Ultrasonic testing device of defect of wheel spoke of engine vehicle

A detection device, ultrasonic technology, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve wheel spoke defects, complex structures, and long distances from the tread surface, etc. problems, to achieve the effect of reliable detection results and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

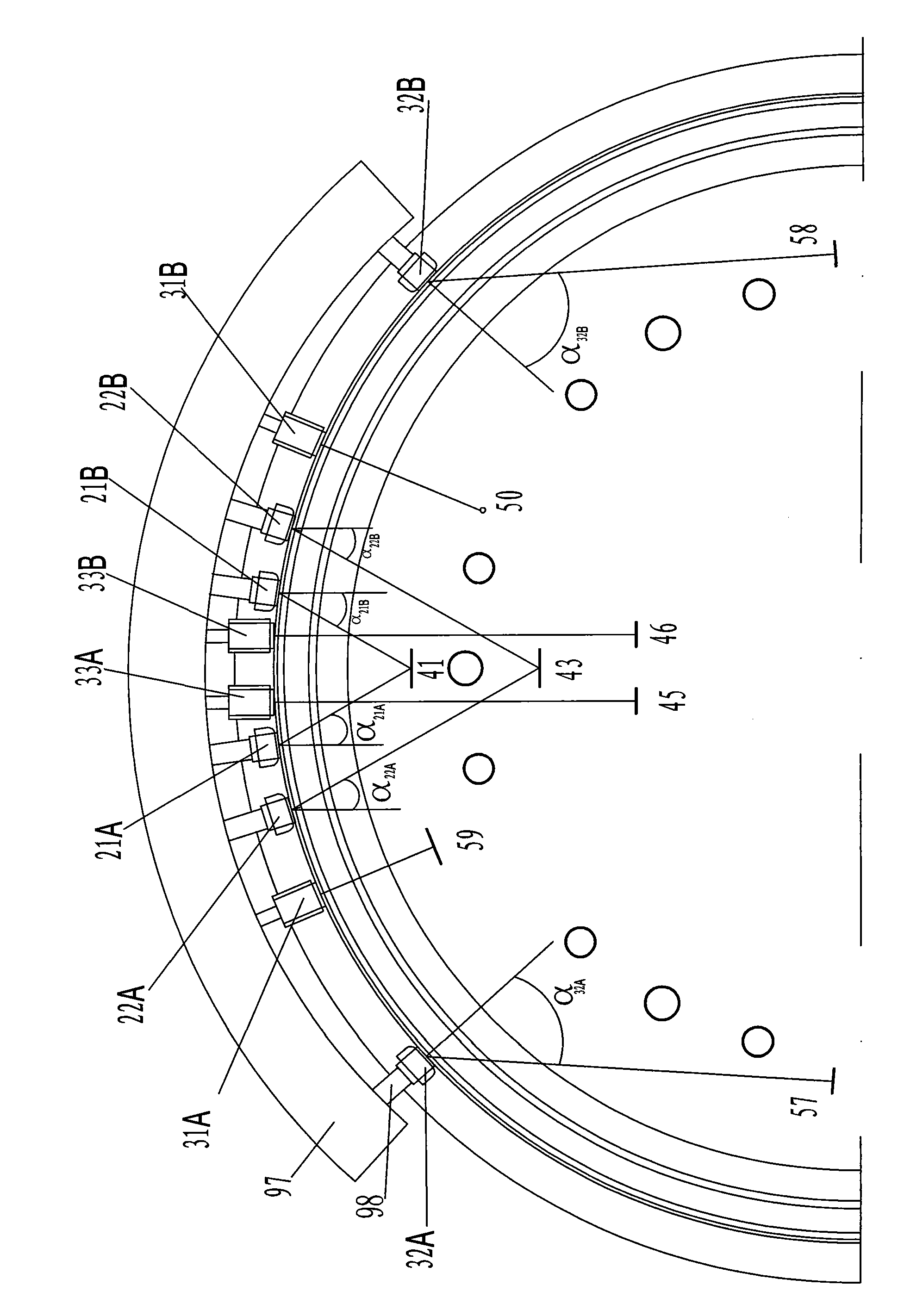

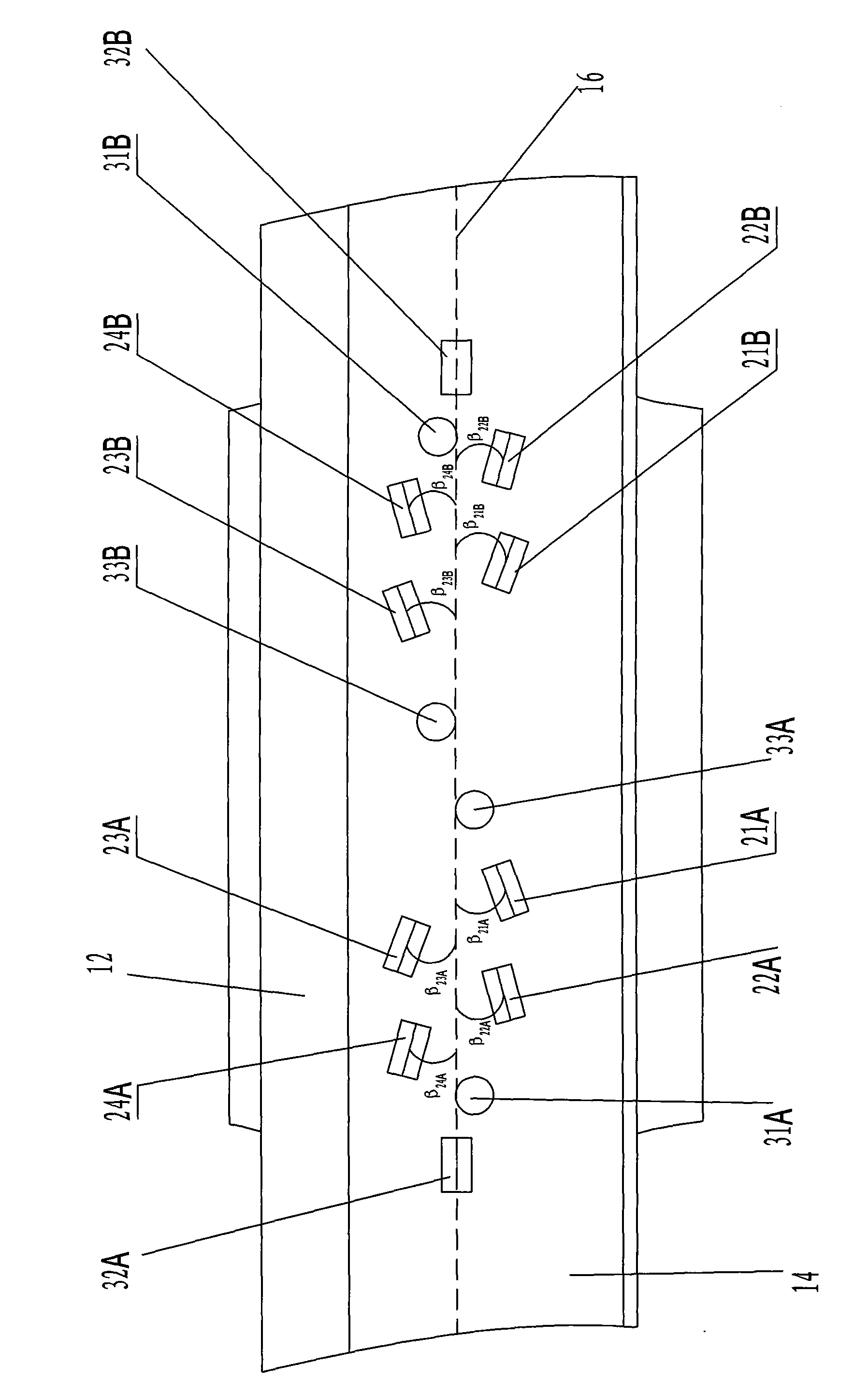

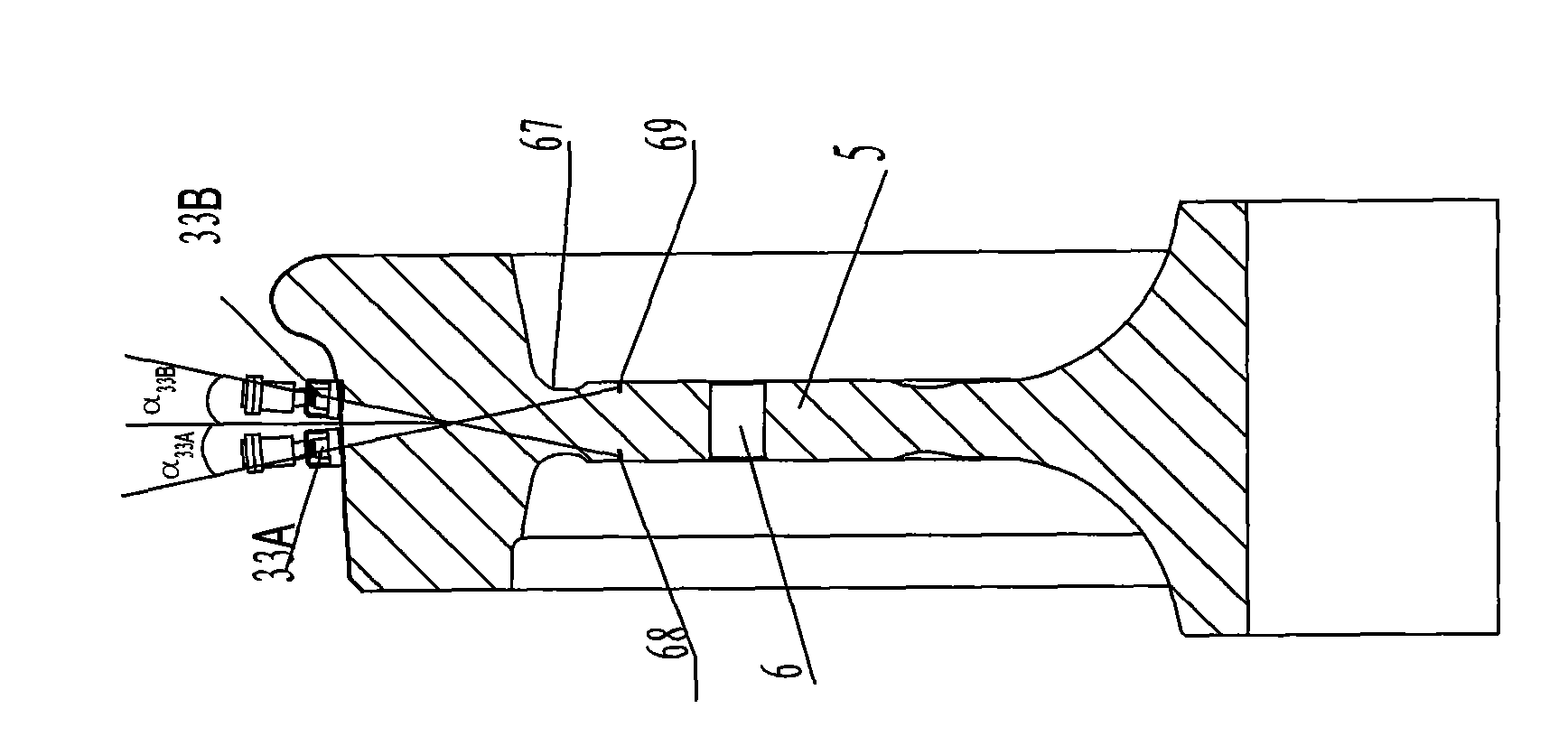

[0040] Figure 1-6 As shown, a specific embodiment of the present invention is: an ultrasonic detection device for wheel spoke defects of a locomotive vehicle, comprising an ultrasonic array probe connected to the probe bracket 97 connected to the control mechanism, and the ultrasonic probe is placed on the tread surface of the wheel 1 of the wheel set 14, the bottom of the wheel rim 12 is placed on the top wheel 91 and the runner 92 of the top runner device; the ultrasonic probe is connected with the data acquisition, data processing and control computer. Ultrasonic probes are four pairs of probes composed of transmitting probes and receiving probes and six probes integrating transceivers, among which: the range of the transmitting angle or receiving angle of each probe in the four pairs of probes is 15-33°. The included angle between the rolling circles, that is, the range of the torsion angle is 5 to 35°, and the emission angle of the transmitting probe in each pair of prob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com