A kind of ceramic composite coating and preparation method thereof

A ceramic coating and ceramic composite technology, applied in the field of ceramic coatings, can solve the problems of high thermal conductivity, reduced service life, and large thermal stress of silicon carbide ceramic coatings, and achieve excellent heat insulation performance, oxidation prevention, and high density. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The ceramic composite coating described in the above-mentioned embodiments can be prepared by the following steps to obtain the ceramic composite coating of the present invention, which can be prepared by the following steps:

[0037] Substrate 30 pre-cleaning treatment;

[0038] Two-dimensional transition metal carbide or carbonitride powder particles, Y 2 o 3 Mix with deionized water, grind after mixing to obtain ceramic slurry;

[0039] Spraying the ceramic slurry on the surface of the substrate 30 after the pre-cleaning treatment, forming a two-dimensional transition metal carbide or carbonitride ceramic coating 20 after spraying;

[0040] A silicon carbide ceramic coating 10 is deposited on the surface of the two-dimensional transition metal carbide or carbonitride ceramic coating 20 to obtain a ceramic composite coating.

[0041] Preferably, the two-dimensional transition metal carbide or carbonitride powder particles, Y 2 o 3 The mass percentage is 40-70%: 1...

Embodiment 1

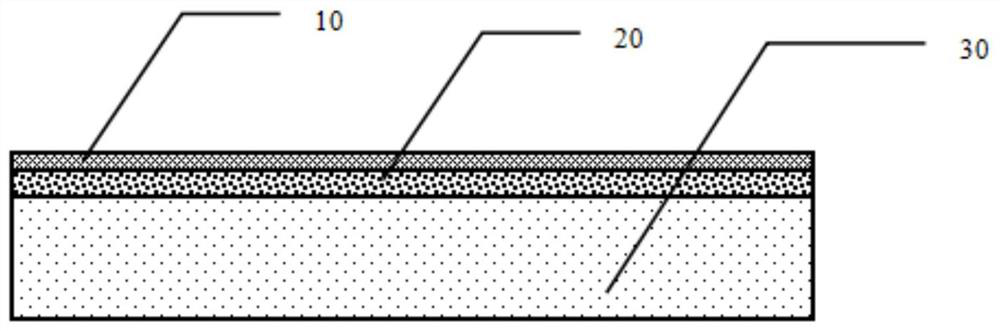

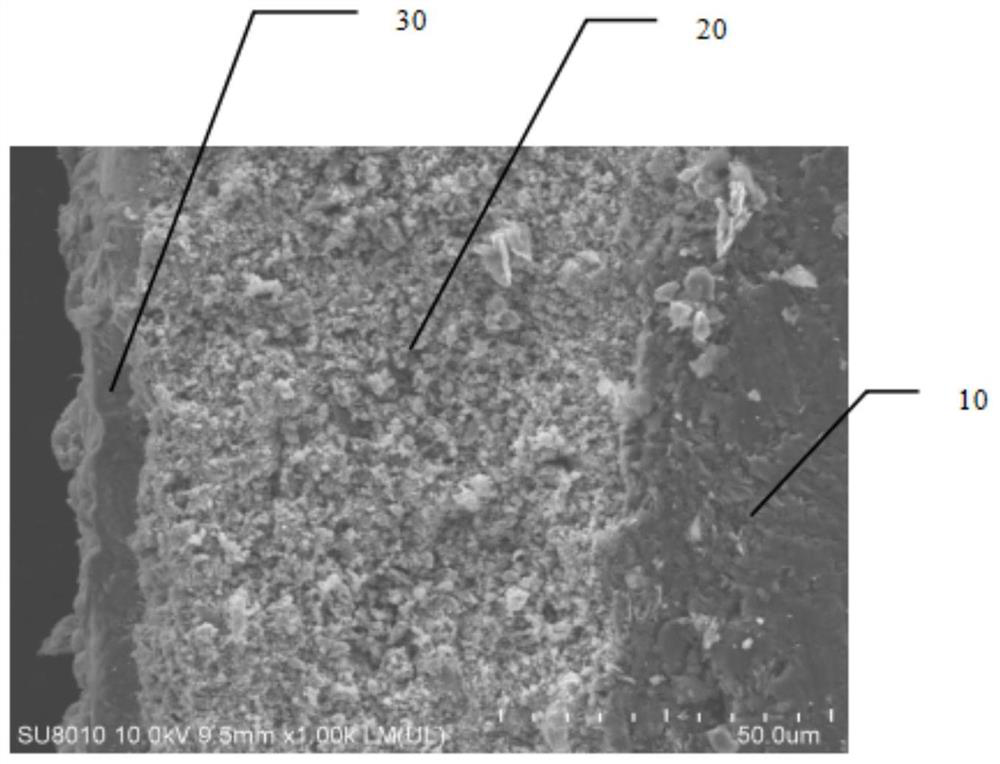

[0071] The present invention provides a ceramic composite coating, comprising a two-dimensional transition metal carbide or carbonitride ceramic coating 20 bonded to the surface of a substrate 30, from the substrate 30 to the two-dimensional transition metal carbide or carbonitride ceramic