Ultrasonic detection device and method for PA-TOFD combined polyethylene pipeline hot-melt butt joint

A PA-TOFD and hot-melt butt joint technology, which is applied in the direction of measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve sound wave attenuation, weaken sound beam diffusivity, receive Echo energy is weak and other problems, to achieve the effect of increasing energy, improving detection depth and imaging effect, and overcoming insufficient ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

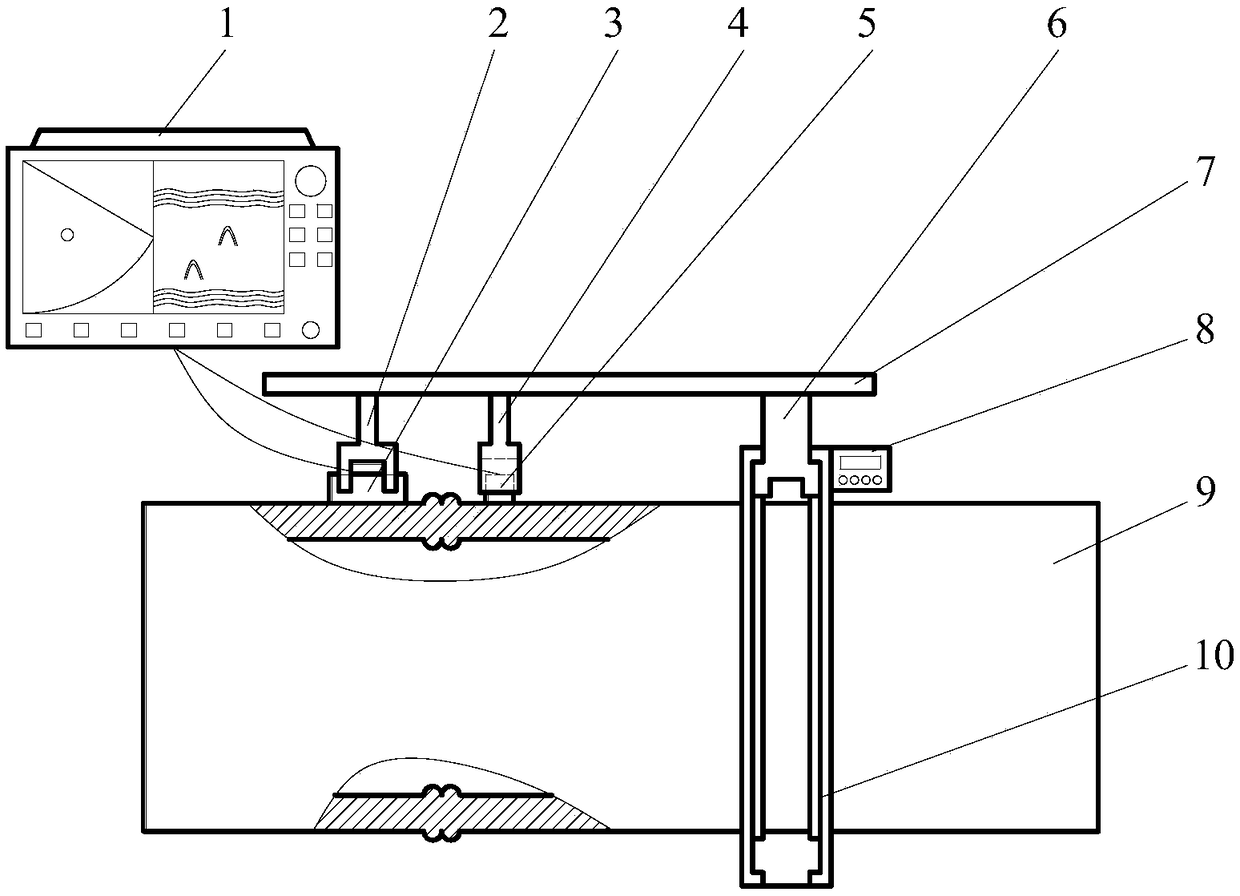

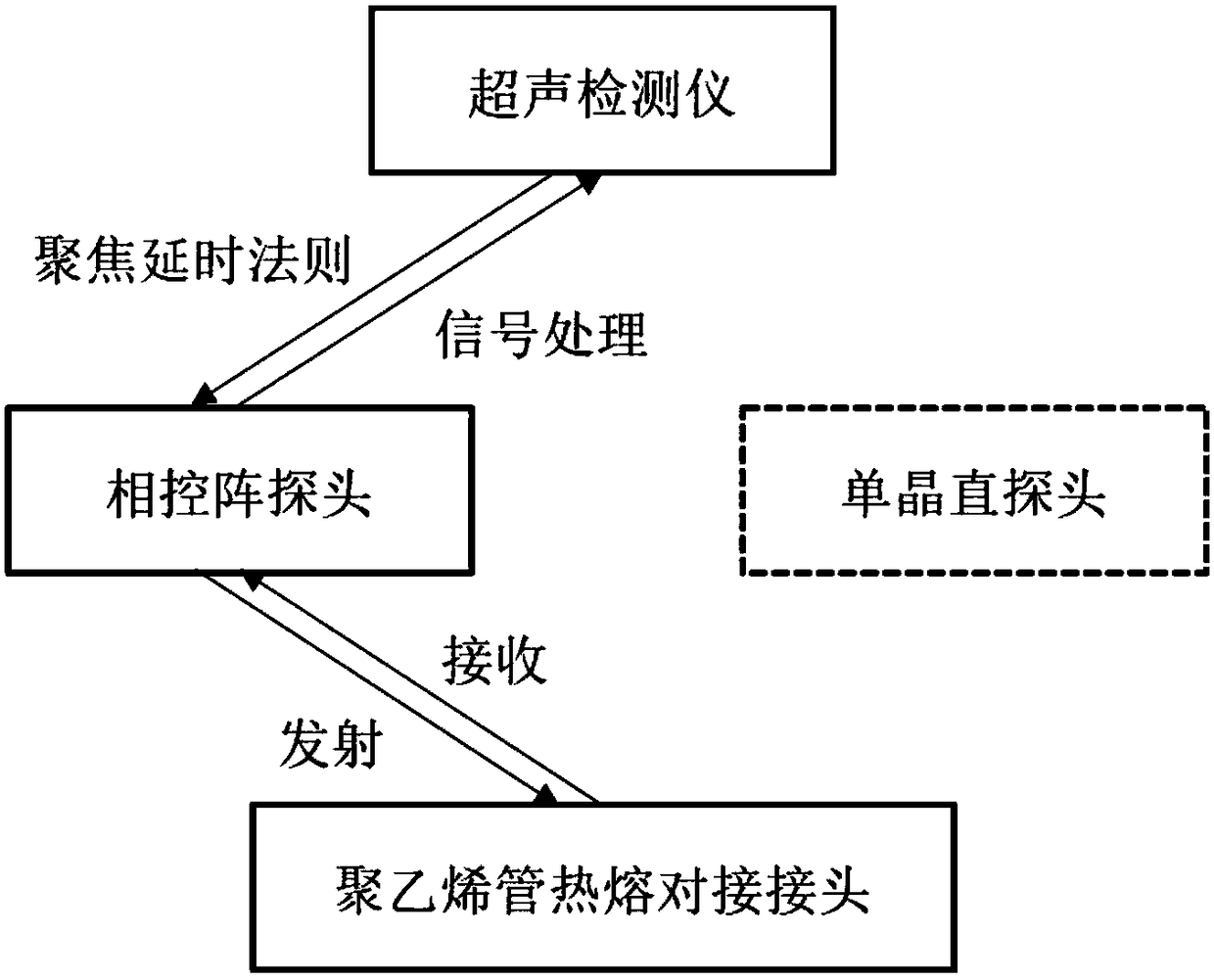

[0050] Embodiment 1: Implementation Example of Conventional Phased Array Scanning Mode

[0051] The phased array detection of the present invention adopts the S-scanning scheme, the phased array probe adopts the form of self-generating and self-receiving, and uses the effective sound path range to cover the detection area as much as possible. The calculation principle of the delay rule of the sound beam focusing is as follows: Figure 7 shown. The waveform adopts longitudinal wave, and the focus depth r and scanning range are determined according to the relative position of the defect and the probe. According to the above detection parameters, the delay time τ of each array element can be calculated by formula 1 i .

[0052]

[0053] In the formula, c is the propagation speed of ultrasonic longitudinal wave in polyethylene; l i is the distance from the i-th array element to the set focal point; τ 0 is the time constant, the purpose is to avoid τ i Negative latency occu...

