Vision detection device used for detecting defects on surface of plastic medicine bottle

A technology of visual inspection device and medicine bottle, which is applied in the direction of measuring device, material analysis by optical means, instrument, etc., to achieve the effect of monitoring product quality, controlling loss, and applying value in large-scale industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

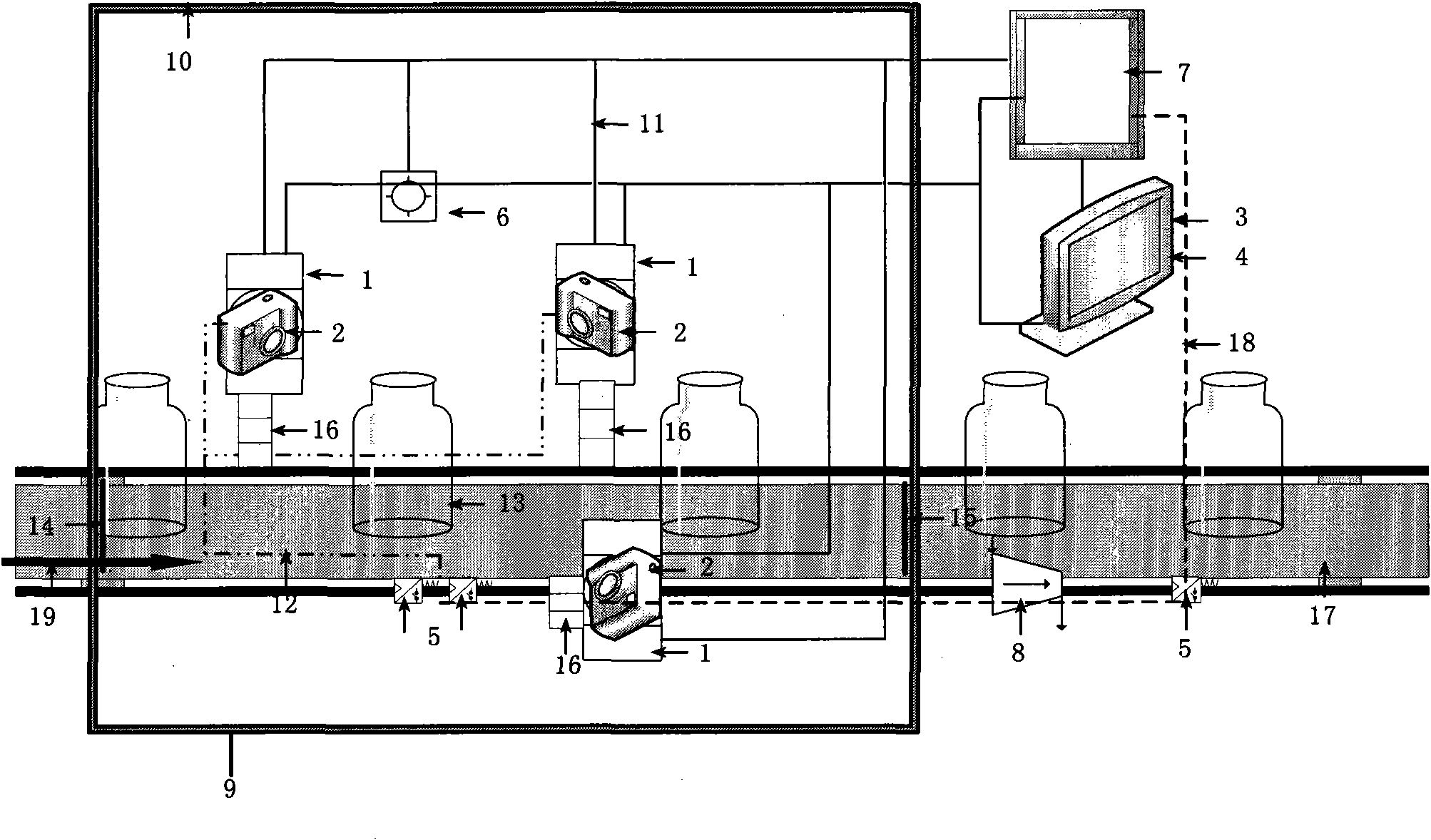

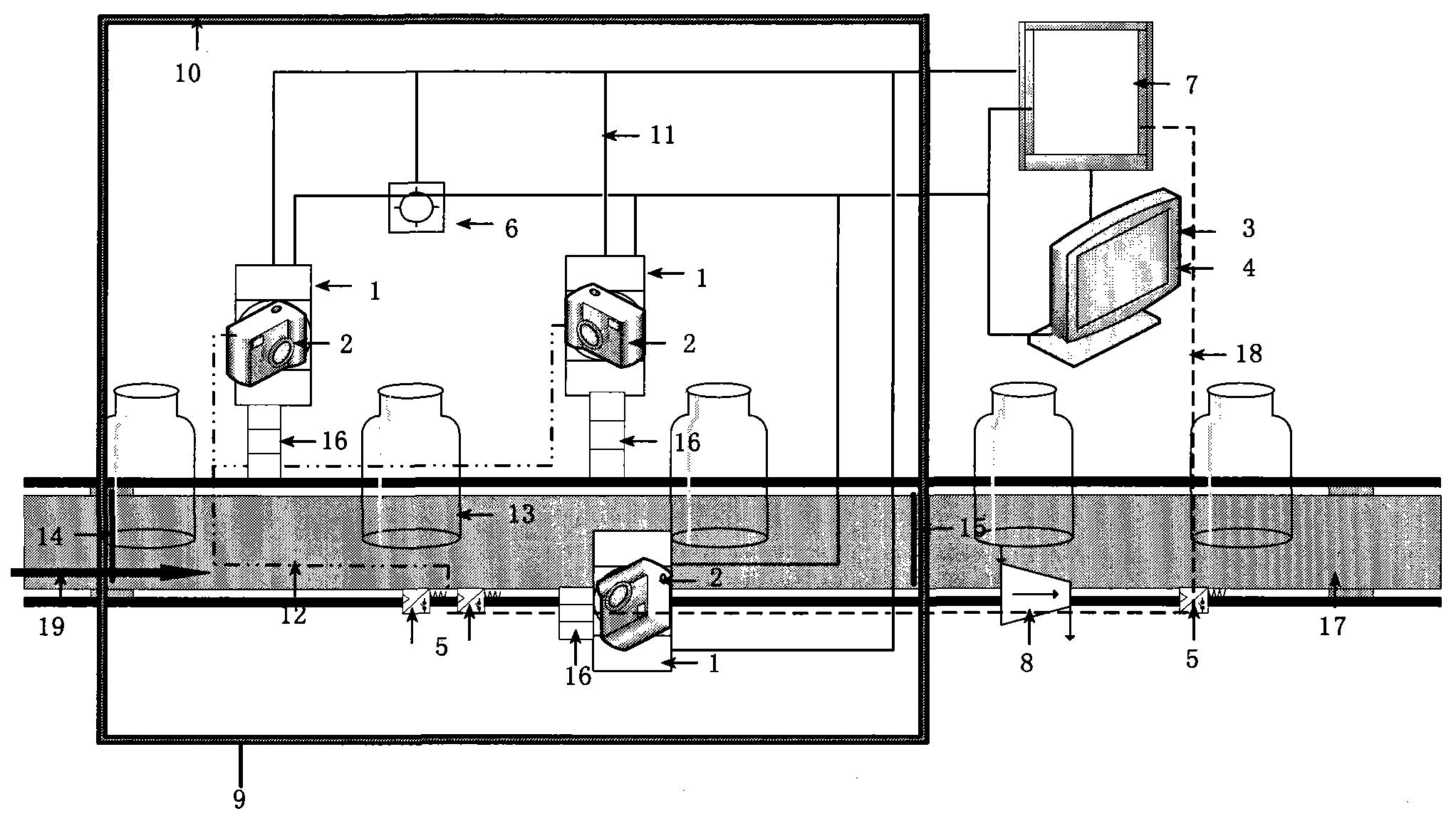

[0020] like figure 1 The present invention is shown as a visual detection device for surface defects of plastic medicine bottles. It consists of ring light source 1, camera 2, control software 3, computer 4, photoelectric sensor 5, point light source 6, electric control cabinet 7, rejecting device 8 and protective cover 9. Three ring light sources 1, three cameras 2 and three photoelectric sensors 5 are respectively arranged in the device of the present invention; the trigger signal line 12 of the photoelectric sensor 5 is connected to the camera 2 to start the image capture function of the camera; the three ring light sources 1 are respectively Installed directly in front of the three cameras 2, there are circular openings with a diameter of 3-7 cm in the middle of the three ring light sources 1, so that the camera lenses can stretch out to find a view. The three cameras 2 are respectively installed on both sides of the conveyor belt 17 with a bracket 16 at 120 degrees, wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com