Solid electrolyte-lithium negative electrode complex, preparation method thereof, and all-solid-state lithium secondary battery

A technology of solid electrolyte and lithium secondary battery, which is applied in the field of electrochemical energy storage, can solve the problem of large interface contact resistance, achieve the effects of reducing interface resistance, increasing specific capacity and cycle life, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

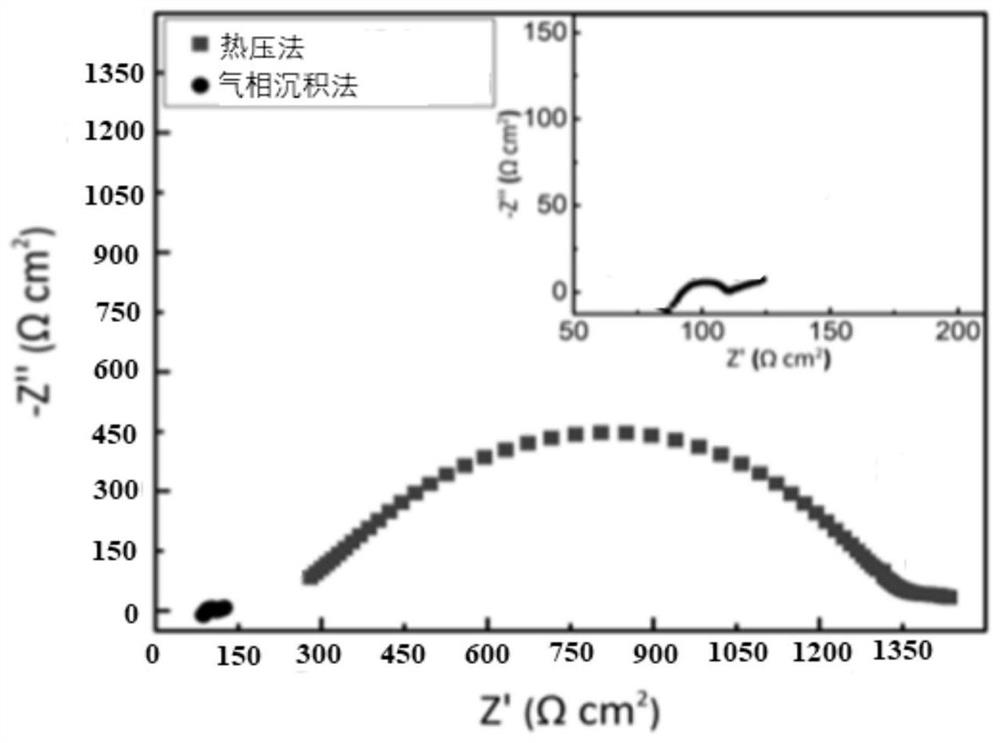

Embodiment 1

[0032] 20 μm lithium metal (1×10 -5 Under Pa vacuum conditions and 800°C), punched into a pole piece with a diameter of 15.6cm, and formed a half-cell with lithium foil. Test the internal resistance of the battery, the obtained curve is as follows image 3 As shown, the internal resistance is about 30Ωcm 2 , the solid electrolyte-lithium anode complex prepared by this method has a small internal resistance, indicating that the contact resistance is better improved.

Embodiment 2

[0036]First prepare the positive electrode, disperse nickel-cobalt-manganese NCM111 (Binbin): acetylene black AB (Betterui): polyvinylidene fluoride PVDF5130 (Shanghai Haiyi) = 95:3:2 (weight ratio), disperse in NMP, control The solid content is 56%, the viscosity is 4000-6000cp, and the stirring time is 6h. Use a coating machine to coat on one side of a 10μm copper foil, and dry to prepare a 100μm thick NCM622 positive electrode sheet.

[0037] Then, a 10 μm lithium metal is vapor-phase-deposited with a 15 μm polyphenylene sulfide solid electrolyte, and the NCM622 positive electrode sheet is used to form a pouch battery. Test the discharge capacity of the battery at different rates, and the obtained curves are as follows Figure 4 As shown, the battery has good rate characteristics and high discharge capacity, up to 260mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com