Wood nondestructive testing device capable of conducting imaging in real time at any angle

A non-destructive testing and real-time imaging technology, applied in the direction of using radiation for material analysis, etc., can solve the problems that the detection device cannot realize the detection of the measured object at any angle, the image acquisition is not timely and inconsistent, and the image acquisition time is long. Improve, reduce human operation, and improve the efficiency of image acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

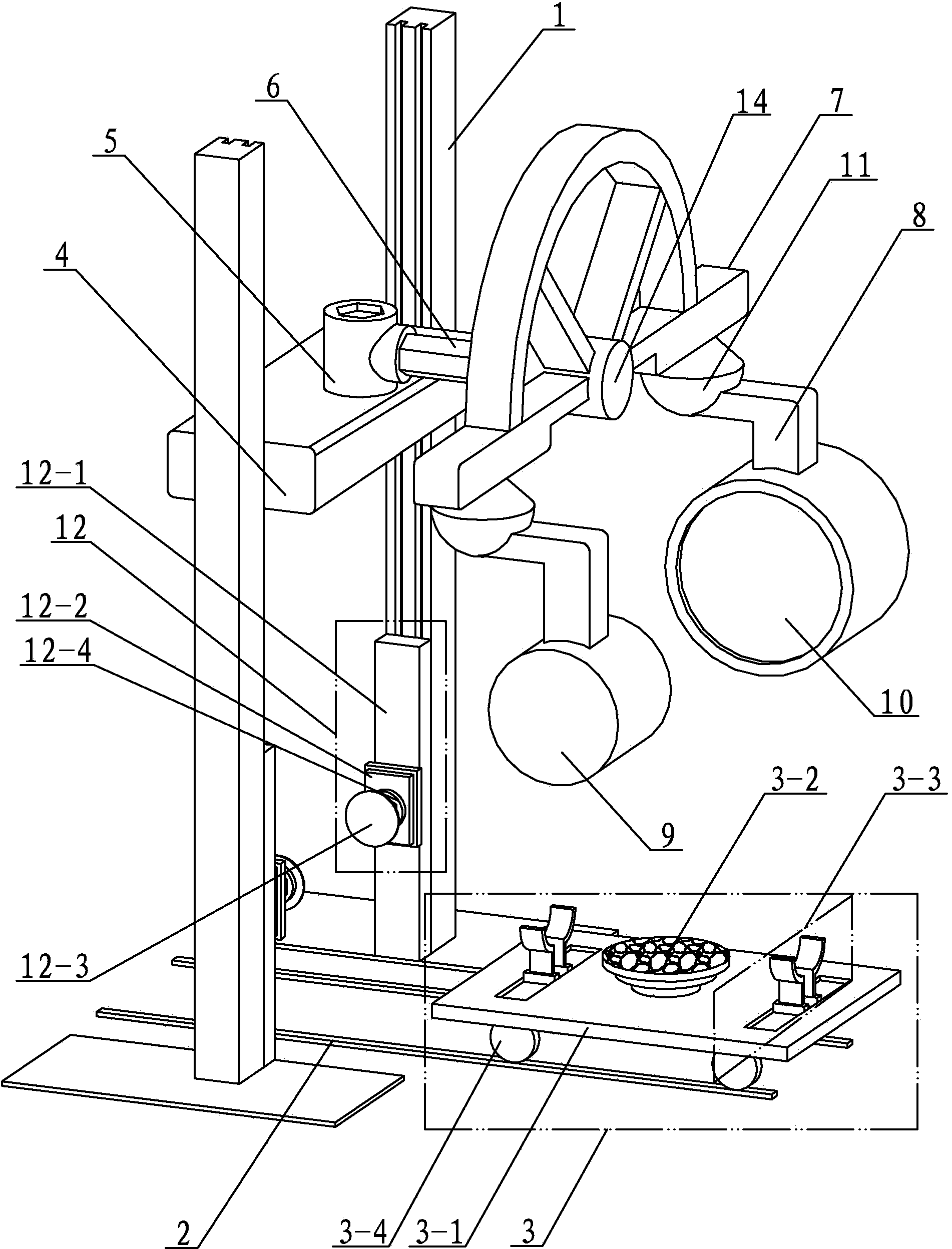

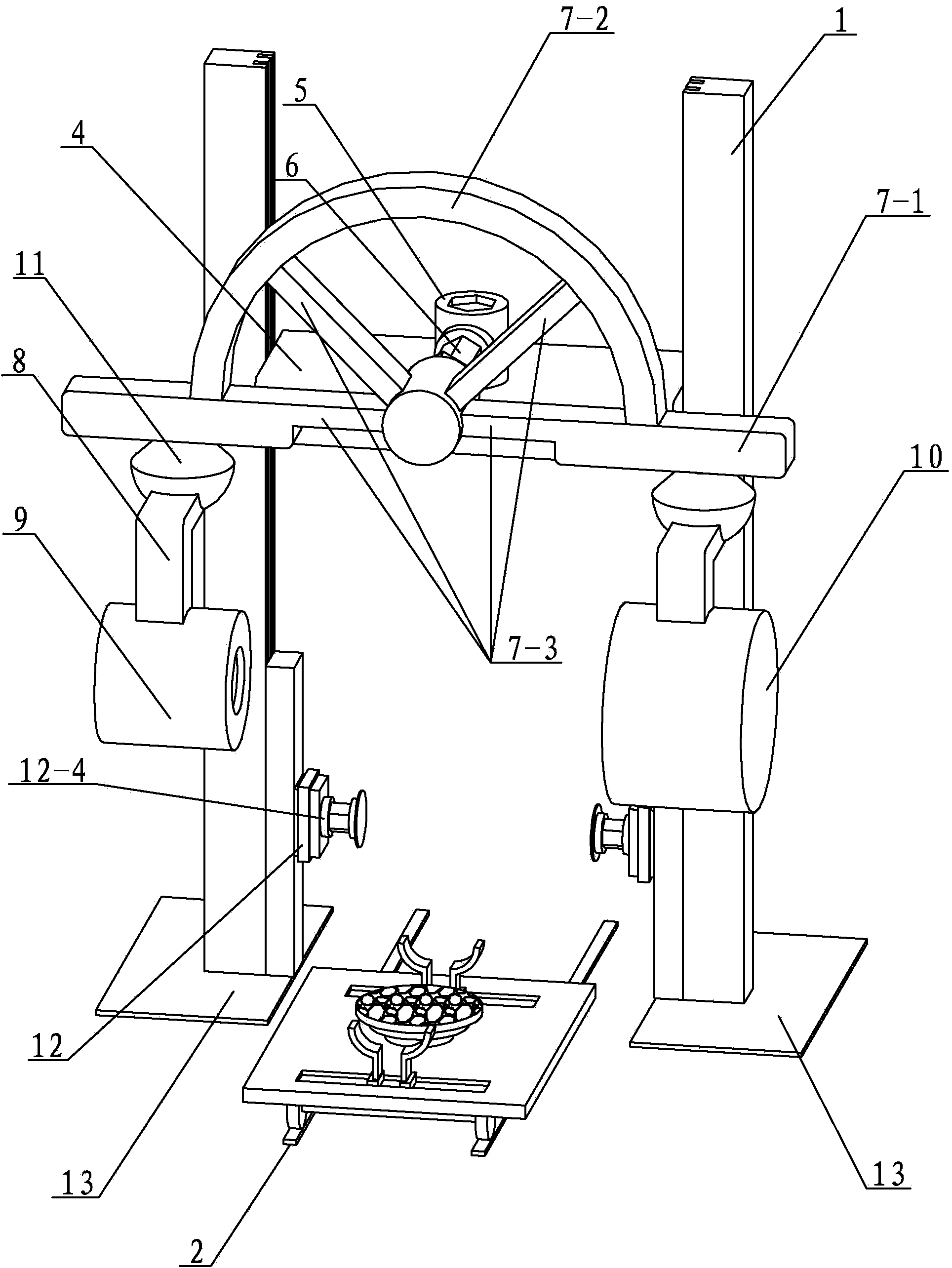

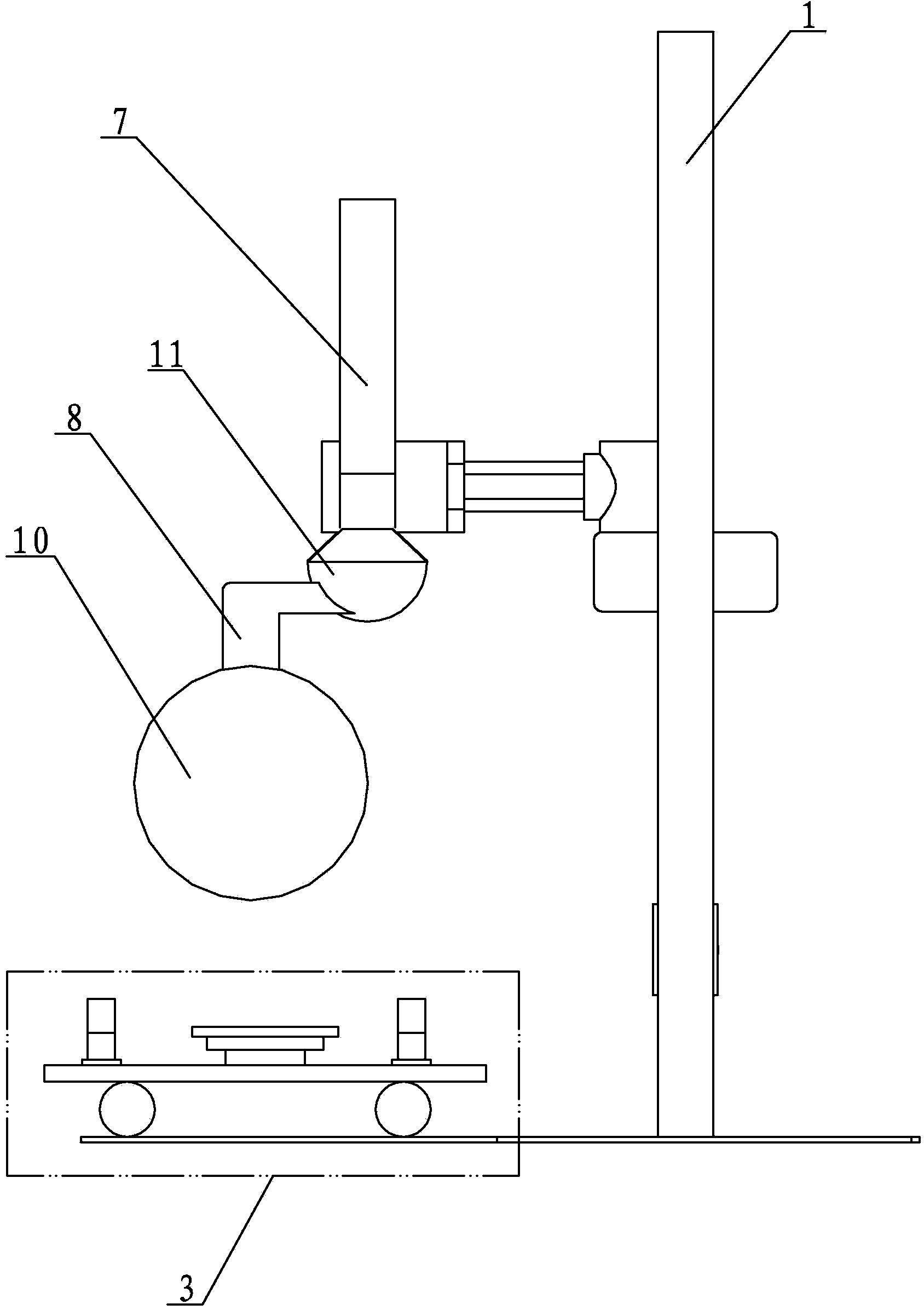

[0018] Specific implementation mode one: combine Figure 1-Figure 5 Describe this embodiment, a wood non-destructive testing device with real-time imaging at any angle in this embodiment, which includes a slide rail 2, a loading vehicle 3 and two brackets 1, the two brackets 1 are vertically arranged side by side, and the slide