight in combination with a pure titanium material and not easy to separate and fall off.

Owner:QILU UNIV OF TECH

High-hardness and high-strength hard alloy saw blade and processing method thereof

The invention discloses a high-hardness and high-strength hard alloy saw blade and a processing method thereof in the field of alloy processing. The hard alloy saw blade comprises the components of tungsten carbide, cobalt powder, tantalum carbide, chromium carbide and vanadium carbide. The processing method comprises the specific steps of step I, processing of tungsten carbide: carrying out carbonization and reduction on tungsten carbide and an additive at the high temperature; step II, ball milling: carrying out ball milling on tungsten carbide and cobalt powder with cylindrical grinding bodies; step III, addition of a forming agent: adding the PEG forming agent; step IV, introduction of a protective gas: introducing nitrogen or argon as the protective gas; step V, punch forming: carrying out punch forming at 30 to 100 tons of pressure; step VI, sintering: carrying out sintering at the temperature of 1400 to 1450 DEG C and the pressure of 10 MPa; and step VII, surface treatment. The hard alloy saw blade processed through the scheme is good in stability, high in size precision, good in compactness and low in damage rate, hardness and strength of a product are improved, brittleness is reduced, and the hard alloy saw blade is more suitable for cutting high-hardness profiles.

Owner:ZUNYI ZHONGBO CEMENTED CARBIDE

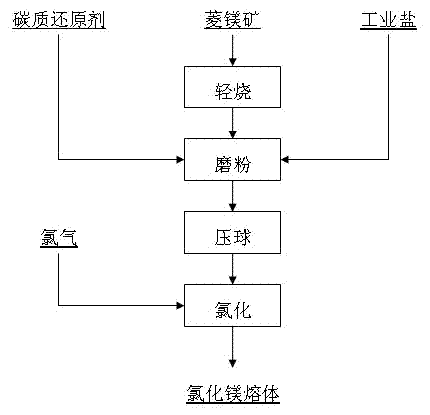

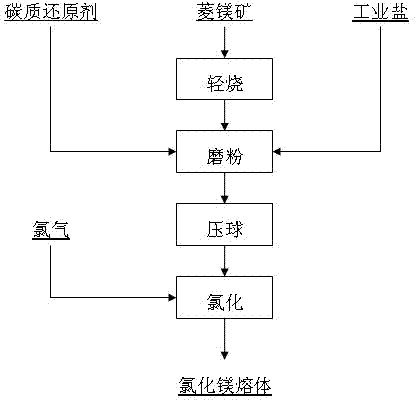

Chlorination process for pressing magnesite into balls through light burning dry method

The invention discloses a process method for pressing magnesite into balls through a light burning dry method to carry out chlorination production of anhydrous magnesium chloride melt. According to the method, the magnesite is subjected to light burning through a furnace kiln; a carbonaceous reducing agent and a dried industrial salt additive are added according to a certain ratio; a mill is adopted to grind into a mixed powder material; the mixed powder material is directly pressed into a briquette through a ball pressing machine; the briquette is conveyed to a chlorination furnace, and reacts with the introduced chlorine gas at a high temperature of 800-1000 DEG C to produce the magnesium chloride melt. Compared to the prior art, the process of the present invention has the following advantages that: the productivity of the chlorination furnace can be improved, the chlorine gas utilization rate can be improved, and the electricity consumption of the chlorination furnace can be reduced.

Owner:GUIYANG AL-MG DESIGN & RES INST

Preparation method of nanocarbon conductive fiber yttrium-barium-copper superconducting material

InactiveCN108046793ACombine tightly and evenlyEasy to prepareMaterial nanotechnologySuperconductors/hyperconductorsBenzoic acidFiber

The invention discloses a preparation method of a nanocarbon conductive fiber yttrium-barium-copper superconducting material, which is made from, by weight, 4.2-5.1 parts of graphene-coated yttrium powder, 4.8-5.2 parts of barium oxide, 5.1-5.3 parts of copper oxide, 1.7-1.8 parts of benzoic acid, 2.1-2.2 parts of methyl methacrylate, 1.3-1.5 parts of sodium carboxymethylcellulose, 3.2-3.5 parts of sodium stearate, 2.2-2.5 parts of potassium carbonate, 1.3-1.5 parts of quicklime, and 1.7-1.9 parts of polyethylene glycol. The preparation method is simple. Yttrium powder is added to a nanocarbonconductive fiber material solution, so that nanocarbon conductive fibers coat yttrium powder. The obtained product isn't agglomerated after thermal treatment. The nanocarbon conductive fibers uniformly closely combine with yttrium powder, so that the conductivity of yttrium powder is improved. The obtained product is high in critical transition temperature, good in superconducting performance, high in critical current density, good in current carrying performance, less in energy dissipation, low in production cost, and high in practical value.

Owner:戚明海

Silicon steam corrosion resistant internal coating for directly protecting carbon fiber and in-situ preparation method thereof

ActiveCN103193514AWill not crack and fall offReduce surface defectsAfter-treatment apparatusPolycrystalline material growthFiberCarbon composites

The invention relates to a silicon steam corrosion resistant internal coating for directly protecting carbon fiber and an in-situ preparation method thereof. The internal coating is prepared by the following steps of: coating a primary pyrolytic carbon substrate layer on the surface of carbon fiber through a chemical vapor deposition mode; then coating a secondary silicon carbide enriched protective layer on the surface of the primary pyrolytic carbon substrate layer through the chemical vapor deposition mode. The invention further relates to a preparation method of the silicon steam corrosion resistant internal coating for directly protecting the carbon fiber. The silicon steam corrosion resistant internal coating obtained by the invention is compact and uniform in structure, is firmly bonded with a carbon fiber body in a carbon / carbon composite material crucible and completely coats the carbon fiber body; and a carbon fiber reinforcing material of the carbon / carbon composite material crucible with the silicon steam corrosion resistant internal coating is not corroded by silicon steam, thus the use reliability of a product is improved, and the service life of the product is prolonged.

