Steel wire rope magnetic memory on-line detection device

A detection device and wire rope technology, applied in the direction of material magnetic variables, etc., can solve problems such as easy distortion, external interference of tangential component signals, difficulty in overcoming jitter, etc., and achieve the effect of overcoming external interference, improving accuracy, and eliminating measurement blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

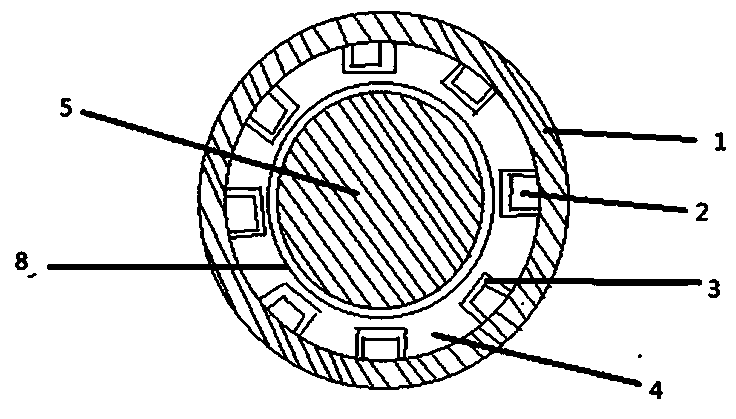

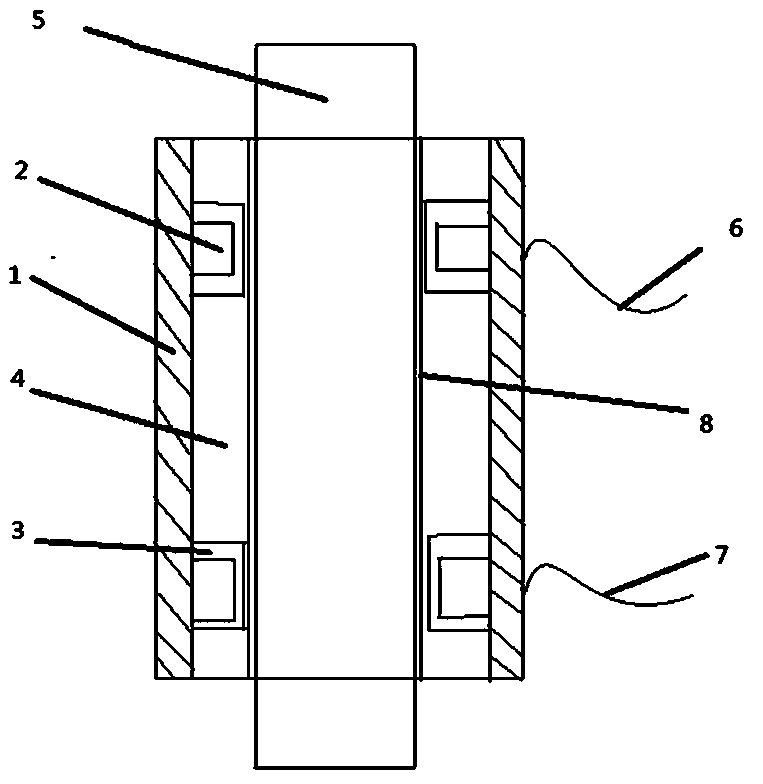

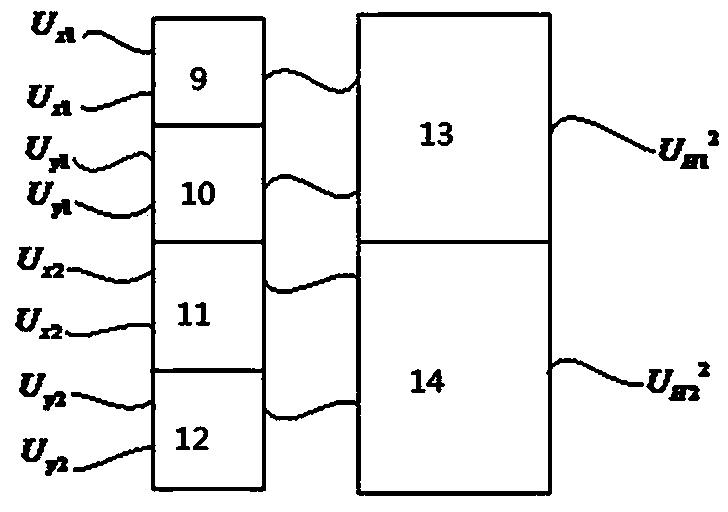

[0013] figure 1 It is a transverse sectional view of the magnetoresistive sensor of the present invention, figure 2 For the longitudinal section of the present invention, the three-dimensional magnetoresistive sensor adopts HMC1053 produced by Honeywell, its resolution is in the micro-Gauss level, and the linear error is not more than 1.8%. Two two-dimensional magnetoresistive sensors measure three-dimensional signals, improving installation convenience and reliability. The first group of magnetoresistive sensors is installed in the same direction as the second group of magnetoresistive sensors (such as Figure 5 , assuming that the sensor measurement direction is x, y, z direction, the direction of the phase component of the measurement method is the z direction, and the measurement of the tangential component is the vector synthesis of the x and y directions, then according to the pin characteristics of the three-dimensional sensor, the first group of sensors and The seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com