Automatic food material loading device

An automatic feeding and equipment technology, applied in the direction of conveyor objects, transportation and packaging, storage devices, etc., can solve the problems of unfavorable physical and mental health of workers, great influence on feeding accuracy, and low degree of automation, so as to improve feeding High efficiency, high accuracy, and reduced work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] At present, most of the feeding operations of food materials are manually operated, with a low degree of automation; the working environment is high temperature and high humidity all the year round, which has a negative impact on the personal health of the operators and is not conducive to the long-term work of the operators; at the same time, when feeding When there are many types of ingredients, the accuracy and efficiency of feeding are greatly affected by the ability and attention of the operator.

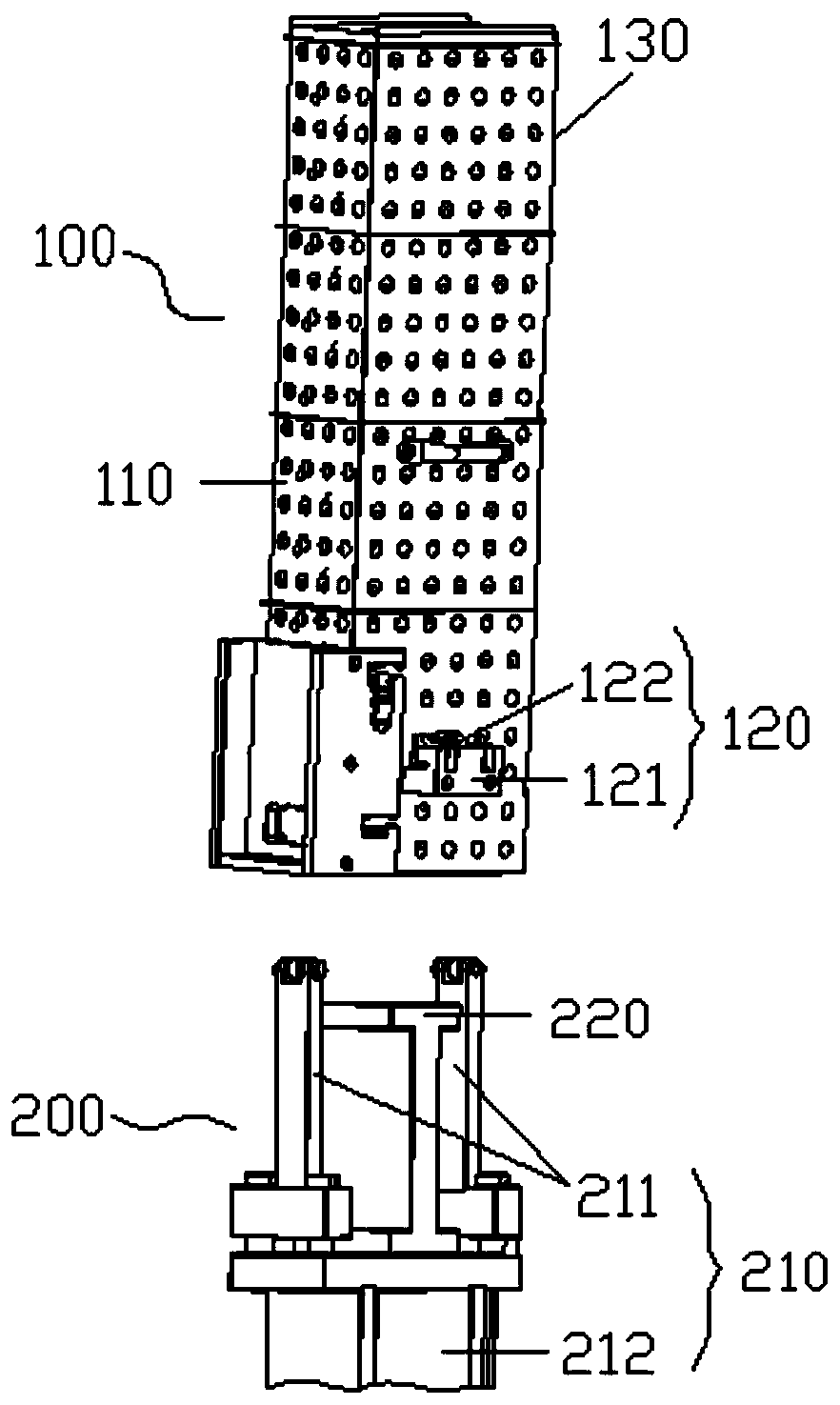

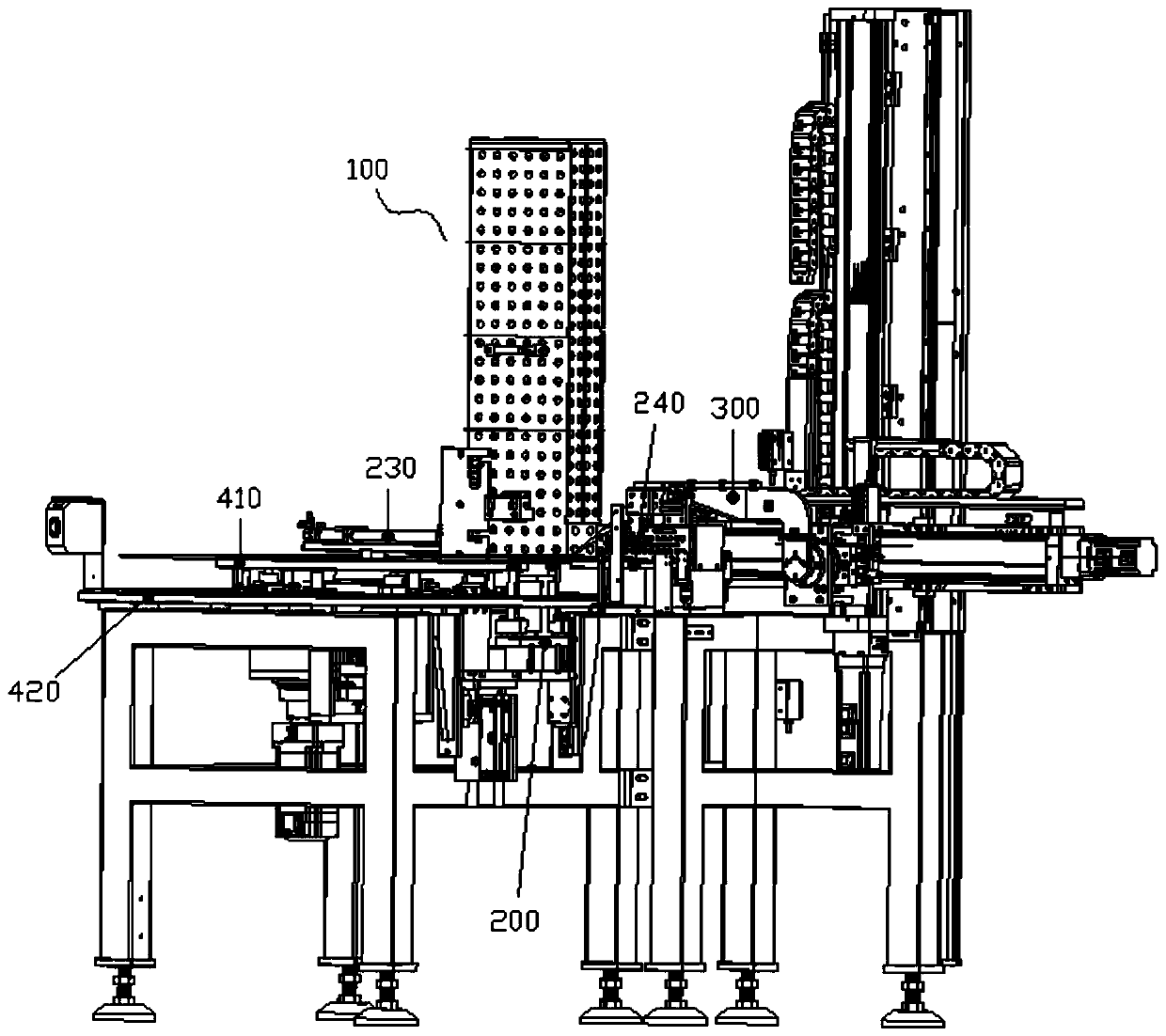

[0028] See Figure 1-3 , in order to solve the above technical problems, this embodiment proposes an automatic feeding equipment for food materials, which can realize automatic feeding of food materials. The food automatic feeding equipment includes a storage mechanism 100 , an unlocking mechanism 200 and a retrieving mechanism 300 .

