Patents

Literature

33results about How to "Same conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

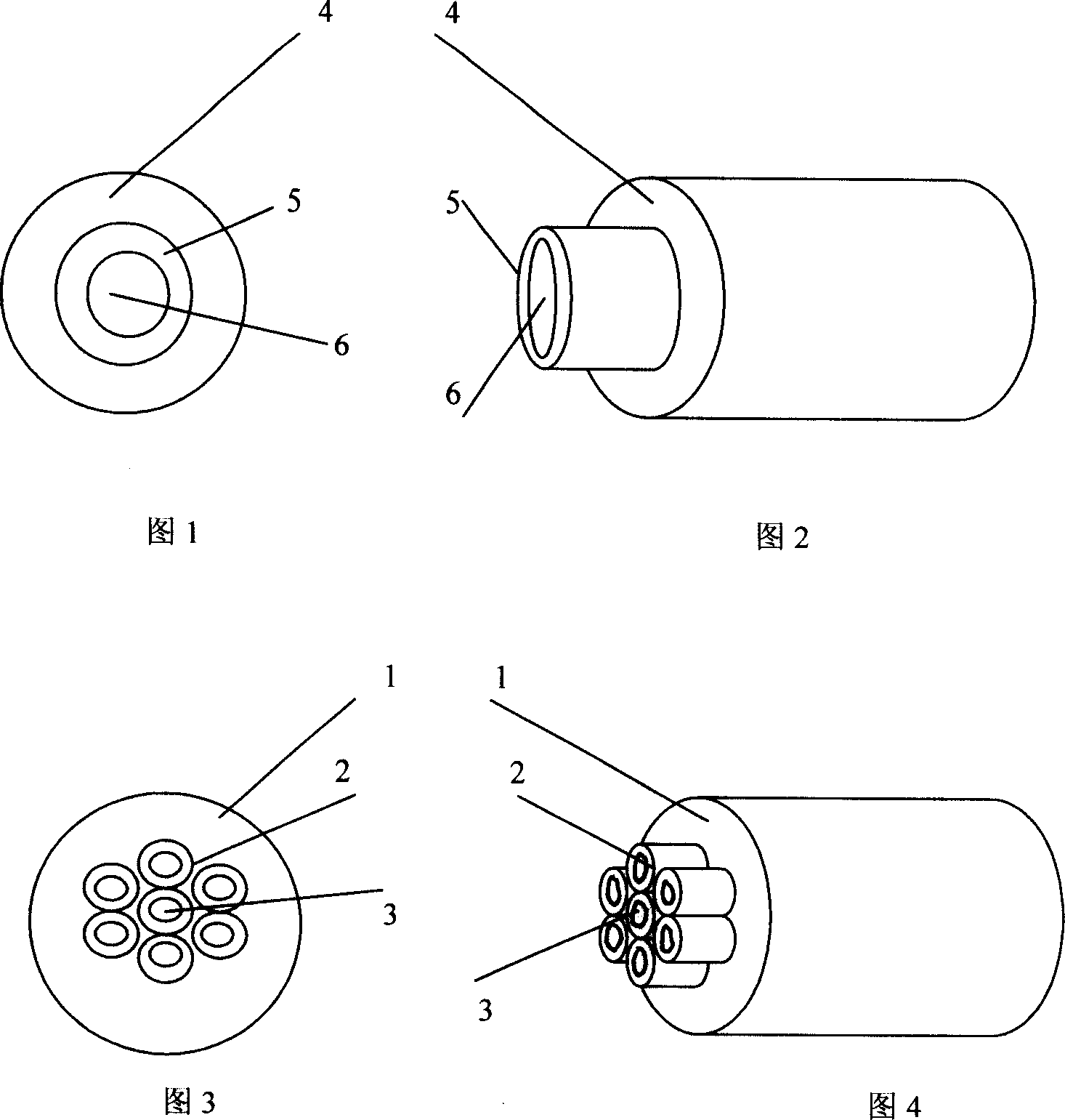

Aluminum core cable and line covered by copper

InactiveCN101086906AGood electrical conductivityHigh strengthRubber insulatorsPlastic/resin/waxes insulatorsCross-linked polyethyleneCopper-clad aluminium wire

The invention uses copper-clad aluminium conductor as conductive wire core whose inner core is aluminium wire and outer is cylinder copper roofing, the conductive wire also can be at least two conductive wire cores of copper-clad aluminium conductor which are parallel or winding with each other, the outer of conductive wire core is covered with insulated layer of PVC or polyethylene or cross-link polyethylene or rubber. The insulated material such as PVC, polyethylene, cross-link polyethylene or rubber is covered around the conductive wire core to produce copper-clad aluminium wire cable. The copper-clad aluminium wire cable possesses the same conductivity as copper core cable with the same specification, weight is light, easy to process, usage is convenient, and copper can be saved for 80% or above, cost of product can be decreased effectively, defects that the surface of aluminium cable is easy to be oxidized, resistance is big, corrosion resistance and machine performance are poor can be avoided.

Owner:大连极速金属复合材料有限公司

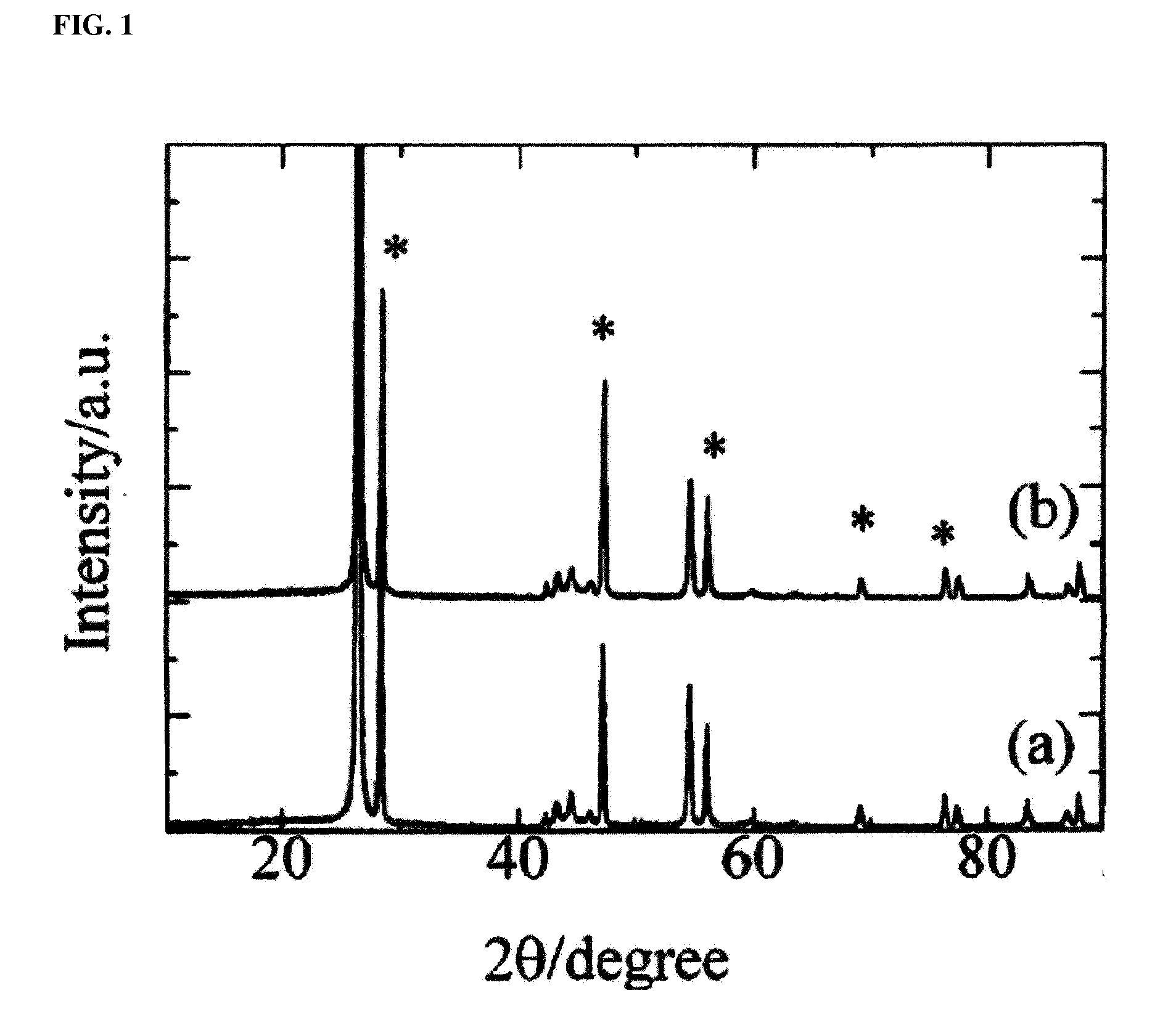

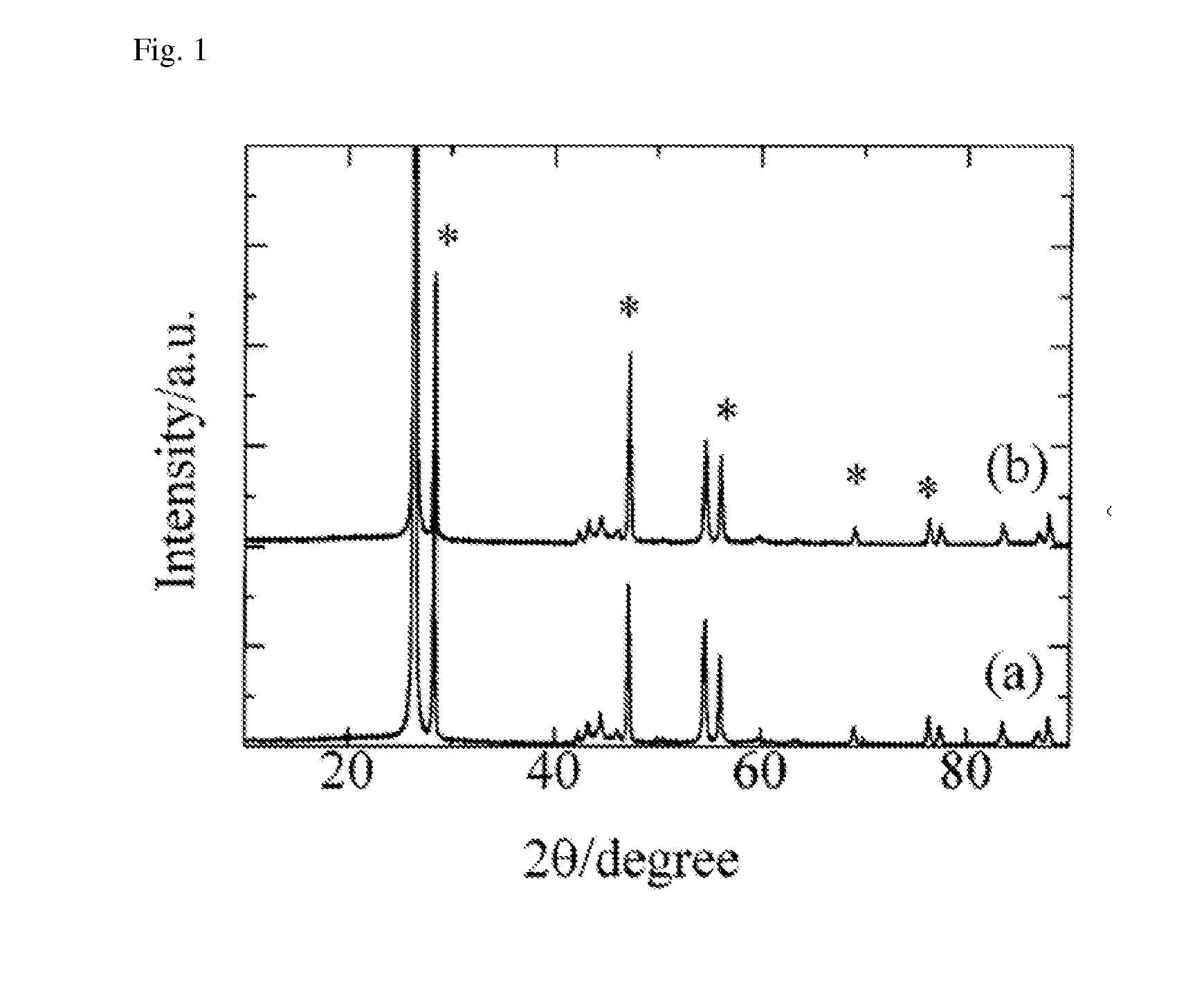

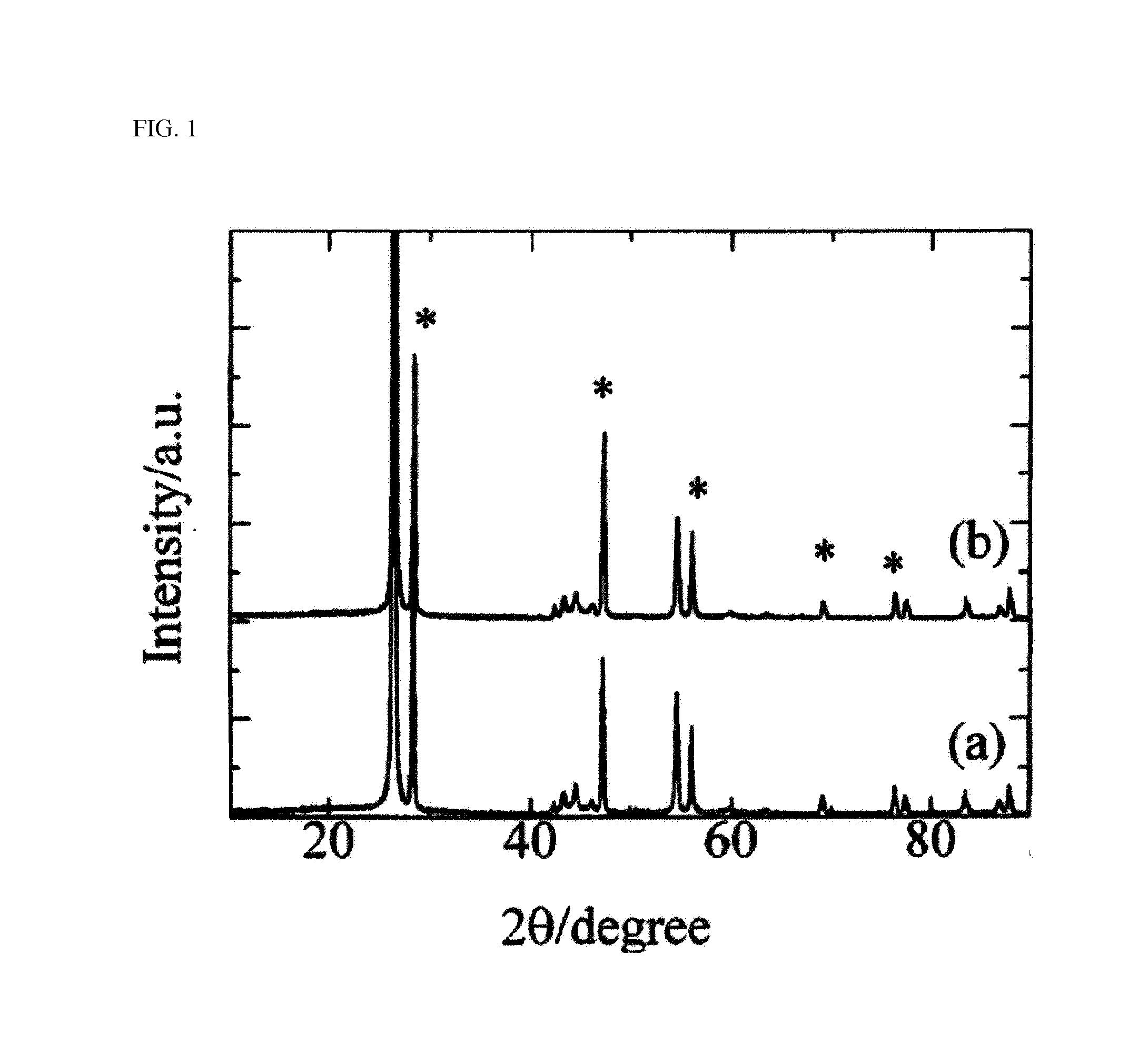

Lithium secondary battery of high energy density with improved energy property

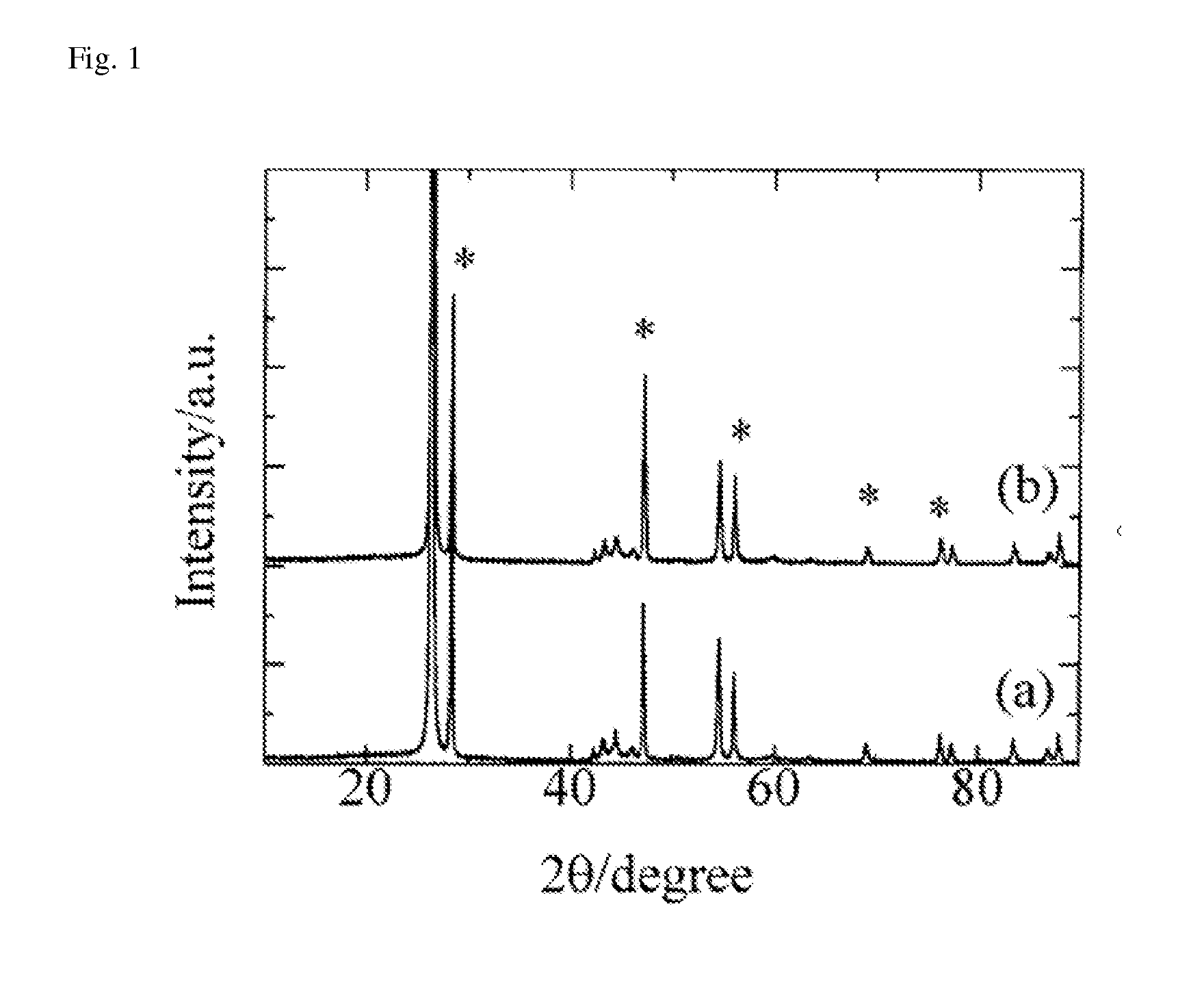

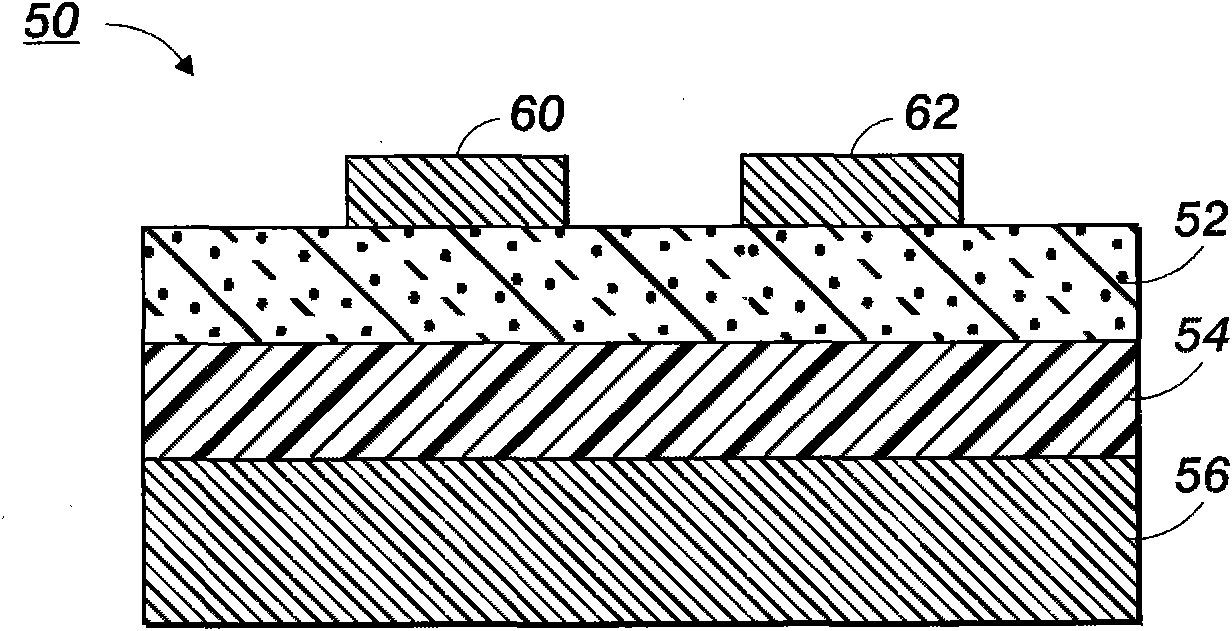

ActiveUS20140099551A1Increase energy densityImprove output characteristicsLi-accumulatorsNon-aqueous electrolyte accumulator electrodesLithiumHigh energy

Disclosed is a high energy density lithium secondary battery including: a cathode that includes, as cathode active materials, a first cathode active material represented by Formula 1 below and having a layered structure and a second cathode active material represented by Formula 2 below and having a spinel structure, wherein the amount of the first cathode active material is between 40 and 100 wt % based on the total weight of the cathode active materials; an anode including crystalline graphite and amorphous carbon as anode active materials, wherein the amount of the crystalline graphite is between 40 and 100 wt % based on the total weight of the anode active materials; and a separator.

