Rod clamping mechanism

A technology of clamping mechanism and rod material, which is applied in the direction of clamping device, clamping, metal processing mechanical parts, etc., can solve the problem of poor stability of the clamping mechanism, and achieve the effect of avoiding large vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

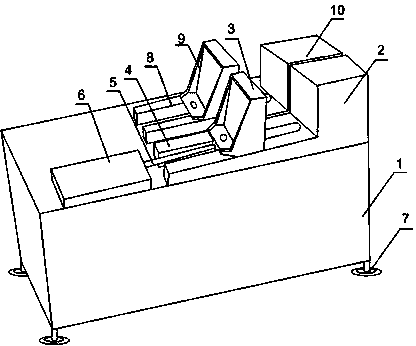

[0018] Such as figure 1 As shown, this embodiment includes a clamping unit, a slideway 4 and a frame 1, the slideway 4 and the clamping unit are placed on the frame 1, the clamping unit includes a movable plate 3 and a fixed plate 2, and the movable plate 3 slides Set on the slideway 4, the fixed plate 2 is set on the frame 1, and also includes a driving mechanism and a positioning mechanism, the driving mechanism is connected to the bottom of the movable plate 3, and the positioning mechanism is arranged in parallel with the clamping unit. On the frame 1, the movable plate 3 and the fixed plate 2 constitute a clamping unit that can change the clamping gap according to the shape and size of the rod material. The fixed plate 2 provided can limit the rod material, and the movable plate 3 can Under the push of the driving mechanism, it advances and retreats quickly to clamp or loosen the rod material; during the material cutting process, the rod material is close to the inner wal...

Embodiment 2

[0020] Such as figure 1 As shown, the present embodiment is based on Embodiment 1. The driving mechanism includes a hydraulic cylinder 6 and a hydraulic motor. The hydraulic cylinder 6 is arranged on the same level as the movable plate 3. The slideway 4 is a U-shaped groove, and the hydraulic cylinder outputs One end of the end 5 passing through the U-shaped groove is connected with the bottom end of the movable plate 3 , and the other end of the U-shaped groove is connected with the fixed plate 2 . In view of defects such as unstable clamping of mechanical clamping and easy noise generation of pneumatic clamping, on the same horizontal plane, the hydraulic motor converts hydraulic energy into mechanical energy output, and the output end 5 of the hydraulic cylinder drives the movable plate 3 to maintain a stable and fast speed to achieve reciprocation Linear motion works; the movable plate 3 is slidably arranged on the U-shaped groove, and the opening of the U-shaped groove ca...

Embodiment 3

[0022] Such as figure 1 As shown, on the basis of Embodiment 1, this embodiment also includes a plurality of studs arranged on the side of the movable plate 3 facing the fixed plate 2 and a plurality of shockproof feet 7 arranged at the bottom of the frame 1 . During the clamping process, in order to better ensure the clamping efficiency, the studs set on the inner wall of the movable plate 3 can engage the rod material, increase the friction between the movable plate 3 and the rod material, and avoid cutting when the cutting mechanism cuts. Cause the mutual collision between the bar material and the baffle plate; when cutting, a large interaction force will be generated between the cutting mechanism and the bar material, and between the bar material and the frame 1, and the shockproof set at the bottom of the frame 1 The pad 7 can offset the generated interaction force, further protect the clamping mechanism and prolong its service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com