Back-and-forth seaming machine, use method of back-and-forth seaming machine and air pipe production line

A reel machine, reciprocating technology, applied in the directions of forming tools, feeding devices, positioning devices, etc., can solve problems such as the influence of the accuracy of the folding shape, and achieve the effect of improving the bite efficiency, high processing efficiency, and smooth movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

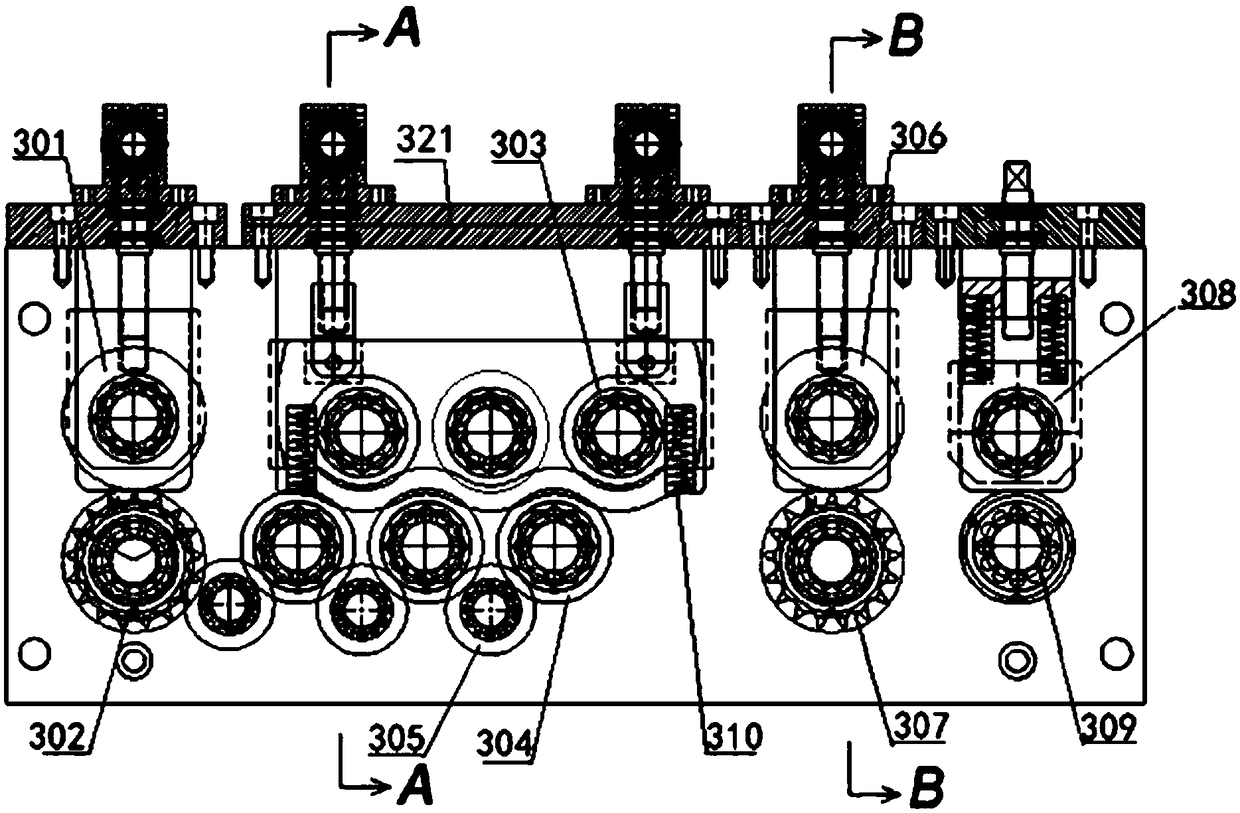

[0073] Such as image 3 As shown, this embodiment provides a leveling and beading machine, which is mainly used for leveling the tortuous sheet material, and performing beading operation on the sheet material after making the sheet material straight. Press out the longitudinal grooves. The leveling and beading machine mainly includes a pair of side plates 315 and a set of feed rollers, a set of leveling rollers, a set of beading rollers and a set of measuring rolls installed in the pair of side plates 315 in sequence. Among them, the feeding roller group is used to push the sheet material, reducing the pulling load of the sheet material in the subsequent process, making the feeding smoother; the leveling roller group is used to flatten the sheet material to make the sheet material straight; The rib roller set is used to press out the longitudinal rib groove on the sheet material, and the longitudinal rib groove will eventually become the rib groove on the side of the air duct...

