Bucket buffering structure of bucket elevator

A buffer structure, bucket elevator technology, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of large force between the hopper and the material, damage, hopper deformation, etc., to improve the service life, avoid damage and deformation, avoid damage and deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

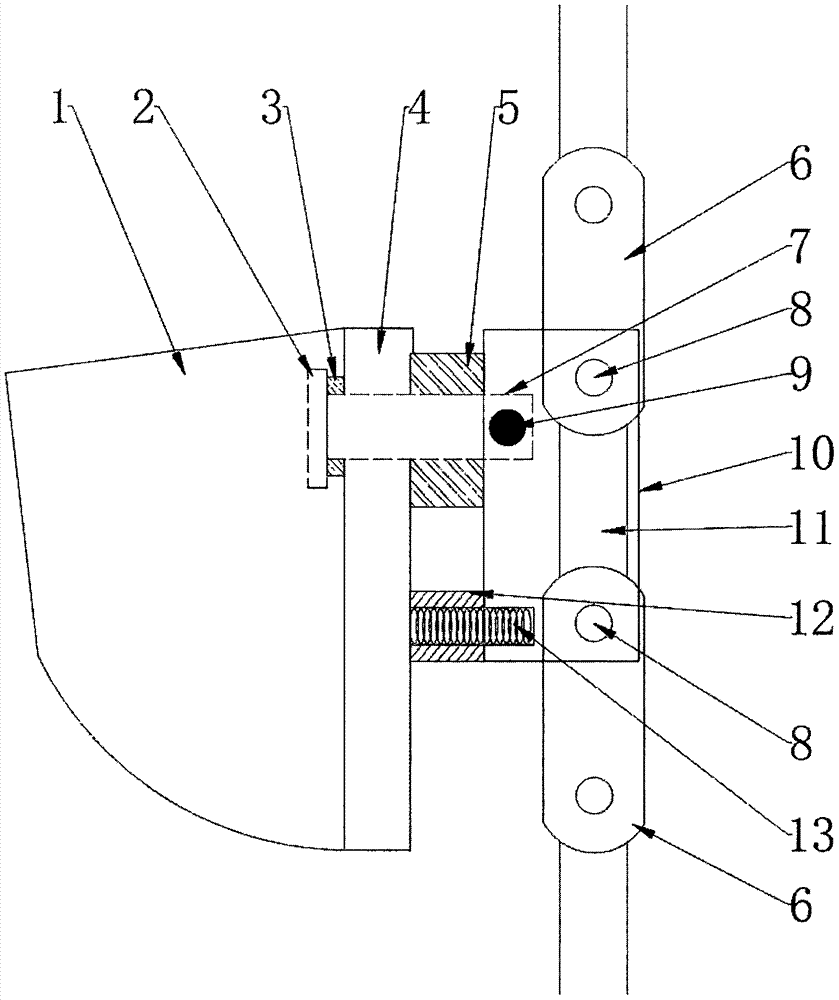

[0015] Such as figure 1 Shown: a hopper buffer structure of a bucket elevator, the bucket elevator drives the hopper 1 by a transmission chain, and the inner chain plate 11 and the outer chain plate 6 of the transmission chain are connected end to end by a chain shaft 8 to form a transmission chain; the hopper buffer structure includes a rectangular The installation block 10, the upper end and the lower end of the installation block 10 are respectively fixed on the ends of the chain shaft 8 at the two ends of the same inner chain plate 11; the left side of the installation block 10 is the hopper 1, and the right part of the hopper 1 is a vertical side plate 4. There is a horizontal fixed rod 7 inside the hopper 1. The cap body 2 at the left end of the fixed rod 7 is located on the left side of the side plate 4. The right end of the fixed rod 7 passes through the side plate 4. The right end of the fixed rod 7 passes through the pin shaft 9 and the mounting block 10. Hinged; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com