Owner:山东道普安制动材料有限公司

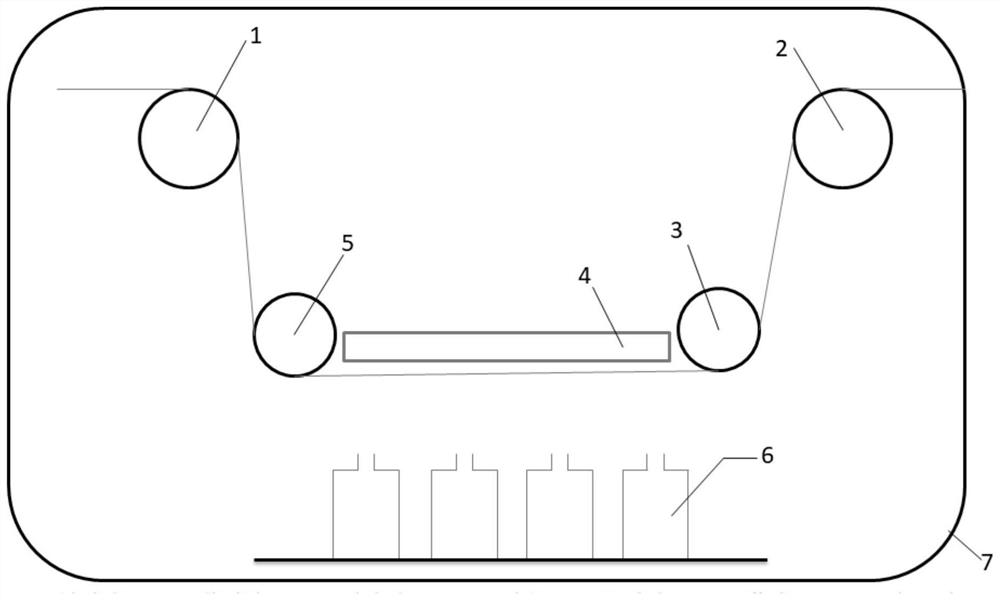

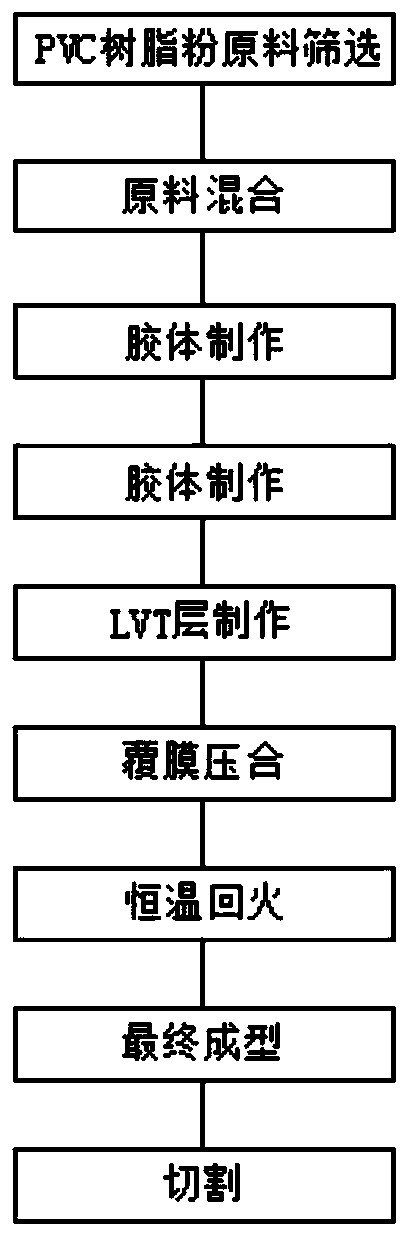

LVT plastic floor production process and device

PendingCN110303689AEasy to connect in sequenceCombine tightly and evenlyFlat articlesScrew conveyorEngineering

The invention relates to the technical field of LVT plastic floors and discloses an LVT plastic floor production process. The production process includes the following steps that S1,PVC resin powder raw material screening is performed; S2,raw material mixing is performed, and a mixture A is obtained after uniform mixing; S3,rubber manufacturing is performed, the mixture A is conveyed to an internal mixer through a spiral conveyor to be machined into rubber; S4,LVT layer manufacturing is performed; S5,film covering press fitting is performed, meanwhile, a PVD abrasion resisting layer and a color film layer are conveyed to a four-roller film covering machine, hot pressing forming together with an LVT layer is performed, and an LVT plastic floor blank body is obtained; S6, constant temperature tempering is performed, and used for making the LVT layer, the PVD abrasion resisting layer and the color film layer combined more compactly and uniformly; S7,final forming is performed, the LVT plastic floor blank body is conveyed into a hydraulic coiling and rolling machine, and pressing and forming are performed; and S8,cutting is performed, and cutting into a needed specification through a cutting machine is performed. The LVT plastic floor production process and device have the beneficial effects that continuous production is achieved, the floor space is saved, manpower is saved, and the production cost is lowered.

Owner:浙江欧耐力新材料有限公司

Polypeptide single-layer film with primary amino exposure amount of 6%, and preparation method and application for polypeptide monolayer film

ActiveCN111671971ARelease stabilityPrevention early intervention treatmentTissue regenerationCoatingsWhole bodyBiology

The invention provides a polypeptide single-layer film with a primary amino exposure amount of 6%, and a preparation method and an application for the polypeptide single-layer film. The polypeptide iscomposed of polypeptide molecules with a molecular weight of (1.48 + / - 0.2) * 10<5> g / mol; the thickness of the single-layer film is 14.6 + / - 0.1 nm; the exposure amount of primary amino groups on the surface of the film is 6 + / - 0.3%; the Zeta potential of the polypeptide single-layer film is minus 4.48 + / - 0.1 mV; and the contact angle of the film is 45 + / - 1 degrees. The polypeptide single-layer film provided by the invention has good stability; the exposure amount of primary amino groups on the surface of the film is accurately controlled to be 6.0 + / - 0.3%; and the polypeptide single-layer film can be applied to an oral implant surface coating material, and can carry antibiotics and antibacterial drugs and stably release the antibiotics and the antibacterial drugs; and the local drug-loaded coating of the polypeptide single-layer film has the advantages of small toxic and side effects on the whole body, strong antibacterial property and the like, is uniformly and tightly combinedwith a pure titanium material, and is not prone to separating and falling off.

