A kind of fiber fabric and preparation method thereof

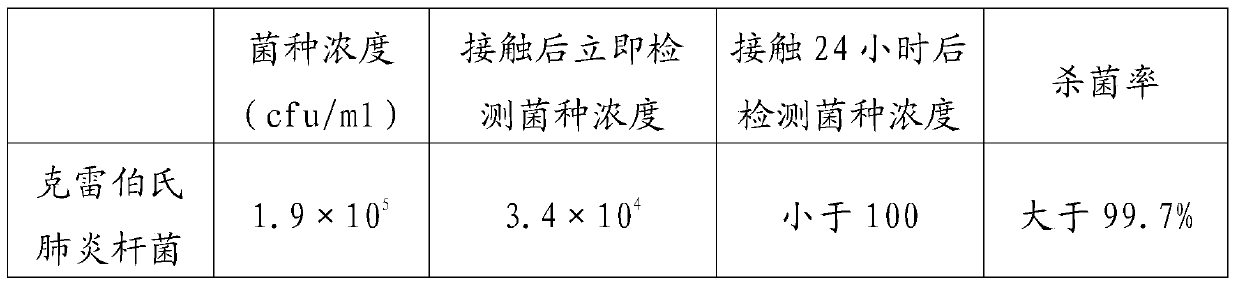

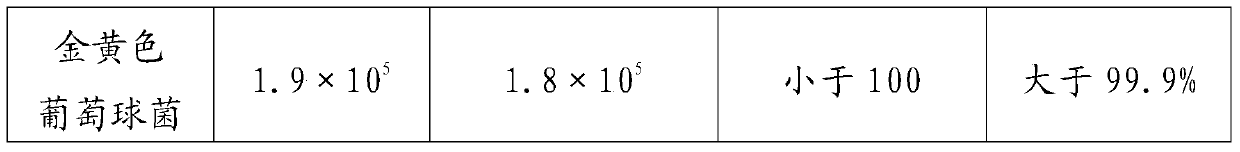

A fiber fabric and fiber technology, applied in botany equipment and methods, fabric, fiber treatment, etc., can solve the problems of easy and gradual loss of antibacterial effect, complex preparation process of antibacterial fiber, etc., to speed up blood circulation and wound healing speed, improve Bactericidal effect, anti-pilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of copper-containing fiber according to the present invention is as follows:

[0027] Taking nylon 66 fiber as an example, put the polymer masterbatch and electrolytic copper powder with a particle size of 5-50nm from the feeding port of the spinning machine, and heat it in the extrusion section until the masterbatch melts (ordinary nylon 6 is about 270°C). ), mix the copper powder and the master batch together, extrude through the extruder, set the extrusion temperature at 210°C, press the extruded mixture into the spinning part quantitatively, spray it out from the spinneret, roll Winding, stretching 3 times in an environment of 120 ° C, until the elongation at break is about 30%, and cooling. Among them, the required fibers with X cross-section can be sprayed out through the spinneret with a special cross-section, and added to the fabric fabric during spinning.

[0028] For spandex fibers, polyester fibers, etc., similar to the above-mentioned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com