Novel high-tech environment-friendly wall coating as well as preparation method and application thereof

A high-tech coating technology, applied in the field of building materials, can solve the problems of latex viscous aging, pulverization, moisture return, easy pulverization, etc., and achieve the effect of strong adhesion of the base surface, solution of moisture return, and smooth wall surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

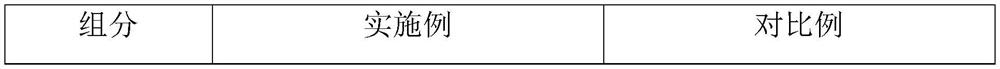

[0051] One embodiment of the present invention provides a kind of preparation method of above-mentioned wall coating, comprises the following steps:

[0052] Weigh sodium silicate, copper sulfate, sodium carbonate, ferrous sulfate, aluminum potassium sulfate, sodium chloride, superphosphate, potassium permanganate, boric acid, urea, water, heavy calcium and silicic acid salt cement;

[0053] Mix the weighed sodium silicate, copper sulfate, sodium carbonate, ferrous sulfate, aluminum potassium sulfate, sodium chloride, superphosphate, potassium permanganate, boric acid, urea and water to make a slurry;

[0054] Mix the weighed heavy calcium and portland cement to make powder.

[0055] In some examples, in the preparation method of wall paint, sodium silicate, copper sulfate, sodium carbonate, ferrous sulfate, aluminum potassium sulfate, sodium chloride, superphosphate, potassium permanganate, boric acid , urea and water are put into the reaction kettle and mixed at 90°C to 11...

Embodiment 1

[0073] Weigh raw materials: sodium silicate (45 degrees, modulus 2.8) 100kg, copper sulfate 0.4kg, sodium carbonate 0.64kg, ferrous sulfate 0.32kg, aluminum potassium sulfate 0.64kg, sodium chloride 0.32kg, superphosphate 0.2kg , potassium permanganate 0.3kg, boric acid 0.32kg, urea 0.1kg and water 20kg; heavy calcium 125kg and Portland cement 368kg.

[0074] Preparation of slurry: Put the weighed sodium silicate, copper sulfate, sodium carbonate, ferrous sulfate, potassium aluminum sulfate, sodium chloride, superphosphate, potassium permanganate, boric acid, urea, and water into the reaction kettle in sequence, The temperature was raised to 100° C. to prepare a slurry.

[0075] Preparation of powder: Fully stir the weighed heavy calcium and portland cement to make powder.

[0076] Add water to the slurry prepared in Example 1 and stir evenly to obtain slurry dilution; then mix and stir the slurry dilution and powder for five minutes to scrape the wall.

[0077] The wall sur...

Embodiment 2

[0079] Weigh raw materials: sodium silicate (45 degrees, modulus 2.8) 100kg, copper sulfate 0.4kg, sodium carbonate 0.32kg, ferrous sulfate 0.32kg, aluminum potassium sulfate 0.64kg, sodium chloride 0.32kg, superphosphate 0.2kg , potassium permanganate 0.3kg, boric acid 0.32kg, urea 0.1kg and water 20kg; heavy calcium 125kg and Portland cement 368kg.

[0080] Preparation of slurry: Put the weighed sodium silicate, copper sulfate, sodium carbonate, ferrous sulfate, potassium aluminum sulfate, sodium chloride, superphosphate, potassium permanganate, boric acid, urea, and water into the reaction kettle in sequence, The temperature was raised to 100° C. to prepare a slurry.

[0081] Preparation of powder: Fully stir the weighed heavy calcium and portland cement to make powder.

[0082] Add water to the slurry prepared in Example 2 and stir evenly to obtain slurry dilution; then mix and stir the slurry dilution and powder for five minutes to scrape the wall.

[0083] The wall sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com