rail 2 is located on the Between the two brackets 1, and perpendicular to the two brackets 1, the loading cart 3 can be slidably arranged on the slide rail 2, and the wood non-destructive testing device also includes a radially moving slide plate 4, a swing connecting block 5, an extension arm 6. Support arm 7, rotation adjustment motor 14, ray emitter 9, receiver 10, two poles 8 and two movable joints 11, the radially movable slide plate 4 can be slidably arranged on the inner side walls of the two brackets 1 Above, the swing connection block 5 is fixedly installed on the radially moving slide plate 4, one end of the extension arm 6 is connected with t...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination figure 1 and figure 2 To illustrate this embodiment, the wood non-destructive testing device of this embodiment further includes two mechanical claws 12 , and the two mechanical claws 12 are respectively slidably arranged at the lower parts of the inner side walls of the two brackets 1 . With such arrangement, the manipulator can clamp and rotate the object to change the position of the object to be detected relative to the loading vehicle, so as to realize all-round detection of the object to be detected. Unnecessary manual operations in this process can be reduced, radiation hazards to operators can be avoided, and detection efficiency can also be improved. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment, each mechanical jaw 12 of this embodiment all comprises clamping slider 12-1, hydraulic cylinder 12-2, clamping rotating motor 12-4 and clamping end 12-3, clamping slider 12 -1 is slidably arranged on the lower part of a support 1, the hydraulic cylinder 12-2 is fixedly arranged on the clamping slider 12-1, and the clamping end 12-3 is arranged on the hydraulic cylinder 12-1 by clamping the rotating motor 12-4. 2 front end. With such arrangement, it is convenient to realize the clamping and rotation of the article. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com