Automated stream line article sorting device for intelligent logistics

A sorting device and assembly line technology, used in sorting, transportation and packaging, conveyors, etc., can solve the problems of high difficulty in spring replacement, easy deformation and damage of springs, unspecified springs, etc. The effect of reducing maintenance costs and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

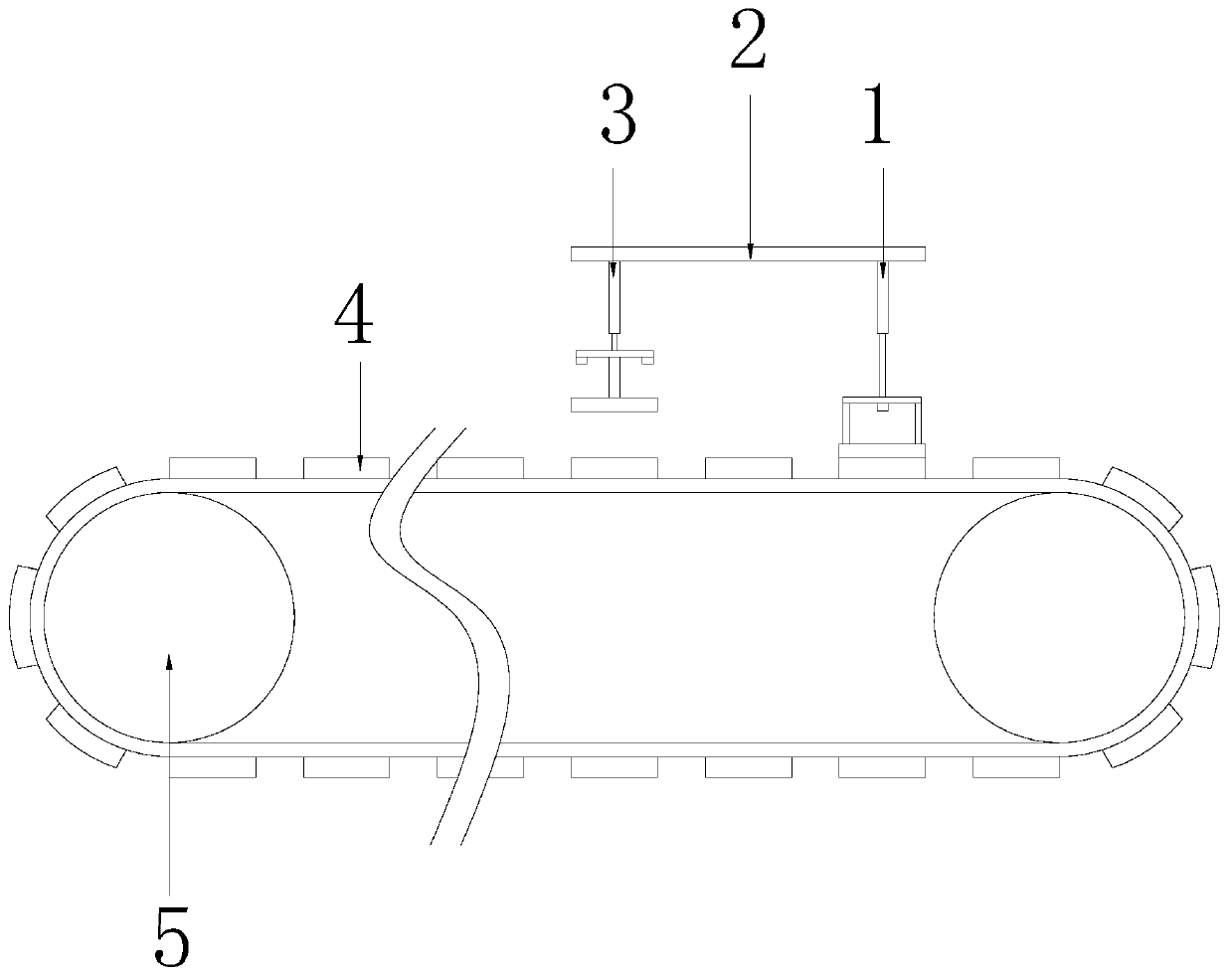

[0040] see Figure 1-14, the present invention provides a technical solution for an automatic assembly line item sorting device for smart logistics: its structure includes a first identification code reading device 1, a mounting plate 2, a second identification code reading device 3, a storage box 4, and a conveyor 5 , the conveyor 5 is evenly distributed with storage boxes 4 equidistantly arranged, the top of the conveyor 5 is provided with a mounting plate 2, one end of the mounting plate 2 is vertically connected with a first identification code reading device 1, and the other end Connect with the second identification code reading device 3;

