Machining locating method of glass guide rail

A glass guide rail and positioning method technology, applied in positioning devices, metal processing equipment, metal processing mechanical parts, etc., can solve problems such as poor stability of the clamping mechanism, and achieve the effect of avoiding large vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

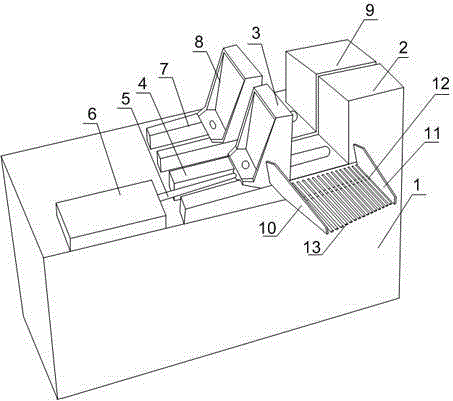

[0021] Such as figure 1 As shown, the present invention is first on the frame of the processing positioning device, the movable baffle and the fixed baffle form a clamping unit that can change the clamping gap according to the shape and size of the glass guide rail, and the fixed baffle that is set can adjust the glass guide rail. Playing a position-limiting role, the movable baffle can quickly advance and retreat under the push of the hydraulic mechanism to clamp or loosen the glass guide rail; during the material cutting process, the glass guide rail is close to the inner wall of the fixed baffle, and the movable baffle Driven by the hydraulic mechanism, it approaches the fixed baffle until the glass guide rail is clamped, and finally the glass guide rail is cut by the cutting mechanism; the processed glass guide rail slides directly and quickly to the special glass guide rail collection equipment through the discharge port ; wherein the processing and positioning device inc...

Embodiment 2

[0023] Such as figure 1 As shown, on the basis of Embodiment 1, the present embodiment includes a left baffle plate 10, a right baffle plate 11, and an inclined base plate 12. Connected, the base plate 12 includes a plurality of sliding rods 13 arranged side by side; the discharge port formed by the left baffle plate 10, the right baffle plate 11 and the bottom plate 12 provides a guiding function for the processed materials and can guide the materials to special collection equipment In the middle, it is beneficial to centralized collection; the inclined bottom plate 12 can make the material slide down automatically under the action of its own gravity. Chips leak out, avoiding the waste chips sliding to the collection equipment with the material and affecting the collection efficiency.

Embodiment 3

[0025] Such as figure 1 As shown, the present embodiment is based on Embodiment 1, the hydraulic mechanism includes a hydraulic cylinder 6 and a hydraulic motor, the hydraulic cylinder 6 is arranged on the same level as the movable baffle 3, the guide rail 4 is a U-shaped groove, and the hydraulic cylinder One end of the output end 5 passing through the U-shaped groove is connected to the bottom end of the movable baffle 3 , and the other end of the U-shaped groove is connected to the fixed baffle 2 . In view of defects such as unstable clamping of mechanical clamping and easy noise generation of pneumatic clamping, on the same horizontal plane, the hydraulic motor converts hydraulic energy into mechanical energy output, and the output end 5 of the hydraulic cylinder drives the movable baffle 3 to maintain a stable and fast speed. Back-and-forth linear motion works; the movable baffle 3 is slidably arranged on the U-shaped groove, and the opening of the U-shaped groove can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com