Microfocus three-dimensional CT imaging detection method for hot-melt welding quality of polyethylene pipelines

A hot-melt welding and CT imaging technology is applied in the field of micro-focus three-dimensional CT imaging detection of polyethylene pipe hot-melt welding quality, which can solve the problems of accuracy and on-site applicability that need to be improved and is not widely used, so as to ensure quality, Guarantee the effect of high radiation intensity and high imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] As a preferred embodiment of the present invention, the present invention discloses a micro-focus three-dimensional CT imaging detection method for polyethylene pipe hot-melt welding quality, the steps of which include:

[0051] a. Arrange the micro-focus three-dimensional CT imaging device: select X-ray tubes and flat panel detectors that are used in conjunction with each other. At both ends of the platform, welding joints are arranged on the detection platform between the X-ray tube and the flat panel detector, and the welding joint can rotate freely and move freely between the X-ray tube and the flat panel detector;

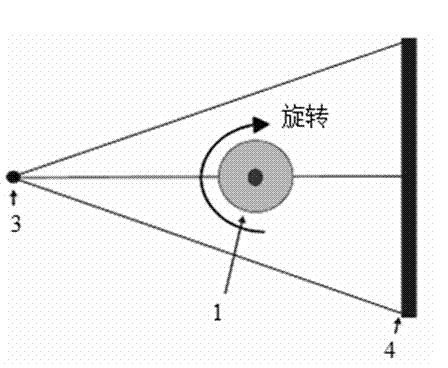

[0052] b. Adjustment of welding joint position: open the X-ray tube, and the conical X-ray beam irradiates the welding joint along the circumference and radial direction of the welding joint. Under the initial voltage and current of the X-ray tube, and under the initial position of the welding joint, The computer obtains and displays the real-time image...

Embodiment 2

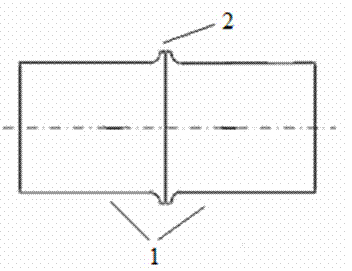

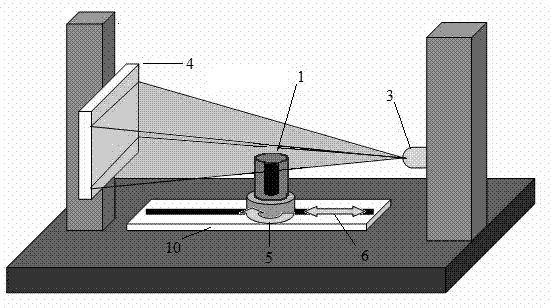

[0060] Concrete application examples of the present invention, such as Figure 1~4 As shown, in the present invention, the micro-focus three-dimensional CT device of the welded joint 2 of the polyethylene pipe 1 includes: an X-ray tube 3 , a flat panel detector 4 , a detection platform 10 , and a computer 11 . The computer integrates various execution programs for performing three-dimensional CT imaging, such as image calibration programs and CT scanning programs, and these integrated programs are existing technologies in the field of CT imaging. First turn on the key switch, start the equipment and the X-ray tube 3 control device, and turn on the main switch; then turn on the corresponding ray control program, and the system executes the automatic training machine; wait for the training machine to be completed, open the image acquisition program, the system rotation axis 5 and the amplification axis 6 Execute automatic zero return, and the flat panel detector 4 is automatical...

Embodiment 3

[0062] The micro-focus three-dimensional CT imaging detection device provided by the present invention is used to detect a defect-free polyethylene pipe welded joint. First, complete the equipment preparation and commissioning according to the technical scheme provided by the present invention, then place the polyethylene pipe joint on the detection platform according to the steps described in the scheme, adjust the tube voltage to 160KV, the tube current to 160μA, the minimum focus size to 179μm, and the magnification factor to 2.24 times, the pixel size of the flat panel detector is 400 μm, the image acquisition response time is adjusted to 500 ms, the image resolution is 1024×1024, the number of superimposed images is 3, and the number of skipped images is 1. The pipe joint rotates at a constant speed on the detection platform, and the rays penetrate the joint from different directions. The flat panel detector automatically receives the radiation signal and sends it to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com