Owner:QILU UNIV OF TECH

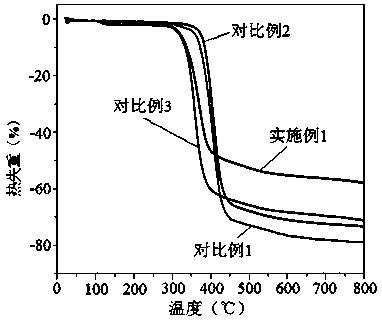

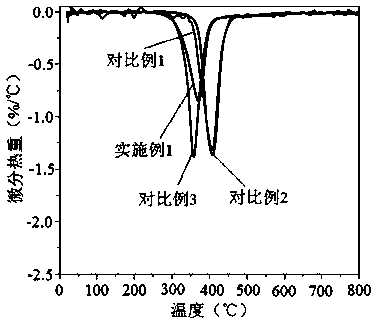

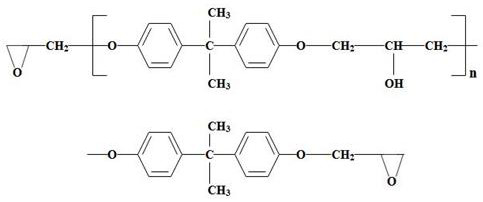

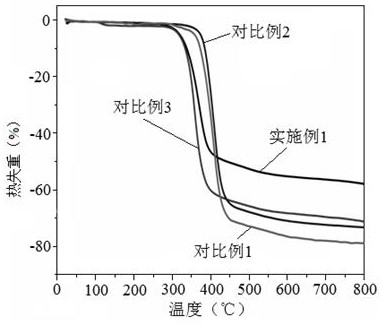

Calcined kaolin-based composite flame retardant for epoxy resin, and preparation and application of calcined kaolin-based composite flame retardant

ActiveCN110628079AImprove flame retardant performanceIncrease carbon residueEpoxyIn situ polymerization

The invention discloses a calcined kaolin-based composite flame retardant for epoxy resin, and preparation and an application of the calcined kaolin-based composite flame retardant; the composite flame retardant takes calcined kaolin particles as a basic component, and ammonium polyphosphate generated by in-situ polymerization is combined with kaolin on the surface of kaolin to form a composite structure. Phosphoric acid and urea are used as raw materials, in-situ polymerization is carried out on the surface of calcined kaolin, and the composite flame retardant is prepared. When the compositeflame retardant is added into epoxy resin, the flame retardant property of the epoxy resin can be improved, the thermal weight loss rate and the heat release rate of the epoxy resin are effectively reduced, and the residual carbon content and the residual carbon compactness are improved. The preparation method is simple and easy to operate, low in cost and ingenious in preparation thought, kaolinand ammonium polyphosphate generated through in-situ polymerization are tightly and uniformly combined, the composite flame retardant has the characteristics of being halogen-free, efficient, environmentally friendly and the like, and the application range of kaolin and epoxy resin is widened.