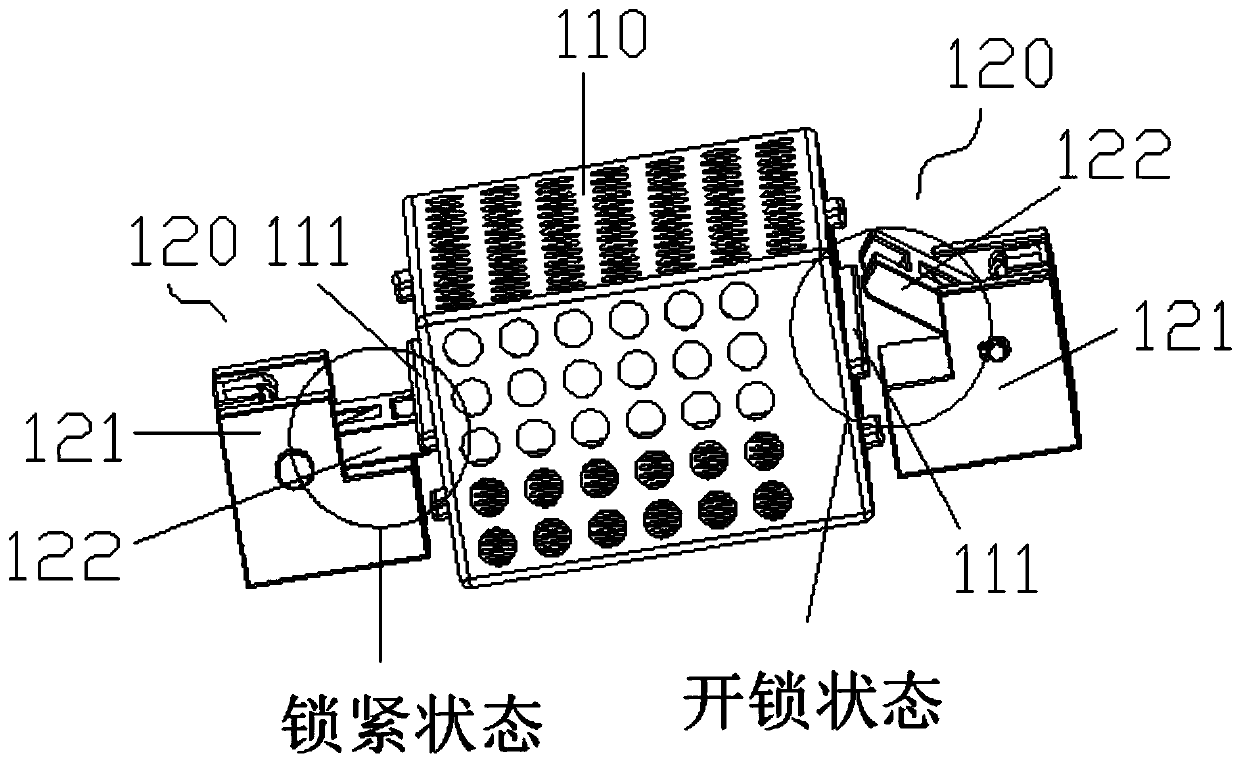

[0029] Among them, see figure 1 , the material storage mechanism 100 includes material frames 110 that are stacked and used to hold foo...

Embodiment 2

[0040] See Figure 1-3 , this embodiment proposes an automatic feeding device for food materials, which can realize automatic feeding of food materials. The food automatic feeding equipment includes a storage mechanism 100 , an unlocking mechanism 200 and a retrieving mechanism 300 .

[0041] Among them, see figure 1, the material storage mechanism 100 includes material frames 110 that are stacked and used to hold food materials, and a locking structure 120 that locks the lowermost material frame 110 in the air. The material frame 110 moves along its stacking direction under the action of gravity. The unlocking mechanism 200 includes an unlocking structure 210 for unlocking the locking mechanism, and a receiving platform 220 for accepting the unlocked material frame 110 . The material taking mechanism 300 is used to move the material frame 110 on the material receiving platform 220 to the next process equipment.

[0042] In order to realize continuous automatic feeding of ...

Embodiment 3

[0052] See Figure 1-3 , this embodiment provides an automatic feeding device for food materials, which also includes a storage mechanism 100 , an unlocking mechanism 200 and a retrieving mechanism 300 .

[0053] Among them, see figure 1 , the material storage mechanism 100 includes material frames 110 that are stacked and used to hold food materials, and a locking structure 120 that locks the lowermost material frame 110 in the air. The material frame 110 moves along its stacking direction under the action of gravity. The unlocking mechanism 200 includes an unlocking structure 210 for unlocking the locking mechanism, and a receiving platform 220 for accepting the unlocked material frame 110 . The material taking mechanism 300 is used to move the material frame 110 on the material receiving platform 220 to the next process equipment.

[0054] See Figure 5 , Different from the above-mentioned embodiments, the material retrieving mechanism 300 provided in this embodiment in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com