Owner:LG ENERGY SOLUTION LTD

Lithium secondary battery of high power property with improved high power density

ActiveUS20140080000A1Improve output characteristicsSame conductivityFinal product manufactureNon-aqueous electrolyte accumulator electrodesLithiumGraphite

Disclosed is a high-output lithium secondary battery including: a cathode that includes, as cathode active materials, a first cathode active material represented by Formula 1 below and having a layered structure and a second cathode active material represented by Formula 2 below and having a spinel structure, wherein the amount of the second cathode active material is between 40 and 100 wt % based on the total weight of the cathode active materials; an anode including crystalline graphite and amorphous carbon as anode active materials, wherein the amount of the amorphous carbon is between 40 and 100 wt % based on the total weight of the anode active materials; and a separator.

Owner:LG ENERGY SOLUTION LTD

Lithium secondary battery of high energy density with improved energy property

ActiveUS20140080001A1Improve adhesionIncrease energy densityFinal product manufactureLi-accumulatorsHigh energyGraphite

Disclosed is a high energy density lithium secondary battery including: a cathode including, as cathode active materials, a first cathode active material represented by Formula 1 below and having a layered structure and a second cathode active material represented by Formula 2 below and having a spinel structure, wherein the amount of the first cathode active material is between 40 and 100 wt % based on the total weight of the cathode active materials; an anode including crystalline graphite having a specific surface area (with respect to capacity) of 0.005 to 0.013 m2 / mAh as an anode active material; and a separator.

Owner:LG ENERGY SOLUTION LTD

Lithium secondary battery of high power property with improved high power density

ActiveUS20140080002A1Improve output characteristicsSame conductivityCharging stationsNon-aqueous electrolyte accumulator electrodesLithiumGraphite

Disclosed is a high-output lithium secondary battery including: a cathode including a cathode active material having an average particle diameter (with respect to capacity) of 0.03 to 0.1 μm / mAh and a layered structure; an anode including crystalline graphite and amorphous carbon as anode active materials, wherein the amount of the amorphous carbon is between 40 and 100 wt % based on the total weight of the anode active materials; and a separator.

Owner:LG ENERGY SOLUTION LTD

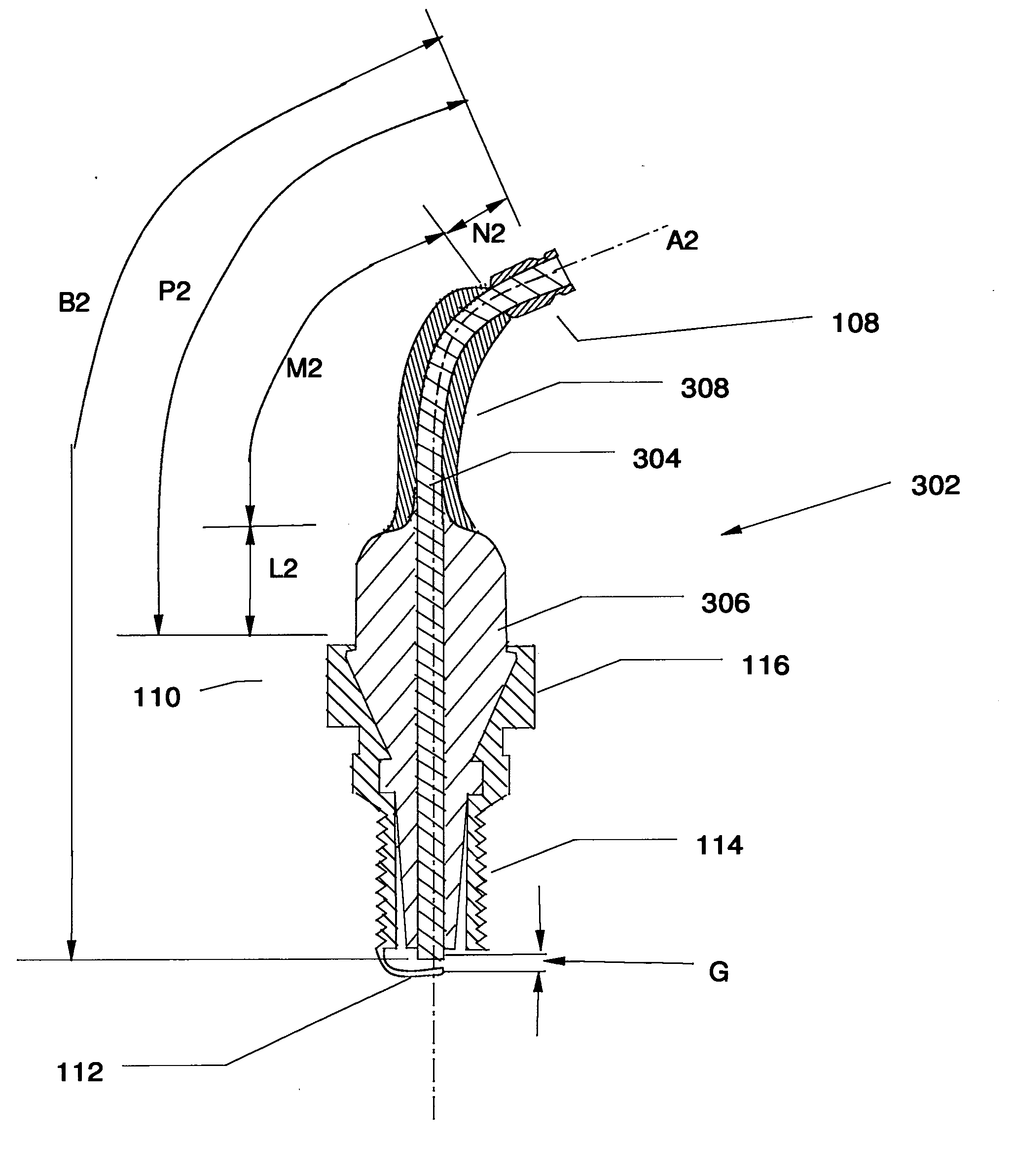

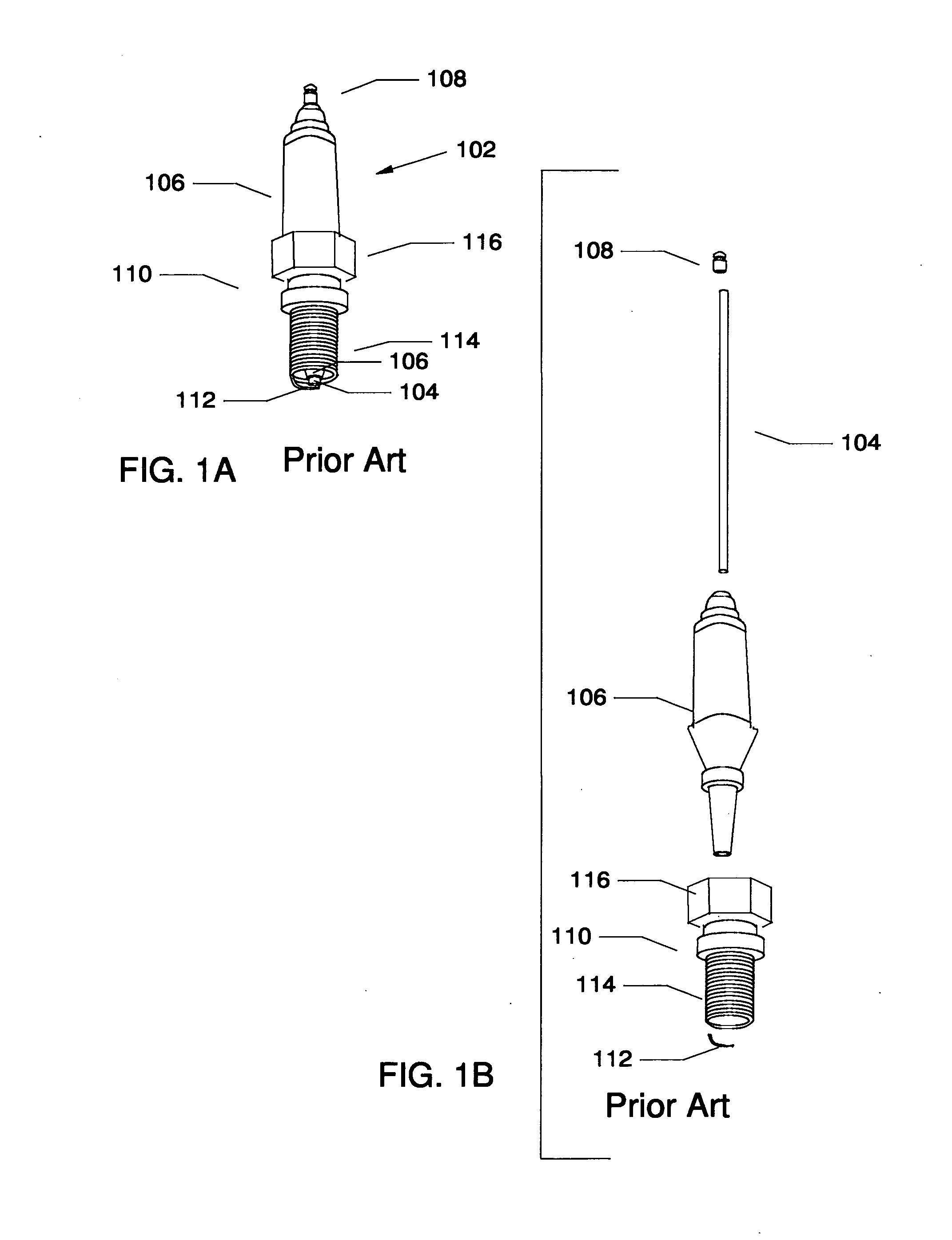

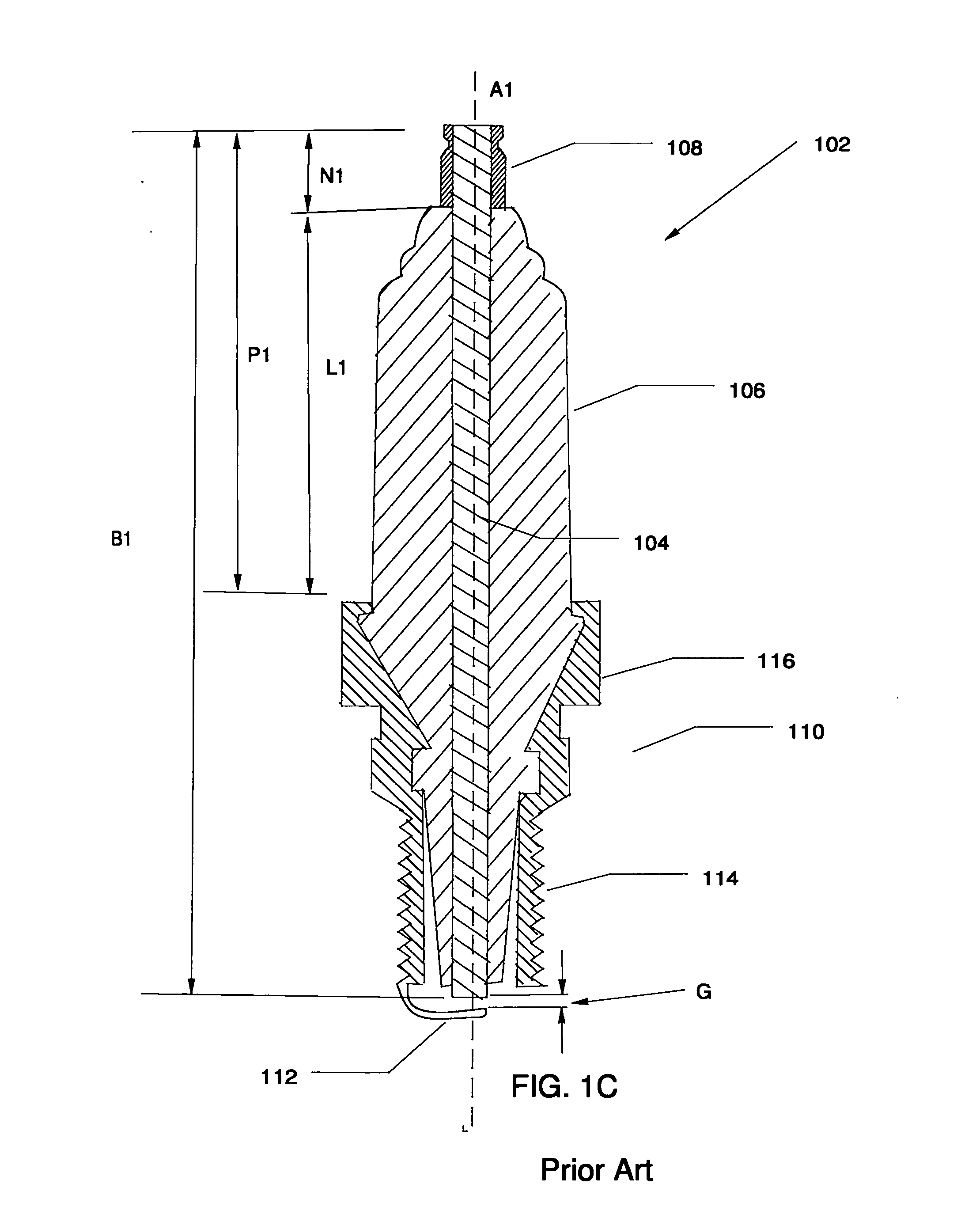

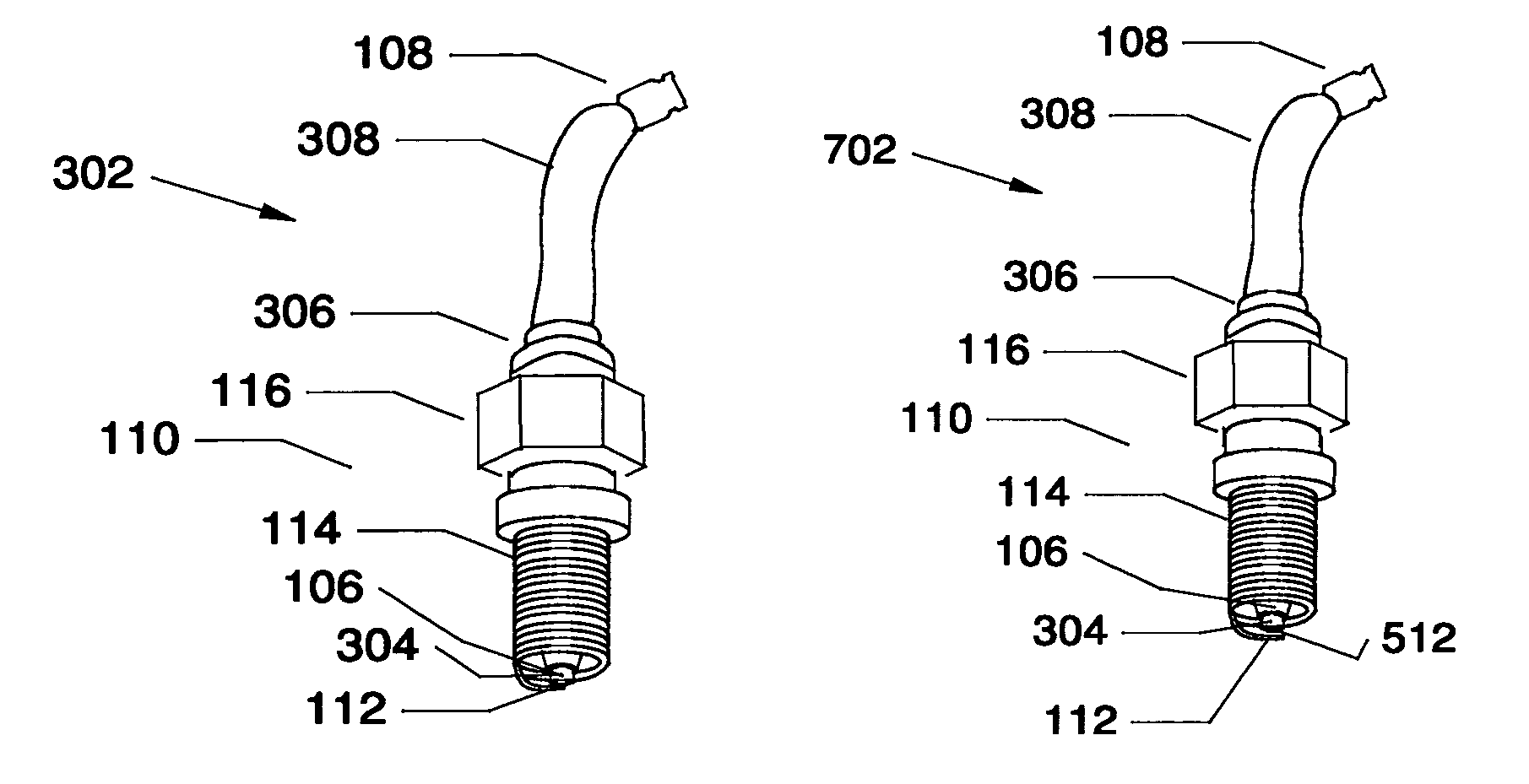

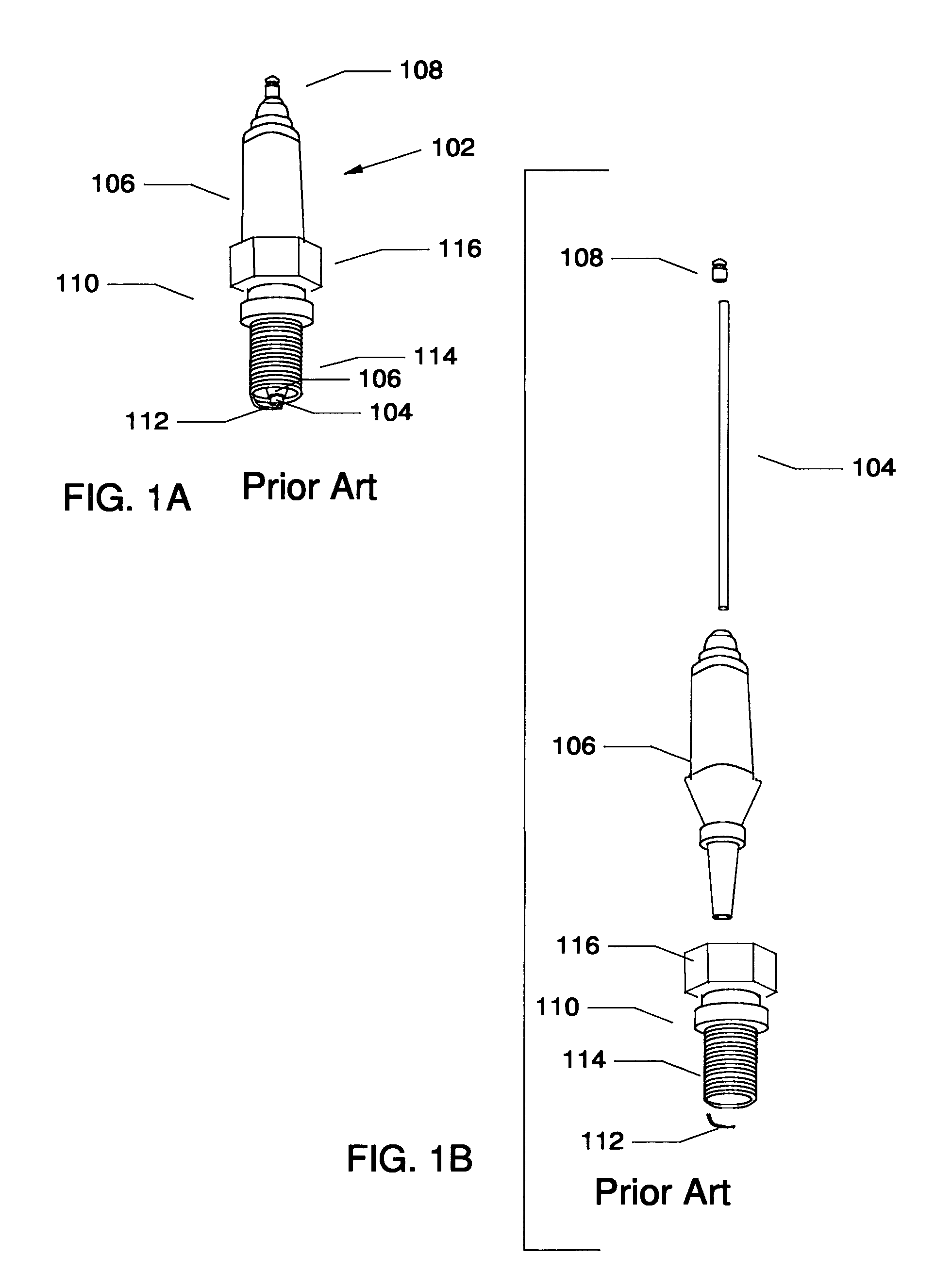

Flexible spark plug

A spark plug designed for fitting in tight spaces of an engine compartment is disclosed. The spark plug has a conductive terminal attached to one end of a flexible central electrode and has a ceramic insulator partially encasing the flexible central electrode. The part of the flexible central electrode between the ceramic insulator and the conductive terminal is encased in a flexible insulator. The flexible part of the central electrode may be bent away from the axis of the ceramic insulator accommodating both installation and servicing of the spark plug in tight spaces.

