Chlorination process for pressing magnesite into balls through light burning dry method

A technology of magnesite and light burning, which is applied in the field of magnesite chlorination to produce molten magnesium chloride, which can solve the problems of low productivity of chlorination furnace and low utilization rate of chlorine gas, so as to improve the utilization rate of chlorine gas, high activity, and increase production capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

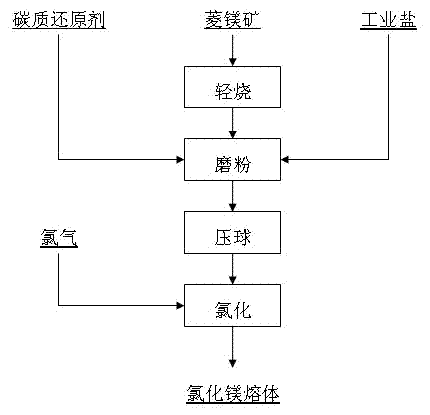

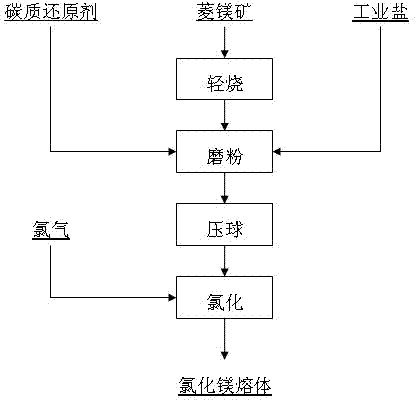

[0015] Embodiment of the present invention: magnesite is mixed with carbonaceous reducing agent and dried NaCl additive after light burning, then ground into mixed powder, pressed into agglomerate by ball press, and this agglomerate is sent into chlorine The melting furnace reacts with chlorine gas at 800-1000°C to produce magnesium chloride melt.

[0016] In the above-mentioned process, the magnesite can also be ground into powder firstly, then lightly burned, then mixed evenly with powdery carbonaceous reducing agent and dried NaCl additive to make mixed powder.

[0017] During the production process, the moisture content of the agglomerates pressed by the briquetting machine is very small, and its total moisture content does not exceed 2%.

[0018] The carbonaceous reducing agent and the dried NaCl additive are added in the following ratio (mass ratio):

[0019] C / MgO=0.2~0.3

[0020] NaCl / (MgO+C)=0.02~0.05.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com