Embodiment 2

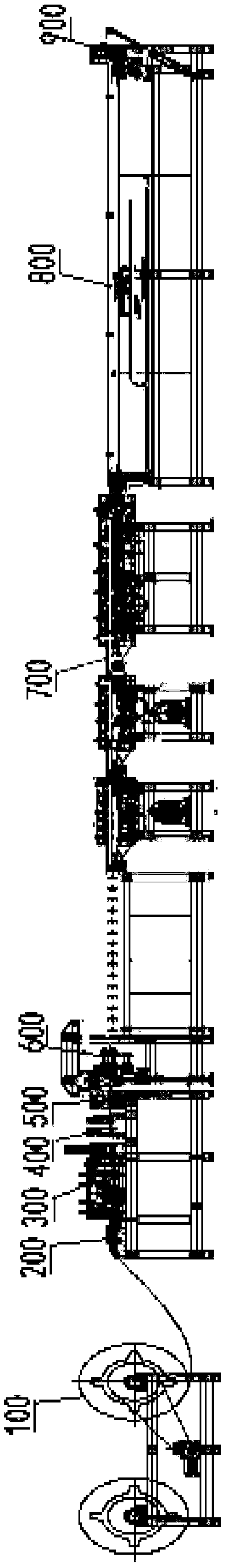

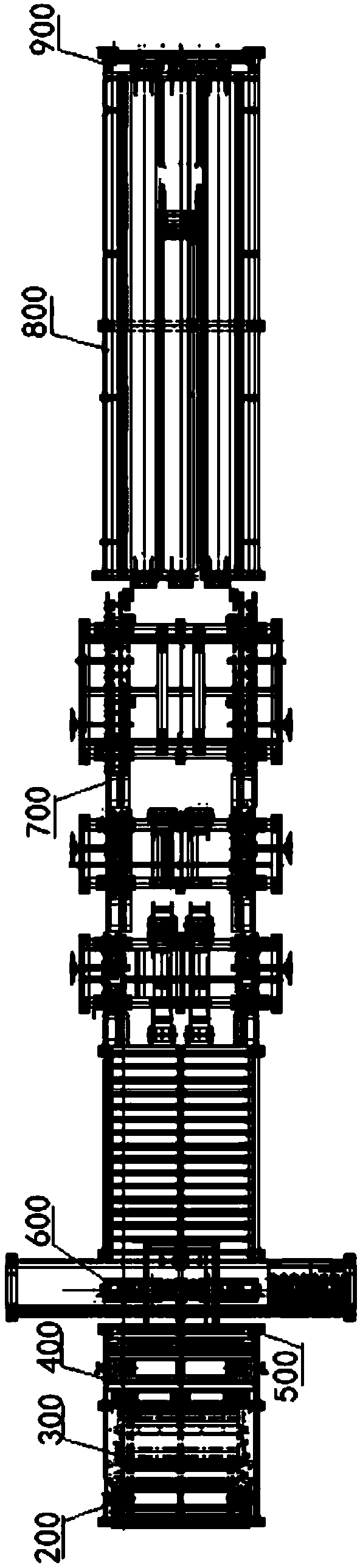

[0090] Such as Figure 1 to Figure 2 As shown, an air duct production line includes a discharging rack 100, a supporting rack 200, a leveling and beading machine 300, a stamping die 400, a shearing machine 500, a seaming riveting machine 600, and a flange machine 700 connected in sequence. , feeding device 800, bending machine 900. Wherein, the leveling and beading machine 300 adopts a leveling and beading machine in Embodiment 1.

[0091] When working, set the sheet to be processed on the material roller of the unloading rack 100 to rise and fix it tightly, let the sheet pass through the support rack 200 and then enter the leveling and beading machine 300, and enter the stamping press after the sheet is finished leveling and beading The punching hole of the mold 400 measures the length of the sheet material to be prepared by measuring rollers, and when the length of the sheet material sent out reaches a set value, the shearing machine 500 cuts the sheet material. After bein...

Embodiment 3

[0094] Such as Figure 11 As shown, this embodiment provides a reciprocating seaming machine, which is mainly used for seaming the opposite sides of the plate to form a hem, so that the plates can be spliced and closed later to form an air duct, which is an air duct Indispensable equipment in production. The back-and-forth biting ruck bone machine mainly includes two major devices, namely the biting device 602 and the feeding device 603; among them, the biting device 602 moves perpendicular to the feeding direction and performs biting processing on the side of the plate, and transports the material. The device 603 is used to control the movement of the board in the feeding direction, and the two cooperate with each other to process the opposite sides of the board in one process. The structure and working principle of the bite device 602 and the material transport device 603 will be described in detail below, and the usage method of the device will be given on this basis.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com