Owner:BISHOP BOBBY GLEN

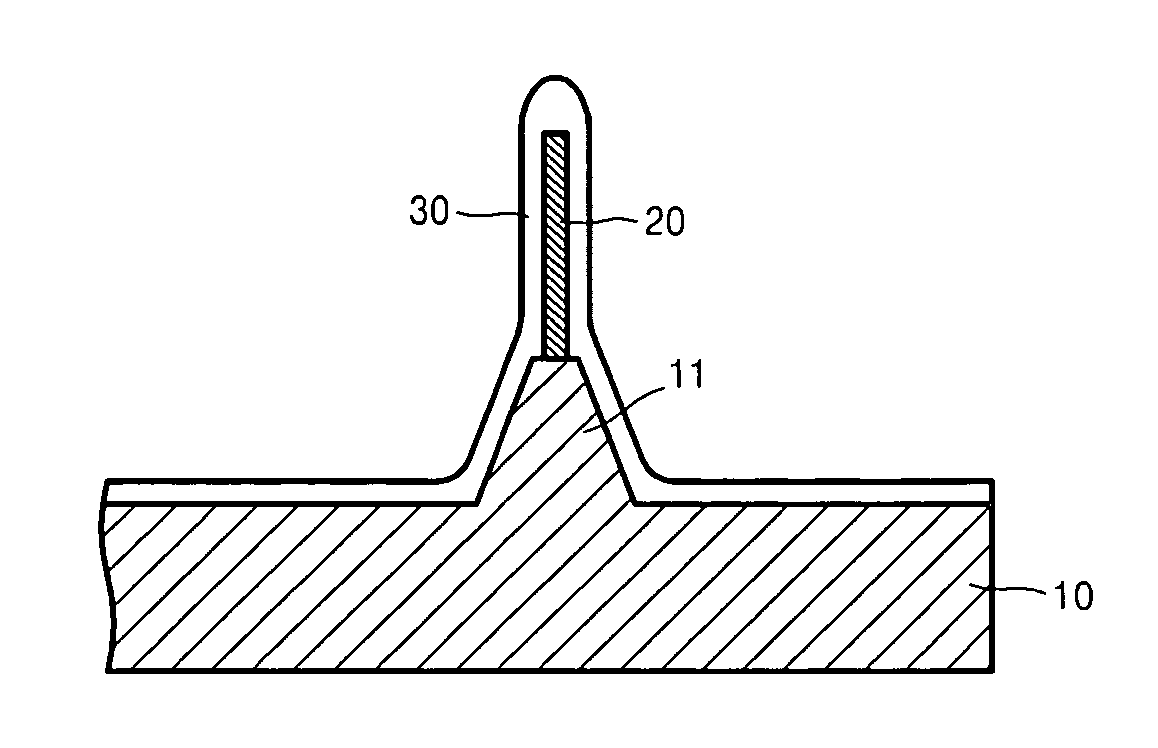

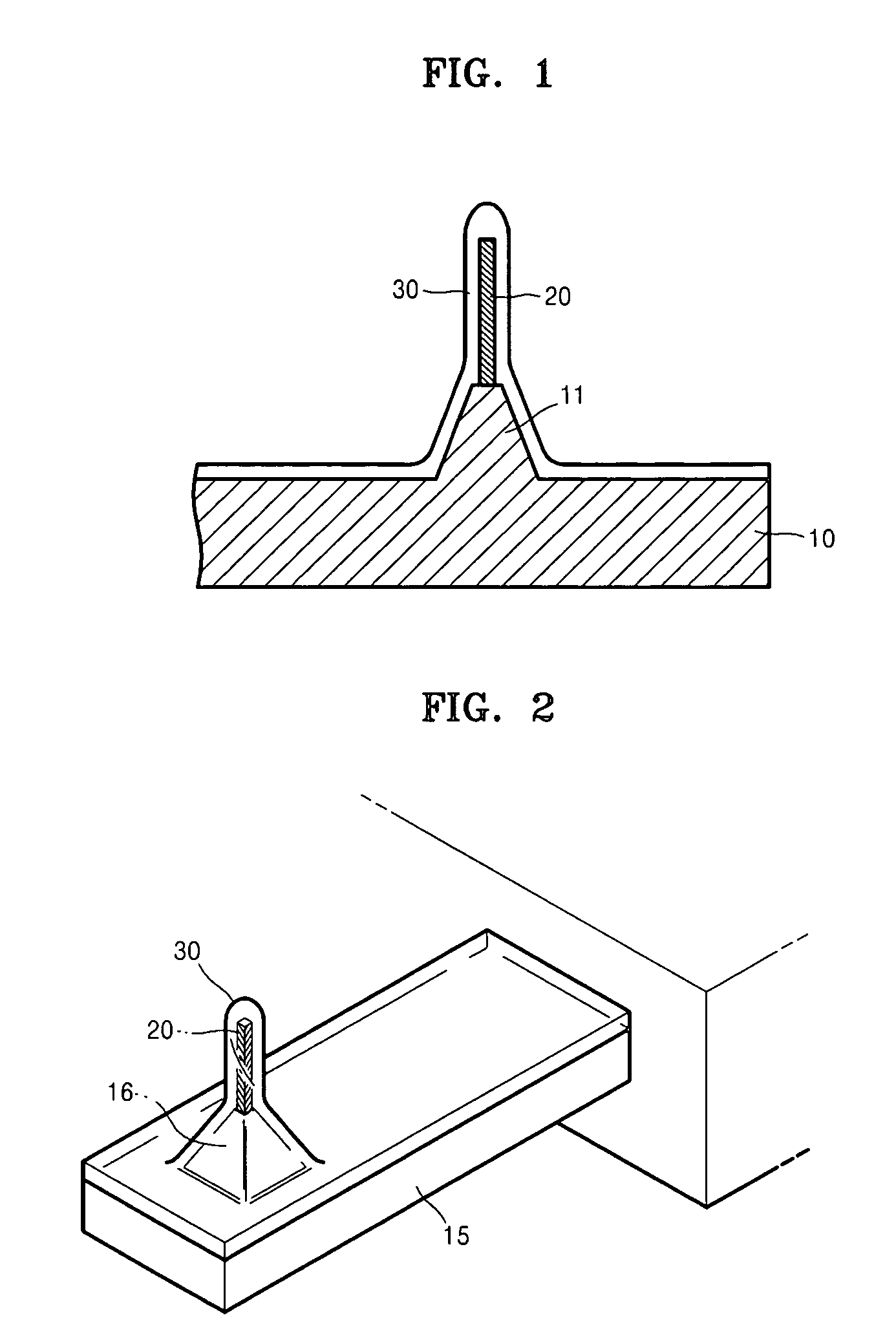

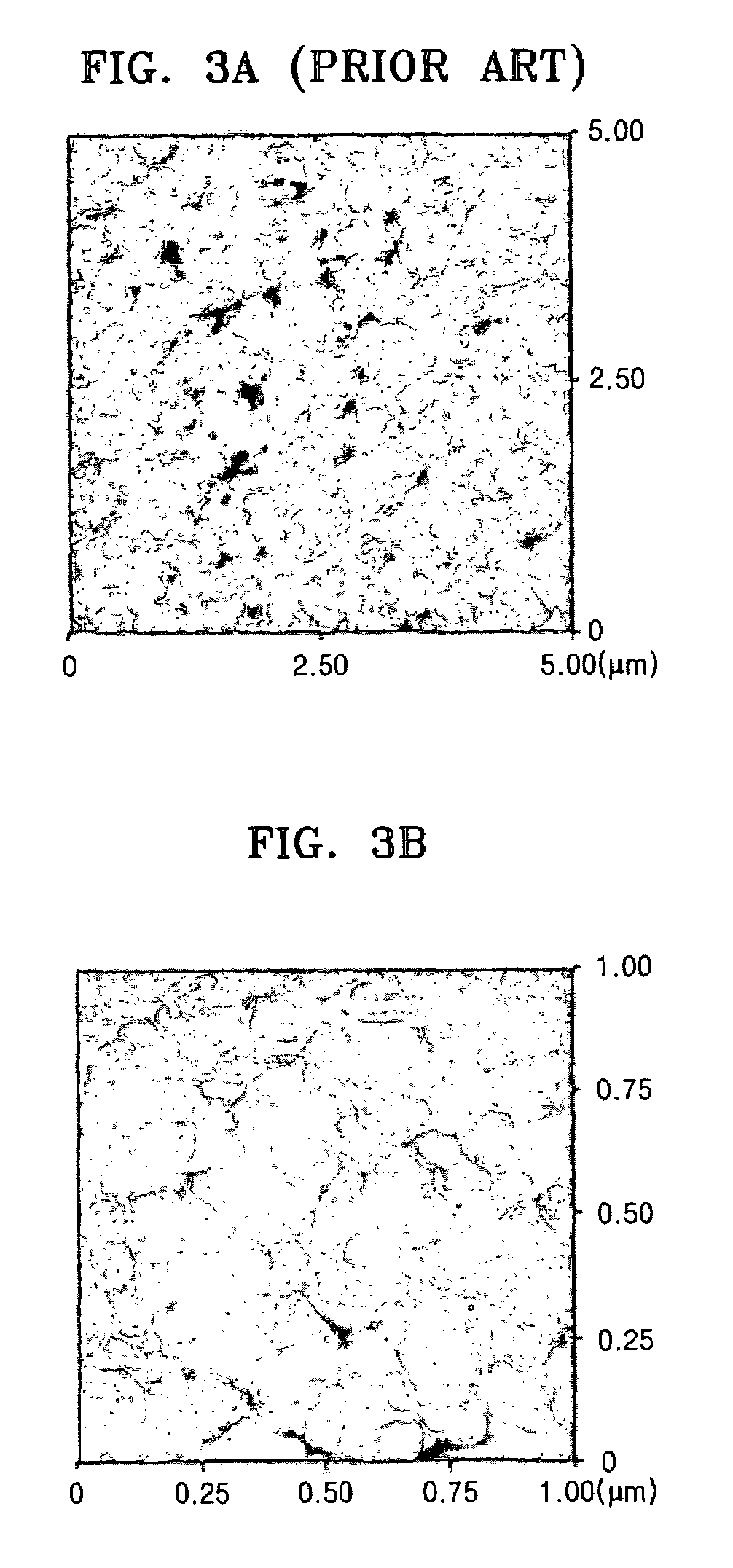

Conductive carbon nanotube tip, probe having the conductive carbon nanotube tip, and method of manufacturing the conductive carbon nanotube tip

ActiveUS7507958B2High resolutionSame conductivitySecateursMaterial analysis using wave/particle radiationRutheniumNanotube

A conductive carbon nanotube tip and a manufacturing method thereof are provided. The conductive carbon nanotube tip includes a carbon nanotube tip substantially vertically placed on a substrate, and a ruthenium coating layer covering a surface of the carbon nanotube tip and extending to at least a part of the substrate. The manufacturing method includes substantially vertically placing a carbon nanotube tip on a substrate, and forming a ruthenium coating layer on the carbon nanotube tip and at least a part of the substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

Lithium secondary battery of high power property with improved high energy density

ActiveUS20140120425A1Same capacityEnhanced high-output characteristic and long lifespan characteristicNon-aqueous electrolyte accumulator electrodesLi-accumulatorsLithiumHigh energy

Disclosed is a high-output lithium secondary battery including: a cathode that includes, as cathode active materials, a first cathode active material represented by Formula 1 below and having a layered structure and a second cathode active material represented by Formula 2 below and having a spinel structure, wherein the amount of the second cathode active material is between 40 and 100 wt % based on the total weight of the cathode active materials; an anode including crystalline graphite having a specific surface area (with respect to capacity) of 0.005 to 0.013 m2 / mAh as an anode active material; and a separator.

