Composite and multi-station full-die-cutting ultrahigh-frequency tag antenna machining equipment and method

A processing equipment, ultra-high frequency technology, used in metal processing, record carriers used in machines, devices for coating liquids on surfaces, etc., and can solve problems such as antenna layer offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

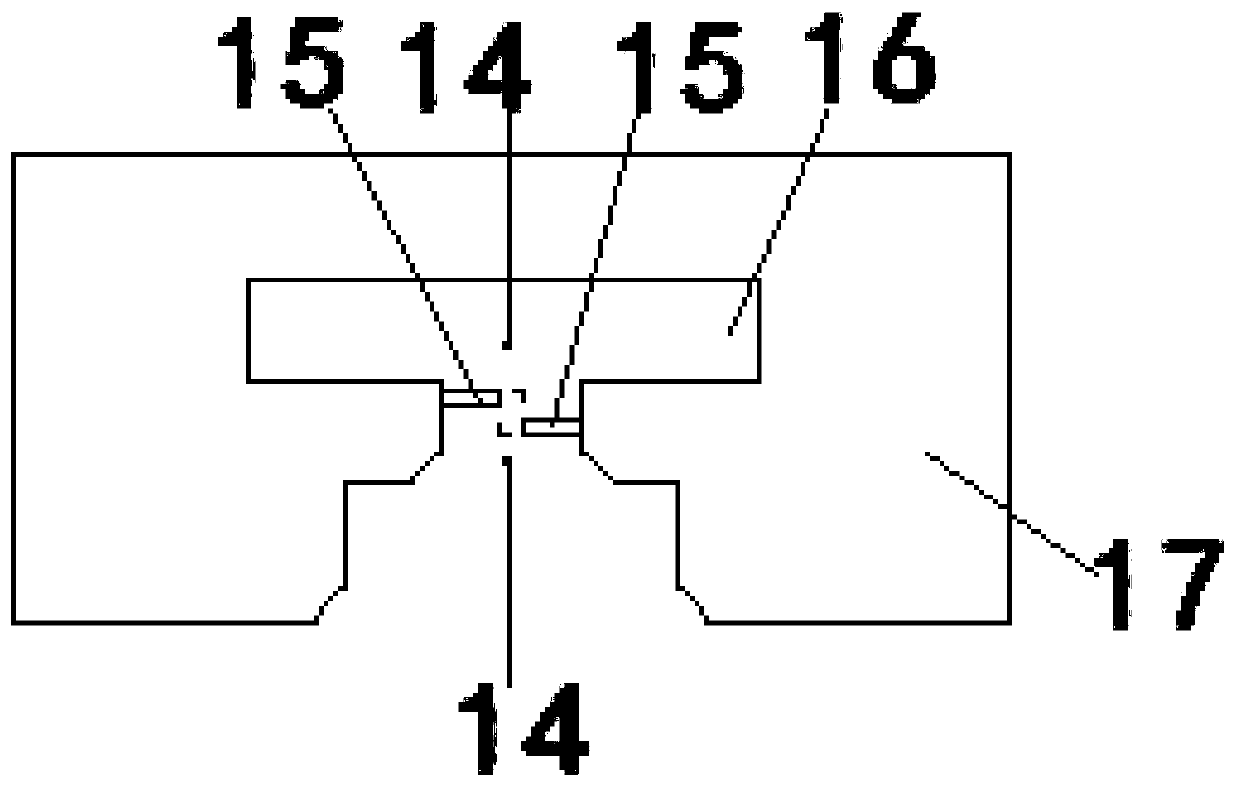

[0110] Specific embodiment 2, specific embodiment 2 is basically the same as present embodiment 1, the difference is: in the production step seven of the processing technology of the UHF electronic tag antenna of full die-cutting in specific embodiment 2, the first die-cutting The mechanism is a die-cutting machine that performs flat die-cutting and / or circular knife die-cutting on the chip binding point 15 and the chip binding positioning point 14 at the same time, that is to say, the first die-cutting mechanism completes the chip binding point 15, The flat die-cutting and / or circular knife die-cutting of the chip binding positioning point 14, for example, all of them are replaced by a flat die-cutting machine with a circular knife die-cutting machine is also a similar operation to perform a one-time flat die-cutting on the antenna layer to form The chip binding point 15 and the chip binding positioning point 14, that is to say, the die-cutting tool of the flat die-cutting mac...

specific Embodiment 3

[0114] The specific embodiment 3, the specific embodiment 3 is basically the same as the present embodiment 1, the difference is: in the production step seven of the processing technology of the full-die-cut UHF electronic tag antenna in the specific embodiment 3, the described method for The first die-cutting mechanism for die-cutting the chip binding positioning point 14 and the chip binding point 15 and the second die-cutting mechanism 10 for die-cutting the peripheral edge of the antenna body 17 are combined into a flat-press die-cutting machine or a circular knife die cutting machine.

