Hydraulic fork truck

A forklift and hydraulic technology, applied in the field of hydraulic forklifts, can solve the problems of shortened service life of anti-skid parts, impact damage of anti-skid parts, goods sliding off the forklift, etc., and achieve the effect of extending service life, reducing impact damage, and simple and convenient replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below:

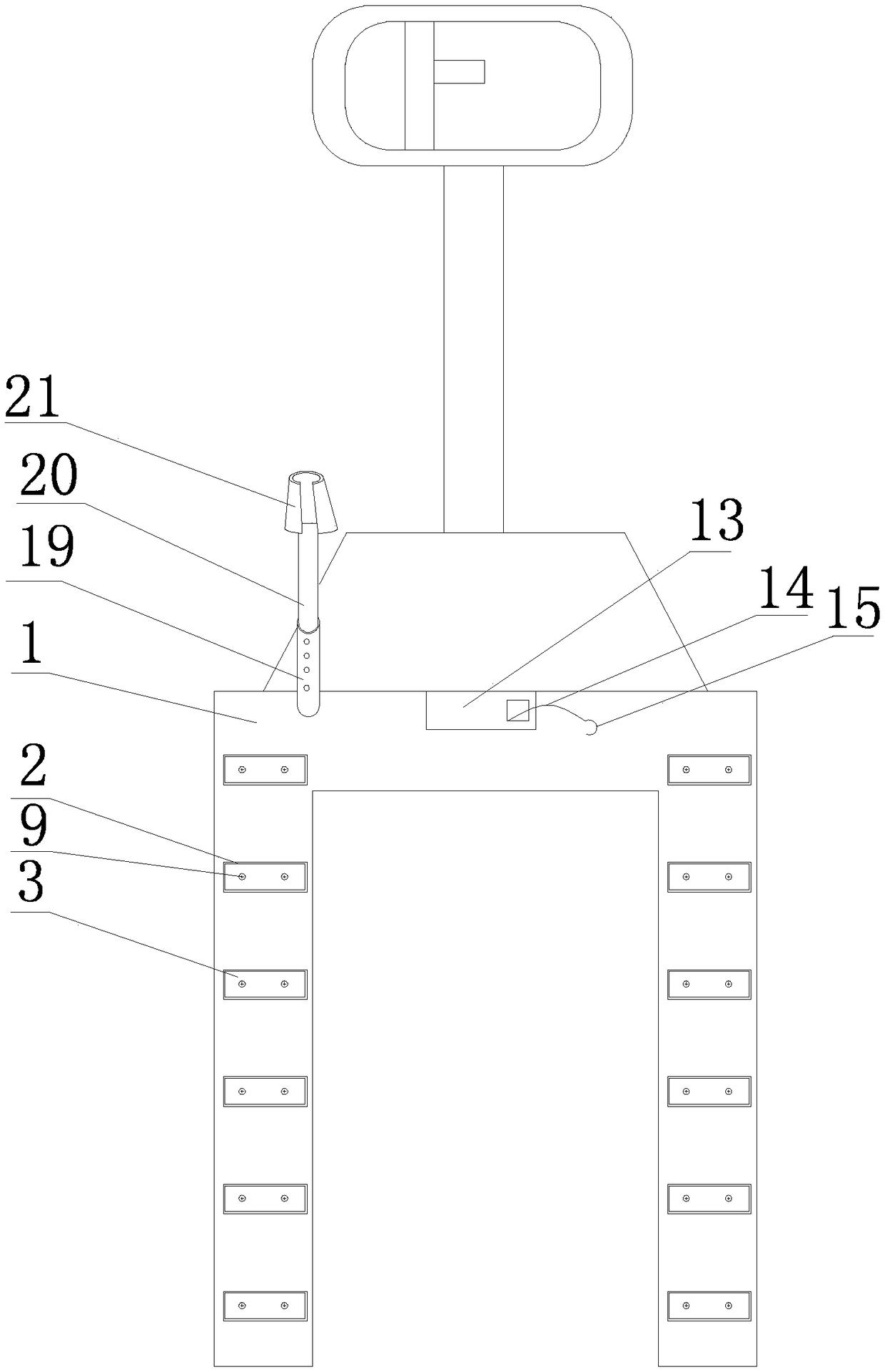

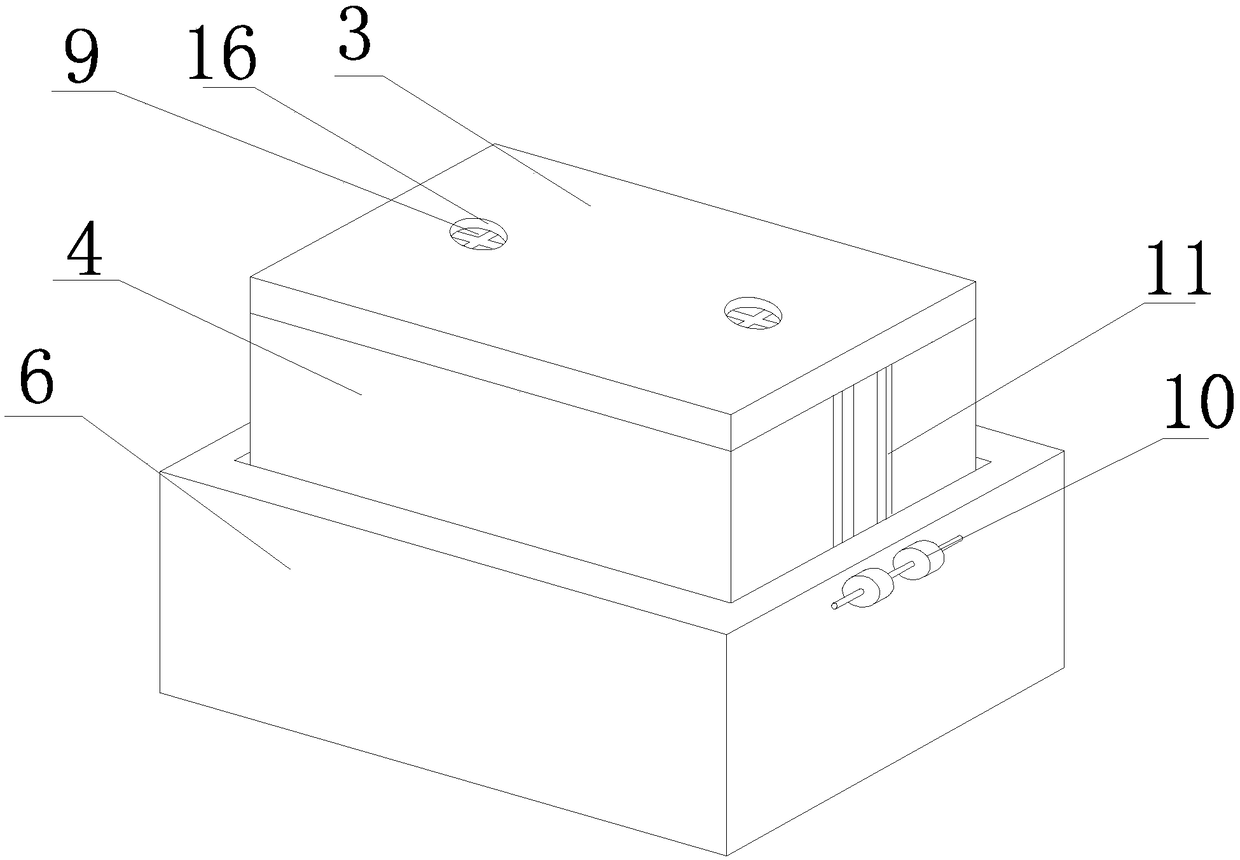

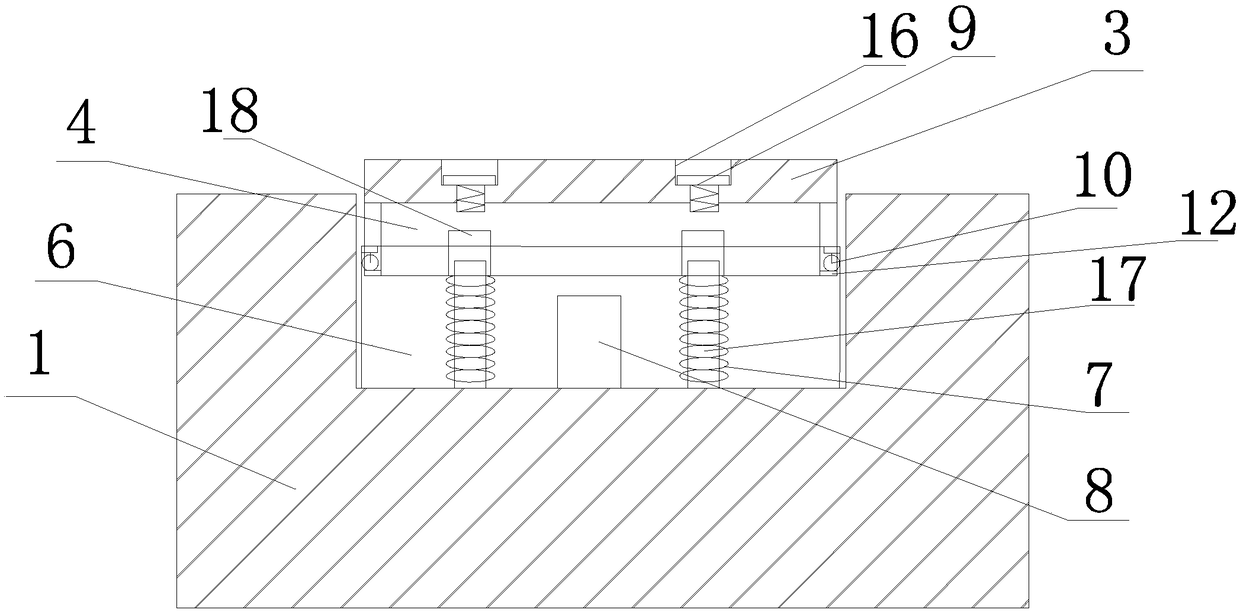

[0021] The forklift of the present invention comprises a hydraulic forklift body, the vehicle plate 1 of the hydraulic forklift is provided with a plurality of grooves 2 uniformly distributed along the length direction of the vehicle plate 1, and each groove 2 is provided with a rubber block 3 And a buffer mechanism for buffering after the rubber block 3 is under pressure, the buffer mechanism includes an upper shell 4 and a lower shell 6 that are movably nested in each other, and a spring that is arranged in the lower shell 6 to play a buffering role 7. The guide column 17 arranged in the lower housing 6, the guide hole 18 arranged at the bottom of the upper housing 4 and matched with the guide column 17, the spring 7 is sleeved on the guide column 17, the lower end of the spring 7 and the lower housing 6, the inner bottom surface is attached, the upper end of the spring 7 is attached to the bottom of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com