Waste removal equipment and technology of aerated concrete green body

An air-entrained concrete and green body technology, which is applied to the field of concrete body bottom skin removal equipment and removal technology, can solve the problems of low bottom skin efficiency, troublesome bottom skin treatment and recovery, and green body damage, etc., and achieves great market value and convenience. The effect of collecting and improving molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

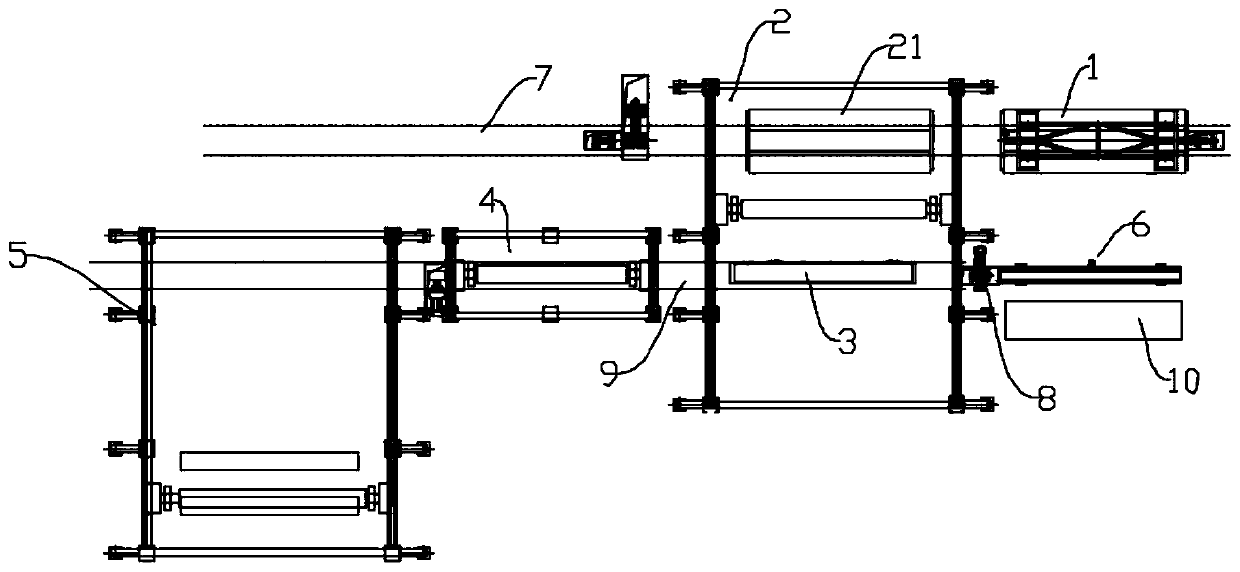

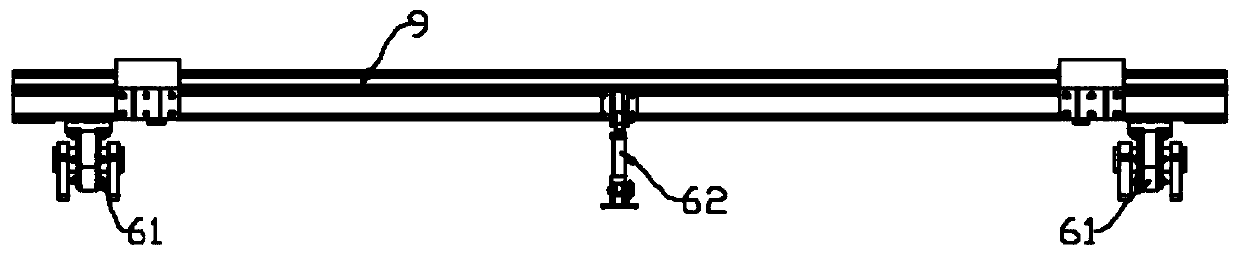

[0038] Such as figure 1 As shown, a bottom skin removal equipment for aerated concrete body is used to sequentially separate the bottom skin of the steamed concrete body, pack the finished concrete products, and clean and collect the bottom skin on the steamed bottom plate. The bottom skin removal equipment mainly includes a steam curing vehicle 1, a green body conveyor 2, a conveying vehicle 3, a splitting machine 4, a blank clamping machine 5, an overturning device 6, a steam curing vehicle track 7, a crushing device 8 and a conveyor vehicle track 9. The specific structure and working principle of the bottom skin removal equipment will be described in detail.

[0039] Among them, the green body conveyor 2 includes a large rectangular frame with a certain height. The frame is provided with grippers or hooks that can move back and forth along the length of the frame. Or rack and pinion drive, the present embodiment adopts the mode of air vehicle hoisting, and the object that ...