coating The direction of extension of the layer 20 also includes the silicon carbide ceramic coating 10 . The silicon carbide ceramic coating 10 is partially embedded in the two-dimensional transition metal carbide or carbonitride ceramic coating 20 with an embedded depth of 3 μm.

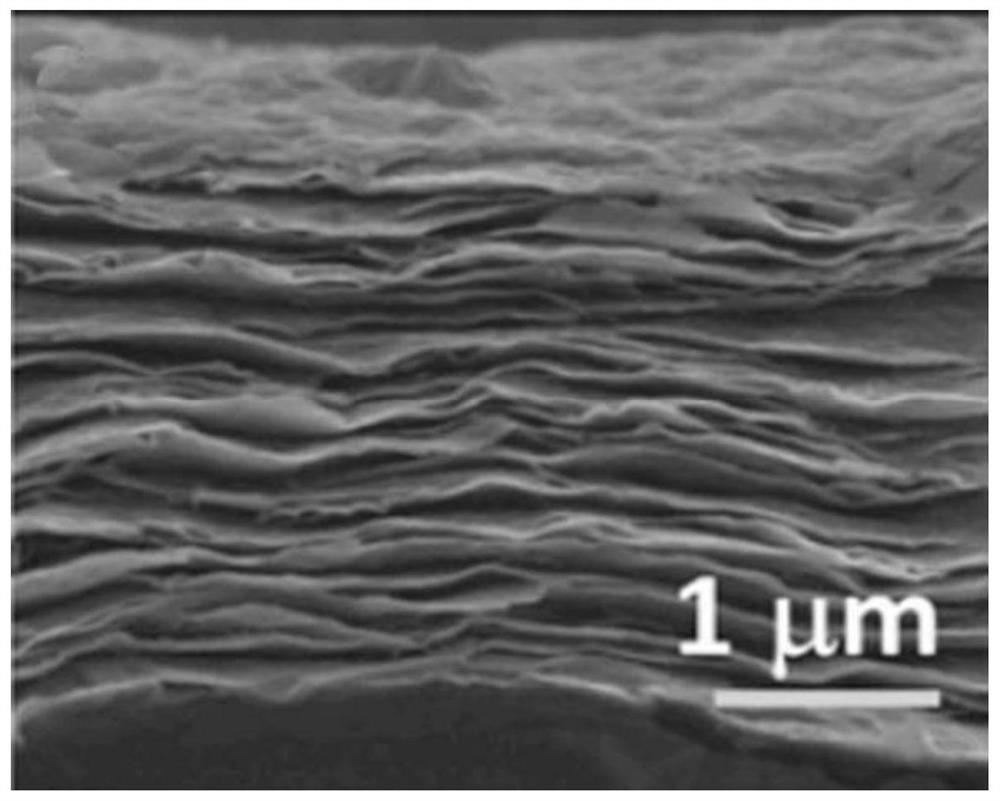

[0072] The two-dimensional transition metal carbide or carbonitride ceramic coating 20 has a lamellar structure, and the distance between the lamellar layers is 100 nm.

[0073] The inside of the two-dimensional transition metal carbide or carbonitride ceramic coating 20 is distributed with holes, the average diameter of the holes is 4 μm, and the holes occupy the two-dimensional transition metal carbide or carbo...

Embodiment 2

[0089] The present invention provides a ceramic composite coating, comprising a two-dimensional transition metal carbide or carbonitride ceramic coating 20 bonded to the surface of a substrate 30, from the substrate 30 to the two-dimensional transition metal carbide or carbonitride ceramic coating The direction of extension of the layer 20 also includes the silicon carbide ceramic coating 10 . The two-dimensional transition metal carbide or carbonitride ceramic coating 20 has a lamellar structure, and the distance between the lamellar layers is 150 nm. The silicon carbide ceramic coating 10 is partially embedded in the two-dimensional transition metal carbide or carbonitride ceramic coating 20 with an embedded depth of 3 μm.

[0090] The inside of the two-dimensional transition metal carbide or carbonitride ceramic coating 20 is distributed with holes, the average diameter of the holes is 8 μm, and the holes occupy the two-dimensional transition metal carbide or carbonitride c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com