Silicon steam corrosion resistant internal coating for directly protecting carbon fiber and in-situ preparation method thereof

A carbon fiber and inner coating technology, which is applied in the field of silicon vapor erosion resistant inner coating and its in-situ preparation, can solve the problems of difficult to completely densify silicon carbide coating, residual blank, uneven coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Technical scheme of the present invention is as follows:

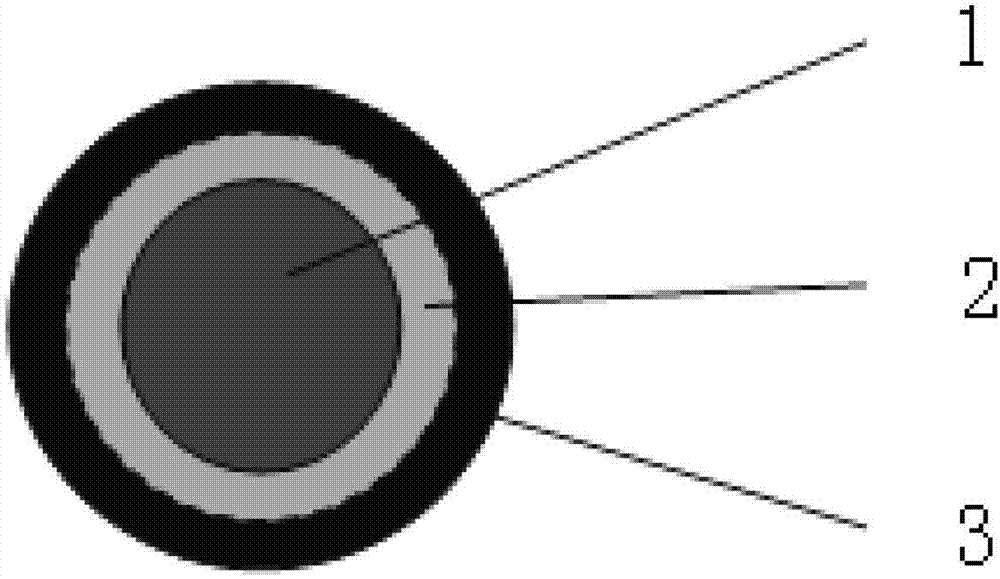

[0013] An anti-silicon vapor erosion inner coating that directly protects carbon fibers. The inner coating covers a primary pyrolytic carbon base layer on the surface of the carbon fiber by chemical vapor deposition, and then passes chemical vapor deposition on the surface of the primary pyrolytic carbon base layer. A layer of secondary silicon carbide protective layer is covered in a sinking manner; the primary pyrolytic carbon base layer is pyrolytic carbon tightly bonded on the surface of the carbon fiber, and the secondary thermal silicon carbide protective layer is Silicon carbide with a tightly and uniformly bonded carbon base layer.

[0014] A method for preparing an anti-silicon vapor erosion inner coating that directly protects carbon fibers, the steps are as follows:

[0015] (1) Place the formed three-dimensional fabric preform in a chemical vapor deposition reaction chamber, and keep it warm for 5-3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com