Embodiment 2

[0047] The bottom skin removal equipment of Embodiment 1 can remove and collect the residual bottom skin on the steam-cured bottom plate by turning over for reuse. However, in actual use, it is found that when the transport vehicle track 9 is turned over to tilt the steam-cured bottom plate on the transport vehicle 3, since the steam-cured bottom plate has a large area and the steam-cured bottom skin has a certain viscosity, It is easy to solidify and stick to the steam-cured bottom plate. Therefore, when turning the steam-cured bottom plate, on the one hand, large pieces of bottom skin are not easy to collect and need to be manually broken into small pieces. It is troublesome to clean up devices such as suction cups. In view of this, the following improvements are made in this embodiment.

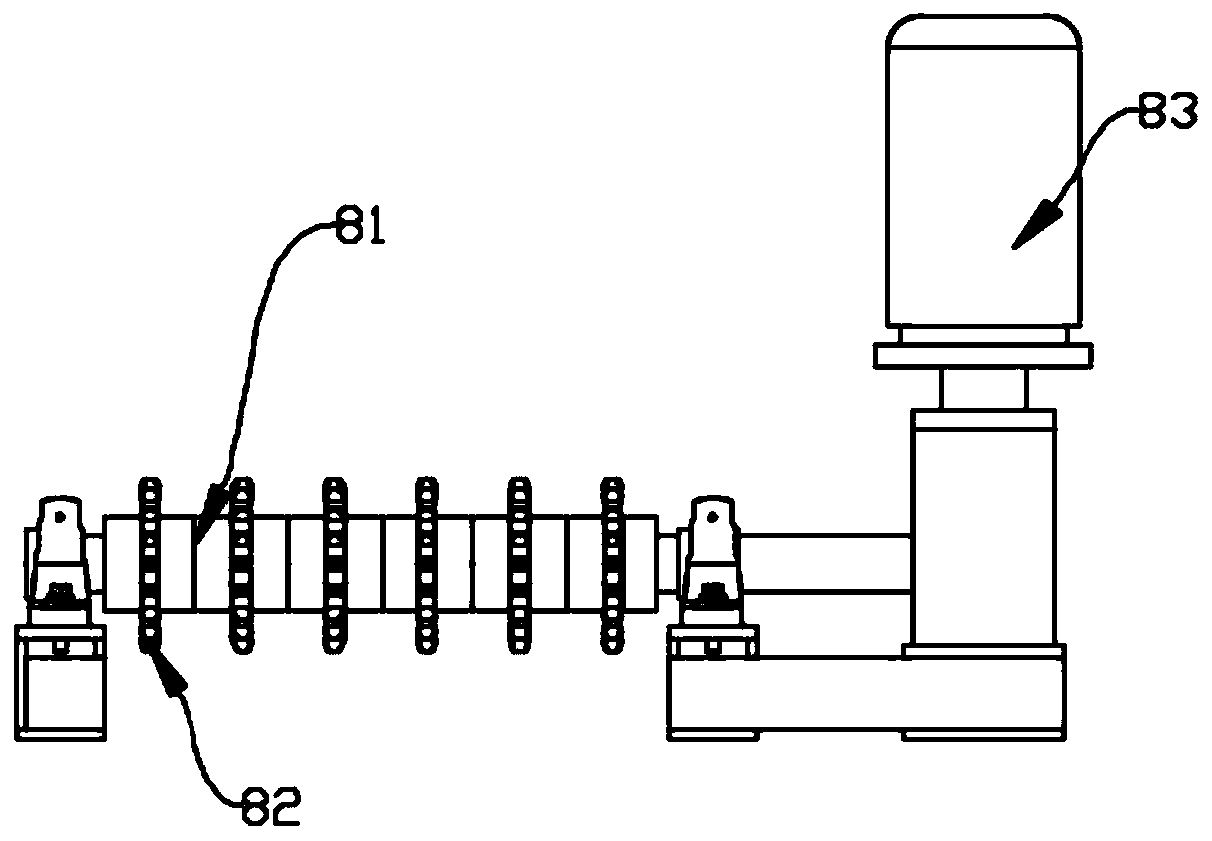

[0048] The bottom skin removal equipment of this embodiment is basically the same as that of Embodiment 1, the difference is that this embodiment is also provided with a crushing device 8...

Embodiment 3

[0052] A bottom skin removal process for an aerated concrete body, using the bottom skin removal equipment in Example 2 to separate the bottom skin from the steam-cured concrete body, turn over and remove the bottom skin on the steam-cured bottom plate after product packaging, and then Describe its specific working process in detail.

[0053] 1. After the steam curing car 1 carrying the steam curing bottom plate and the green body comes out of the autoclave through autoclaving and curing, it moves on the steam curing car track 7 to such as figure 1 In the position 21 to be transferred below the green body conveyor 2 shown, the steam curing vehicle 1 stops moving. Then, the green body conveyor 2 works, and the hook is controlled to lift the steam-cured bottom plate, and the steam-cured bottom plate is transported to the transport vehicle 3, and the initial position of the transport vehicle 3 is figure 1 location shown.

[0054] 2. The conveying vehicle 3 moves to transport th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com