Curved mirror reflector and production method thereof

A technology for a curved mirror and a manufacturing method, which is applied to mirrors, layered products, etc., can solve the problems of affecting the precision of the mirror, rapid expansion of micro-cracks, and high tempering costs, achieving high overall reliability, good safety protection, and enhanced The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

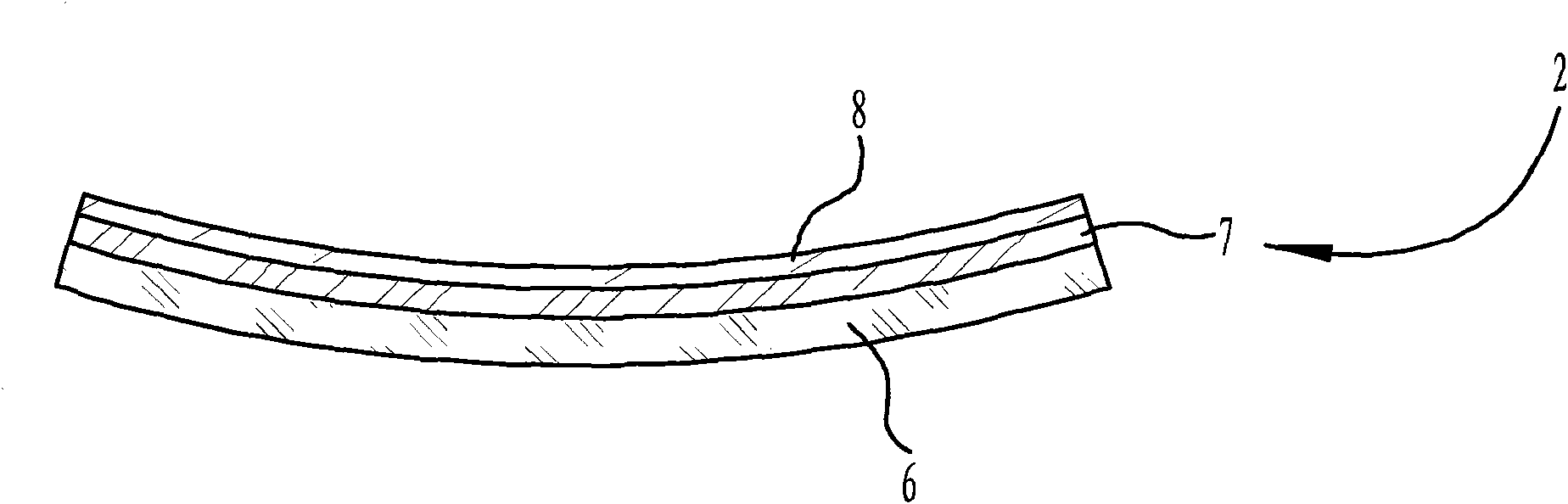

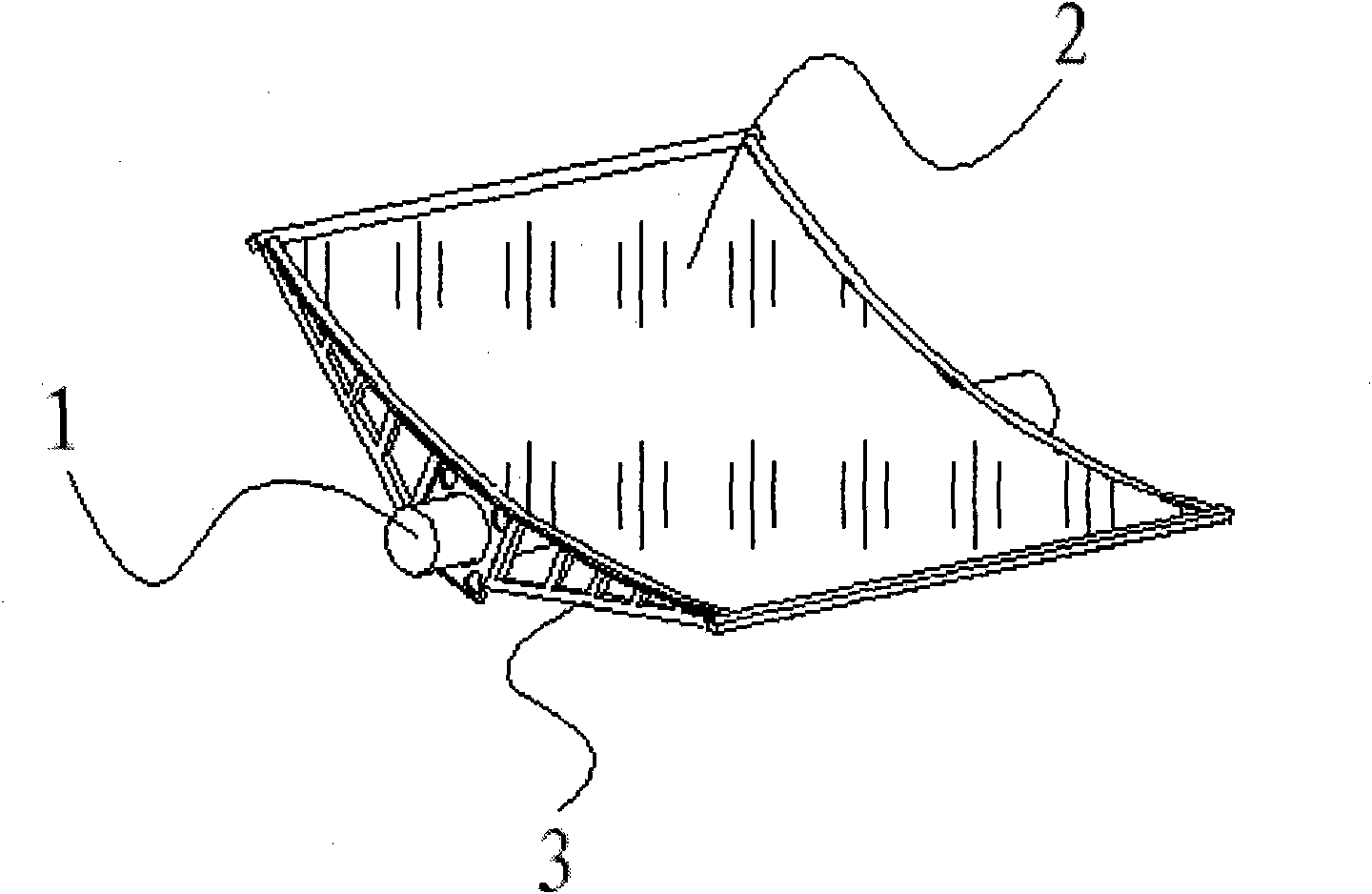

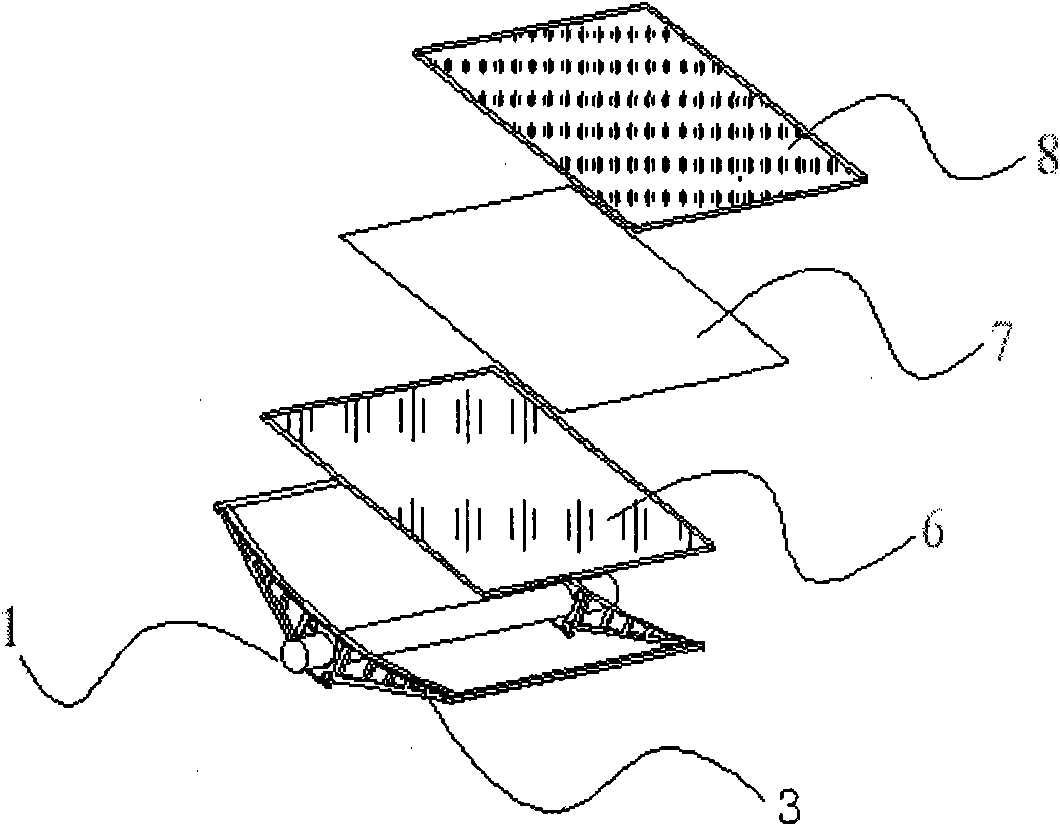

[0045] figure 1 is a cross-sectional view of a curved reflector according to an embodiment of the present invention. figure 1 Among them, the curved reflector 2 is cured and molded by the flat glass structure 6, the intermediate bonding layer 7 and the flat glass mirror 8 to form a composite curved reflector.

[0046] Specifically, the flat glass mirror 8 can be a high-quality float flat glass mirror body, and is preferably non-edging and / or non-tempered glass with a thickness of 1.8-2 mm. The planar glass structure 6 is a single layer of planar glass, preferably non-edged and / or non-tempered glass with a thickness of 1.8-2 mm. The intermediate adhesive layer 7 has a certain thickness, for example greater than 0.1mm, preferably greater than 0.2mm, and can be selected as high-quality ethylene vinyl acetate copolymer (EVA) sheet or polyvinyl butyral (PVB) sheet. Perhaps this intermediate bonding layer 7 also can select the bonding layer that is made of high-quality EVA, PVB sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com