Composite conductive agent and preparation method thereof and electrode material containing composite conductive agent

A technology of composite conductive agent and electrode material, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of weakening the conductivity of graphene lithium ion steric hindrance effect, etc., to improve the electron transport ability and electron transport performance. , the effect of reducing the demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

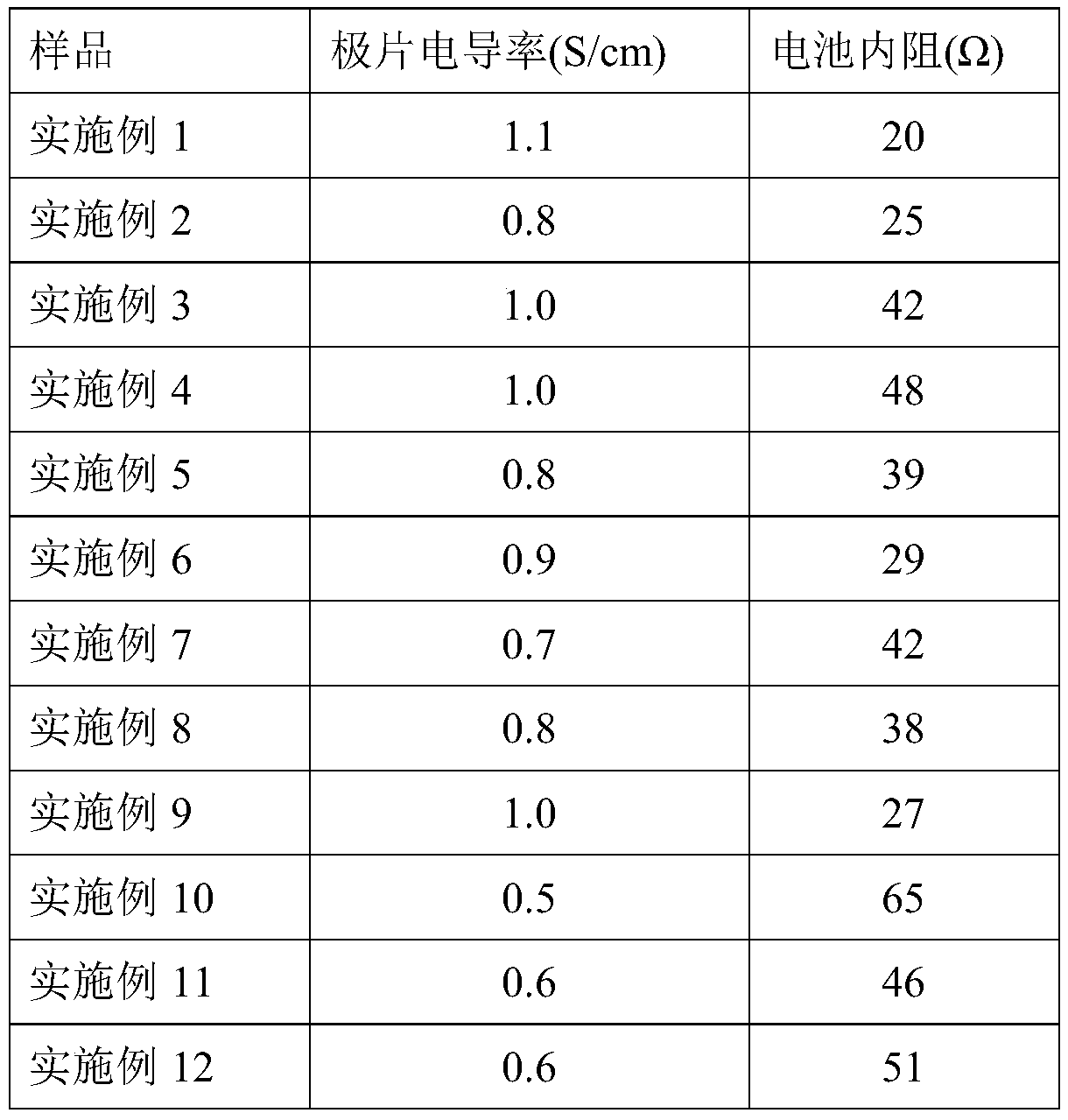

[0055] This embodiment provides a composite conductive agent and its preparation method

[0056] The preparation method of composite conductive agent described in this embodiment is as follows:

[0057] (1) Disperse 9 g of graphene oxide in 1.8 kg of tetrahydrofuran to obtain a graphene oxide dispersion, wherein the diameter of the graphene oxide is 0.05 μm.

[0058] (2) Add 1 g of carbon nanotubes to 20 mL of concentrated nitric acid, heat to reflux at 75 °C for 4 h, filter after cooling, wash twice with deionized water, centrifuge, dry at 80 °C for 6 h, and redisperse in tetrahydrofuran to obtain Oxidized carbon nanotube dispersion, wherein the carbon nanotubes have a diameter of 50 nm and a length of 5 μm.

[0059] (3) Mix the graphene oxide dispersion obtained in step (1) with the carbon dioxide nanotube dispersion obtained in step (2), then add 0.1 g of 1-(3-dimethylaminopropyl)-3-ethane A mixed solution of carbodiimide hydrochloride (EDC) and 0.1 g of N-hydroxysuccinim...

Embodiment 2

[0065] This embodiment provides a composite conductive agent and its preparation method

[0066] The preparation method of composite conductive agent described in this embodiment is as follows:

[0067] (1) Disperse 5 g of graphene oxide in 1.5 kg of tetrahydrofuran to obtain a graphene oxide dispersion, wherein the graphene oxide has a diameter of 0.5 μm.

[0068] (2) Add 1 g of carbon nanotubes to 20 mL of concentrated nitric acid, heat to reflux at 90°C for 0.5h, filter after cooling, wash twice with deionized water, centrifuge, dry at 80°C for 6h, and redisperse in tetrahydrofuran, A dispersion of oxidized carbon nanotubes was obtained, wherein the carbon nanotubes had a diameter of 500 nm and a length of 0.5 μm.

[0069] (3) Mix the graphene oxide dispersion obtained in step (1) with the carbon dioxide nanotube dispersion obtained in step (2), then add 0.1 g of 1-(3-dimethylaminopropyl)-3-ethane A mixed solution of carbodiimide hydrochloride (EDC) and 0.1 g of N-hydroxy...

Embodiment 3

[0071] This embodiment provides a composite conductive agent and its preparation method

[0072] The preparation method of composite conductive agent described in this embodiment is as follows:

[0073] (1) Disperse 15 g of graphene oxide in 2 kg of tetrahydrofuran to obtain a graphene oxide dispersion, wherein the graphene oxide has a diameter of 1 μm.

[0074] (2) Add 1 g of carbon nanotubes to 20 mL of concentrated nitric acid, heat and reflux at 60°C for 12h, filter after cooling, wash twice with deionized water, centrifuge, dry at 120°C for 2h, and redisperse in tetrahydrofuran to obtain Oxidized carbon nanotube dispersion, wherein the carbon nanotubes have a diameter of 100 nm and a length of 1 μm.

[0075] (3) Mix the graphene oxide dispersion obtained in step (1) with the carbon dioxide nanotube dispersion obtained in step (2), then add 0.1 g of 1-(3-dimethylaminopropyl)-3-ethane A mixed solution of carbodiimide hydrochloride (EDC) and 0.1g of N-hydroxysuccinimide (N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com