Patents

Literature

33results about How to "Low carbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Building silt soil non-sintered ceramic aggregate and preparation method thereof

ActiveCN102617107ASimple technical processEasy accessSolid waste managementSolid componentEnvironmental resistance

The invention discloses a building silt soil non-sintered ceramic aggregate, which is characterized by comprising solid components and water, wherein every kilogram of solid components comprise the following components in percentage by weight: 60-80 percent of building silt soil, 2-5 percent of cement, 2-5 percent of quick lime, 2-5 percent of desulfurized gypsum, 2-7 percent of perlite, 2-8 percent of fly ash and 5-10 percent of water glass; and the amount of the water accounts for 45-60 percent of the total mass of the solid components. The invention also discloses a preparation method of the ceramic aggregate. The ceramic aggregate and the preparation method thereof have the characteristics of simple pretreatment of building silt soil, simple preparation process and capabilities of eliminating industrial wastes such as fly ash and desulfurized gypsum without large-sized calcining equipment and expanding the utilization approach of the solid waste material; and by adopting a non-sintering process, the ceramic aggregate and the preparation method thereof have the advantages of environmental protection effects such as energy conservation and low carbon compared with a roasting process.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

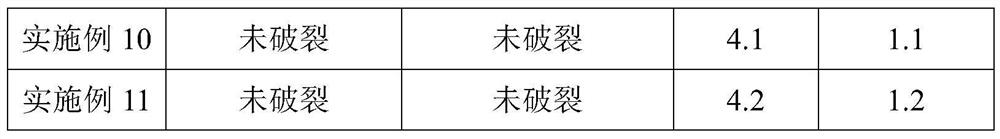

Municipal sludge non-sintered ceramsite and production method thereof

The invention discloses a municipal sludge non-sintered ceramsite and a production method thereof. The municipal sludge non-sintered ceramsite is produced from, by weight, 40-60% of municipal sludge, 20-30% of cement, 5-10% of fly ash, 3-7% of desulfurized gypsum, 3-7% of slag micro-powder and 4-6% of sodium silicate, wherein the municipal sludge is deodorized municipal sludge, and the content of the municipal sludge is controlled to be 70-80%; the content of free water in the desulfurized gypsum is 10-15%, the average granularity is 20-50 [mu]m, and the 200 mesh screen residue is 5.2%; the ignition loss of the slag micro-powder is 1.77%, and the specific surface area of the reduced slag micro-powder is 450 m<2> / kg; and the sodium silicate is powdery, the mass percentage of water-insoluble substances is not greater than 0.04%, the mass percentage of water is not greater than 25%, the modulus is 2.6-2.8, and the granularity is 20-40 meshes. The municipal sludge non-sintered ceramsite can digest a large amount of municipal sludge, and also can digest fly ash, slag micro-powder, desulfurized gypsum and other industrial wastes, so the utilization approach of above solid wastes is widened; and compared with a roasting technology, a non-sintering technology adopted by the above product has the advantages of energy saving, low carbon and environmental protection.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

