Preparation method of avalanche photodiode diffusion structure and diode diffusion structure

An avalanche photoelectric and diffusion structure technology, applied in the field of photodetectors, can solve the problems of complexity and cost reduction, increase of breakdown voltage deviation, external circuit, high cost, etc., to reduce relative deviation, improve sample yield, The effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

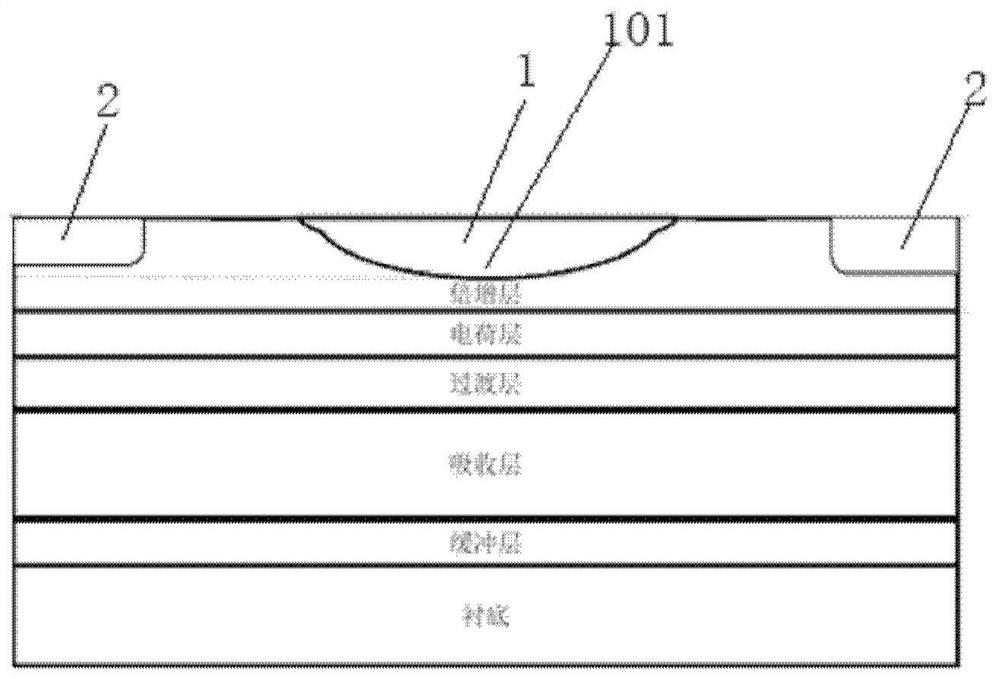

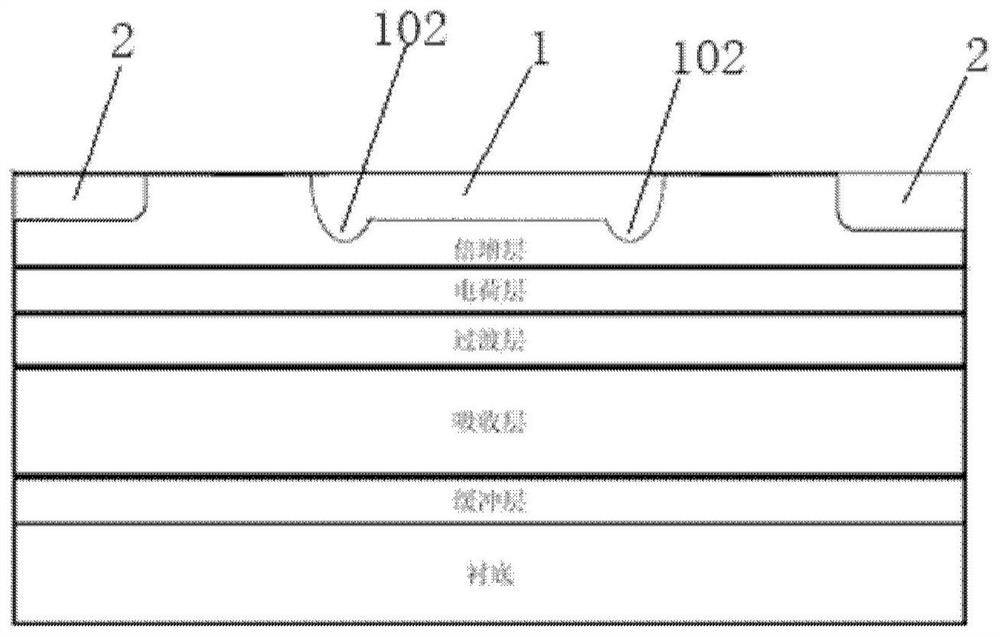

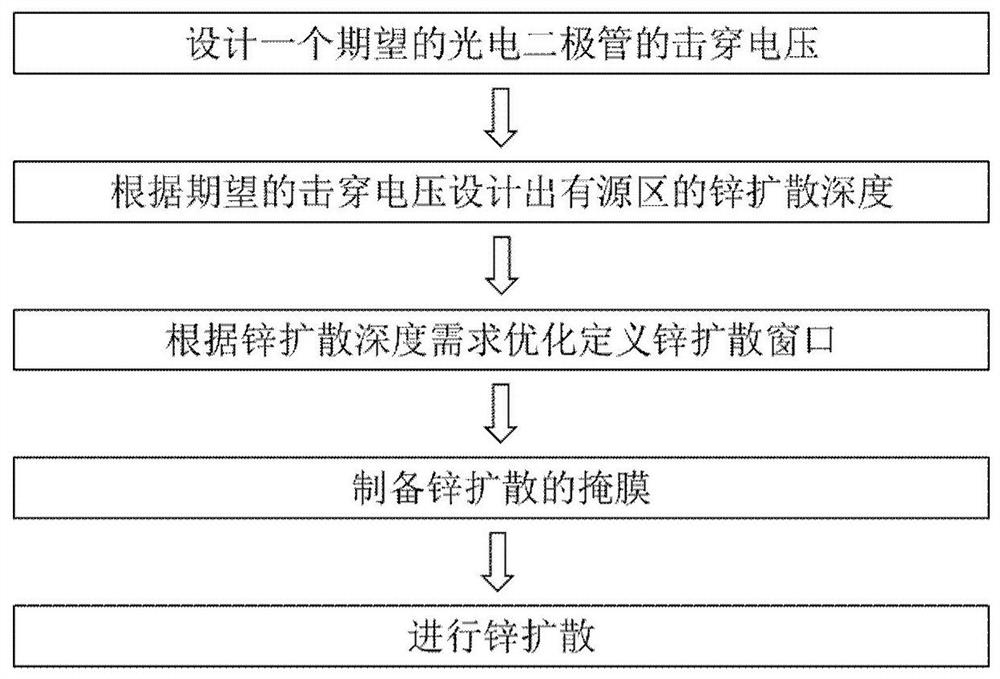

[0035] An embodiment of the present invention provides a method for preparing an avalanche photodiode diffusion structure, see figure 1 with figure 2 , the method includes: on the epitaxial wafer of the avalanche photodiode, under the effect of the first photolithography mask, perform the first dopant diffusion to obtain the central circular diffusion main junction region 1 and the diffusion main junction region 1 Diffusion tank regions 2 separated by a preset distance; under the action of the second photolithography mask, the second dopant diffusion is performed, so that the depth of the central region 101 or edge region 102 of the diffusion main junction region is greater than that of the through The depth of the diffusion main junction region is obtained by the first dopant diffusion, thereby obtaining the avalanche photodiode diffusion structure.

[0036] The embodiment of the present invention is illustrated by taking the first dopant diffusion and the second dopant dif...

Embodiment 1

[0050] In this embodiment, a 32*32 avalanche photodiode array is selected, and nearly 100 points are selected from it to test the breakdown voltage. The avalanche photodiode includes a central circular diffusion main junction region 1 , a diffusion tank region 2 , and two guard ring regions 3 between the diffusion main junction region 1 and the diffusion groove region 2 .

[0051] The test results are as Figure 10 As shown, it can be seen that the maximum breakdown voltage value in the test results does not exceed 75.1V, and the minimum value is greater than 74.3V, that is, the breakdown voltage deviation is <±0.4V, and the relative voltage deviation is <±1%.

[0052] It shows that the avalanche photodiode of this embodiment suppresses the edge breakdown and ensures a large breakdown voltage, and the uniformity of the breakdown voltage is excellent.

[0053] Another embodiment of the present invention also provides an avalanche photodiode diffusion structure, which includes:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com