Owner:LG ENERGY SOLUTION LTD

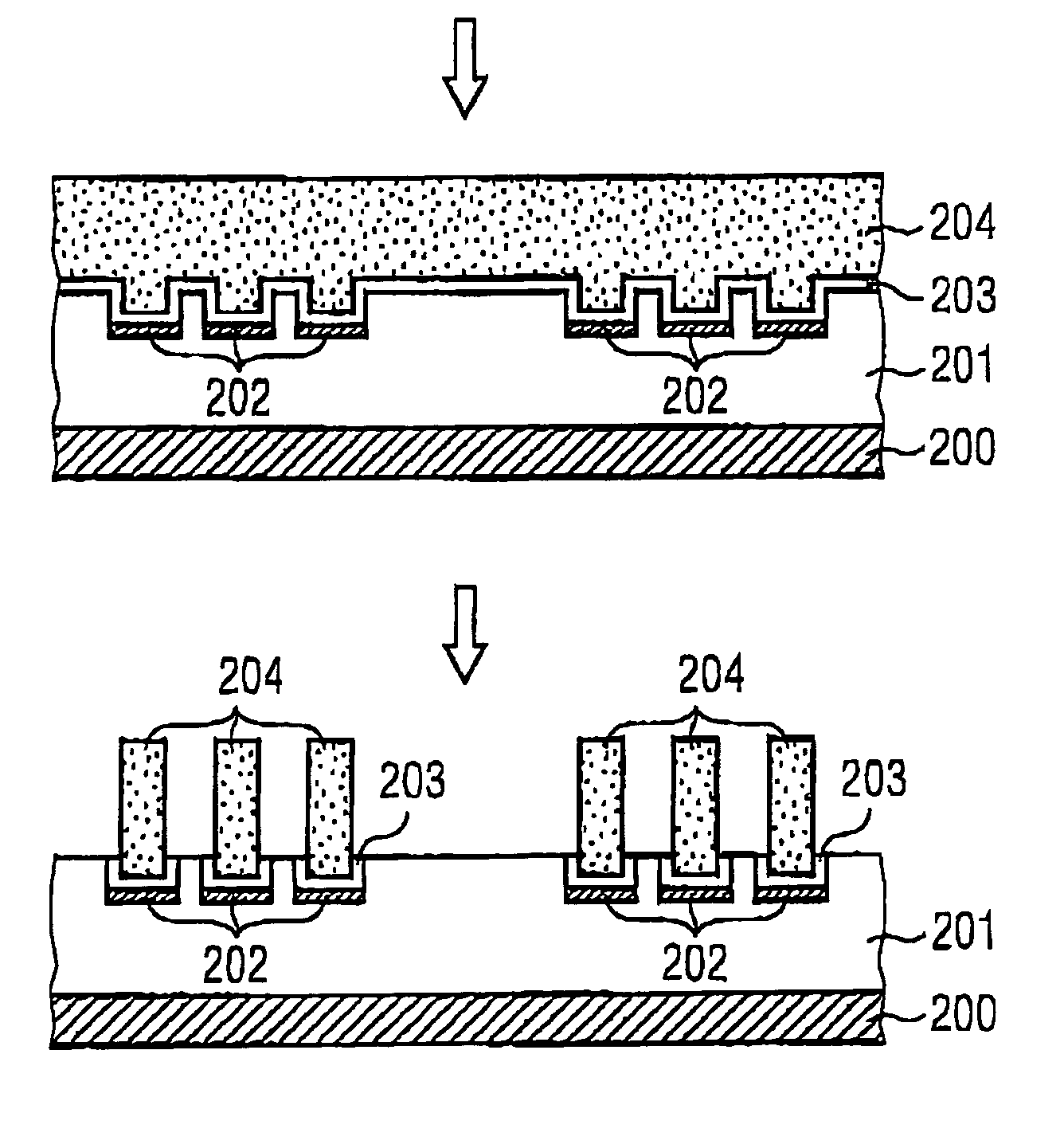

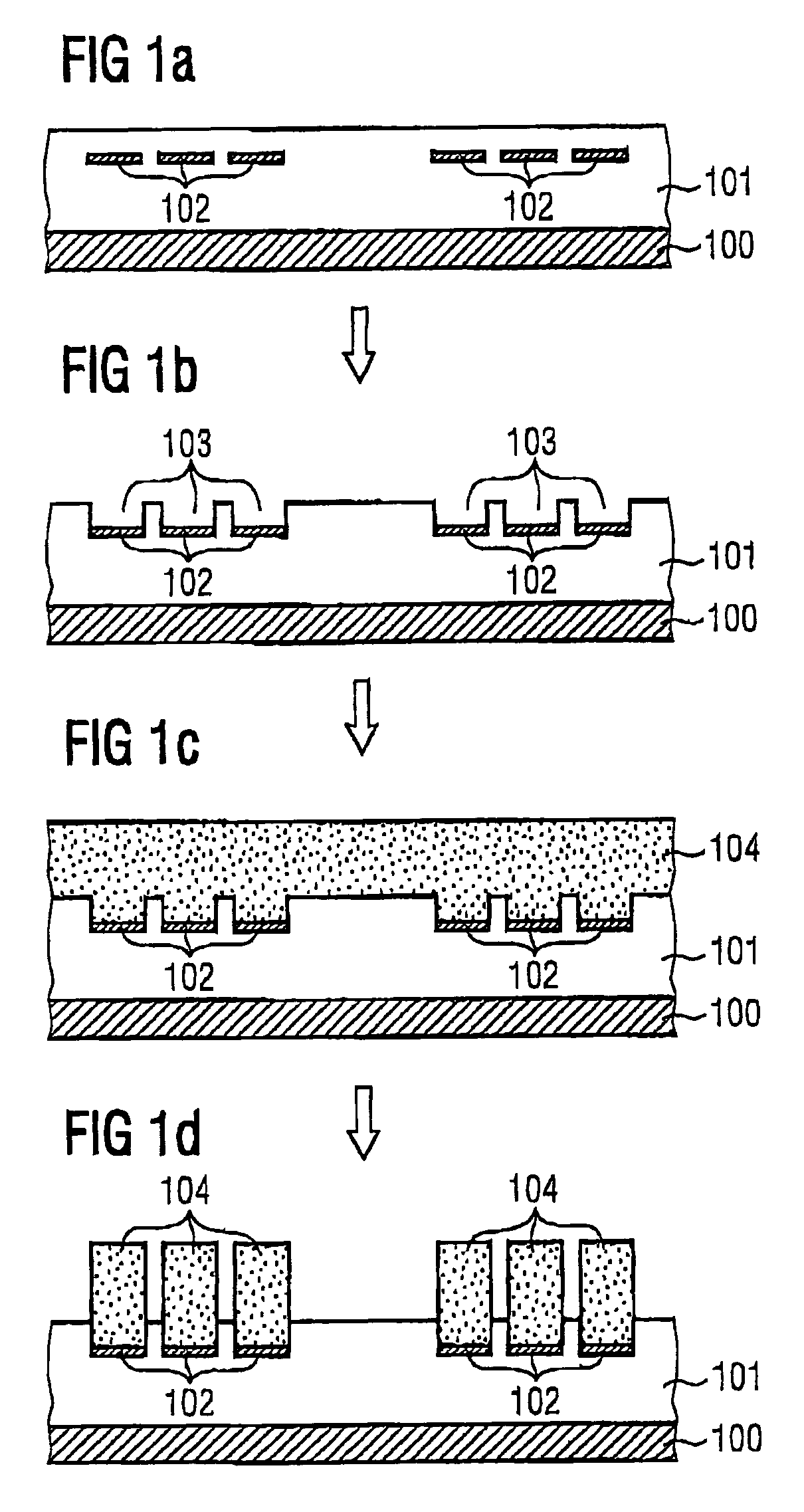

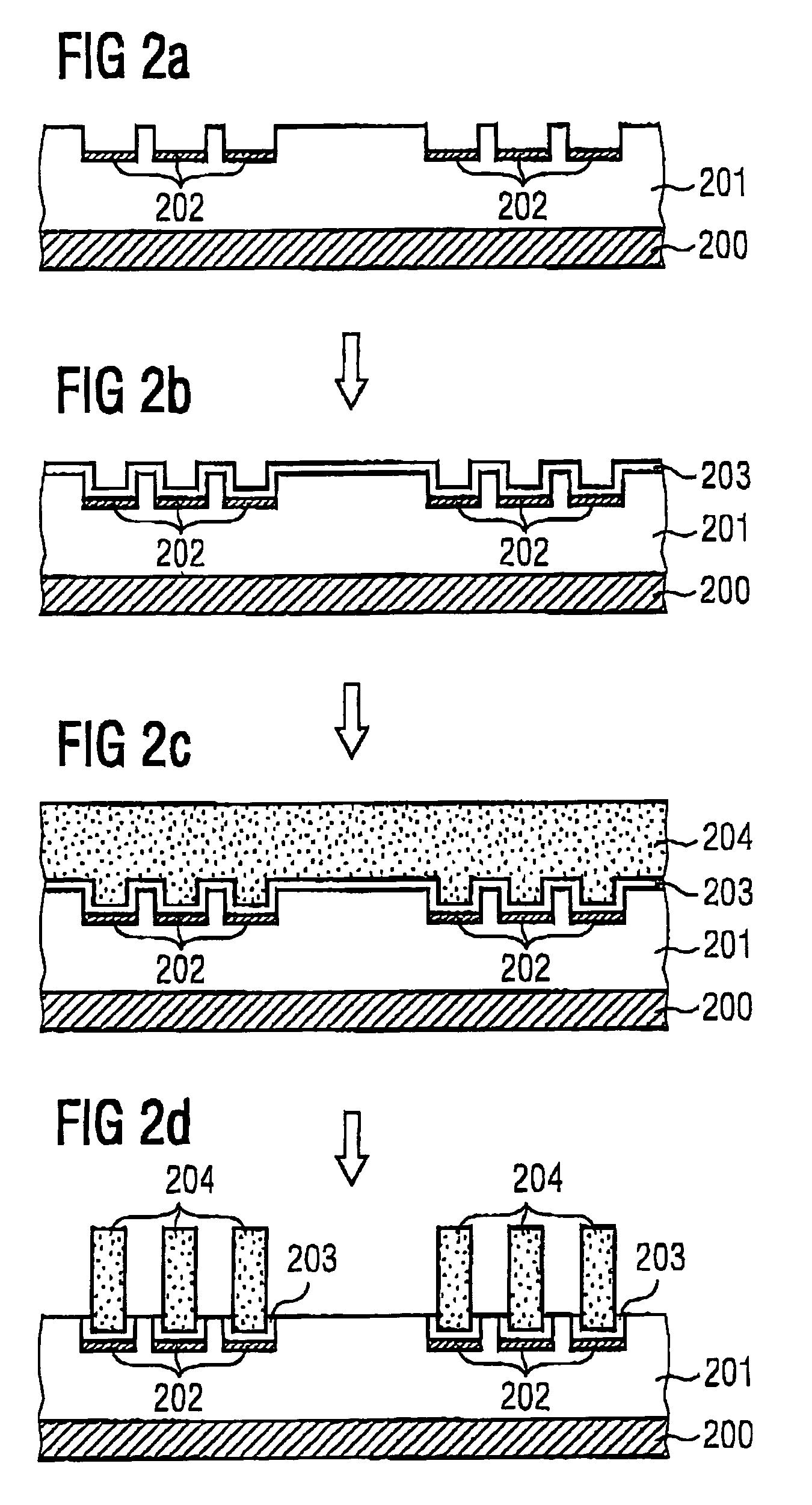

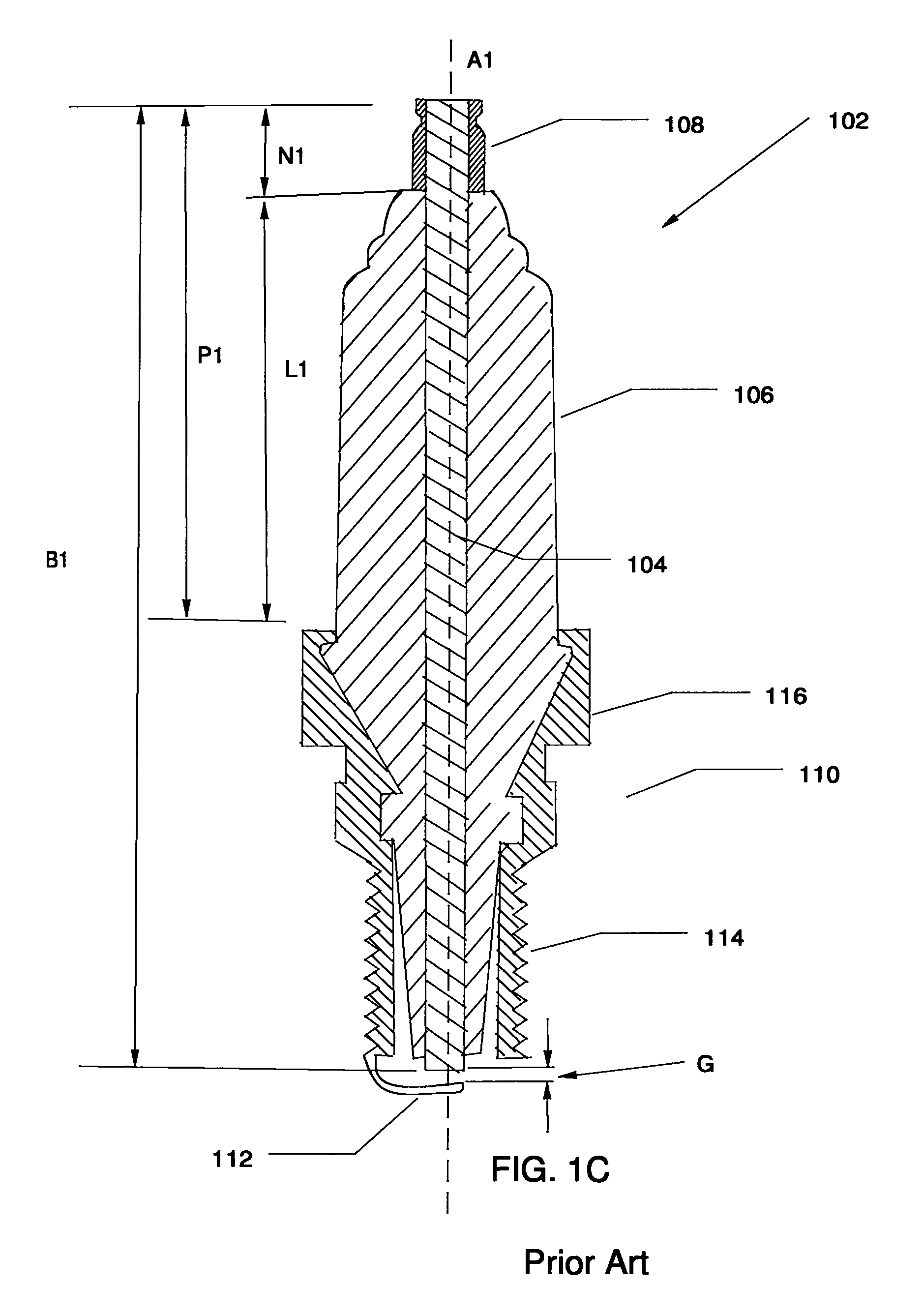

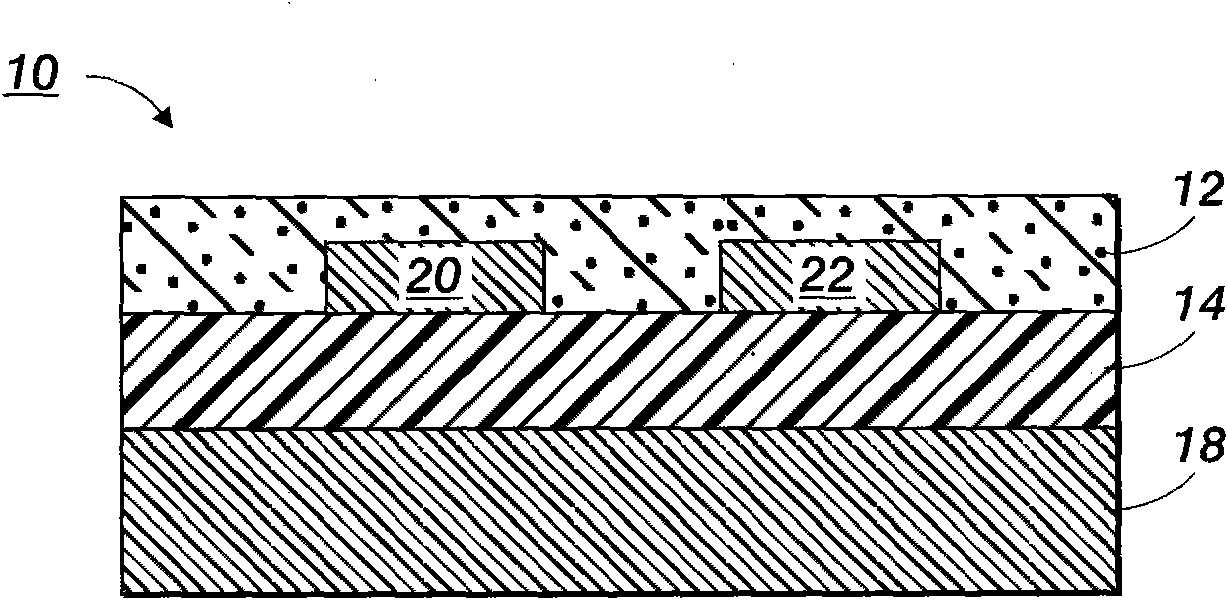

Method for fabricating a microelectronic circuit including applying metal over and thickening the integrated coil to increase conductivity

InactiveUS7005360B2Lower impedanceImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingMicroelectronic circuitsEngineering

A method for fabricating a microelectronic circuit having an improved electrically conductive element. The method includes providing a finished processed microelectronic circuit having a monolithically integrated coil and having a passivation layer situated above at least the monolithically integrated coil. The method further comprises removing at least part of the passivation layer above the monolithically integrated coil and applying a metal layer above the monolithically integrated coil so that the metal layer is electrically coupled to the monolithically integrated coil.

Owner:INFINEON TECH AG

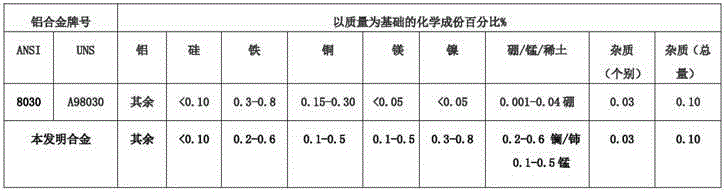

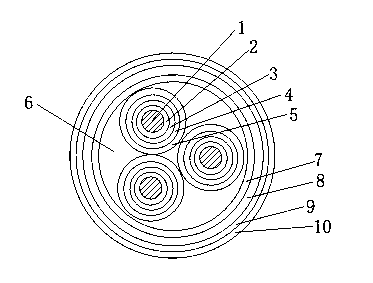

High-conductivity and high-heat conductivity aluminum-iron-nickel-rare earth alloy

InactiveCN104658630AImprove conductivityGood correlationMetal/alloy conductorsRare-earth elementImpurity

The invention relates to the technical field of aluminum alloys and specifically provides an ultrahigh-conductivity and high-heat conductivity aluminum alloy. The ultrahigh-conductivity and high-heat conductivity aluminum alloy is characterized by comprising 0.2-0.6% by mass of Fe, 0.3-0.8% by mass of Ni and 0.2-0.6% by mass of rare earth element Ce or La or mixture of Ce and La; meanwhile, one or two or three in an additive A is additionally added, the additive A is Mg, Cu, Mn or the mixture thereof, the mass content of each is 0.1-0.5%, and the content of the total additive is controlled within 0.9%; meanwhile, other impurities are controlled as follows: the individual content is less than 0.03% and the total content is less than 0.1%; the balance is Al and inevitable impurities. The aluminum alloy has high conductivity of above 61.8% IACS, excellent heat conductivity and a heat conduction coefficient of 225W / m.k or above, thereby being an excellent aluminum alloy cable material and high-performance heat conduction material.

Owner:朱岳群

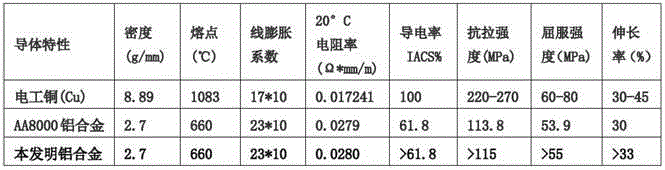

High-strength power cable

InactiveCN103106980AImprove conductivityImprove mechanical propertiesPower cables with screens/conductive layersMetal/alloy conductorsPower cableElectrical conductor

The invention discloses a high-strength power cable. The high-strength power cable comprises cable cores, and each cable core is formed by stranding of three insulated wire cores. Filler is arranged in gaps of the cable cores, a wrapping tape layer is wrapped outside the cable cores, an isolating layer and an armor layer are sequentially wrapped outside the wrapping tape layer in an extruded mode, and an outer protective jacket is wrapped on the outermost layer of the cable in an extruded mode. Each insulated wire core is composed of a conductor, an inner shielding layer, an insulating layer, an outer shielding layer and a metal shielding layer, wherein the inner shielding layer, the insulating layer, the outer shielding layer and the metal shielding layer are sequentially wrapped outside the conductor in an extruded mode. The high-strength power cable has the advantages of being good in conductivity, high in mechanical performance, creeping and aging resistant, high temperature resistant, good in corrosion resistant performance, long in service life, and the like, and is suitable for voltage classes of 0.6KV-35KV and dry or humid sites with temperature of 200 DEG C, 180 DEG C, 105 DEG C and 90 DEG C or below; and the high-strength power cable can be installed indoors or outdoors, also can be installed in a vertical mode or in a supported mode or in a laid mode along a wall, and even can be installed underground in a directly buried mode.

Owner:WUXI SHUGUANG CABLE

Corrosion-resistant grounding alloy and preparation method thereof

InactiveCN108559895AGrain refinementImprove negative chargeSolid state diffusion coatingRare-earth elementCorrosion resistant

The invention discloses a corrosion-resistant grounding alloy and a preparation method thereof and relates to the technical field of grounding metals. The corrosion-resistant grounding alloy disclosedby the invention comprises the following components: 94-96% of Al, 3-5% of Cu, 0.05-0.1% of RE and inevitable impurity elements. The preparation method comprises the following steps: 1, burdening according to requirements of various components of the grounding alloy; 2, smelting to obtain alloy melt; 3, pouring in a vacuum room; 4, performing homogenizing annealing on the casting; 5, performing shot blasting; 6, performing pre-oxidation treatment on the casting surface. By adding trace rare earth elements into the alloy, aims of refining grains, improving electronegativity in each region on the material surface, stabilizing a protective film layer and increasing corrosion resistance are achieved. Pure copper is replaced with an aluminum alloy, the cost is reduced, the same conductivity isachieved, and the problem that heavy metal pollution to the environment is caused by the conventional copper and zinc is solved.