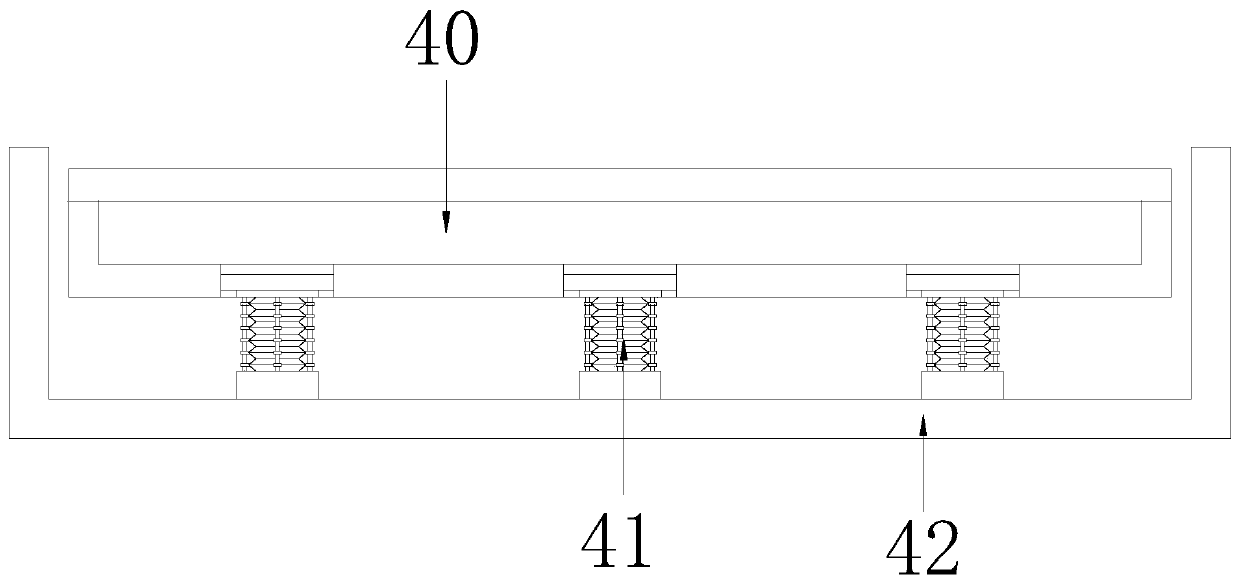

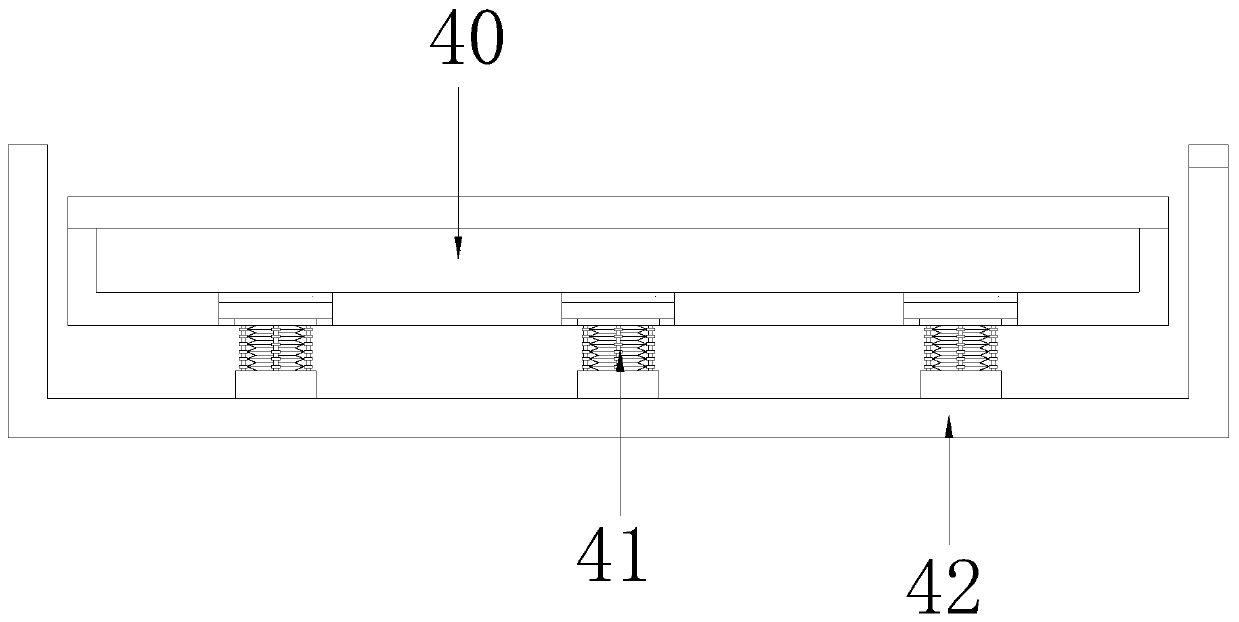

[0041] The storage box 4 includes a hinged inner box 40, a telescopic mechanism 41, an outer box 42, a second-order hole 43, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com