Doubling winder

A technology of yarn doubling machine and yarn guide mechanism, applied in textiles and papermaking, etc., can solve the problems of inconsistent tightness, affecting the quality of textile products, and economic losses of enterprises, so as to ensure the winding effect, ensure tension, and improve winding. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below:

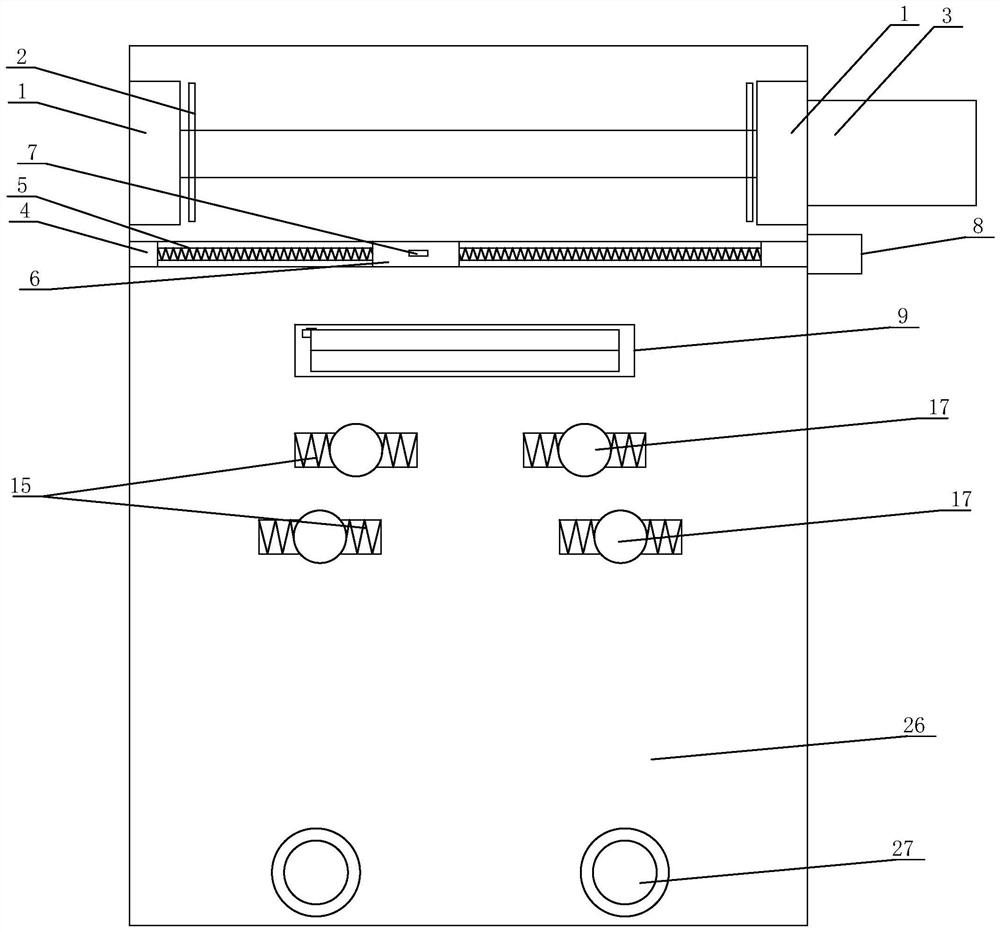

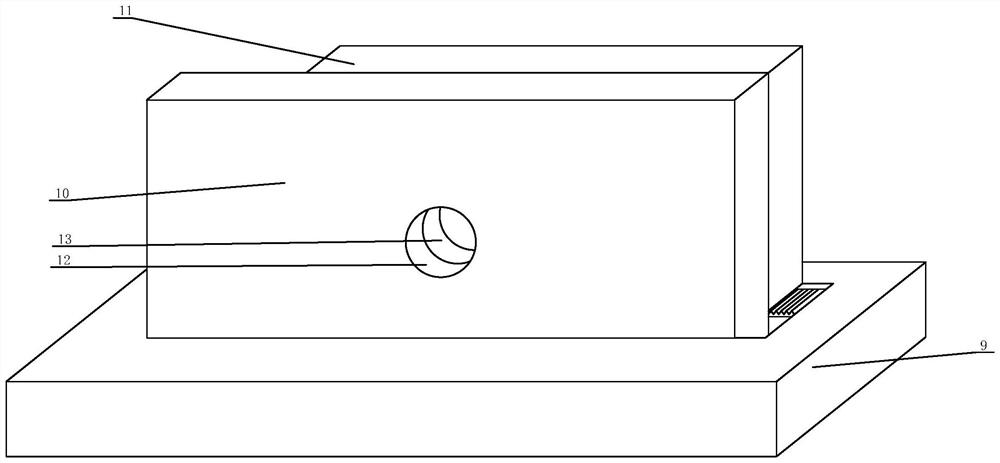

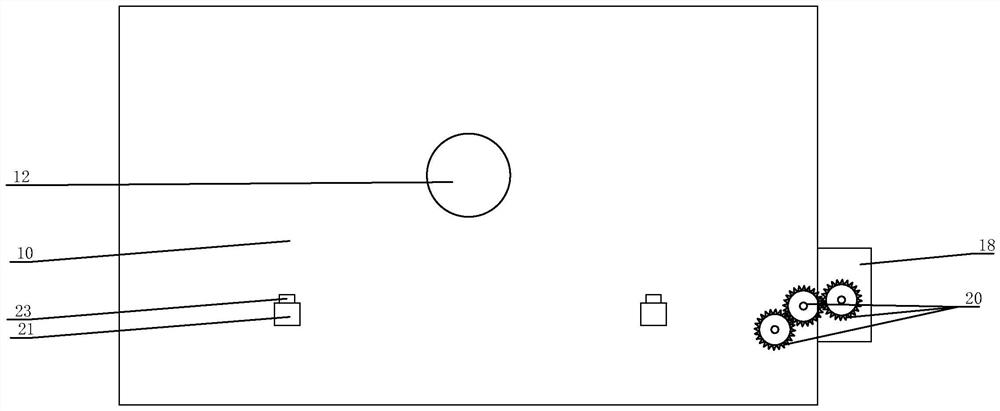

[0021] A yarn doubling machine, which includes a bottom plate 26, a rotating seat 27, a tension adjustment mechanism, a deceleration mechanism, a yarn guide mechanism and a winding mechanism are arranged on the bottom plate 26 in sequence, and the winding mechanism includes two symmetrically arranged on the bottom plate 26. The mounting seat 1, the drum 2 rotatably connected between the two mounting seats 1 and the first motor 3 fixed on the side of the mounting seat 1 for driving the drum 2 to rotate; the yarn guide mechanism includes a mounting plate 4, and the upper surface of the mounting plate 4 A chute is provided, and a lead screw 5 is horizontally arranged in the chute. Both ends of the lead screw 5 are sheathed with bearings, and are rotatably connected with the two ends of the chute through the bearings, and a slider 6 is fixed on the lead screw 5. Both sides of the slider 6 are in contact with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com