Owner:安徽兴广泰新能源技术有限公司

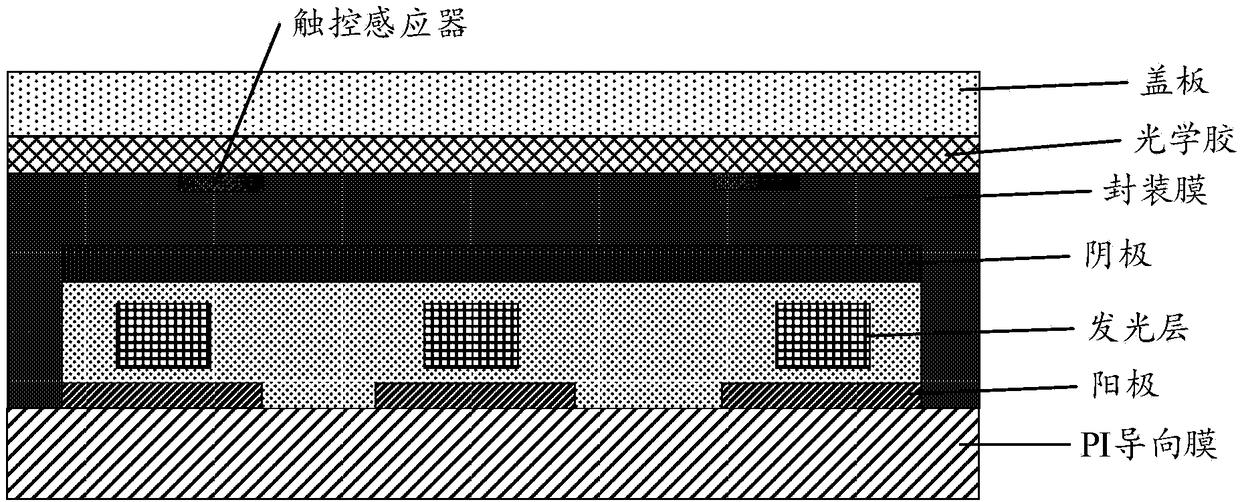

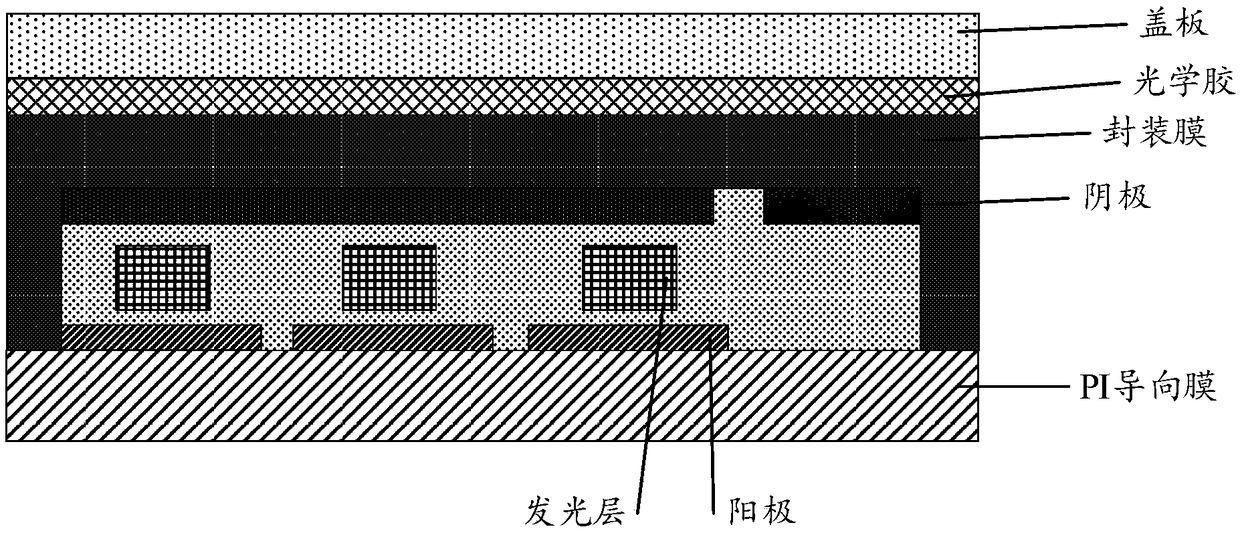

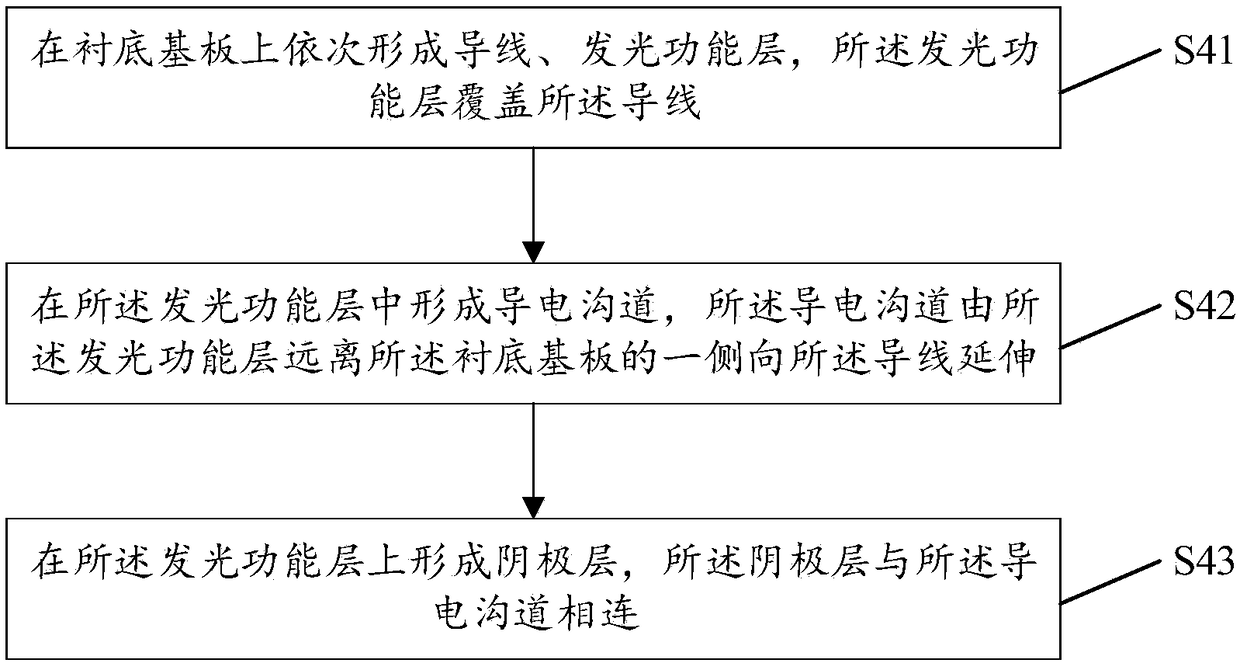

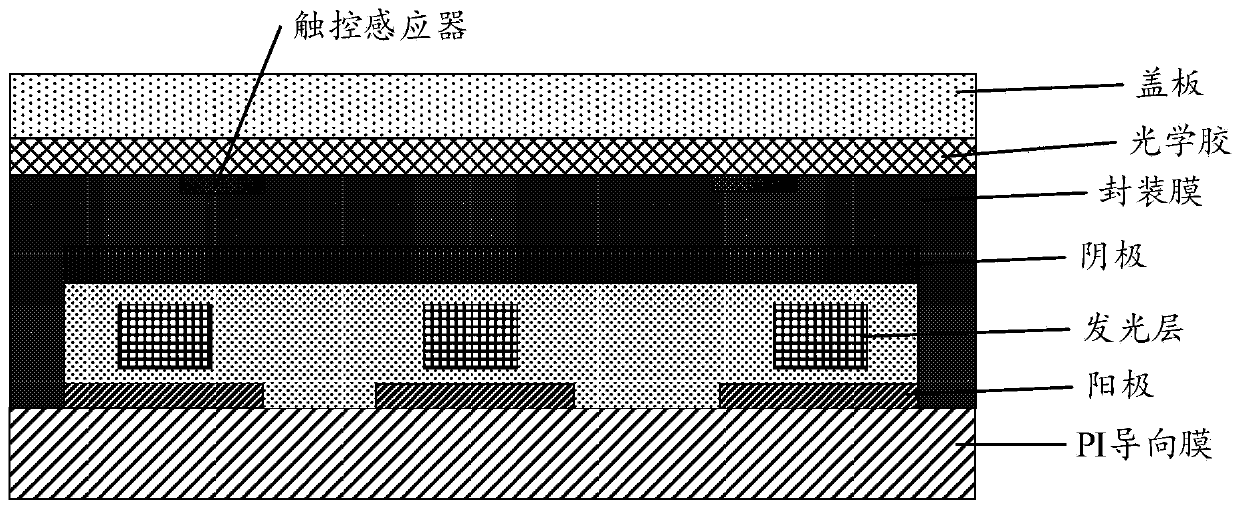

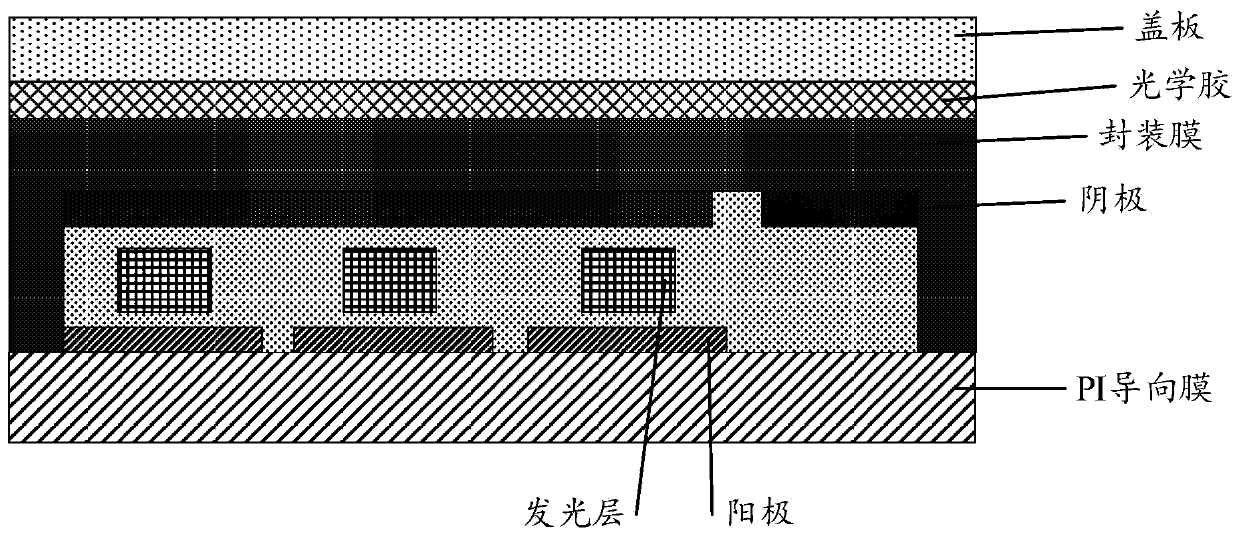

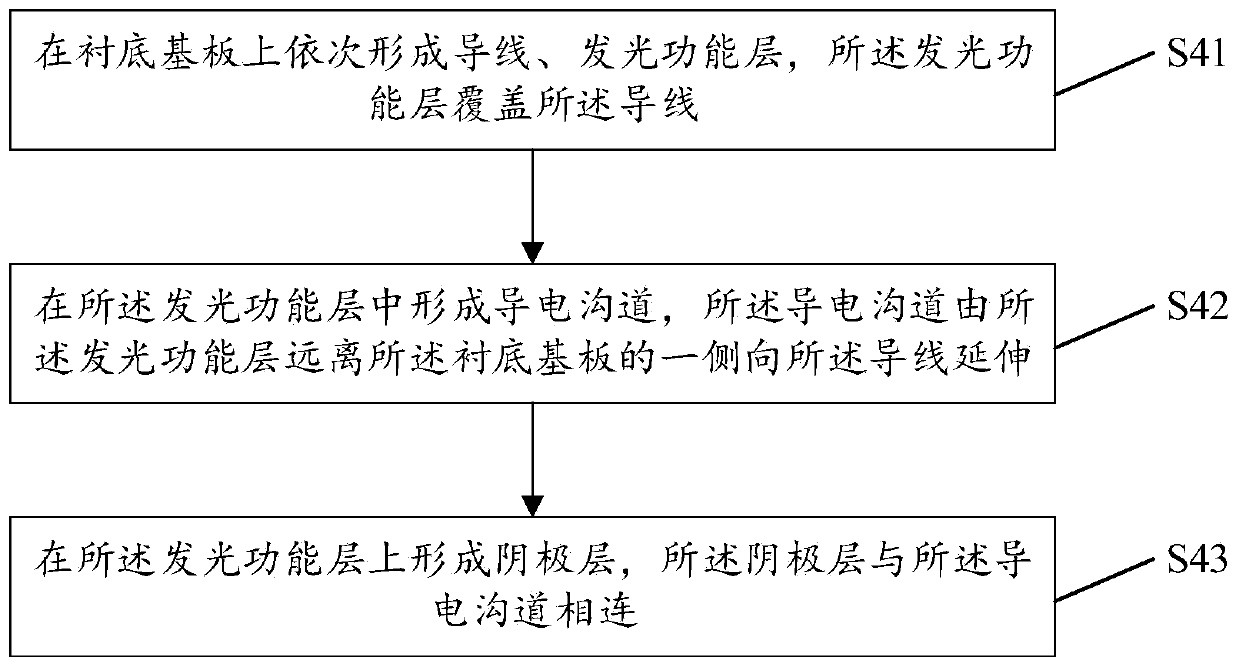

Display panel and production method thereof as well as display device

ActiveCN108231673AAvoid touch blind spotsAchieve connectionSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention relates to the technical field of display and particularly relates to a display panel and a production method thereof. The production method of the display panel comprises the followingsteps: successively forming lead wires and a light-emitting function layer on a substrate, wherein the light-emitting function layer covers the lead wires; forming conducting channels in the light-emitting function layer, wherein the conducting channels extend from one side away from the substrate of the light-emitting function layer to the lead wires; forming a cathode layer on the light-emittingfunction layer, wherein the cathode layer is connected with the conducting channels. According to the scheme, conducting particles are poured into the light-emitting function layer to form the conducting channels, so that the cathode is connected with the lead wires; the wiring length between the cathode and the lead wires is reduced; the touch control blind area on the display panel caused by the oversized wiring area is avoided.

Owner:BOE TECH GRP CO LTD

Flexible spark plug

Owner:BISHOP BOBBY GLEN

Feature forming process using plasma treatment

InactiveCN101885470ALow process temperatureShort heating (annealing) timeMaterial nanotechnologyNanostructure manufactureMaterials scienceForming processes

A process comprising: (a) forming a feature comprising uncoalesced silver-containing nanoparticles; (b) heating the uncoalesced silver-containing nanoparticles to form coalesced silver-containing nanoparticles; and (c) subjecting to a plasma treatment the uncoalesced silver-containing nanoparticles or the coalesced silver-containing nanoparticles, or both the uncoalesced silver-containing nanoparticles and the coalesced silver-containing nanoparticles, wherein the feature prior to the action (c) exhibits a low electrical conductivity but the electrical conductivity of the feature subsequent to the actions (b) and (c) is increased by at least about 100 times, wherein the action (c) is undertaken during one or more of prior to the heating, or during the heating, or after the heating.