Owner:LANZHOU UNIVERSITY

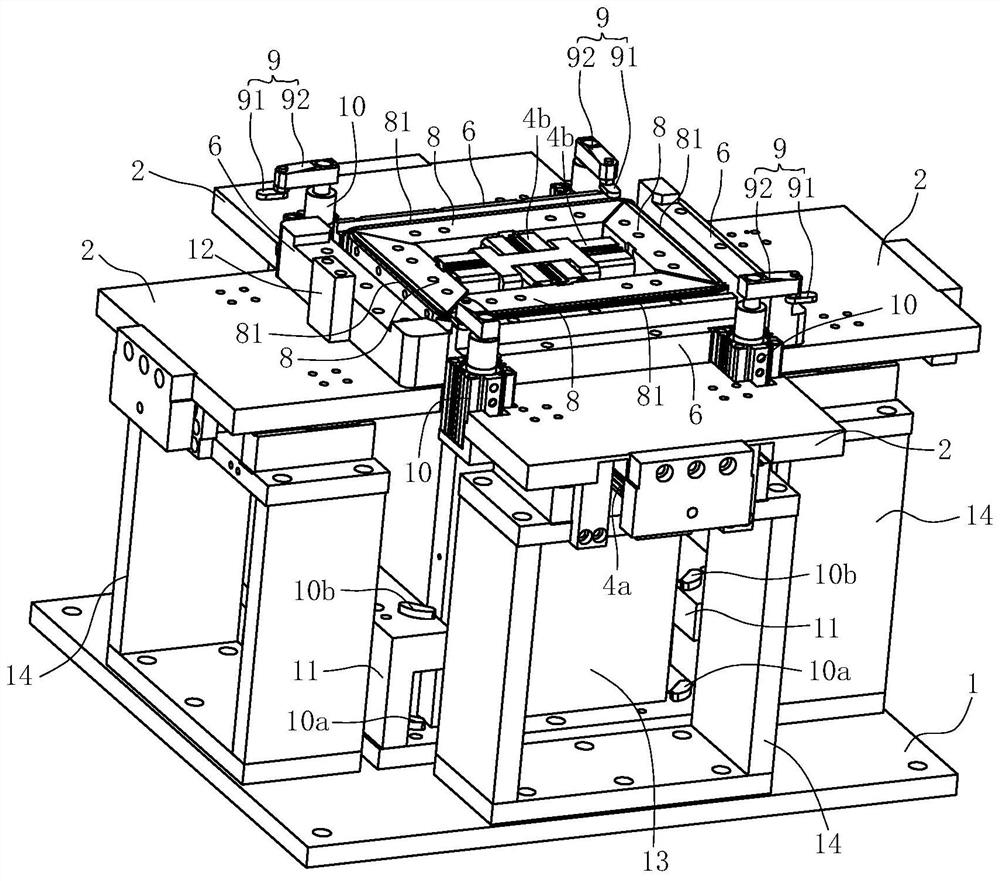

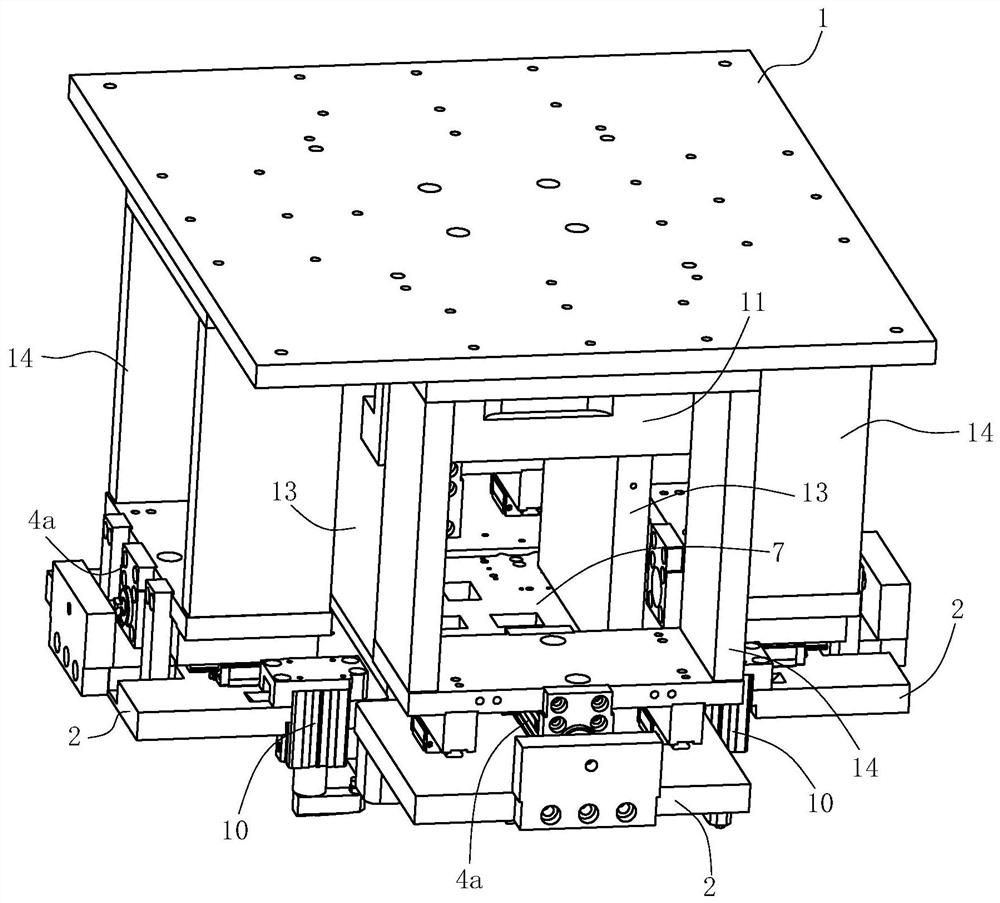

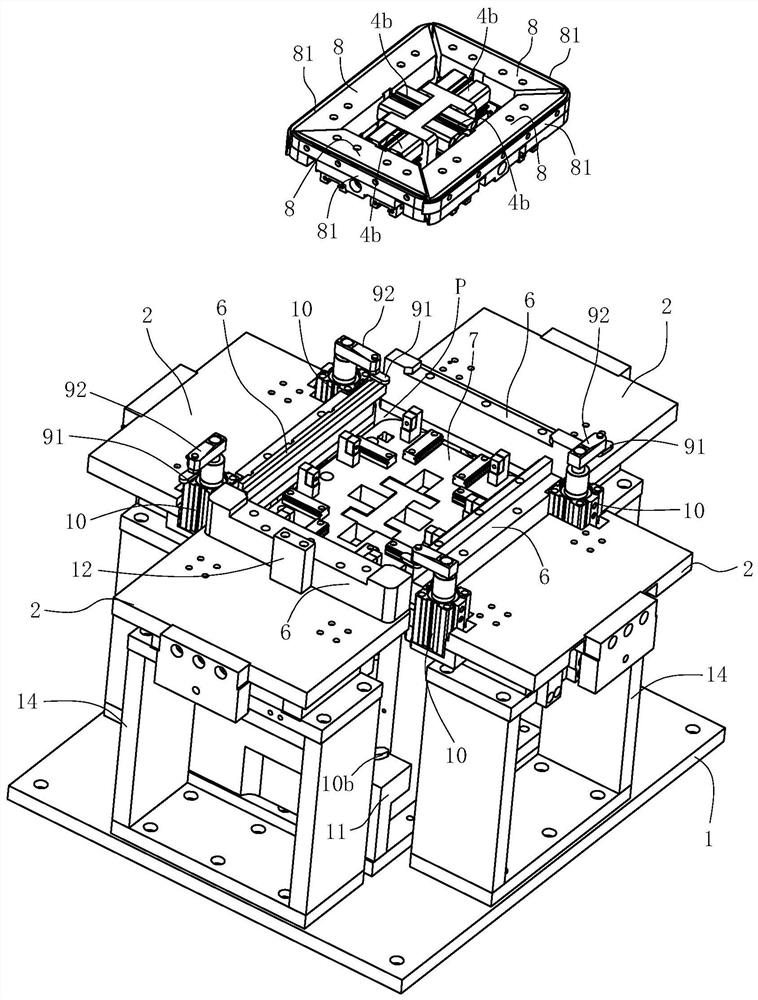

Laser welding tool for welding the stainless steel panel and the vertical barrel together

ActiveCN111168238BNot easy to shakeCombine tightly and evenlyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSS - Stainless steel

The invention relates to a laser welding tool for welding a stainless steel panel and a vertical bucket, which is characterized in that: it includes a table top; four outer support platforms are constrained on the table top and driven by a first cylinder to slide, and the four pieces The outer support platforms form a space, and each outer support platform is fixed with an outer pressing block; the bottom limit structure is set on the table to form a limit for the bottom of the vertical bucket placed in the space; the middle support platform is fixed on the The table top is located in the space surrounded by four outer support platforms; the four inner support blocks are all constrained on the table top and driven by the second cylinder to slide, and the outward movement of the inner support blocks can press the inner wall of the vertical barrel and Adjacent to the welding position; multiple upper pressing blocks, each upper pressing block is correspondingly installed on the corner cylinder and can be deflected and moved up and down. This tooling can effectively ensure that the opening periphery of the vertical bucket is closely and evenly combined with the inner hole wall of the installation hole of the stainless steel panel, the top of the opening periphery is kept flush with the top surface of the sink panel, and the workpiece is placed easily and conveniently.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Method for preparing nanocarbon conductive fiber coated niobium-aluminum superconducting wire

InactiveCN107464631AUniform compositionImprove performanceSuperconductor device manufacture/treatmentCable/conductor manufactureFiberNiobium

The invention discloses a method for preparing a nanocarbon conductive fiber coated niobium-aluminum superconducting wire. The method is characterized in that aluminium powder is added into a nanocarbon conductive fiber material solution to coat nanocarbon conductive fibers with aluminium powder, clustering is prevented after heat treatment, the electric conductivity is improved, and aluminium powder is prevented from oxidation. According to the method, the phenomena that a precursor has high probability of fracture in high temperature and heating equipment is specially demanded during traditional quick heating and quick cooling treatment are avoided, and the obtained superconducting wire is uniform in ingredient, favorable in performance, effectively lowered in cost and favorable for large-scale production.

