Nondestructive flaw detection method for aluminum alloy bar by adopting ultrasonic technology

A non-destructive flaw detection and aluminum alloy technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of large error and low flaw detection work efficiency, and achieve the effect of small error, high work efficiency and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

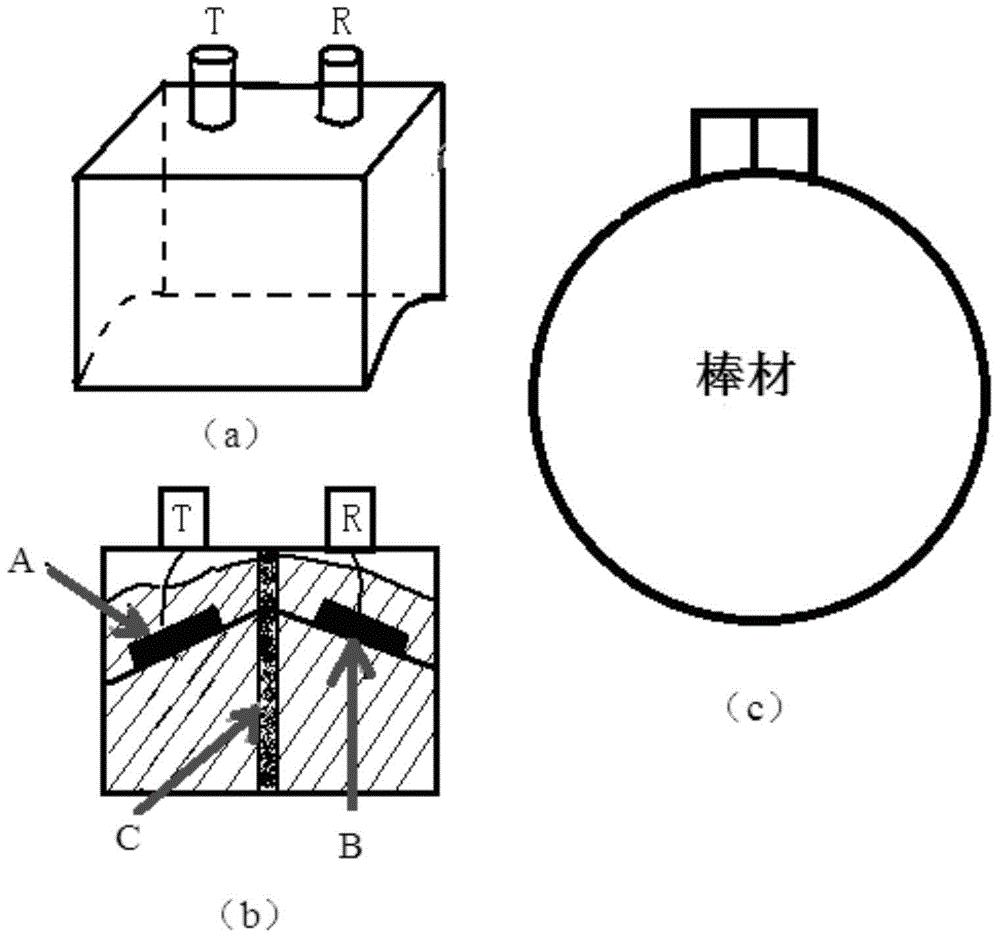

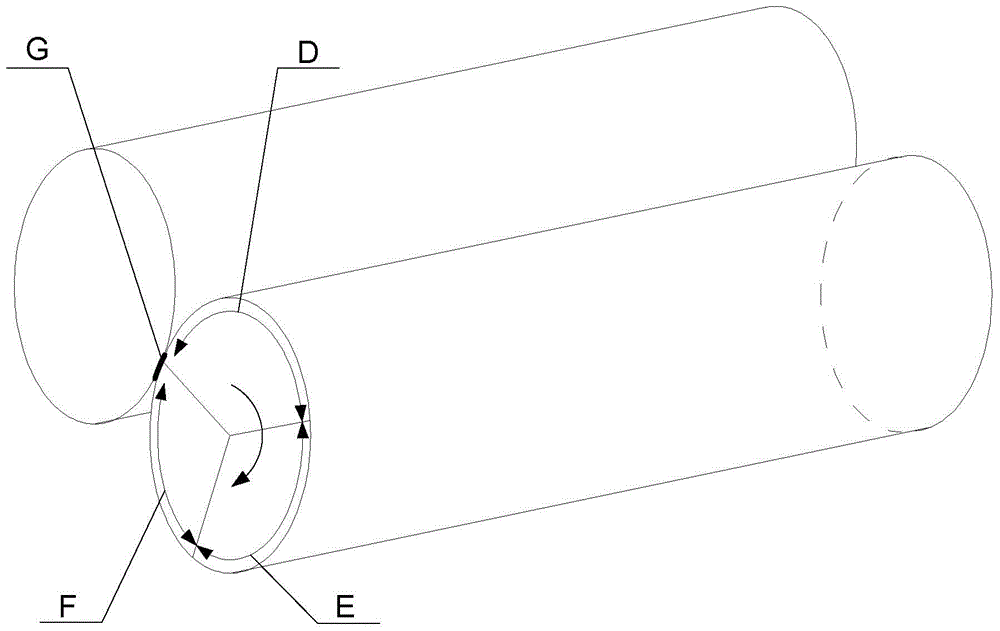

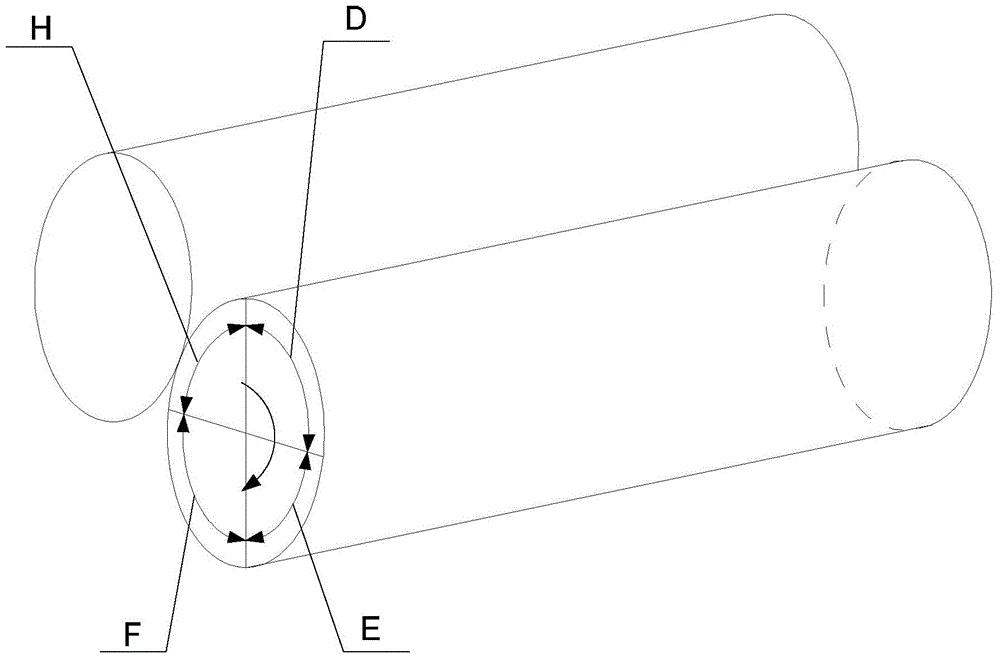

[0015] Specific implementation mode one: the following combination Figure 1 to Figure 6 To illustrate this embodiment, the non-destructive detection method for aluminum alloy rods using ultrasonic technology described in this embodiment, the method includes the following steps:

[0016] Step 1. Grinding the bottom of the longitudinal-wave dual crystal probe to form an inner arc, which matches the outer arc of the aluminum alloy bar to be detected;

[0017] Step 2. Draw the Φ1.2mm flat-bottomed hole distance-amplitude DAC curve and the Φ0.8mm flat-bottomed hole distance-amplitude DAC curve using the flat-bottomed hole test block; and adjust the flaw detection sensitivity, which includes benchmark sensitivity, detection sensitivity and scanning sensitivity ;

[0018] Step 3. Place the longitudinal wave dual crystal probe on the outer surface of the aluminum alloy bar to be tested, and scan along the longitudinal direction of the bar; the scanning speed is ≤ 200mm / s, and the ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com