Owner:XEROX CORP

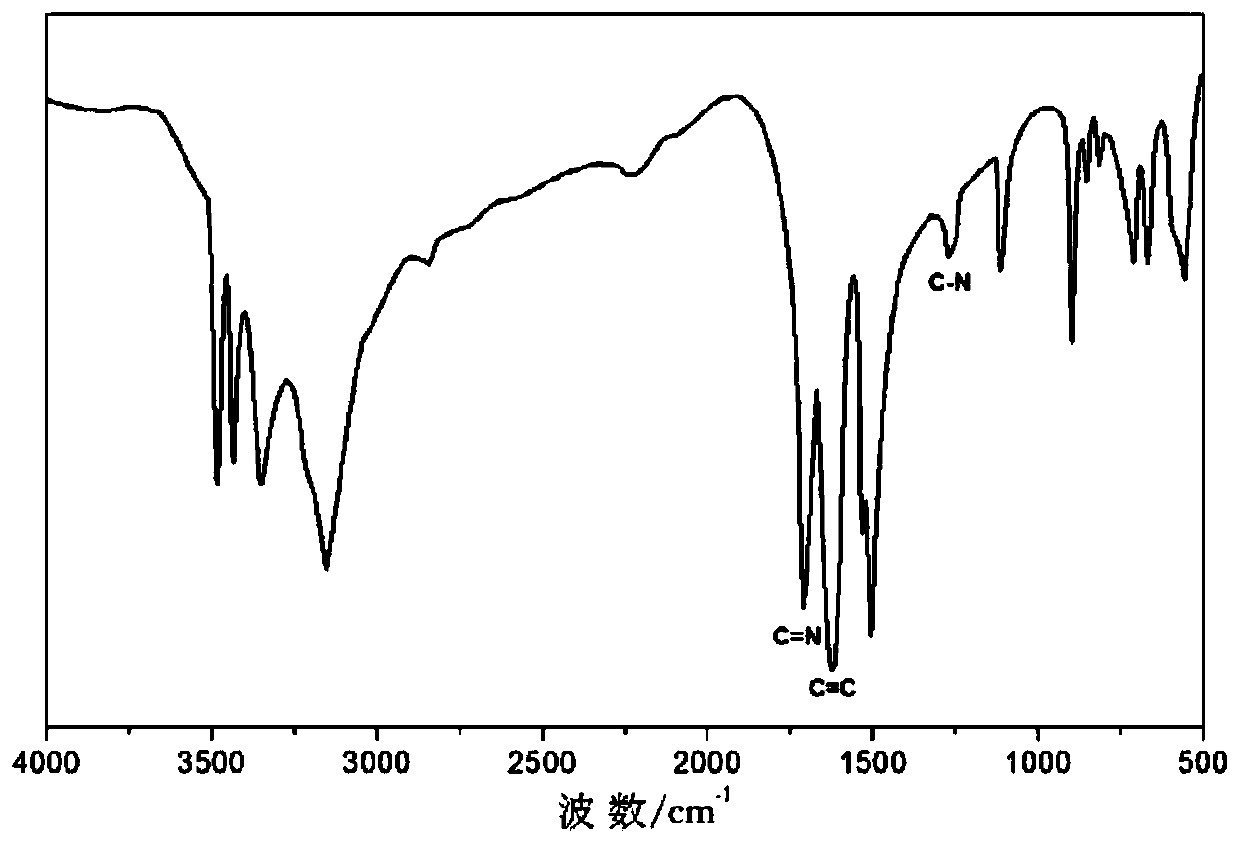

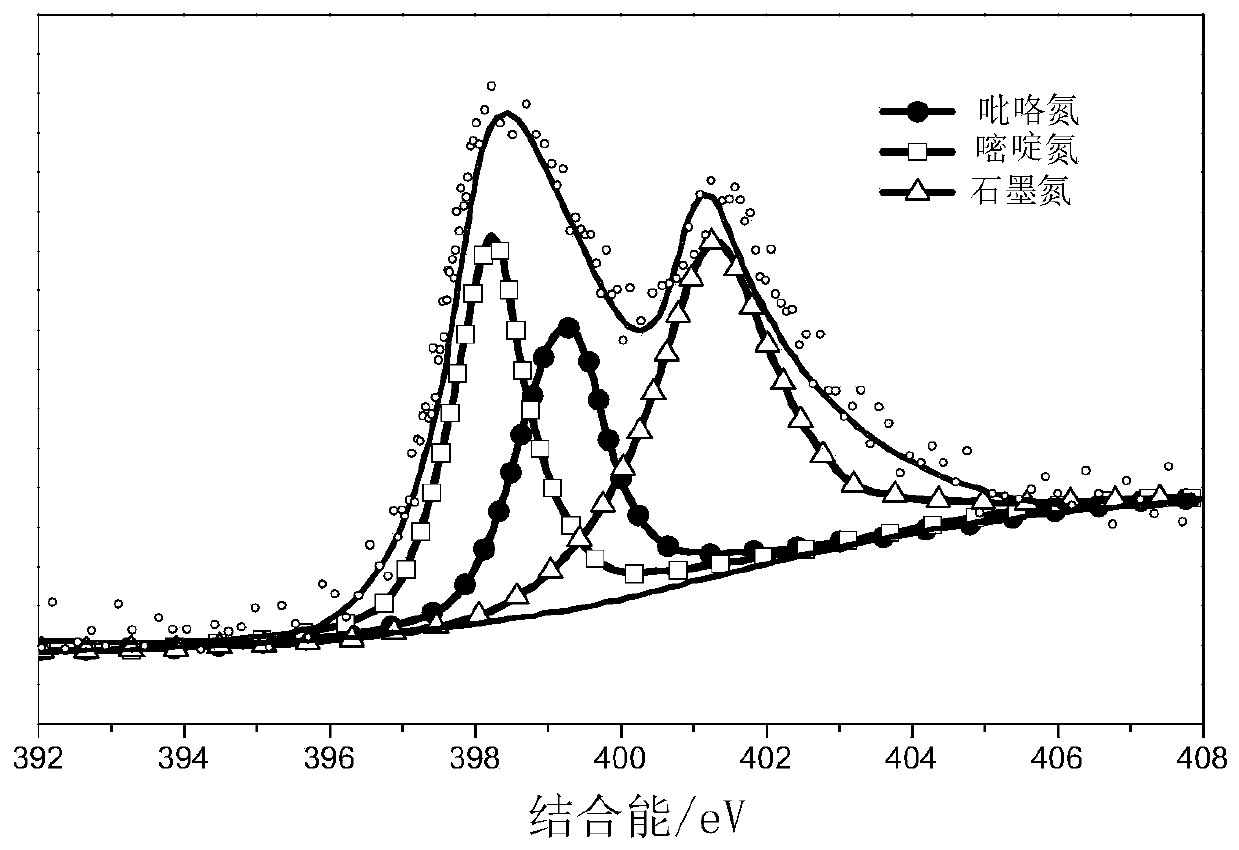

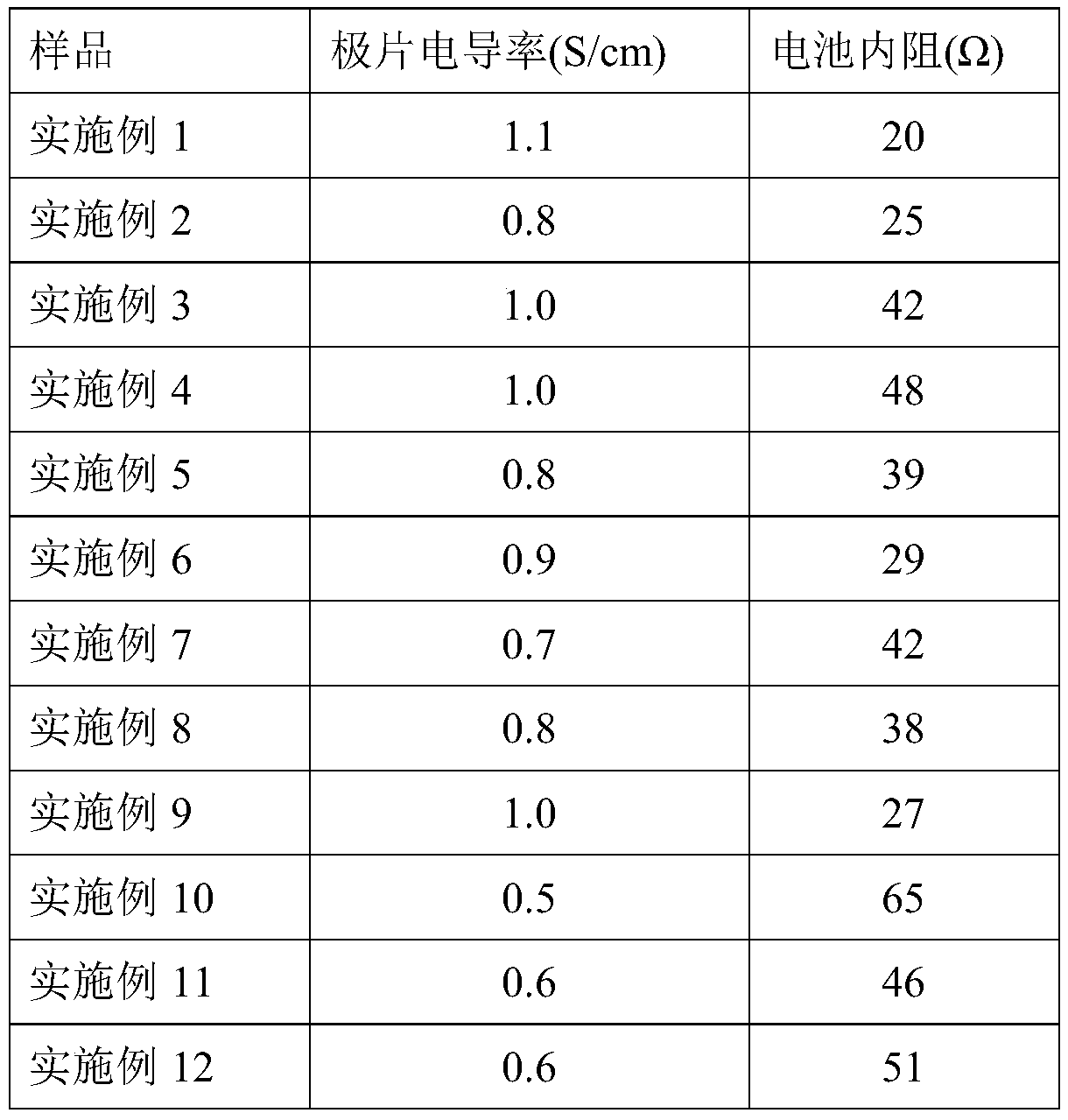

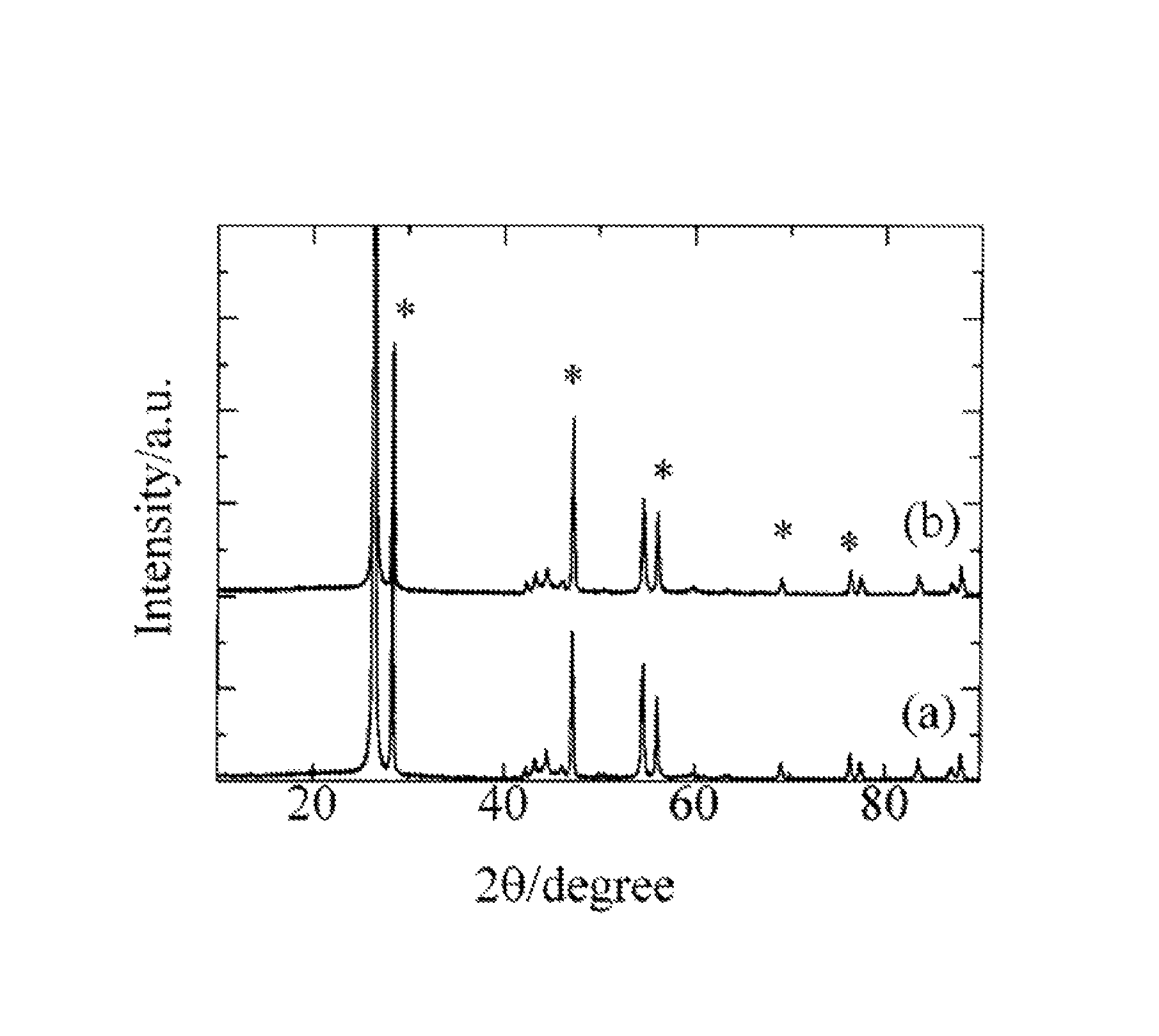

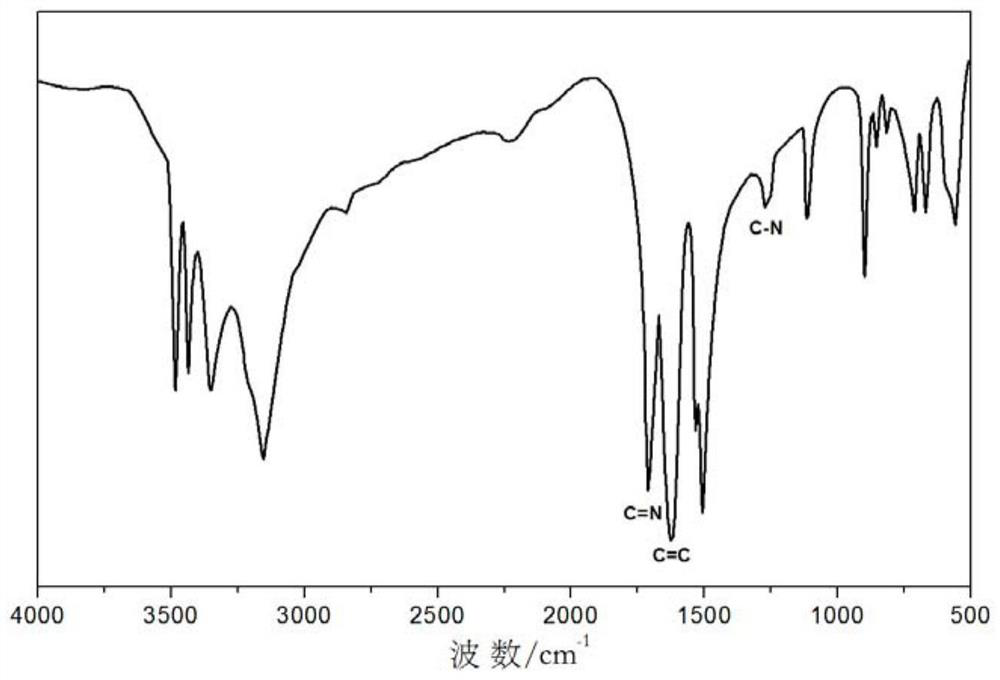

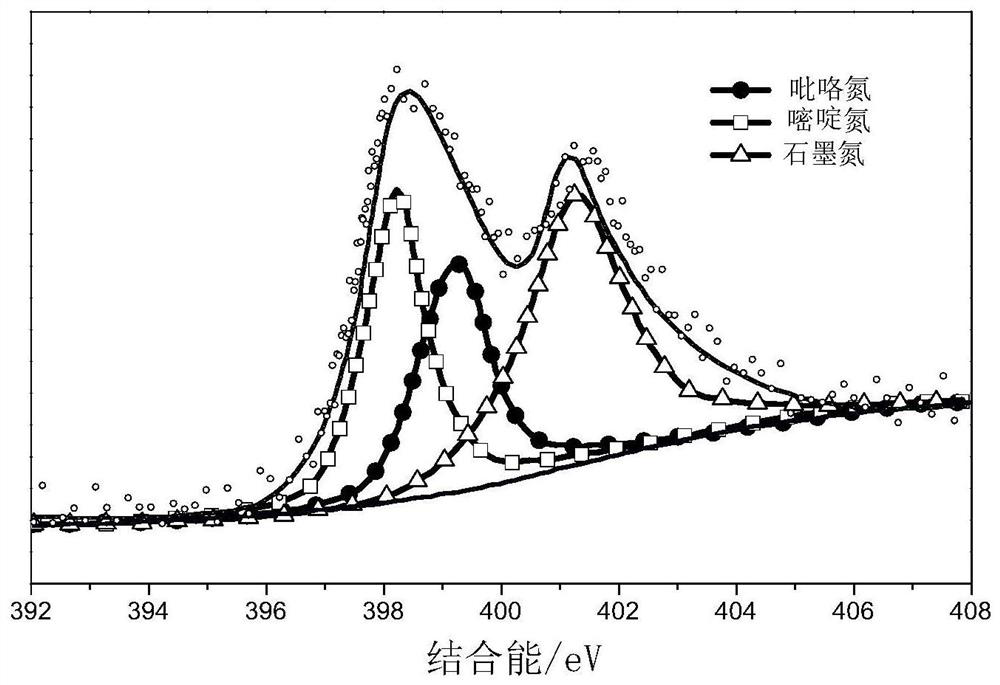

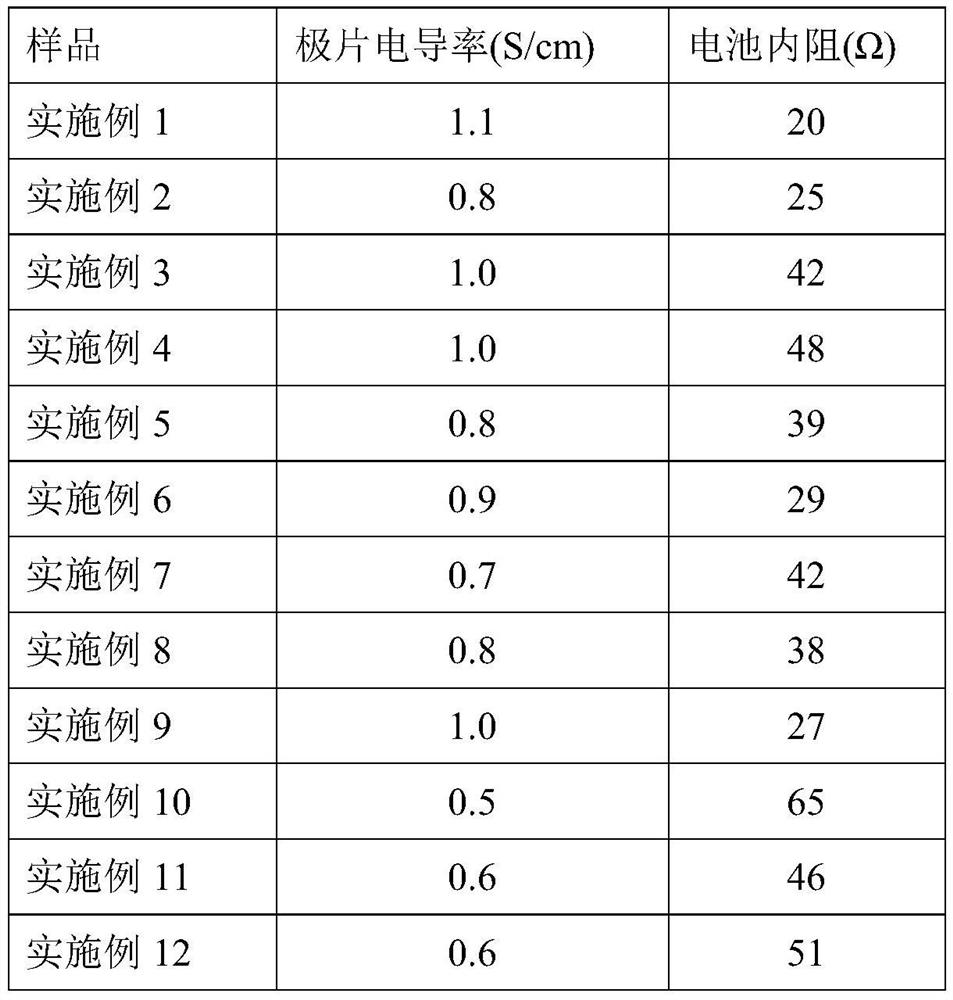

Composite conductive agent and preparation method thereof and electrode material containing composite conductive agent

ActiveCN110739460AGood dispersionImprove transmission performanceCell electrodesSecondary cellsInternal resistanceCarbon nanotube

The invention relates to a composite conductive agent and a preparation method thereof and an electrode material containing the composite conductive agent. The composite conductive agent comprises graphene and carbon nanotubes. The graphene and the carbon nanotubes are connected through chemical bonds. The graphene and the carbon nanotubes are bridged by the chemical bonds so that the electron transfer between the two conductive agents can be enhanced, the surface contact with the active material and the long-range conductive capability of the conductive agent are both considered, the steric hindrance effect of the graphene on lithium ions can also be reduced, the dispersion capability in the electrode material can be improved and the conductivity of the electrode piece containing the composite conductive agent is enabled to be as high as 0.5-1.1 S / cm and the internal resistance of the battery containing the composite conductive agent is enabled to be as low as 20-65ohm. The preparation method is simple and easy to operate and realizes the chemical bond connection between the graphene and the carbon nanotubes and dopes nitrogen atoms in the conductive agent through NHS treatment sothat the electron transfer rate inside the electrode can be effectively improved after the conductive agent is added into the electrode and the electrical conductivity is further enhanced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

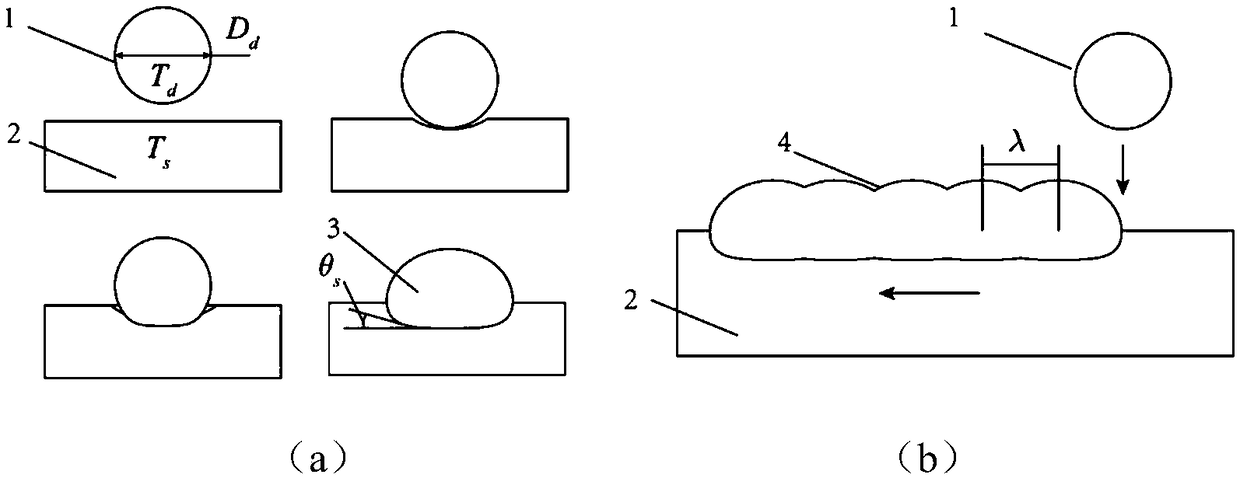

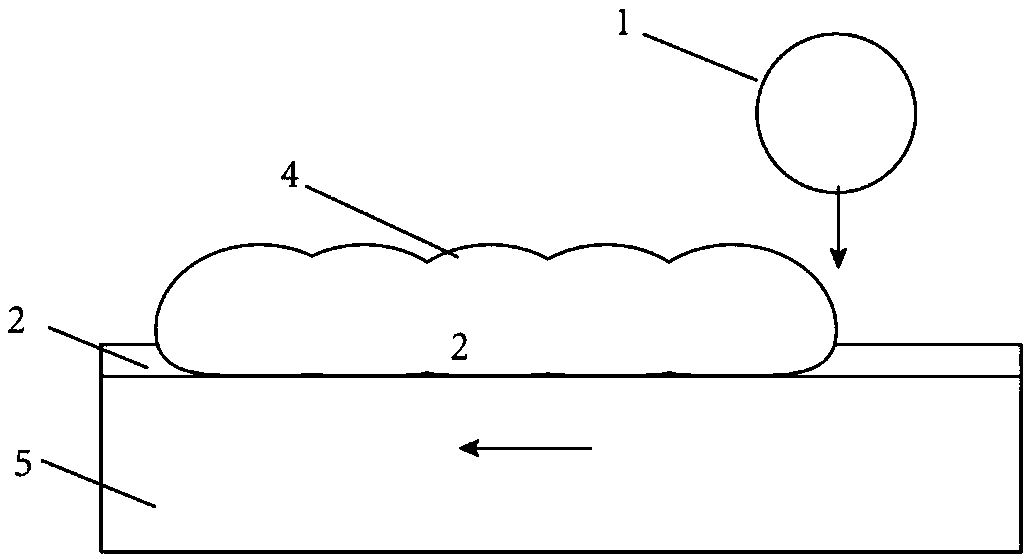

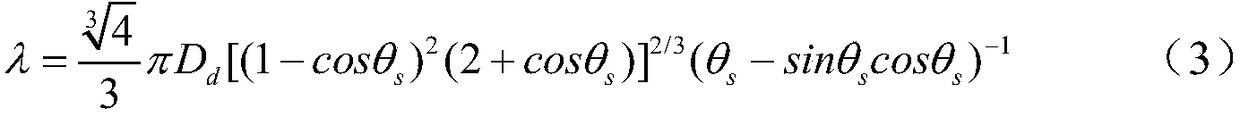

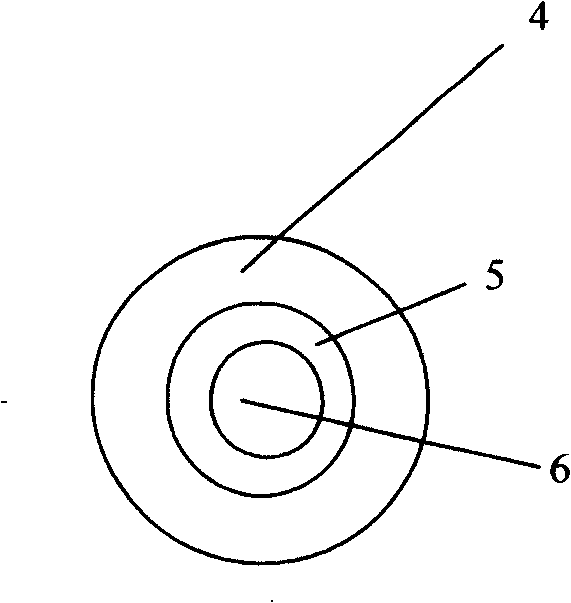

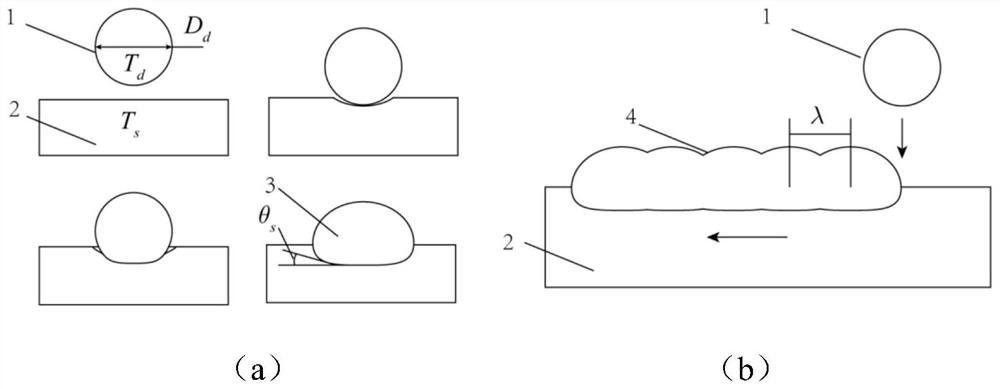

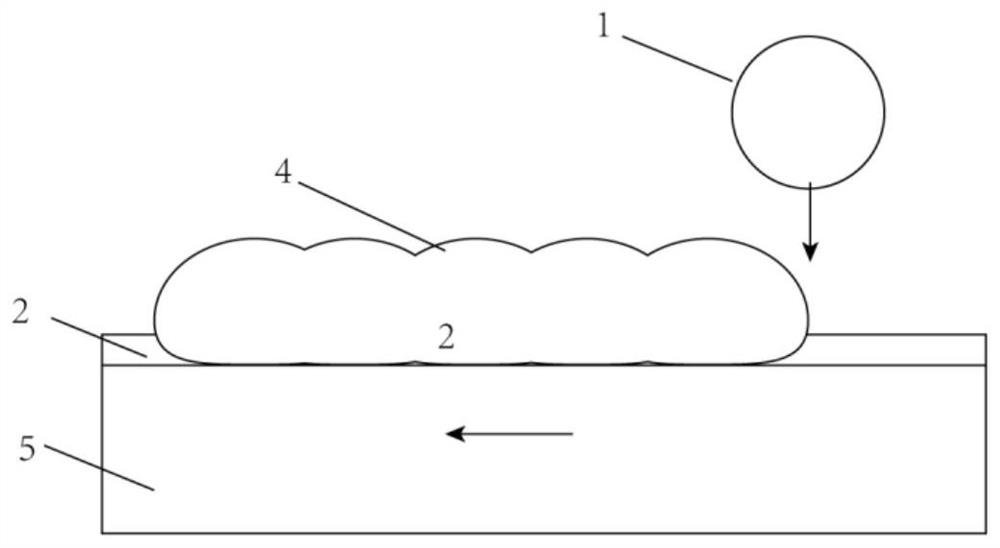

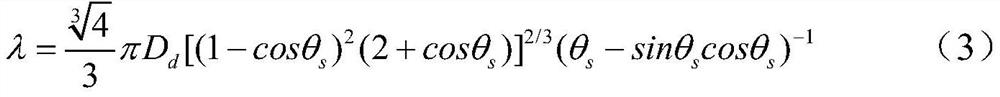

Circuit printing method through uniform metal liquid drops

ActiveCN108907201ASame conductivityMeet the needs of bonding strengthTurbinesOther manufacturing equipments/toolsMolten stateMicroelectronic circuits

The invention discloses a circuit printing method through uniform metal liquid drops. The technical problem that an existing microelectronic circuit manufacturing method is poor in practicability is solved. According to the technical scheme, a block metal material in a market supply state is melted, the metal liquid drops in a molten state are sprayed out for printing drop by drop, and through metallurgical bonding among the printing metal liquid drops, it is guaranteed that the electrical conductivity of a printed conducting circuit is the same as that of a dense metal material. Meanwhile, through deposition of the high-temperature liquid drops, a thermoplastic matrix is melted so as to form the conducting circuit with the bottoms of the metal liquid drops being embedded into the matrix,the requirement for the bonding strength of the conducting circuit can be met, the post-processing process of the circuit is reduced, low-cost short-process printing of the circuit is realized, and practicability is good.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

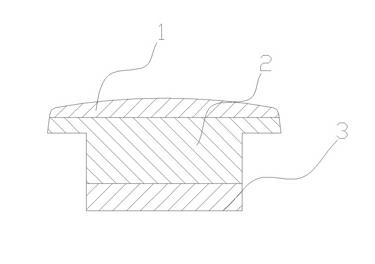

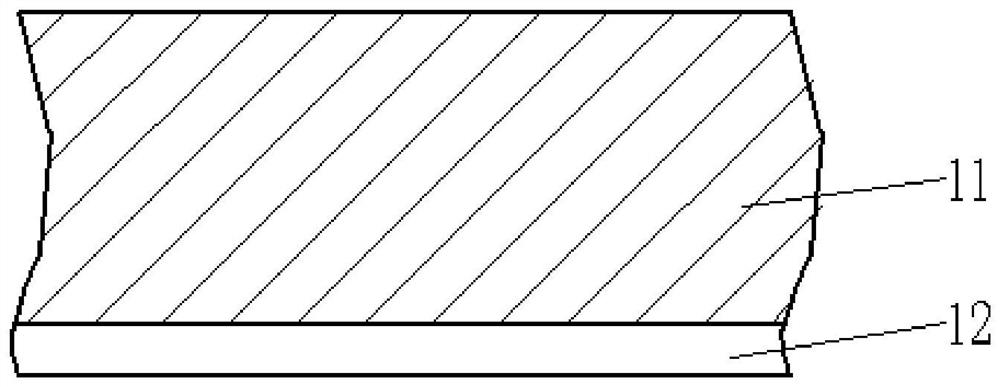

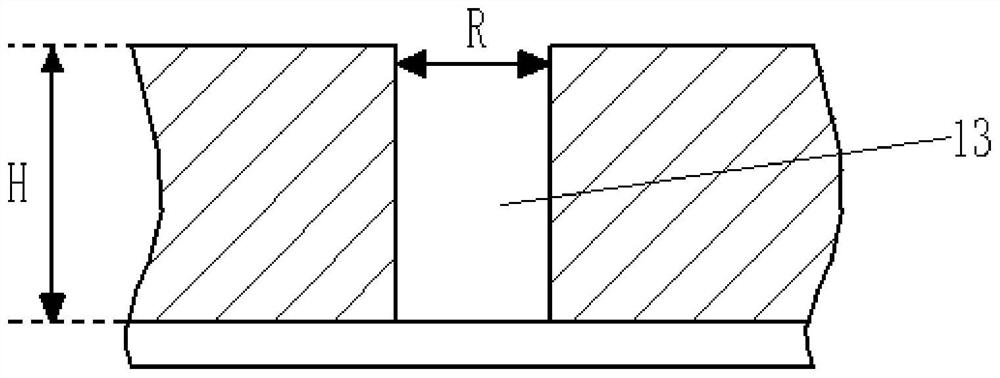

Copper-coated aluminum electromagnetic wire

InactiveCN101246762AHigh strengthLow densityRubber insulatorsPlastic/resin/waxes insulatorsHigh resistanceElectrical conductor

The invention is a copper-clad aluminum conductor magnetic wire, the inner core is aluminum wire clad with a layer of cylinder copper sheet, the magnetic wire can also be a magnetic wire having two or more parallel or winding copper-clad aluminum conductors, the magnetic wire is covered with an insulting layer. Or insulating materials such as paper, insulating paint or fiberglass are covered outside the conductor to form a magnetic wire with an insulating layer. The copper-clad aluminum core magnetic wire has same conductivity as that of same-sized copper-core magnetic wire having same size, light weight, processing simplicity and usage convenience, saves more than 80% copper, effectively lowers cost, and overcomes the following drawbacks: easy oxidability, high resistance, poor corrosion resistance and mechanical property of the aluminum-core magnetic wire.

