A kind of composite conductive agent, its preparation method and electrode material containing it

A composite conductive agent, graphene technology, applied in battery electrodes, circuits, electrical components and other directions, can solve the problems of weakening the conductivity of graphene lithium ion steric hindrance effect, etc., to improve the electron transport capacity, the preparation method is simple and easy Operation, the effect of improving the electron transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

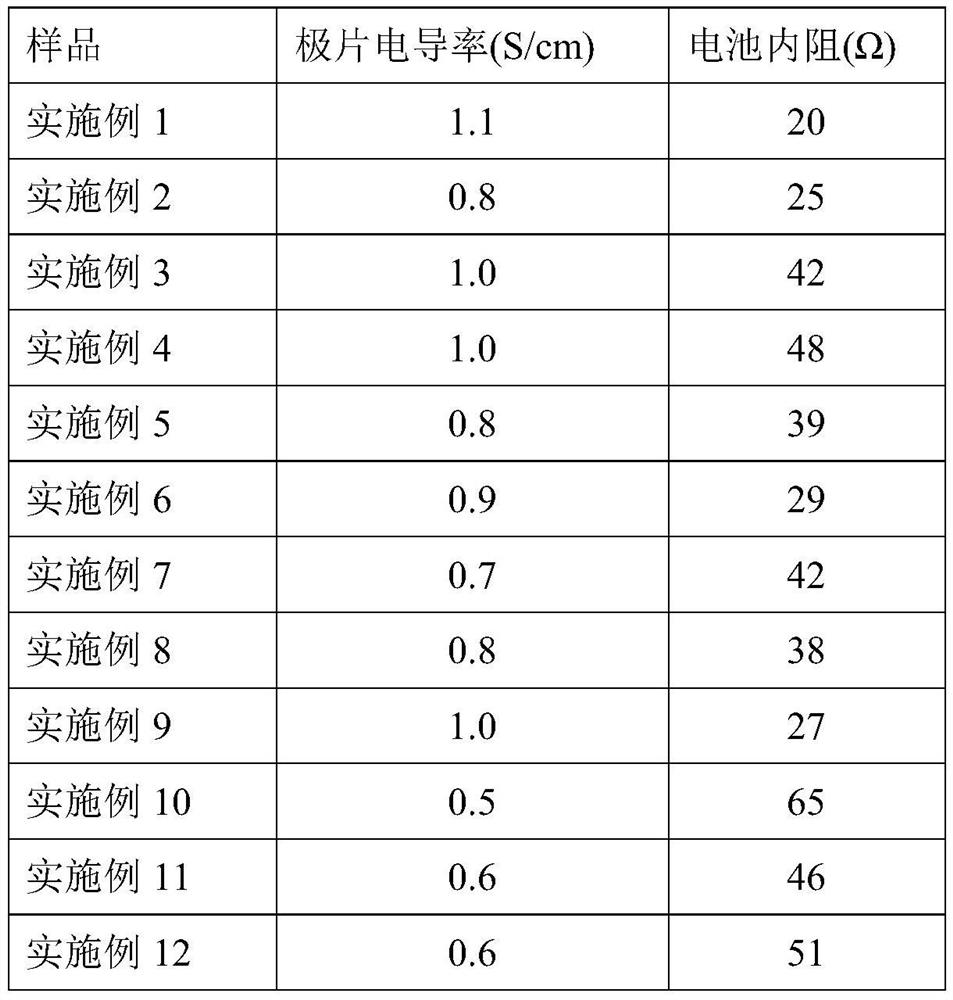

Embodiment 1

[0055] This embodiment provides a composite conductive agent and a preparation method thereof.

[0056] The preparation method of the composite conductive agent of the present embodiment is as follows:

[0057] (1) 9 g of oxide oxide is dispersed in 1.8 kg of tetrahydrofuran to obtain a graphene dispene, wherein the oxide oxide has a diameter of 0.05 μm.

[0058] (2) 1 g of carbon nanotubes were added to 20 mL of concentrated nitric acid, and heat refluxed at 75 ° C for 4 h, and then filtered, washed twice with deionized water, centrifuged, at 80 ° C for 6 h, redistributed in tetrahydrofuran, obtained Carbon oxide nanotube dispersion, wherein the carbon nanotubes have a diameter of 50 nm and a length of 5 μm.

[0059] (3) Mix the oxide nanotube dispersion obtained by step (1) and the carbon oxide nanotube dispersion obtained by step (2), adding 0.1 g of 1- (3-dimethylaminopropyl) -3-B Mixed solution of base carbon diimide hydrochloride (EDC) and 0.1 g of N-hydroxybutyimide (NHS), ...

Embodiment 2

[0065] This embodiment provides a composite conductive agent and a preparation method thereof.

[0066] The preparation method of the composite conductive agent of the present embodiment is as follows:

[0067] (1) 5 g of oxide oxide is dispersed in 1.5 kg of tetrahydrofuran to obtain a graphene dispene dispersion, wherein the oxide oxide has a diameter of 0.5 μm.

[0068] (2) 1 g of carbon nanotubes were added to 20 mL of concentrated nitric acid, and the heat reflux was 0.5 h at 90 ° C, and then filtered, washed twice with deionized water, centrifuged at 80 ° C for 6 h, and redistributed in tetrahydrofuran. The carbon oxide nanotube dispersion is obtained, wherein the carbon nanotube has a diameter of 500 nm and a length of 0.5 μm.

[0069] (3) Mix the oxide nanotube dispersion obtained by step (1) and the carbon oxide nanotube dispersion obtained by step (2), adding 0.1 g of 1- (3-dimethylaminopropyl) -3-B Mixed solution of carbon diimide hydrochloride (EDC) and 0.1 g of N-hydr...

Embodiment 3

[0071] This embodiment provides a composite conductive agent and a preparation method thereof.

[0072] The preparation method of the composite conductive agent of the present embodiment is as follows:

[0073] (1) 15 g of oxide oxide is dispersed in 2 kg of tetrahydrofuran to obtain a graphene dispene, wherein the oxide oxide has a diameter of 1 μm.

[0074] (2) 1 g of carbon nanotubes were added to 20 mL of concentrated nitric acid, and heat reflux at 60 ° C for 12 h, and then filtered, washed twice with deionized water, centrifuged, 120 ° C for 2 h, and reissue in tetrahydrofuran. Carbon oxide nanotube dispersion, wherein the carbon nanotubes have a diameter of 100 nm and a length of 1 μm.

[0075] (3) Mix the oxide nanotube dispersion obtained by step (1) and the carbon oxide nanotube dispersion obtained by step (2), adding 0.1 g of 1- (3-dimethylaminopropyl) -3-B Mixed solution of base carbon diamine hydrochloride (EDC) and 0.1 g of N-hydroxybutyimide (NHS), at 150 ° C temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com