Embodiment 2

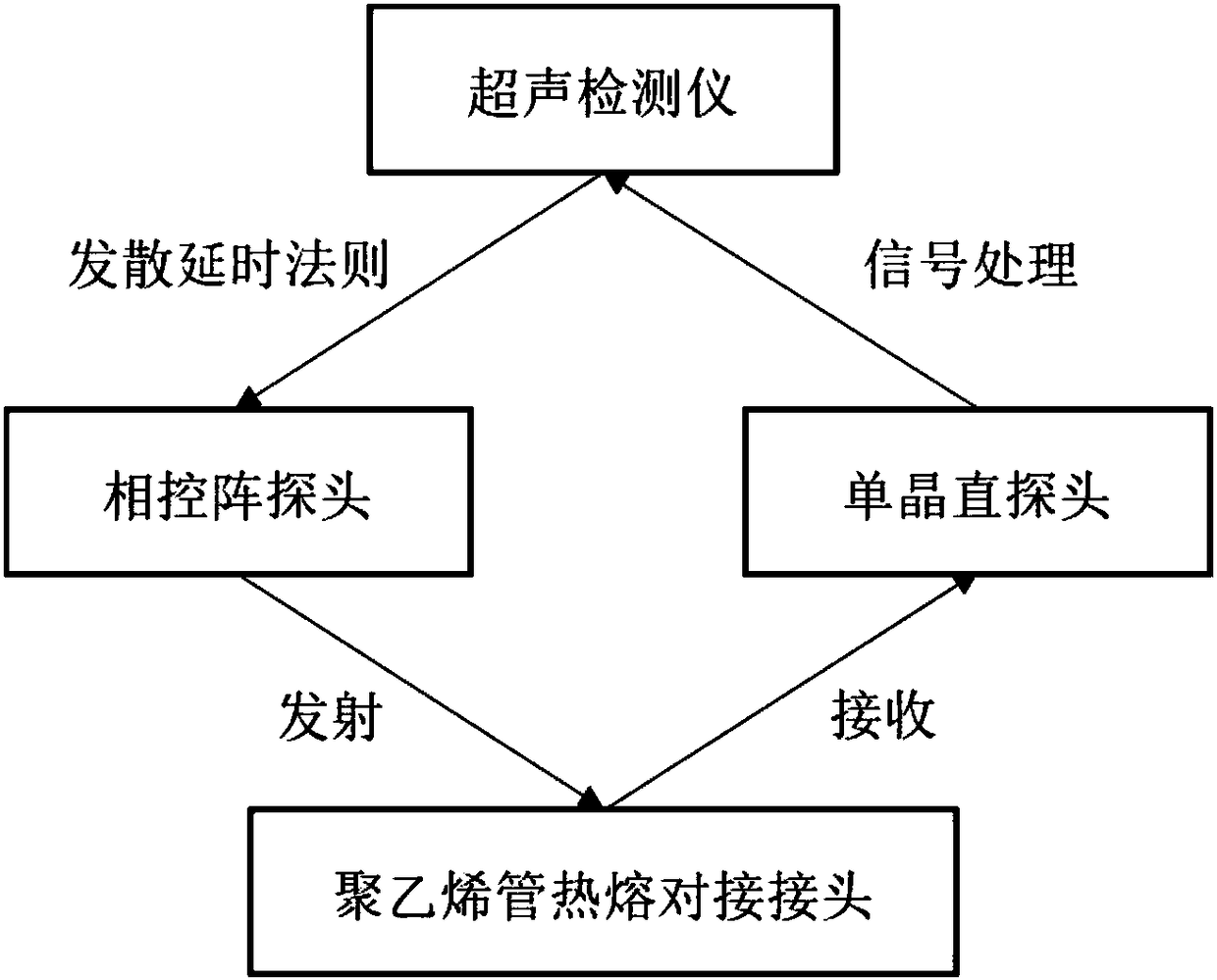

[0057] Embodiment 2: Example of detection method combining phased array and TOFD

[0058] When the present invention detects TOFD, a phased array probe is used as the sound wave emission probe. In order to make the sound wave emitted by the phased array probe have good diffusivity, the excitation of the phased array probe adopts the time delay rule that makes the sound wave diverge, and the sound beam The calculation principle of the divergent delay law is as follows: Figure 8 shown. In the actual TOFD detection, set the number n of array elements participating in the cylindrical wave emission and the curvature radius R of the cylindrical wave. According to the above detection parameters, the delay time τ of each array element can be calculated by formula 2 i .

[0059]

[0060] In the formula, d is the array element spacing of the probe; τ 0 is the time constant, the purpose is to avoid τ i Negative latency occurs.

[0061] Also take the above-mentioned probe as an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com