Array ultrasonic detection technology of complex surface microdefect

A complex curved surface and ultrasonic detection technology, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids and process detection response signals, etc., can solve the problems of low detection accuracy, low detection efficiency, missed detection, etc. Manpower and material resources, the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The implementation of the complex curved surface micro-defect array ultrasonic detection technology proposed by the present invention generally includes the following steps:

[0028] (1) Set the detection signal waveform according to the material properties, processing methods and main characteristics of internal defects (depth, position, etc.) of the components to be detected;

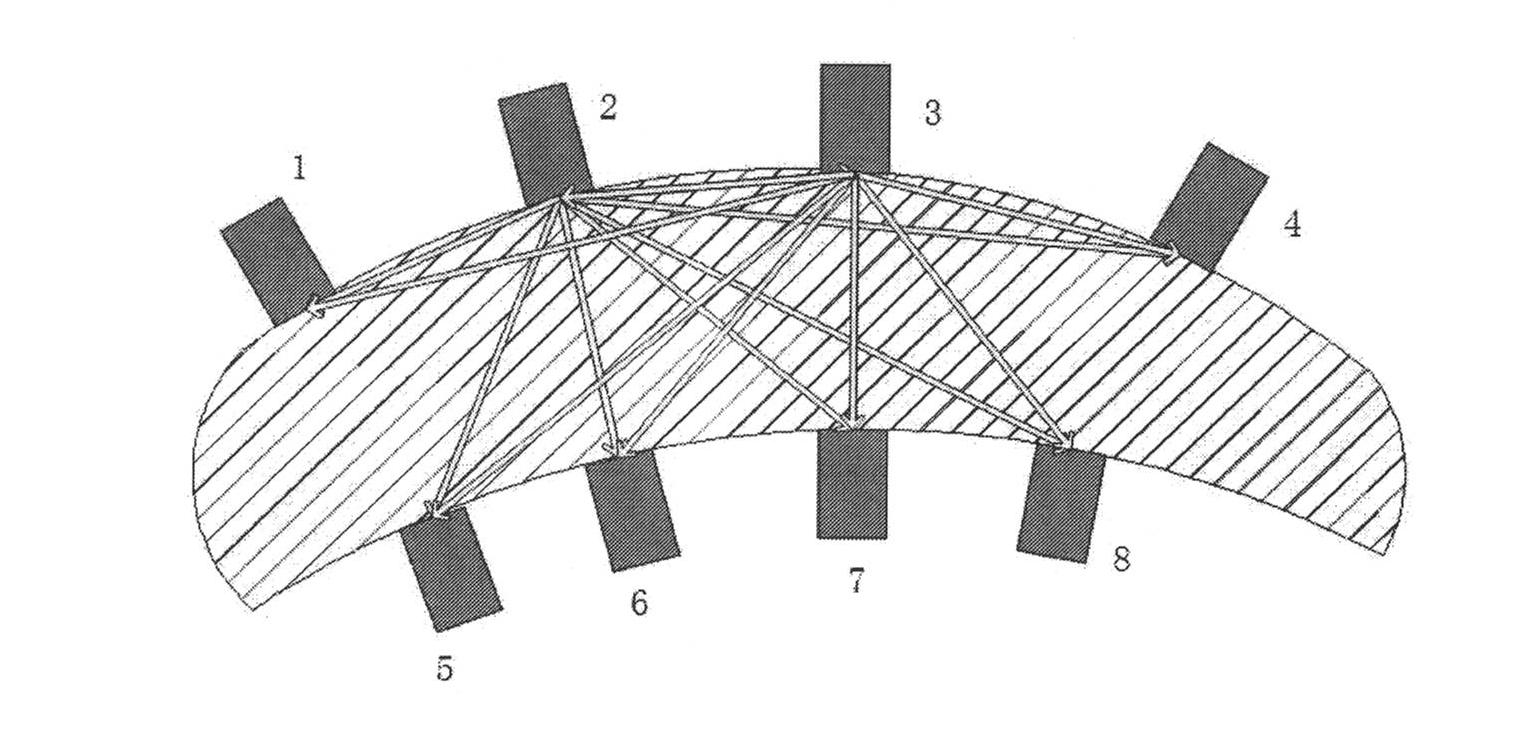

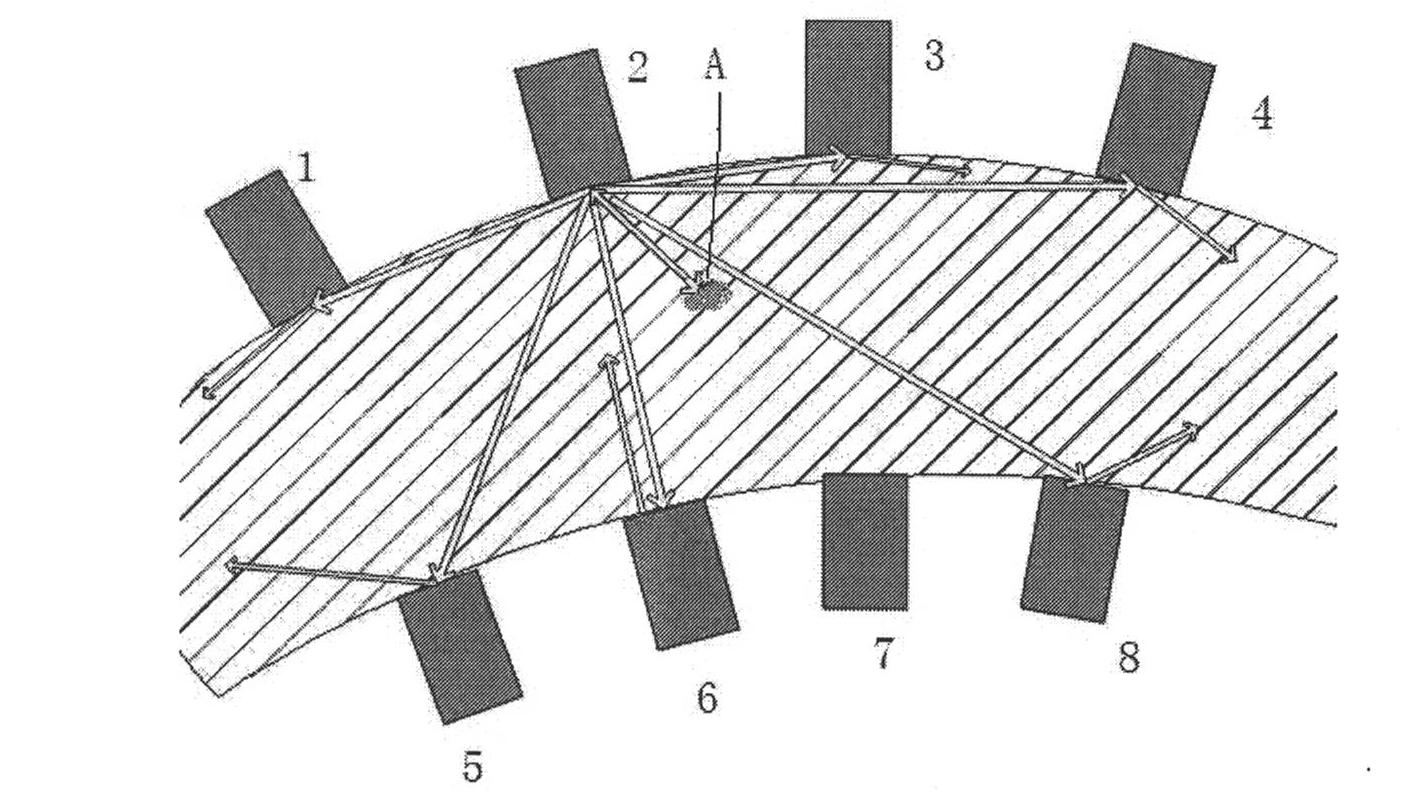

[0029] (2) According to the shape of the detected component and the detection accuracy requirements, set the arrangement form of the transducer array that meets the detection requirements (mainly determine the number and position of the transducer arrangement);

[0030] (3) Select the probe type according to the selected detection signal waveform, calculate the excitation mode of the corresponding electric excitation signal, the arrangement angle of the probe, use the electric excitation signal to excite the ultrasonic transducer to generate the required ultrasonic signal and send it to the test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com