Owner:大连极速金属复合材料有限公司

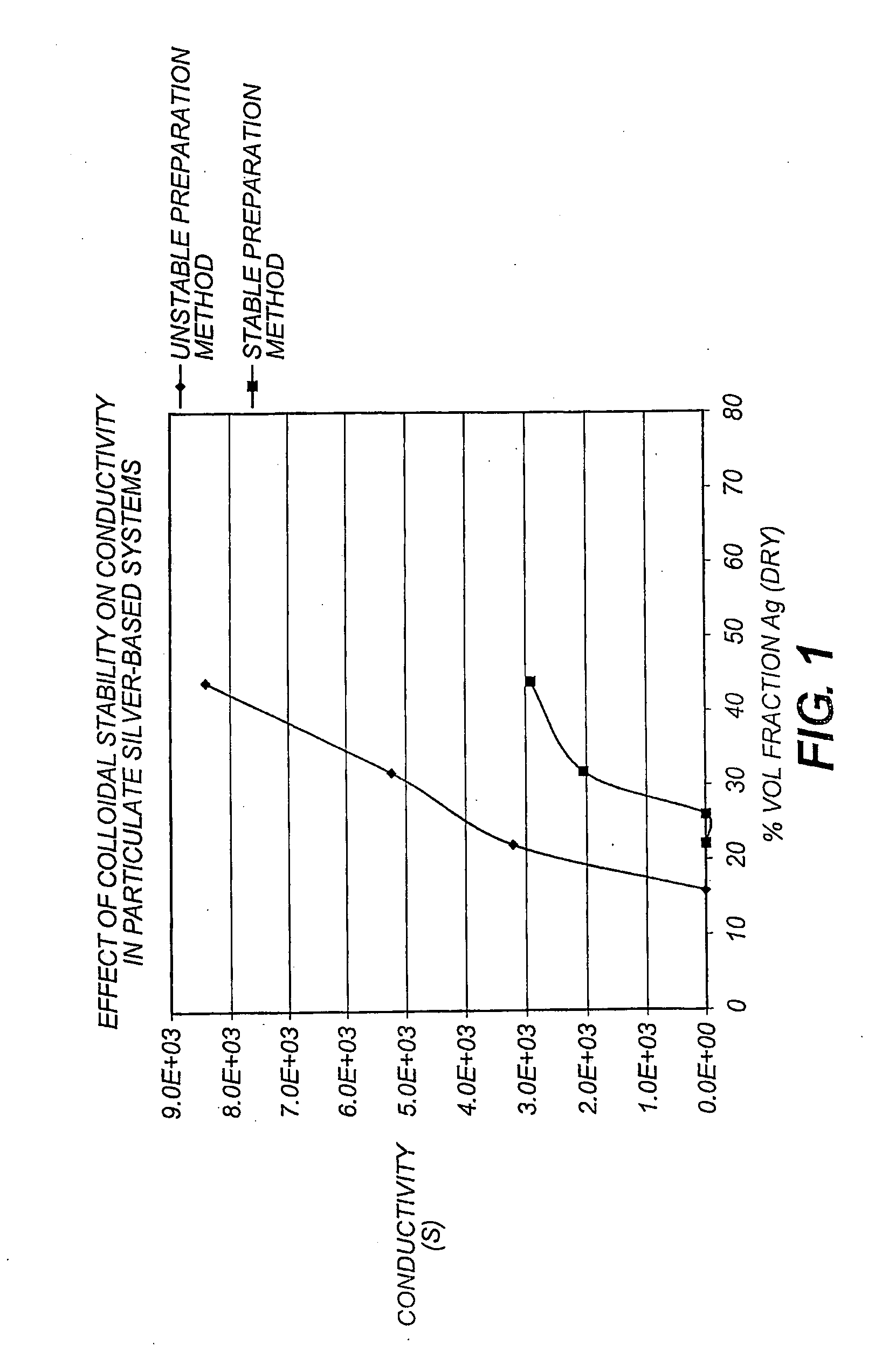

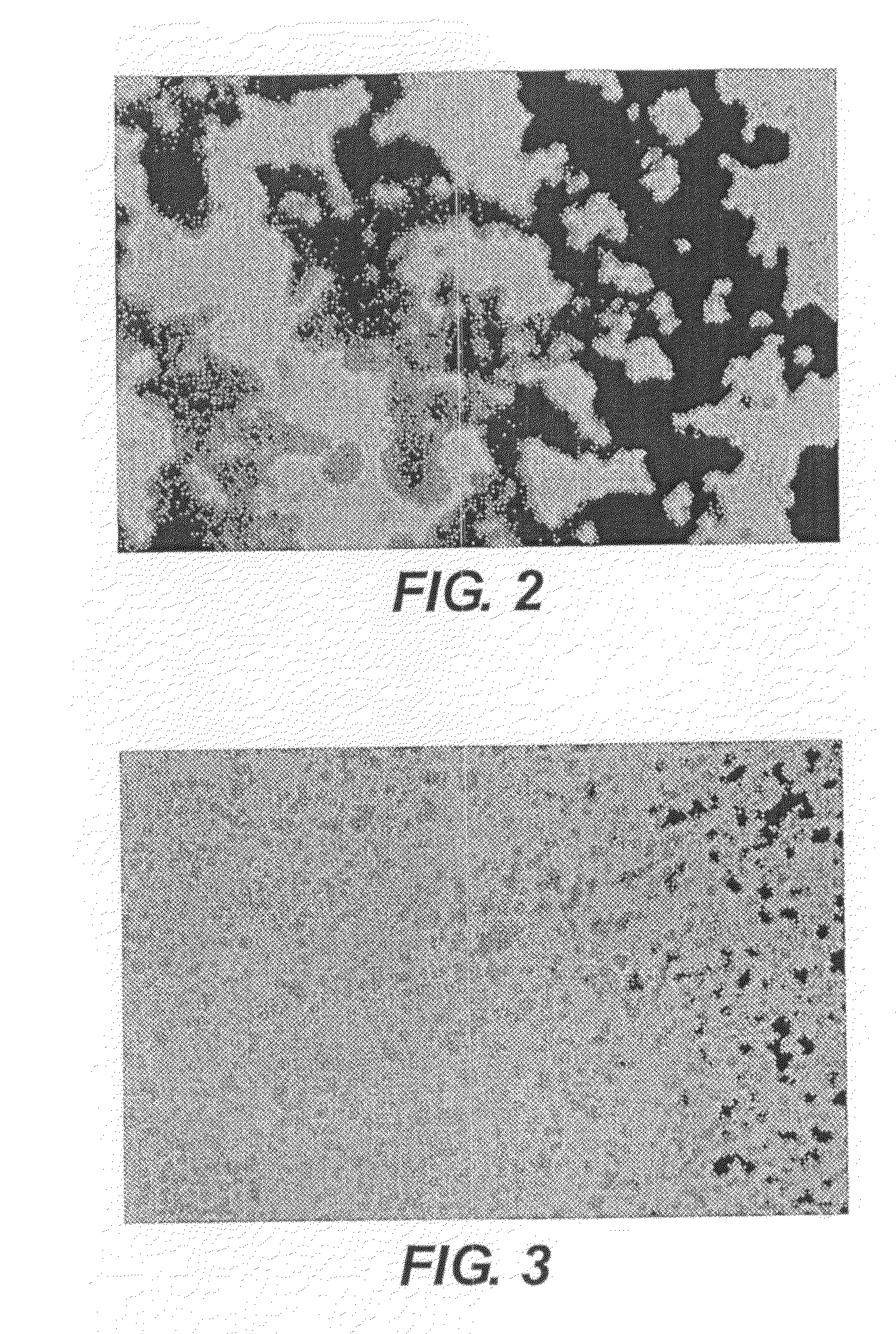

Conductive composite material

InactiveUS20090200520A1High transparencyEasy to produceConductive materialPrinted circuit aspectsColloidMaterials science

Owner:EASTMAN KODAK CO

Method for Printing Circuits with Uniform Metal Droplets

ActiveCN108907201BSame conductivityMeet the needs of bonding strengthTurbinesOther manufacturing equipments/toolsMolten stateMetallic materials

The invention discloses a method for printing circuits with uniform metal droplets, which is used to solve the technical problem of poor practicability of the existing microelectronic circuit manufacturing methods. The technical solution is to melt the bulk metal material supplied in the market, spray out molten metal droplets for drop-by-drop printing, and ensure the conductivity of the printed conductive circuit and the conductivity of the dense metal material through the metallurgical combination of the printed metal droplets. Sex is the same. At the same time, when the high-temperature droplets are deposited, the thermoplastic substrate is melted to form a conductive circuit embedded in the substrate at the bottom of the metal droplet, so as to meet the needs of the bonding strength of the conductive circuit, reduce the post-processing process of the circuit, and realize the low-cost and short-process printing of the circuit. Good practicality.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Copper-intermediate silver contact for relay

The invention discloses a copper-intermediate silver contact for a relay, and the contact provided by the invention consists of contacts, tail ends and intermediates, wherein the contacts and the tail ends are made of a silver material; and the intermediates are made of a copper material. The copper-intermediate silver contact for the relay disclosed by the invention has the characteristics of low cost, saved precious metal and the like while maintaining the original characteristics of high conductivity, low resistance, good contact and efficient conductance, thereby according with the requirements of low carbon, high efficiency and sustainable development to an industrial product nowadays.

Owner:SANYOU CORP LTD

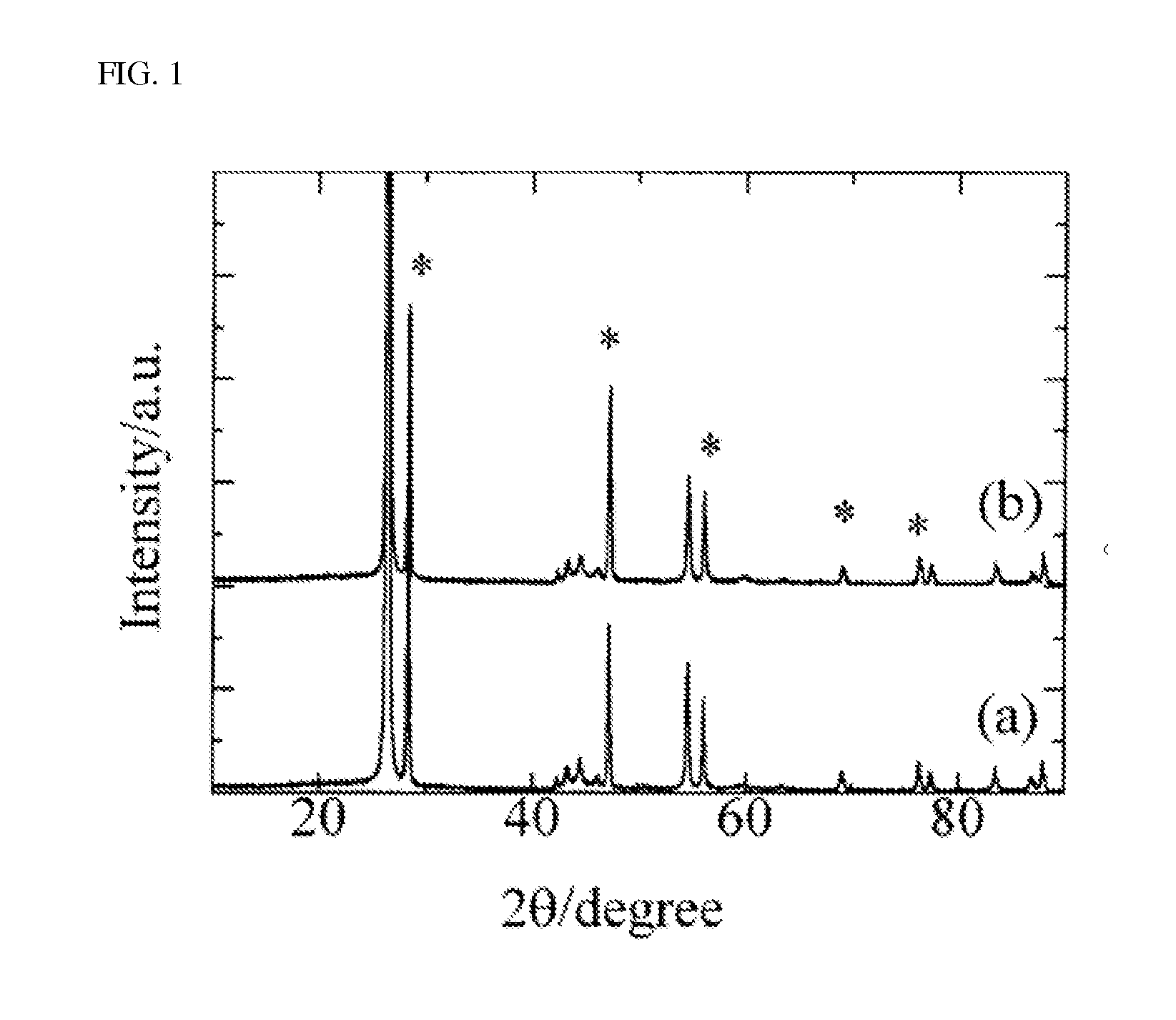

Lithium secondary battery of high power property with improved high power density

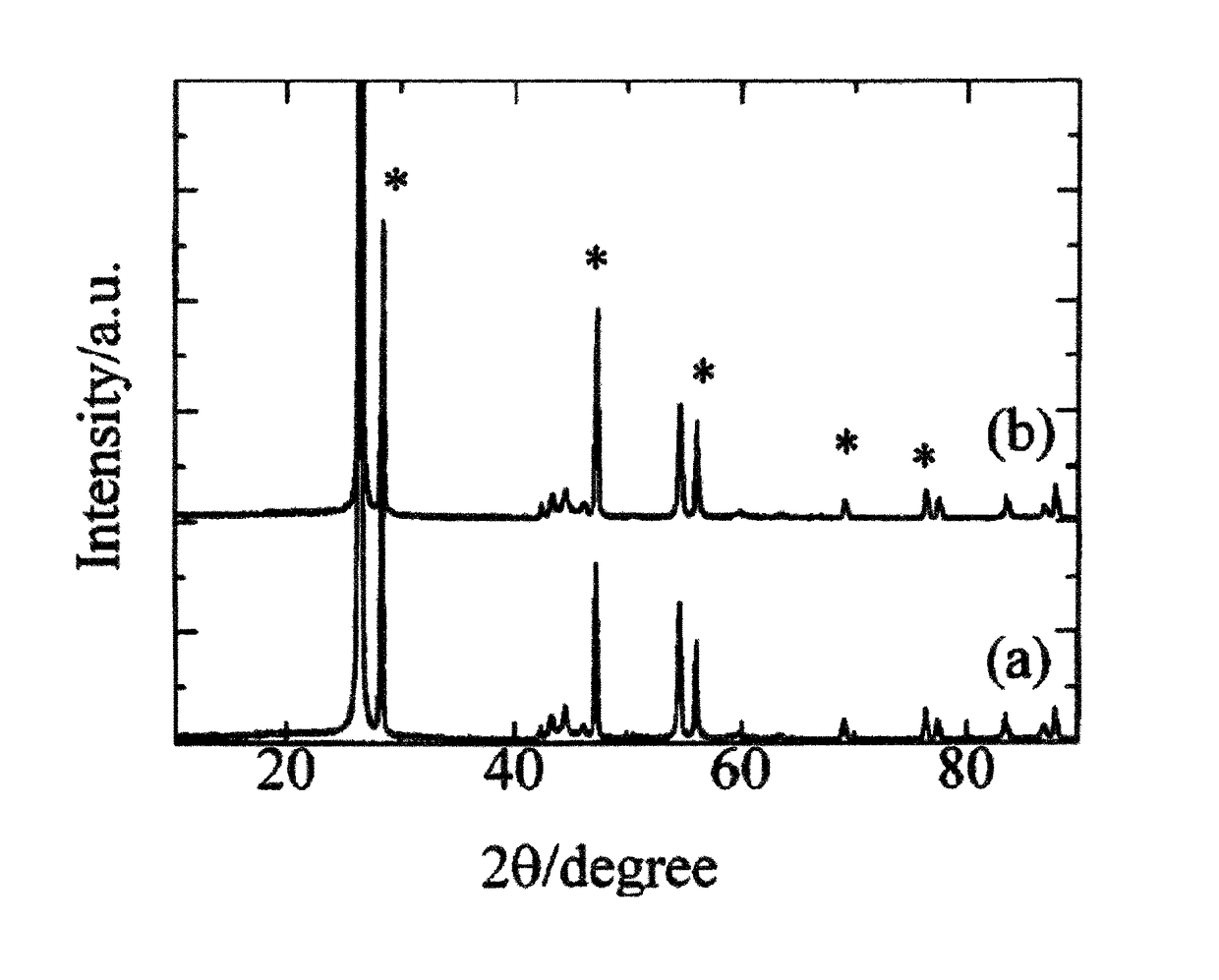

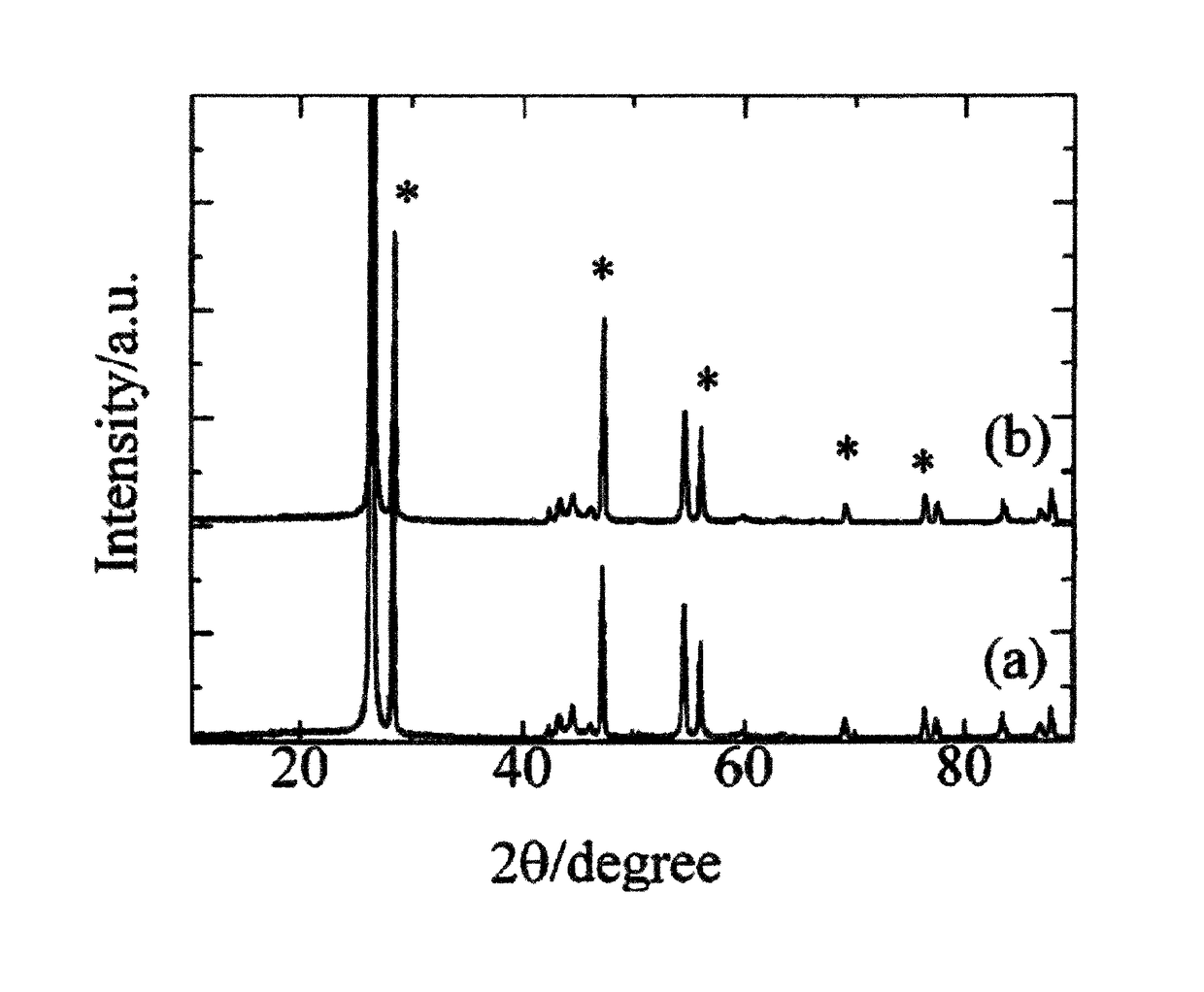

ActiveUS9263737B2Improve output characteristicsSame conductivityFinal product manufactureActive material electrodesLithiumSpinel

Disclosed is a high-output lithium secondary battery including: a cathode that includes, as cathode active materials, a first cathode active material represented by Formula 1 below and having a layered structure and a second cathode active material represented by Formula 2 below and having a spinel structure, wherein the amount of the second cathode active material is between 40 and 100 wt % based on the total weight of the cathode active materials; an anode including crystalline graphite and amorphous carbon as anode active materials, wherein the amount of the amorphous carbon is between 40 and 100 wt % based on the total weight of the anode active materials; and a separator.

