Telescopic boom of walking hanging scaffold

A technology of telescopic arm and hanging pan, which is applied in the field of telescopic arm of the step hanging pan, which can solve the problems of affecting the overall strength of the shaft wall, increasing construction costs, time-consuming and laborious, etc., and achieves the effects of uniform force, avoiding damage, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

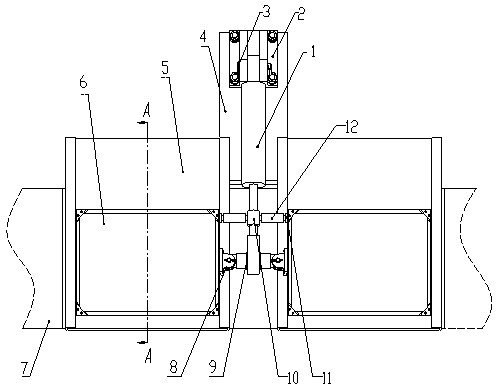

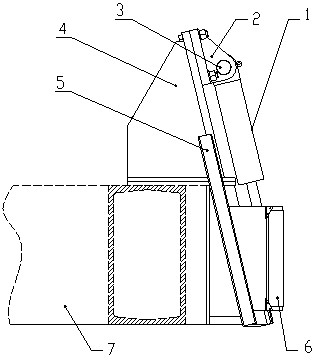

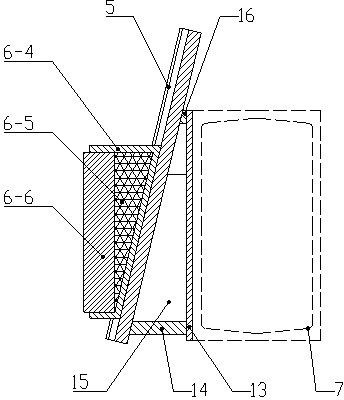

[0014] Such as figure 1 with figure 2 As shown, the telescopic arm of the step suspension plate is composed of the wedge angle connection seat 4 fastened on the ring beam 7, the single ear support 2 fastened on the wedge angle connection seat 4, the pin shaft 3, and the hydraulic cylinder 1. Assemblies, the sliding wedge assembly that slide wedge block 6, guide groove 5 constitute, and the counterrotating assembly that double ear sliding sleeve 10, counterrotating screw mandrel 12, positioning screw mandrel 11 etc. constitute three components. Wherein, the inclined plane angle of the single-ear support 2 installed on the wedge-angle connecting seat 4 is equal to the inclined angle of the sliding wedge 6, and the inclined angle of the sliding wedge 6 is generally 13-20 degrees, according to the friction coefficient of the friction panel and the well wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com