A machining apparatus for an electrode ear of an electric cell

A technology of processing equipment and battery cells, which is applied in the field of battery tab processing equipment, can solve the problems of damaging battery tabs and increasing the defective rate of battery tabs, and achieves the effect of high precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

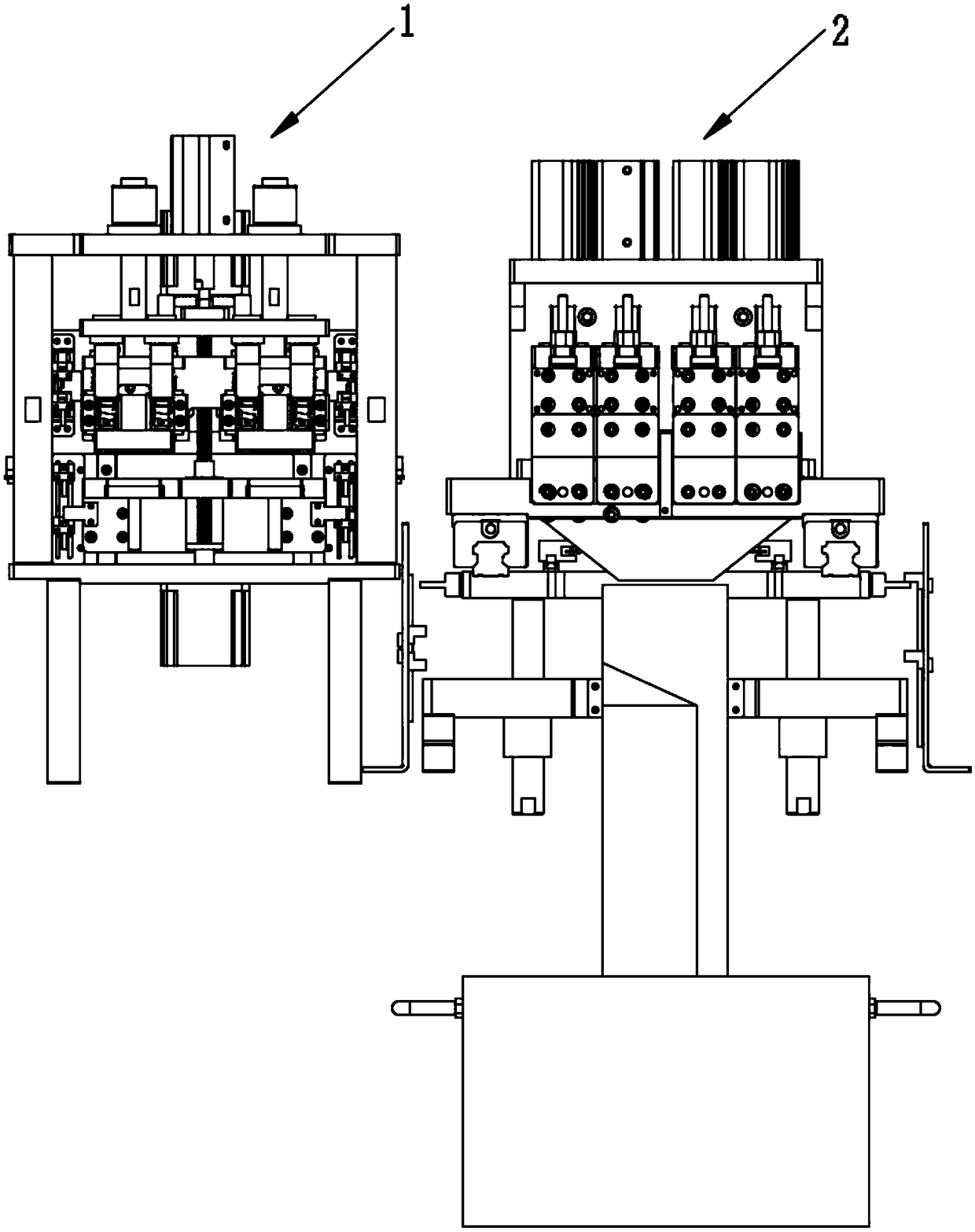