Owner:LG ENERGY SOLUTION LTD

A kind of composite conductive agent, its preparation method and electrode material containing it

ActiveCN110739460BGood dispersionImprove transmission performanceCell electrodesSecondary cellsInternal resistanceCarbon nanotube

The invention relates to a composite conductive agent, a preparation method thereof and an electrode material containing the same. The composite conductive agent includes graphene and carbon nanotubes, and the graphene and carbon nanotubes are connected by chemical bonds. In the present invention, graphene and carbon nanotubes are bridged by chemical bonds, which enhances the electron transfer between the two conductive agents, takes into account the surface contact with the active material and the long-range conductivity of the conductive agent, and at the same time reduces the resistance of graphene to lithium ions. The steric hindrance effect improves the dispersion ability in the electrode material, so that the conductivity of the pole piece containing the composite conductive agent is as high as 0.5-1.1S / cm, and the internal resistance of the battery containing it is as low as 20-65Ω. The preparation method of the present invention is simple and easy to operate. It not only realizes the chemical bond connection between graphene and carbon nanotubes, but also makes the conductive agent doped with nitrogen atoms through NHS treatment, so that it can effectively increase the electron density inside the electrode after it is added to the electrode. The transfer rate and conductivity are further enhanced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A kind of corrosion-resistant grounding alloy and preparation method thereof

InactiveCN108559895BImprove micro-domain negative chargeStability protectionSolid state diffusion coatingRare-earth elementCopper

The invention discloses a corrosion-resistant grounding alloy and a preparation method thereof and relates to the technical field of grounding metals. The corrosion-resistant grounding alloy disclosedby the invention comprises the following components: 94-96% of Al, 3-5% of Cu, 0.05-0.1% of RE and inevitable impurity elements. The preparation method comprises the following steps: 1, burdening according to requirements of various components of the grounding alloy; 2, smelting to obtain alloy melt; 3, pouring in a vacuum room; 4, performing homogenizing annealing on the casting; 5, performing shot blasting; 6, performing pre-oxidation treatment on the casting surface. By adding trace rare earth elements into the alloy, aims of refining grains, improving electronegativity in each region on the material surface, stabilizing a protective film layer and increasing corrosion resistance are achieved. Pure copper is replaced with an aluminum alloy, the cost is reduced, the same conductivity isachieved, and the problem that heavy metal pollution to the environment is caused by the conventional copper and zinc is solved.

Owner:安徽兴广泰新能源技术有限公司

Lithium secondary battery of high energy density with improved energy property

ActiveUS9601756B2Increase energy densityImprove output characteristicsActive material electrodesLi-accumulatorsLithiumHigh energy

High energy density lithium secondary batteries are disclosed herein. In some embodiments, a high energy density lithium secondary battery includes a cathode, an anode, and a separator. The cathode includes a first cathode active material having a layered structure and a second cathode active material having a spinel structure, wherein the amount of the first cathode active material is between 40 and 100 wt % based on the total weight of the cathode active materials. The anode includes crystalline graphite and amorphous carbon as anode active materials, wherein the amount of the crystalline graphite is between 40 and 100 wt % based on the total weight of the anode active materials.

Owner:LG ENERGY SOLUTION LTD

Display panel, manufacturing method thereof, and display device

ActiveCN108231673BAvoid touch blind spotsAchieve connectionSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention relates to the field of display technology, in particular to a display panel, a manufacturing method thereof, and a display device. A method for manufacturing a display panel, comprising: sequentially forming a conductive line and a light-emitting functional layer on a base substrate, the light-emitting functional layer covering the conductive line; forming a conductive channel in the light-emitting functional layer, and the conductive channel is formed by the light-emitting functional layer The side of the light-emitting functional layer away from the base substrate extends toward the wire; a cathode layer is formed on the light-emitting functional layer, and the cathode layer is connected to the conductive channel. The solution provided by the present invention forms a conductive channel by injecting conductive particles into the light-emitting functional layer, realizes the connection between the cathode and the wire, reduces the length of the wire between the cathode and the wire, and avoids the display panel caused by the excessively large wire area. touch blind area.

Owner:BOE TECH GRP CO LTD

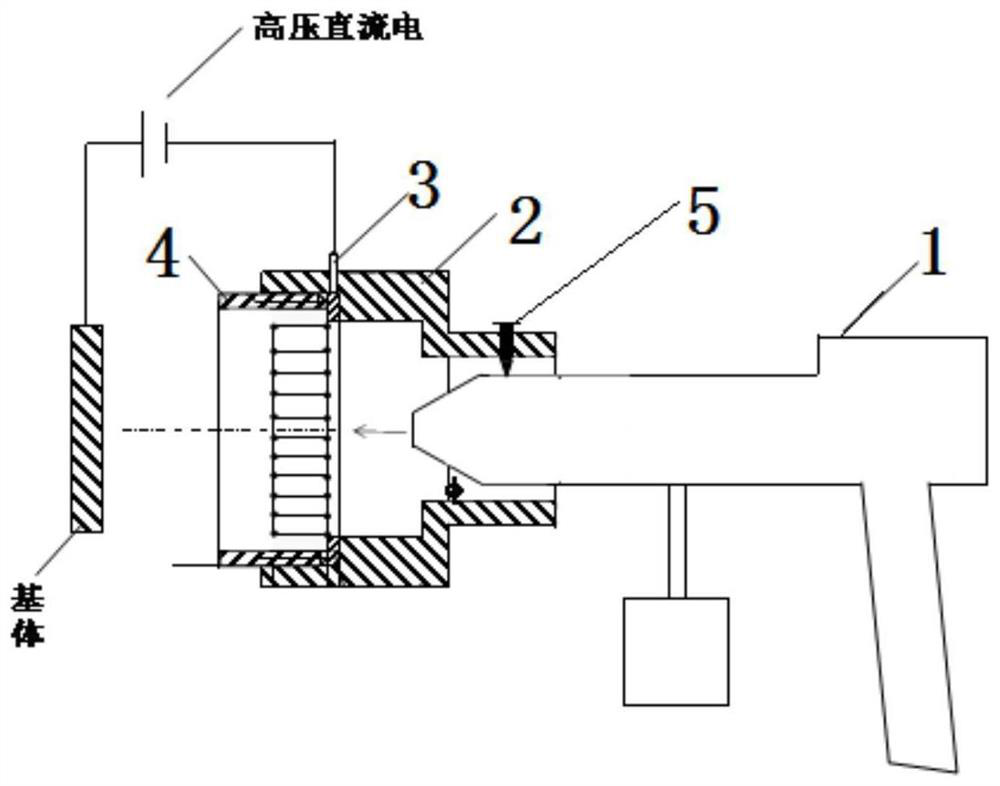

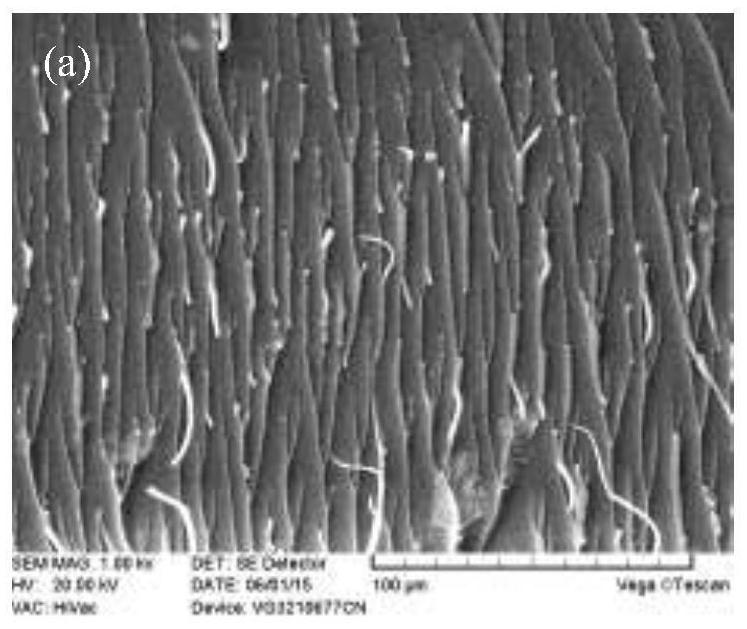

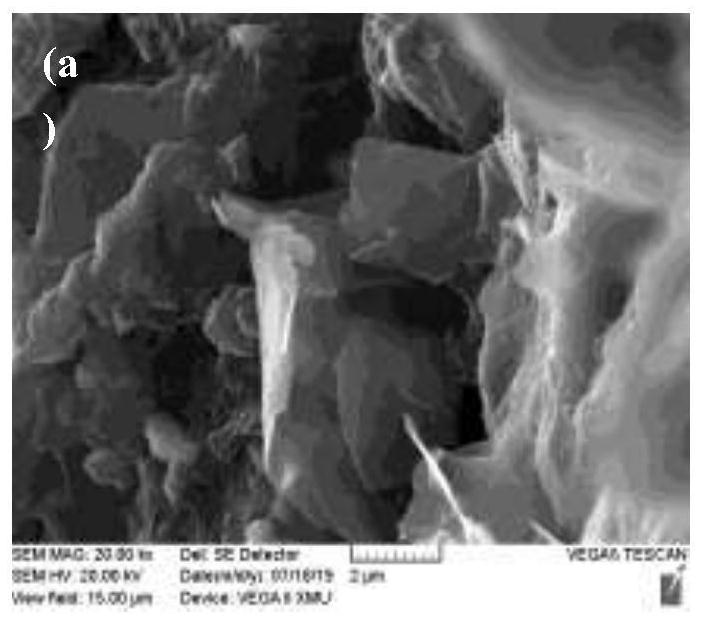

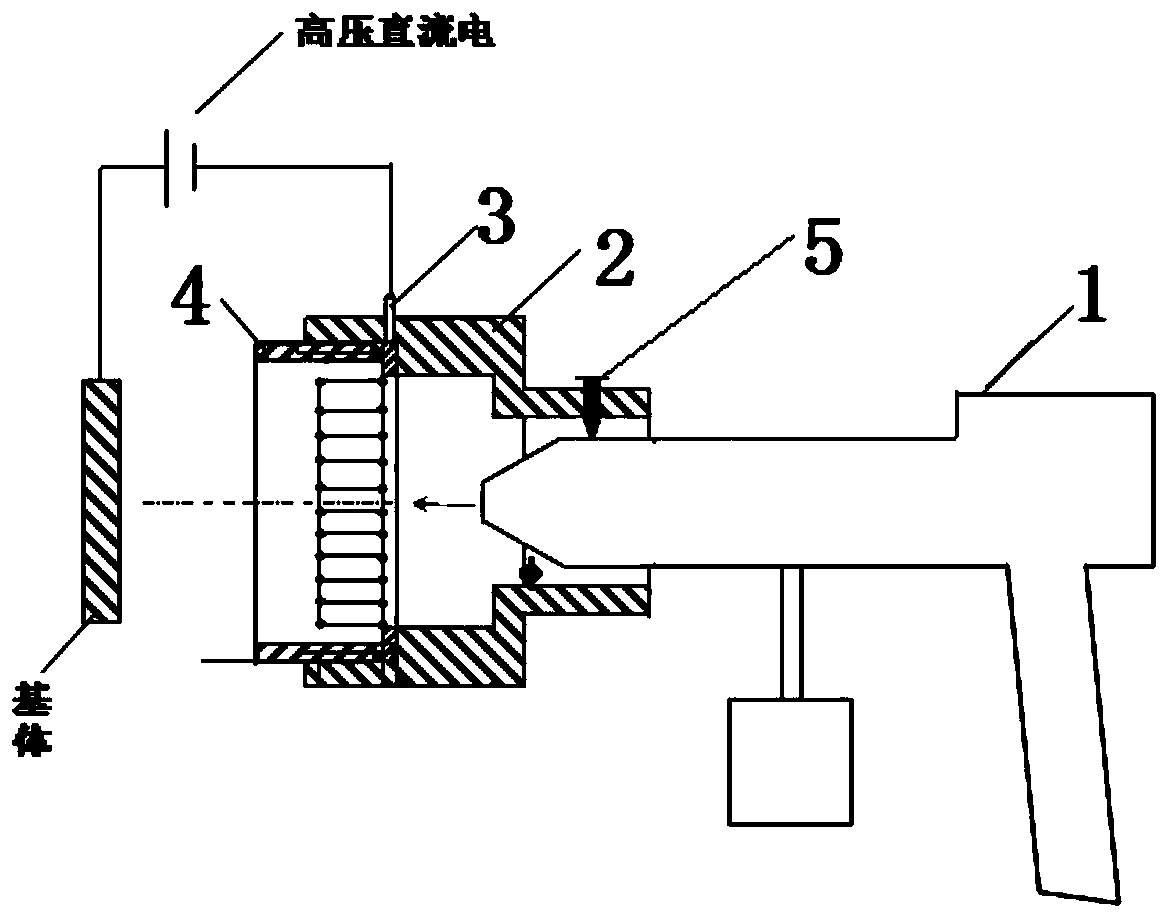

A preparation device for channel-type organic conductive coating

ActiveCN111250284BReduce the content of conductive particlesSame conductivitySpraying power supplySpray discharge apparatusConductive coatingHigh-voltage direct current

The invention discloses a preparation device for a channel-type conductive coating, which includes an air spray gun. The nozzle of the air spray gun is connected to an electrode net through a polymer material plug, and the electrode net is connected to a substrate through a high-voltage direct current power supply. The conductive particles in the coating on the substrate are erected in the coating, and several conductive particles can be connected to each other to form a conductive path, so that the conductive particles are oriented in the coating, and the problem of the chaotic distribution of conductive particles in the existing conductive coating is solved; Reduce the conductive particle content of the conductive coating, and make the conductivity of the surface and the bottom layer of the coating the same, so as to solve the problem that the high content of conductive particles in the conductive coating will adversely affect the corrosion resistance and other properties of the coating.

Owner:XIAN UNIV OF TECH

Preparation device for channel type organic conductive coating

ActiveCN111250284AReduce the content of conductive particlesSame conductivitySpraying power supplySpray discharge apparatusConductive coatingHigh-voltage direct current

The invention discloses a preparation device for a channel type conductive coating. The device comprises an air spray gun, a nozzle of the air spray gun is further connected with an electrode net through a high polymer material plug, the electrode net is connected with a base body through a high-voltage direct-current power source, conductive particles sprayed in paint on the base body are erectedin the coating through an electrostatic field, several conductive particles can be mutually connected to form a conductive path, so that the conductive particles are directionally arranged in the coating, and the problem that conductive particles in an existing conductive coating are disorderly distributed is solved; and the content of the conductive particles in the conductive coating is reduced, the conductivity of the middle surface and the conductivity of the bottom layer of the coating are the same, and adverse effects on the corrosion resistance and other properties of the coating due to the high content of the conductive particles in the conductive coating are avoided.

Owner:XIAN UNIV OF TECH

Lithium secondary battery of high energy density with improved energy property

ActiveUS9985278B2Increase energy densityImprove output characteristicsCell electrodesLi-accumulatorsLithiumHigh density

Disclosed is a high energy density lithium secondary battery including a cathode. The cathode contains, as cathode active materials, a first cathode active material having a layered structure and a second cathode active material having a spinel structure. The amount of the first cathode active material is between 40 and 100 wt % based on the total weight of the cathode active materials. The high density lithium secondary battery further comprises an anode, including crystalline graphite having a specific surface area (with respect to capacity) of 0.005 to 0.013 m2 / mAh as an anode active material, as well as a separator.

Owner:LG ENERGY SOLUTION LTD

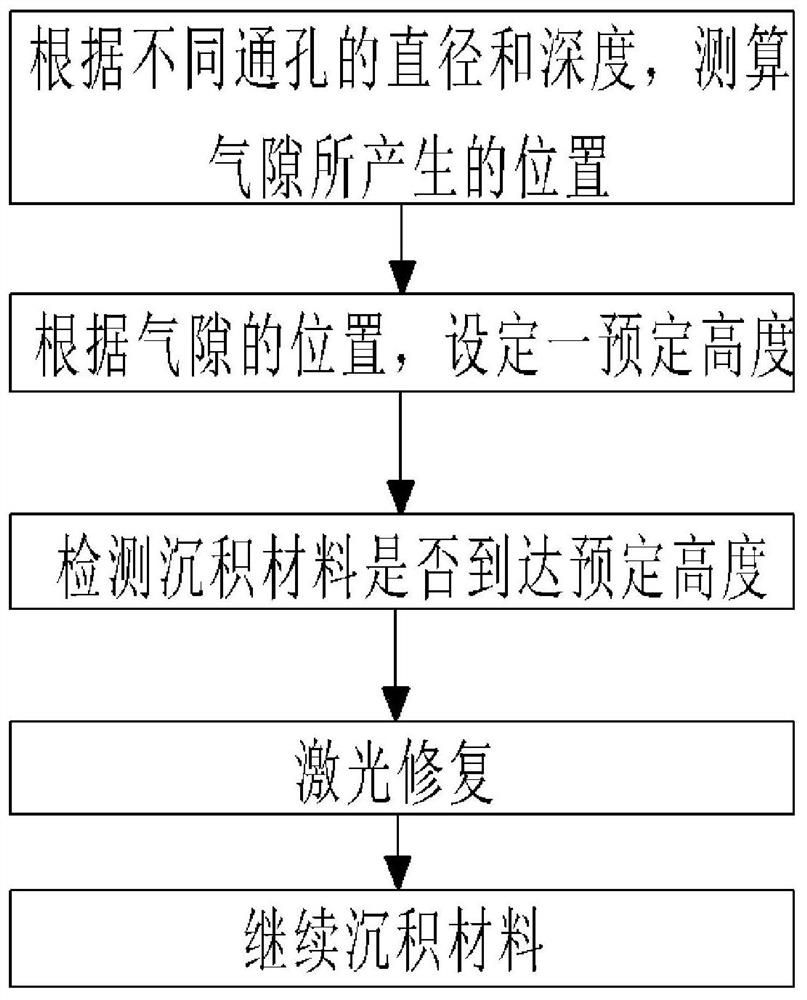

A kind of laser processing method of through hole

ActiveCN111430296BSame conductivityAvoid gatheringSemiconductor/solid-state device manufacturingLaser processingEngineering

The invention provides a laser processing method of a through hole. The method comprises the following steps of forming a material with a preset height, performing laser repair on an air gap positionto change the air gap into a concave hole with a larger opening and a shallower depth, and filling the material for the second time to form a final conductive through hole. According to the invention,the air gap can be eliminated, the electrical conductivity of each position of the through hole can be ensured to be the same, and the current accumulation or open circuit is prevented.

Owner:福唐激光(苏州)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com