Owner:SUZHOU NANER MATERIAL TECH CO LTD

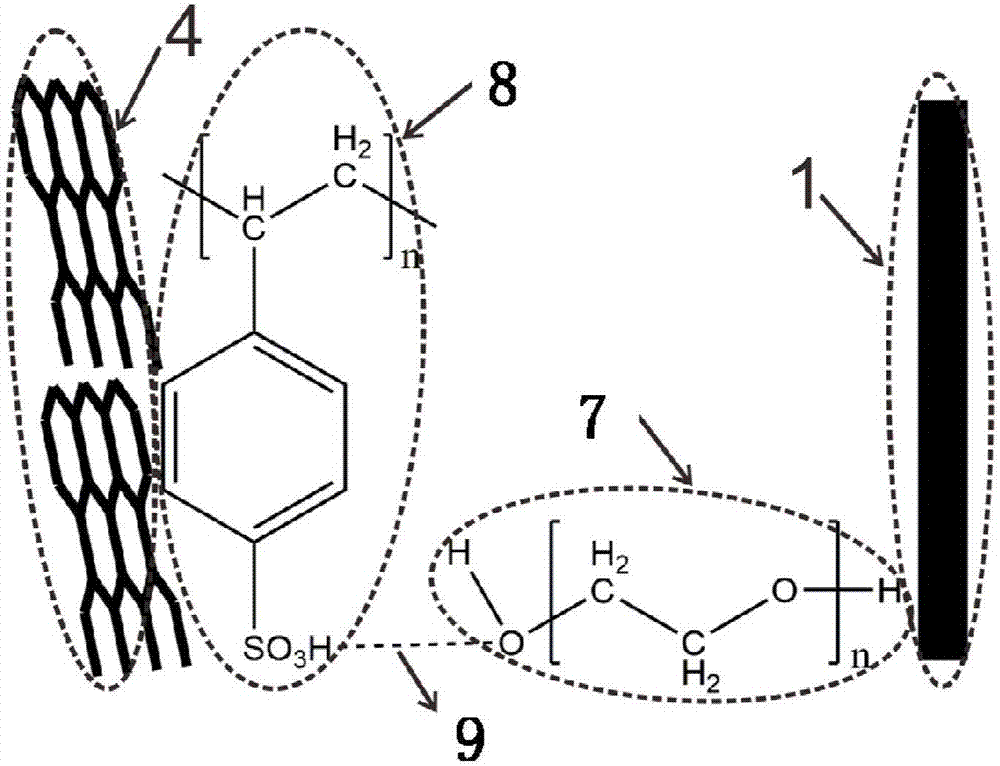

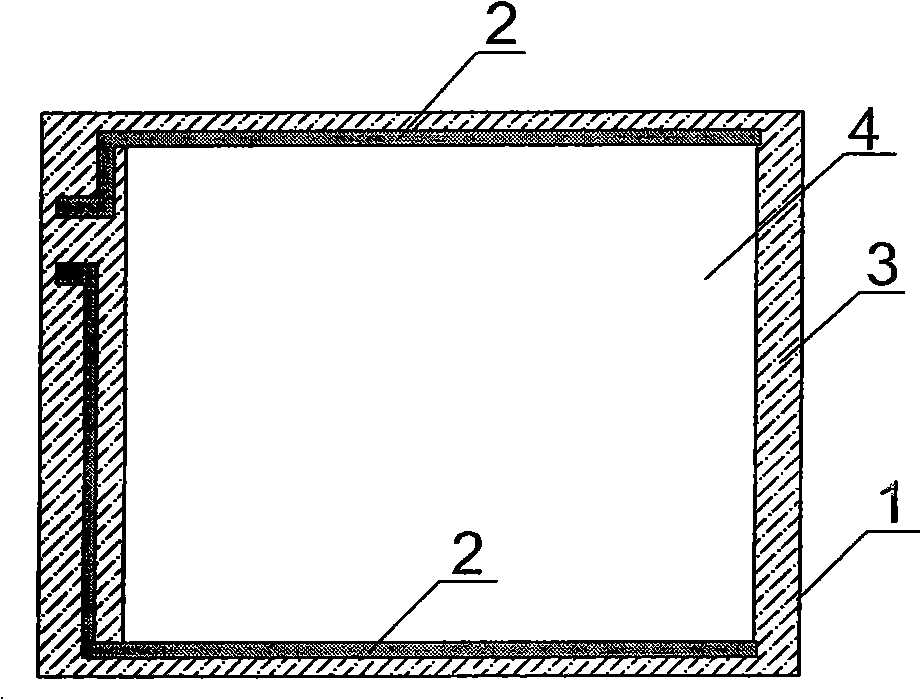

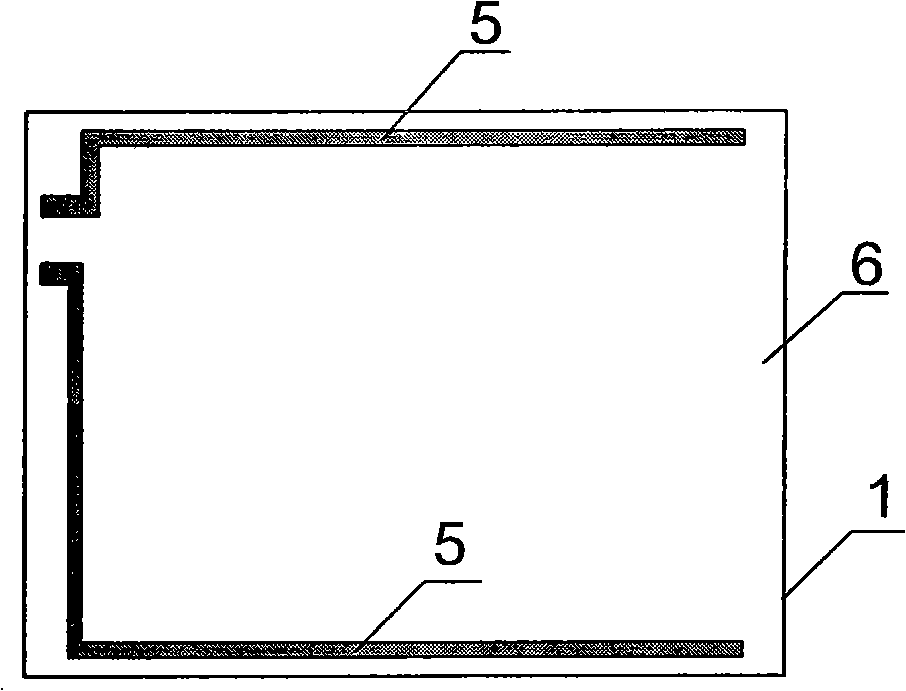

