Steel structure cutting demolition vehicle

A technology of steel structure and cutting platform, which is applied in the direction of building construction, building maintenance, construction, etc., can solve the problems of a large amount of construction land occupation and rusting conditions, and achieve the effect of reducing construction land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

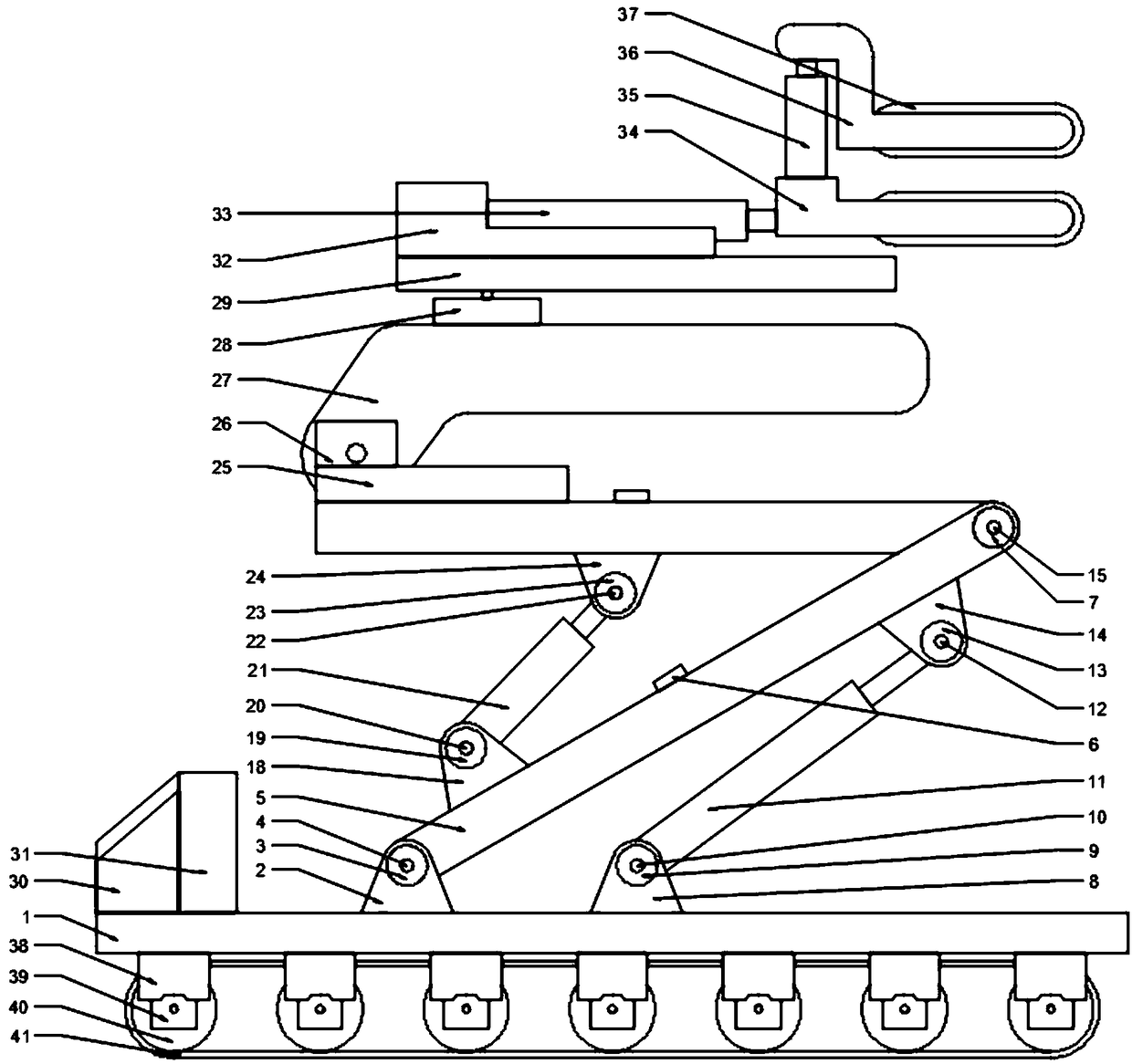

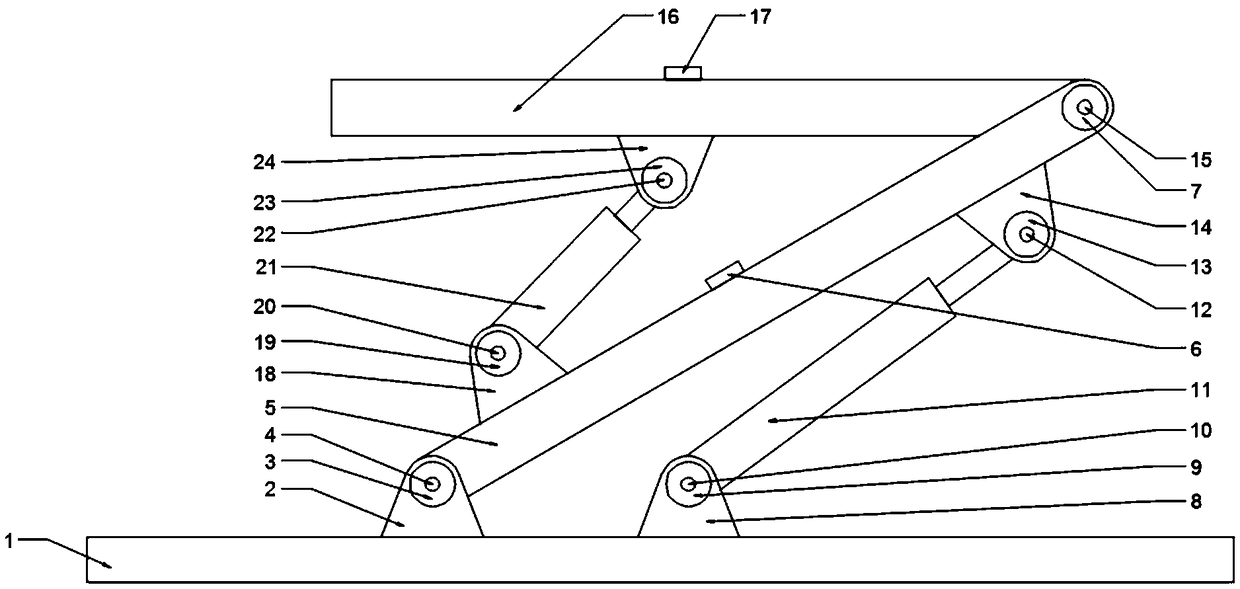

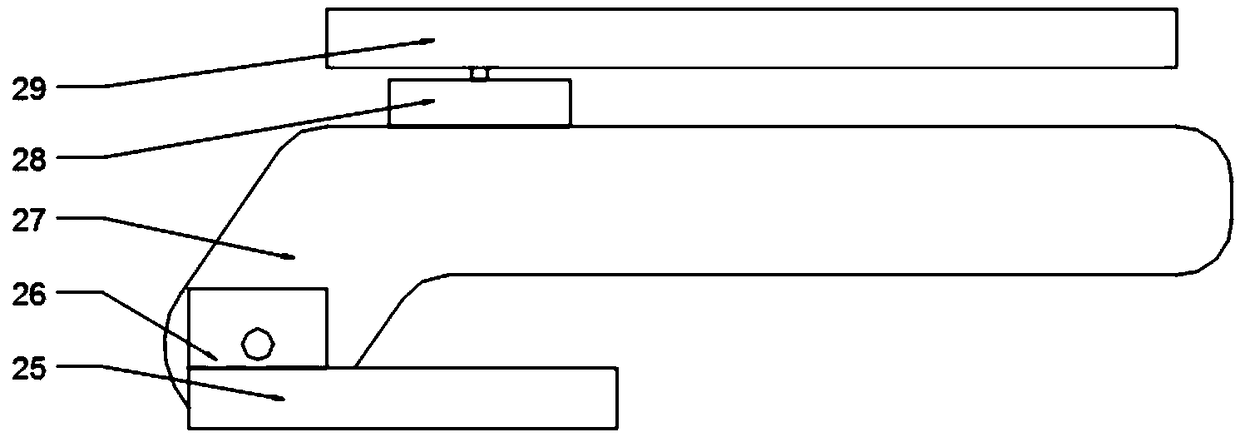

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, a steel structure cutting and dismantling vehicle includes a base 1, the base 1 is located above the ground, a mechanical arm mechanism is arranged above the base 1, and the mechanical arm mechanism is installed by a mechanical arm fixedly connected above the base 1 Frame 2, the mechanical arm bearing 3 installed on the mechanical arm mounting frame 2, the mechanical arm shaft 4 inserted on the mechanical arm bearing 3, the mechanical arm one 5 fixedly connected with the mechanical arm shaft 4, installed on the mechanical arm one 5 The multi-axis sensor-6 and the bearing 7 of the mechanical arm, the fixed-end mounting frame 8 of the fixed-end of the mechanical arm-linear motor located on the top of the base 1, the linear motor mounted on the fixed-end mounting frame 8 of the mechanical arm-linear motor Motor fixed end bearing 9, the mechanical arm lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com