Copper-coated aluminum electromagnetic wire

A technology of electromagnetic wire and copper-clad aluminum, which is applied in the field of electromagnetic wire, can solve the problems of limited application range, corrosion resistance and mechanical performance strength not as good as copper, and large contact resistance, etc., to achieve convenient use, good conductivity, and small contact resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

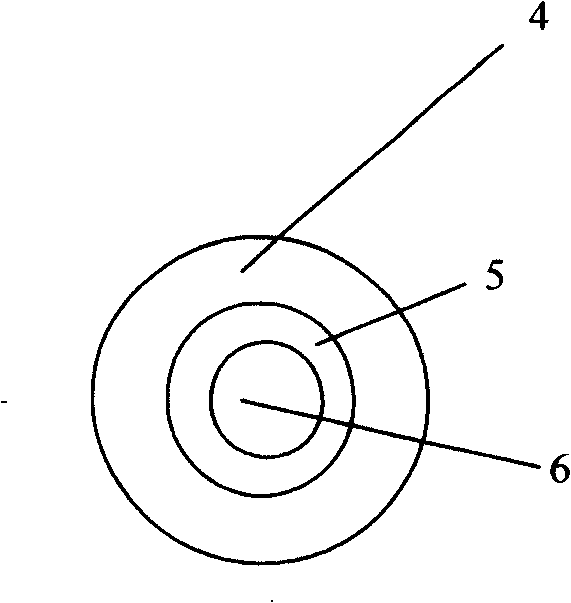

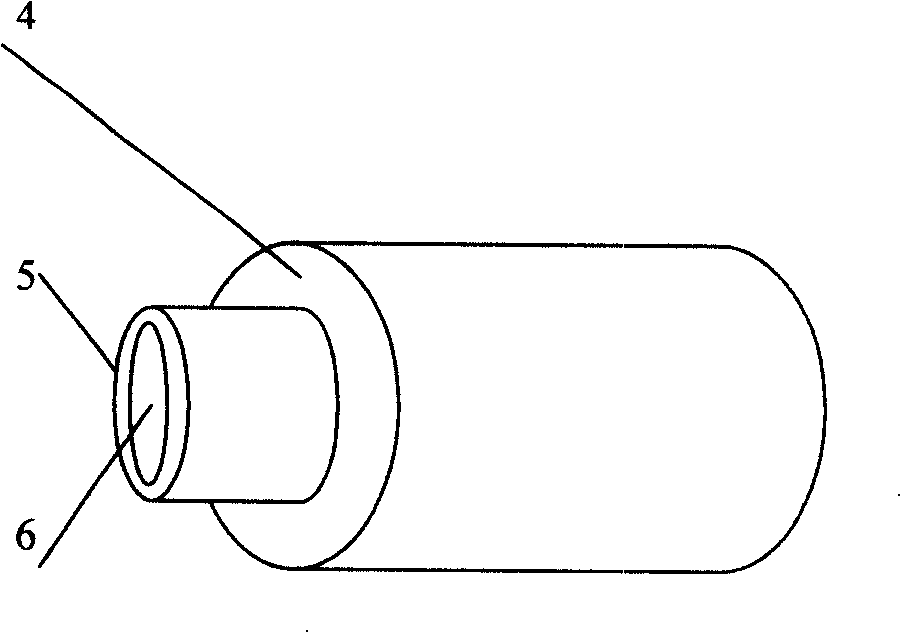

[0009] Embodiment one, a kind of circular cross-section copper clad aluminum core magnet wire of the present invention (see figure 1 , figure 2 ), the inner circle of the electromagnetic wire is an aluminum wire 6 outsourcing a layer of cylindrical copper 5 electromagnetic wire, forming a copper-clad aluminum conductor wire, a single electromagnetic wire outsourcing with polyvinyl chloride or polyethylene or cross-linked polyethylene or Layer of rubber insulating material4. The implementation plan is exactly the same as the production process of ordinary copper core wires, that is, the insulation material is extruded around the copper-clad aluminum conductor through an extruder, and then cooled, rewinded, printed and packaged to become a finished copper-clad aluminum core electromagnetic wire.

Embodiment 2

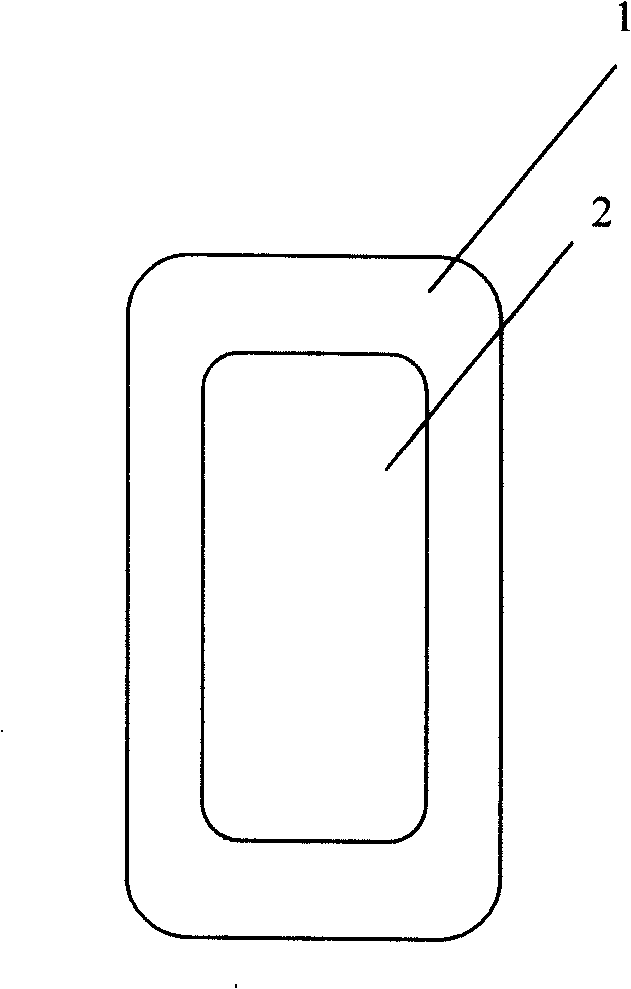

[0010] Embodiment two, a copper clad aluminum core magnet wire with a rectangular cross-section of the present invention (see image 3 , Figure 4 ), the inner core 2 of the electromagnetic wire is a rectangular aluminum wire covered with a layer of rectangular cylindrical copper-covered electromagnetic wire, forming a copper-clad aluminum conductor wire. Using copper-clad aluminum conductors as raw materials, the conductors are processed into non-insulated round or flat electromagnetic wires through traditional processes, or wrapped around the conductors with insulating materials such as paper, insulating varnish and (or) glass filaments, to form strips. Magnet wire with insulation. Magnet wires are wound into transformer coils and soaked in insulating oil to form insulated solenoid coils. The copper-clad aluminum core magnet wire has the same electrical conductivity as the copper core magnet wire of the same specification. It is light in weight, easy to process, and conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com