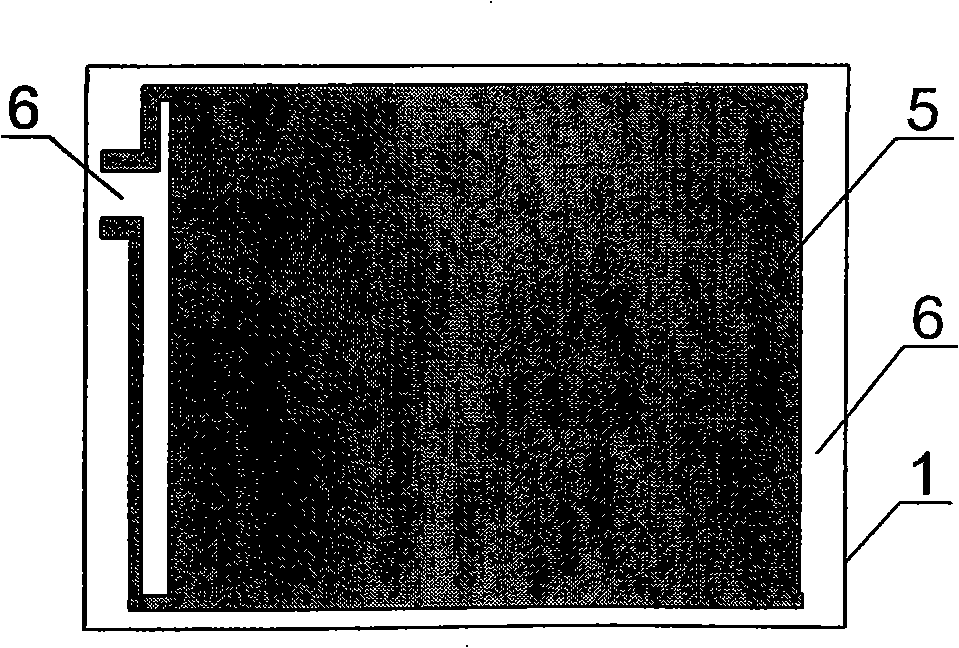

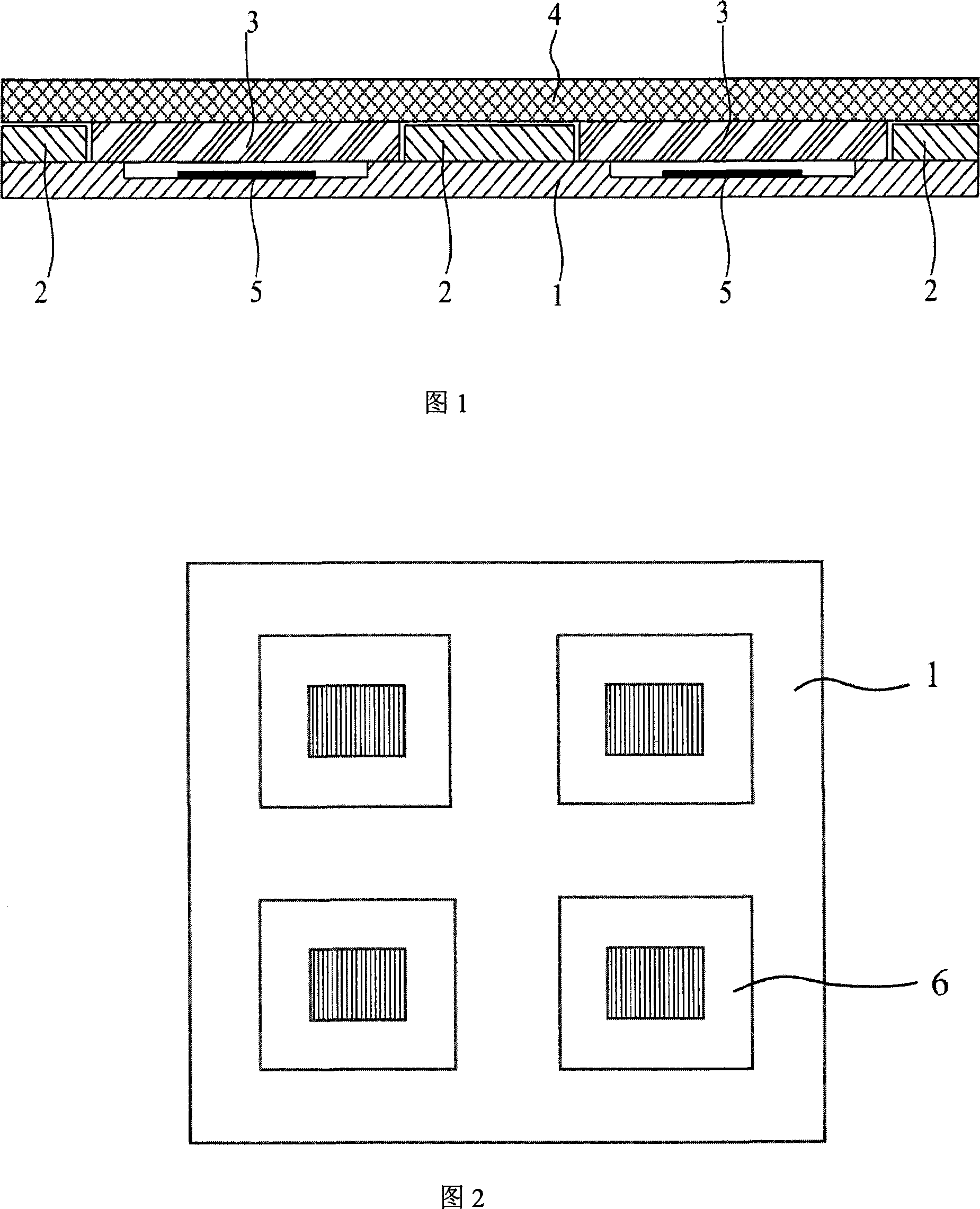

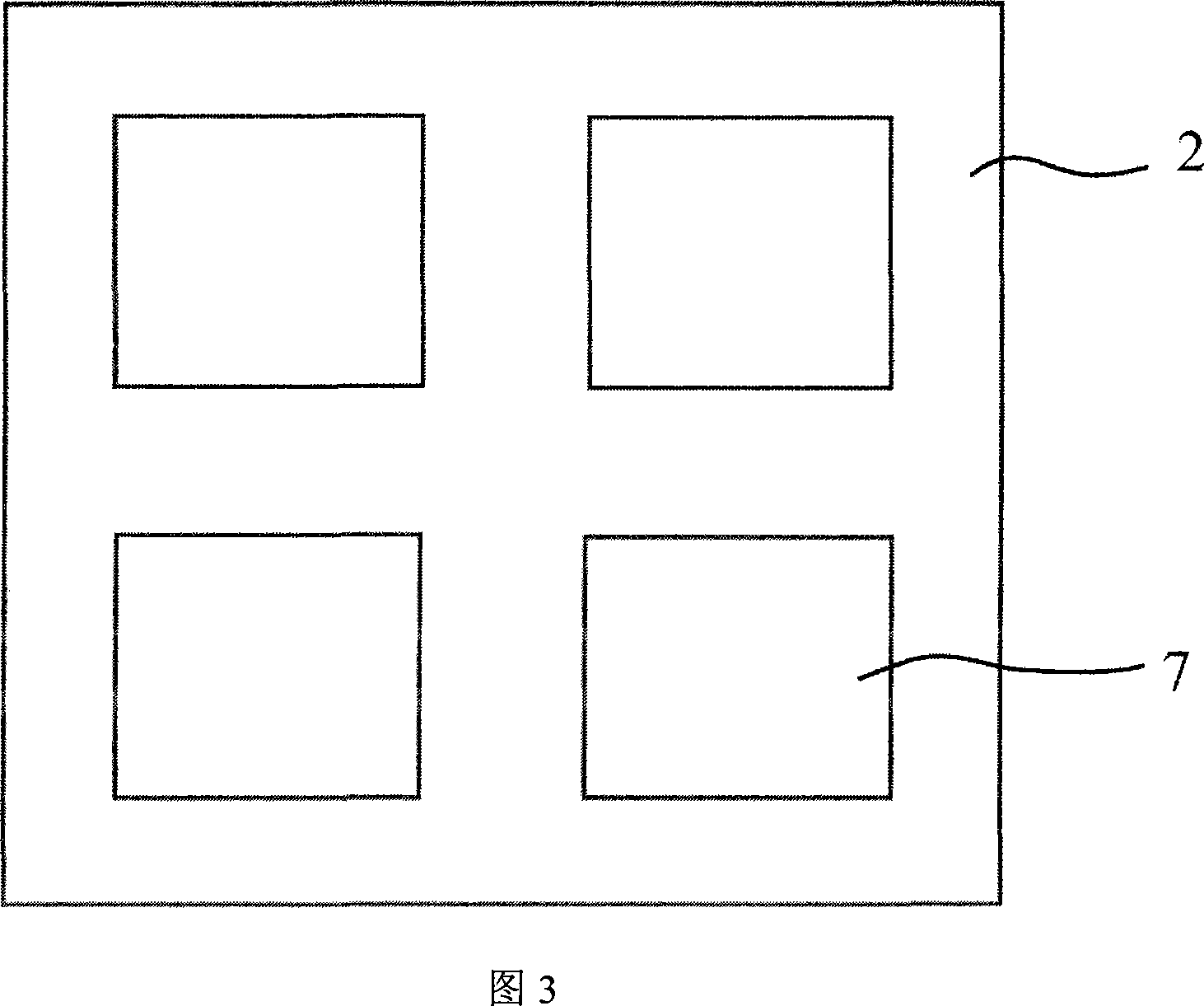

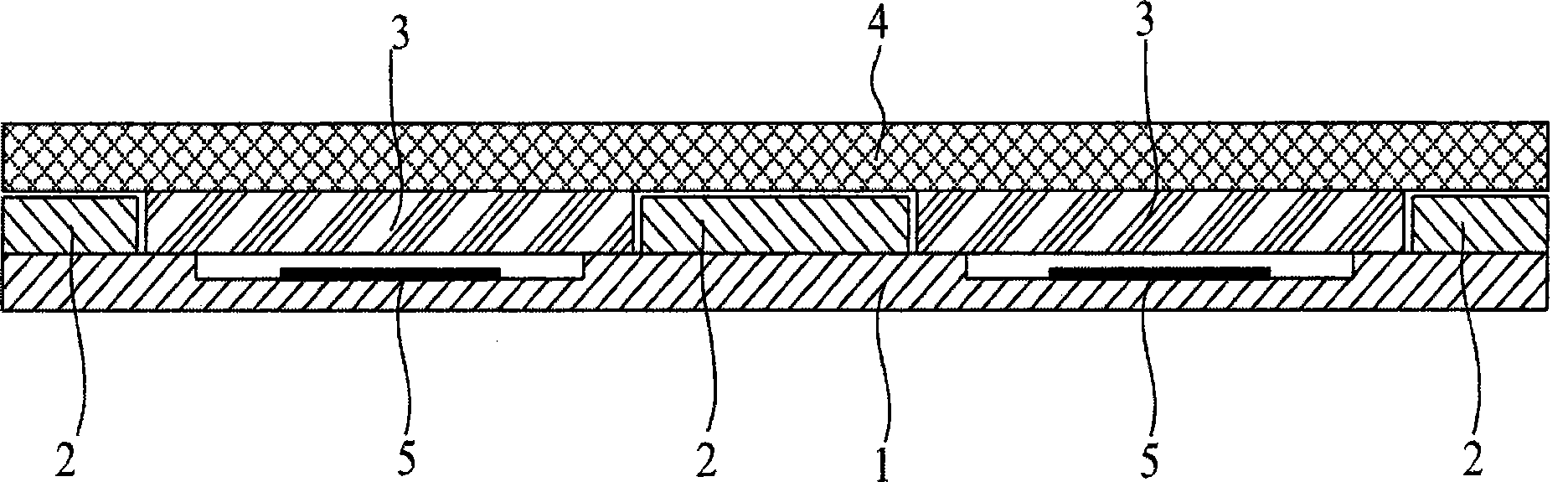

Novel packaging device of organic EL device and its packaging method

ActiveCN101222025BSimple structureSimple and fast operationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringOrganic electroluminescence