[0115] That is to say, the first die-cutting mechanism and the second die-cutting mechanism 10 are merged into a flat die-cutting machine or a circular knife die-cutting machine, which can complete the flat die-cutting of the chip binding point 15 and the chip binding positioning point 14 at one time. Cutting and / or circular knife die-cutting and carrying out flat die-cutting and / or circul...

specific Embodiment 4

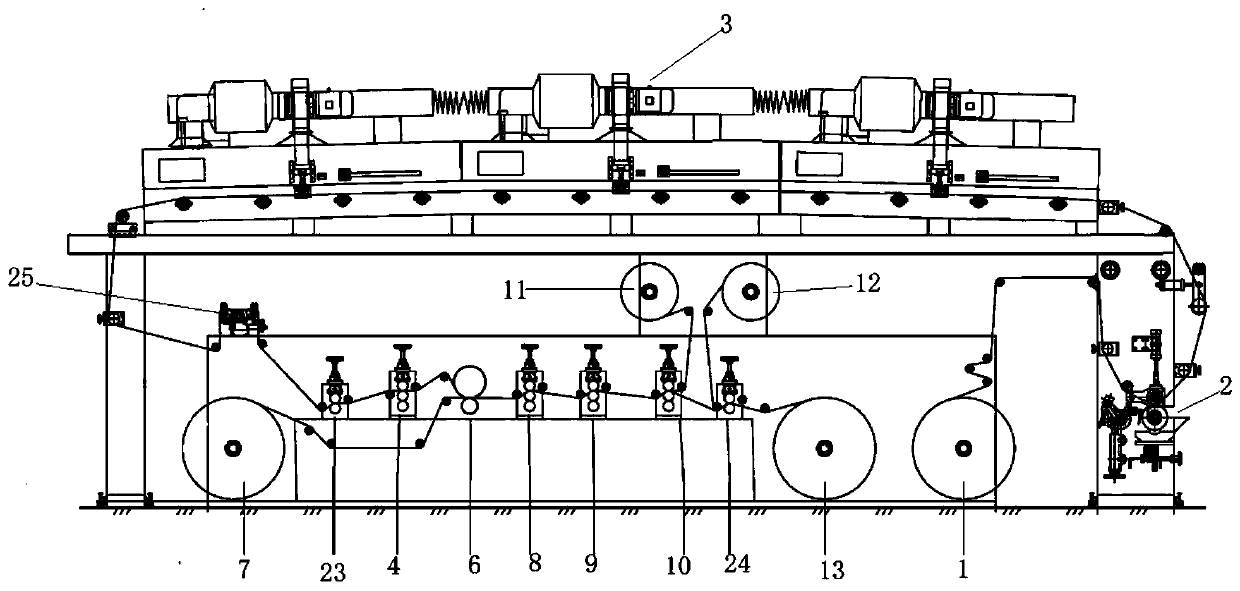

[0118] Specific embodiment 4, see Figure 5 , The specific embodiment 4 is basically the same as the present embodiment 1, the difference is: in the specific embodiment 4, there are two chip binding points, and the processing equipment also includes a second row of waste rewinding mechanism 26;

[0119]The first die-cutting mechanism is used to carry out one of the chip binding points, the redundant antennas on both sides of the antenna layer or the redundant antennas on both sides of the first base material layer and the antenna layer, and the redundant first base material layers on both sides. The first flat-press die-cutting machine of flat-press die-cutting or the first round-knife die-cutting machine 8 of circular knife die-cutting, and be used for carrying out flat-press die-cutting to another chip binding point 15 and chip binding positioning point 14 The second flat-press die-cutting machine for cutting or the second round-knife die-cutting machine 9 for round-knife di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com