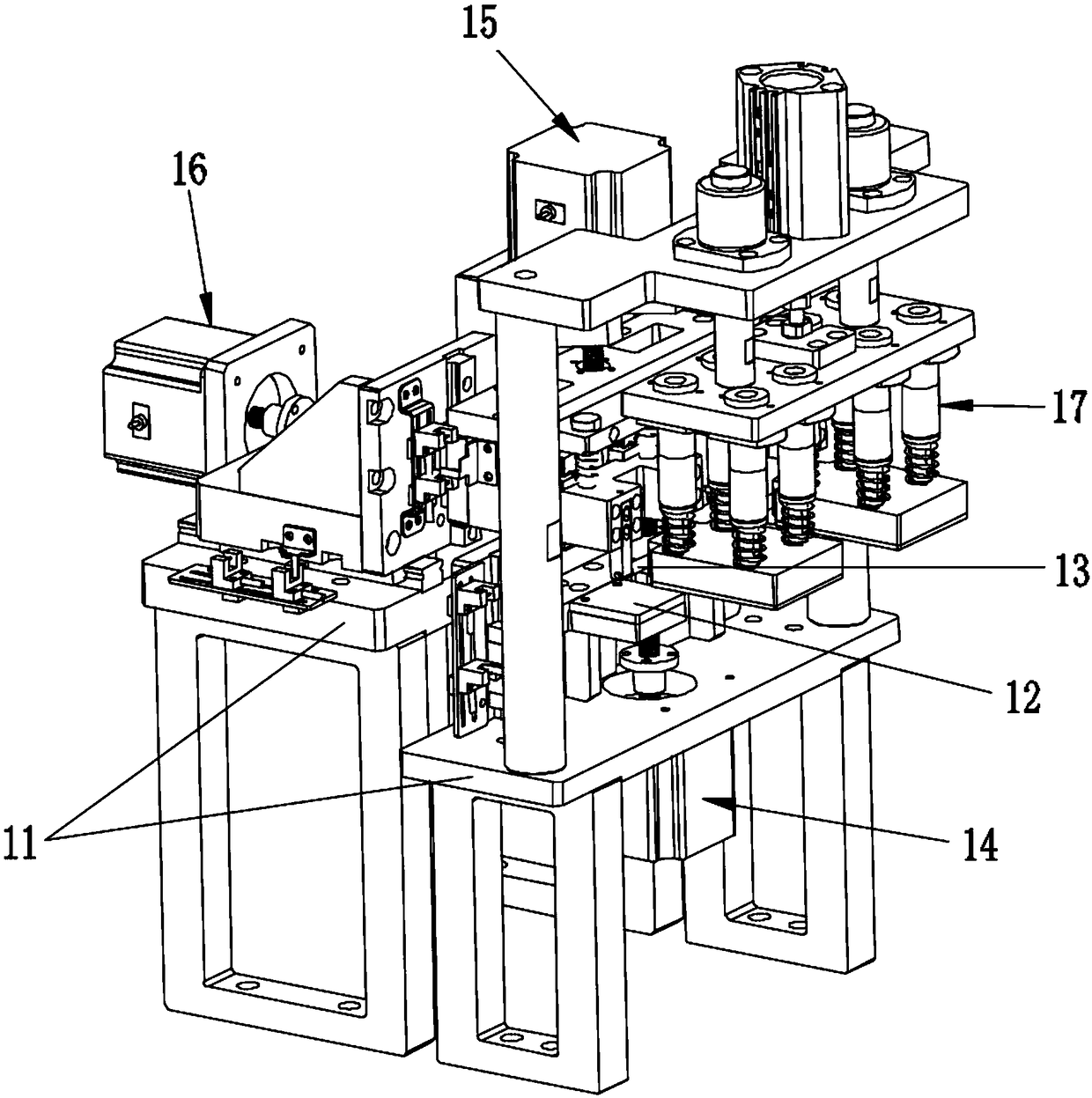

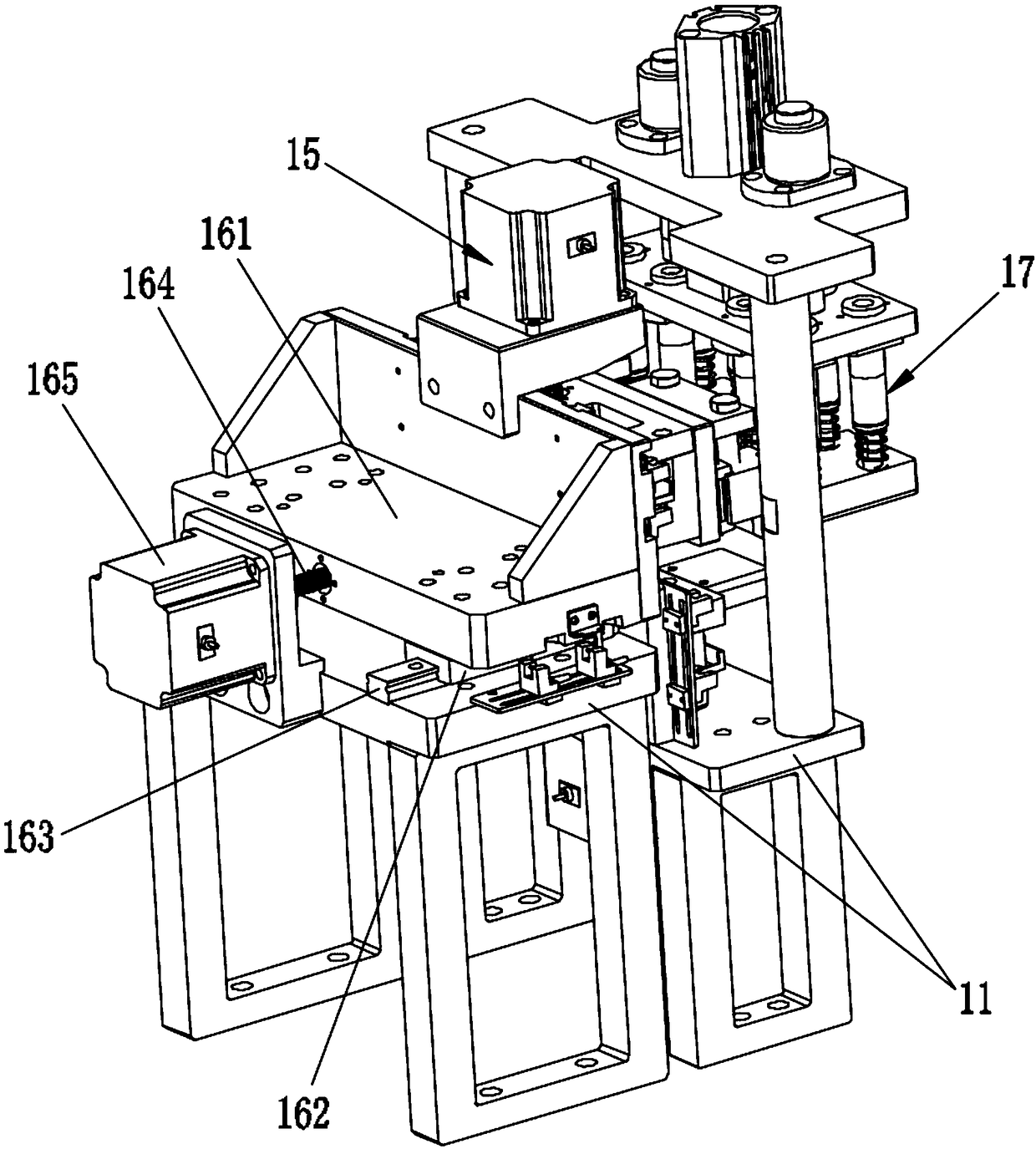

[0032] Such as Figure 1 to Figure 5 As shown, the present invention provides a cell tab processing equipment, which includes a cell tab shaping mechanism 1 and a cell tab cutting mechanism 2; the cell tab shaping mechanism 1 includes a workbench 11, The carrying platform 12 for supporting the tab, the pressure roller 13 for rolling the tab carried by the carrying platform 12, the first driving assembly 14 for driving the movement of the carrying platform 12, and the pressure roller 13 for driving the longitudinal movement The second drive assembly 15, the third drive assembly 16 for driving the pressure roller 13 to move laterally and the cell pressing device 17 for pressing the cell; the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com