The invention discloses a novel packaging device for an organic electroluminescent device, comprising a cover plate, a locating plate and a packaging holding apparatus, wherein, a groove which corresponds to a substrate is arranged on the cover plate and the substrate contact face of the organic electroluminescent device; hygroscopic agents are arranged inside the groove; the locating plate is provided with a locating hole the size of which is consistent with that of the substrate and arranged above the cover plate; the side face of the substrate which is provided with an organic electroluminescent layer faces towards and passes through the locating hole and is led into the groove; the packaging holding apparatus is arranged above the substrate which is closely connected with the cover plate. The packaging device of the invention can solve substrate slippage and deviation due to unequal stress during the packaging process, thereby packaging precision is guaranteed; packaging efficiency is improved; equipment requirements and production cost are reduced. Particularly, the invention has strong maneuverability on packaging of small and medium-sized substrates and large-sized cover plates and meets actual requirements.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

Calcined kaolin-based composite flame retardant for epoxy resin and its preparation and application

ActiveCN110628079BImprove flame retardant performanceIncrease carbon residueEpoxyIn situ polymerization

The invention discloses a calcined kaolin-based composite flame retardant for epoxy resin and its preparation and application. The composite flame retardant uses calcined kaolin particles as a basic component, and ammonium polyphosphate produced by in-situ polymerization is formed on the surface of kaolin and Kaolin combines to form a composite structure. Using phosphoric acid and urea as raw materials, the composite flame retardant was prepared by in-situ polymerization on the surface of calcined kaolin. Adding it to epoxy resin can improve the flame retardant performance of epoxy resin, effectively reduce the thermal weight loss rate and heat release rate of epoxy resin, and improve its carbon residue and carbon density. The preparation method of the present invention is simple and easy to operate, low in cost, and ingenious in preparation ideas. Through in-situ polymerization, kaolin and ammonium polyphosphate produced by in-situ polymerization are closely and uniformly combined. The composite flame retardant has the characteristics of halogen-free, high efficiency, and environmental friendliness. The scope of application of kaolin and epoxy resins.

Owner:LANZHOU UNIVERSITY

Silicon steam corrosion resistant internal coating for directly protecting carbon fiber and in-situ preparation method thereof

ActiveCN103193514BWill not crack and fall offReduce surface defectsAfter-treatment apparatusPolycrystalline material growthFiberCarbon composites

The invention relates to a silicon steam corrosion resistant internal coating for directly protecting carbon fiber and an in-situ preparation method thereof. The internal coating is prepared by the following steps of: coating a primary pyrolytic carbon substrate layer on the surface of carbon fiber through a chemical vapor deposition mode; then coating a secondary silicon carbide enriched protective layer on the surface of the primary pyrolytic carbon substrate layer through the chemical vapor deposition mode. The invention further relates to a preparation method of the silicon steam corrosion resistant internal coating for directly protecting the carbon fiber. The silicon steam corrosion resistant internal coating obtained by the invention is compact and uniform in structure, is firmly bonded with a carbon fiber body in a carbon / carbon composite material crucible and completely coats the carbon fiber body; and a carbon fiber reinforcing material of the carbon / carbon composite material crucible with the silicon steam corrosion resistant internal coating is not corroded by silicon steam, thus the use reliability of a product is improved, and the service life of the product is prolonged.

Owner:山东道普安制动材料有限公司

Method for preparing alkaline sizing agent in cation rosin

InactiveCN100480466CReduce churnReduce processing costsWater-repelling agents additionCardboardFiber

Owner:SHAANXI UNIV OF SCI & TECH

A kind of fiber fabric and preparation method thereof

ActiveCN104975364BImprove breathabilityLarge outer surface areaBiocideMonocomponent polyurethanes artificial filamentFiberPolymer science

The invention relates to a fiber fabric with good antibacterial and moisture absorption and perspiration properties, at least a part of the fibers of which contain copper, and the copper is added to the fibers during the spinning process. The invention also relates to a method for the preparation of a fibrous fabric comprising the step of adding copper powder to at least a portion of the fibers used in the fabric, wherein said copper powder is mixed with fibers or polymer masterbatches in molten state. The fiber of the fiber fabric of the present invention has an X-shaped cross-section, which has a larger surface tension than ordinary fibers, and can form a plurality of tiny drainage and ventilation channels to improve the water absorption and drainage and air permeability of the fiber fabric; the present invention In the spinning stage, the copper element has been implanted into the fiber, and it is evenly and tightly combined with the fiber, which can improve the bactericidal effect, and the copper element can be kept for a long time, and it can still have good antibacterial and deodorizing effects after repeated washing.

Owner:PRIDEWOOD INT

Method for preparing organic composite inorganic electrochromic films

The invention discloses a method for preparing organic composite inorganic electrochromic films. The prepared inorganic film is a WO3 film, and organic doping materials are phenylamine / o-phenylenediamine. SiO2 colloid crystals are used as templates, the WO3 film is filled into gaps of the colloid crystals, the porous films with regular pore arrangement are formed after the SiO2 colloid crystal templates are removed, the porous films are soaked into prepared organic matter precursors, and the organic composite inorganic electrochromic film materials are obtained through drying, pulling and drying.

Owner:靖江市浩鑫电气机械配件有限公司

Preparation method of inorganic base electrochromic composite film

Owner:南通通易航天科技股份有限公司

A high-hardness and high-strength cemented carbide saw blade and its processing method

Owner:ZUNYI ZHONGBO CEMENTED CARBIDE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com