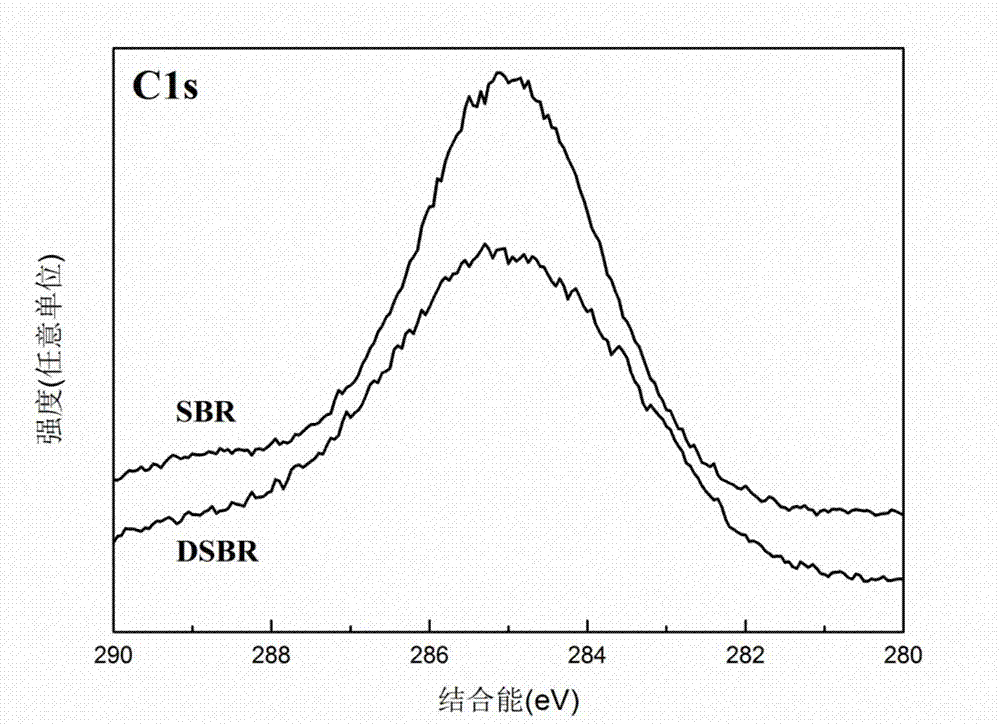

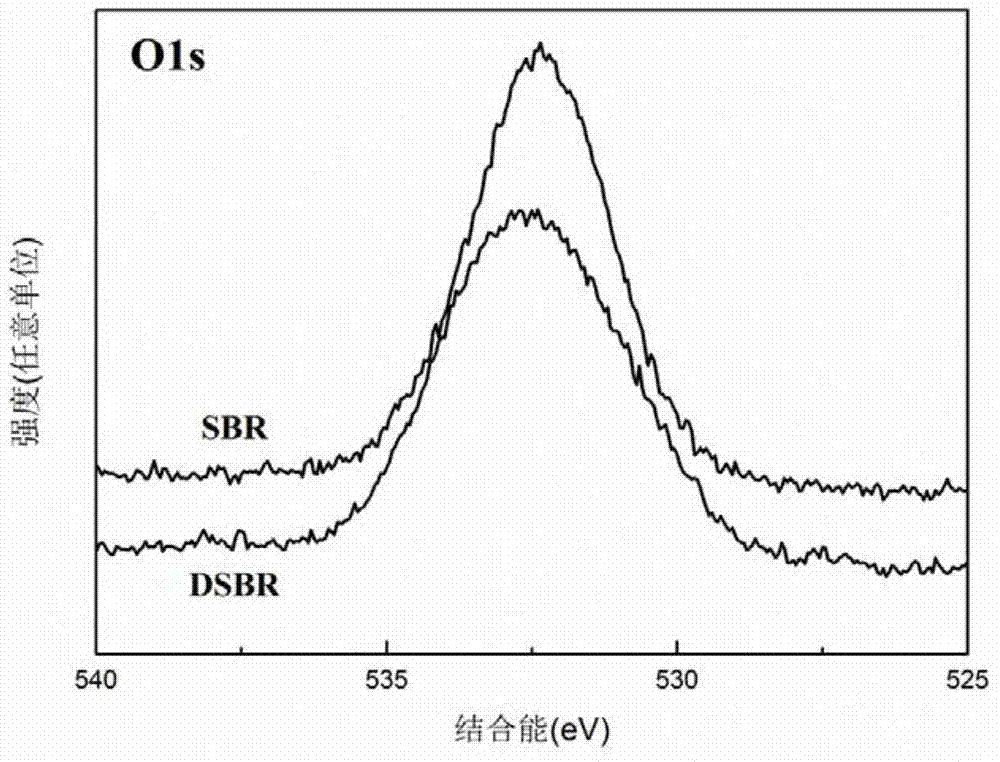

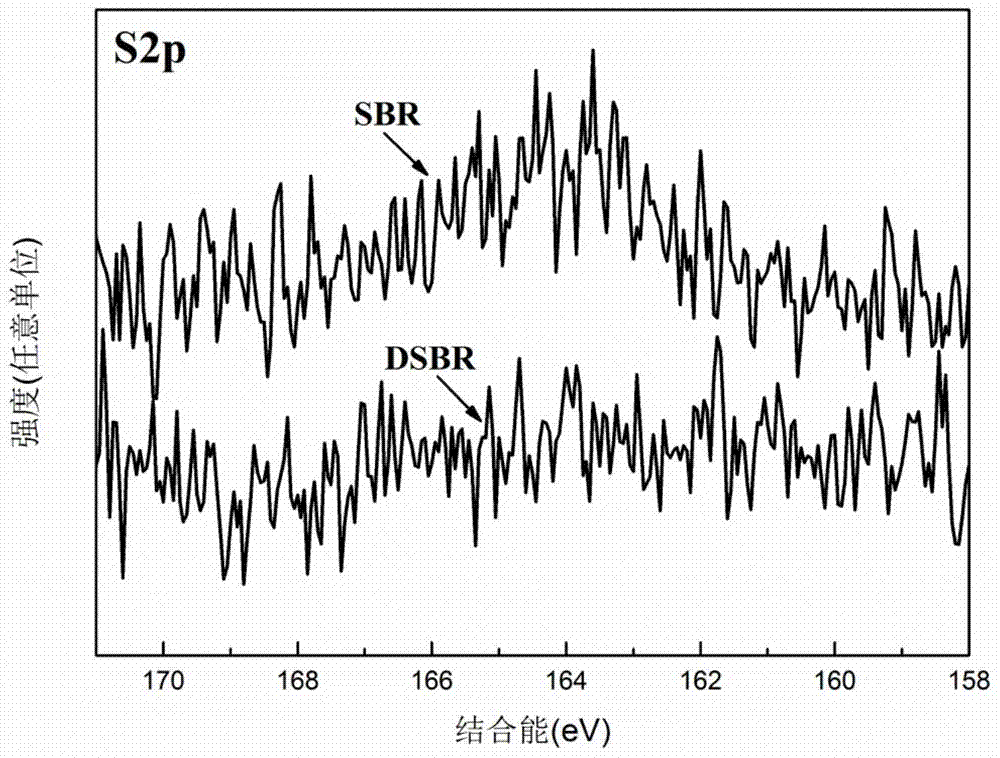

Method for desulfurating and regenerating waste rubber by using microbes

ActiveCN103923945AIntegrity guaranteedLow carbonPlastic recyclingMicroorganism based processesCulture fluidWaste rubber

The invention relates to a method for desulfurating and regenerating waste rubber. Microbes and waste vulcanized rubber powder co-culture desulphurase generated in the metabolic process to catalyze breakage of the S-S or S-C cross bond on the surface of vulcanized rubber, so that the surfaces of waste vulcanized rubber particles are decrosslinked in a certain depth range, thus reaching the purpose of desulfuration and regeneration of waste rubber. In the method, the medium component of Gordonia amicalis with good desulfurating effect and the conditions of the coculture desulfurization process are determined, wherein the conditions include the glucose concentration and strain inoculum size in a culture medium, as well as the reaction temperature and time, culture solution pH and reactor stirring speed in a reaction process; through measurement of crosslinking density of rubber powder and the detection of the surface element content of the rubber powder show that the crosslinking density and the surface elemental sulfur content of the desulfurated rubber powder are reduced and the oxygen content of the desulfurated rubber powder is increased, compared with undesulfured rubber powder.

Owner:BEIJING UNIV OF CHEM TECH

Method for processing dandelion fiber by electrostatic flocking

ActiveCN104742487AReduce processing costsEasy to collectLiquid surface applicatorsLamination ancillary operationsCooking & bakingEnvironmental resistance

The invention discloses a method for processing a dandelion fiber by electrostatic flocking, which comprises the steps of feeding, adhesive coating and scraping, electrostatic flocking, baking, brushing, and after-finish. According to the invention, a novel natural fiber material is developed and utilized, so that an effect of changing waste material into things of value is achieved; the dandelion fiber is low in processing cost and convenient to collect; and the dandelion fiber has an effect of clearing away heat and has a health effect. However, the length of the dandelion fiber is only 10-15 mm, so that the dandelion fiber does not have spinnability, can not be used for spinning and only can be used as a filler material. Electrostatic flocking is a new production process produced by using the natural characteristics of charges, provides a direction for the application of a novel natural fiber in textiles, and meets the requirements of textiles on environmental protection, low carbon, and health.

Owner:IANGSU COLLEGE OF ENG & TECH

Technique for making mouldproof antibacterial wood plastic composite

The invention relates to a mouldproof antibacterial wood plastic composite, comprising the following components in percentage by weight: 20-45% of polypropylene, 50-70% of crop straw powder, 0.2-8.0% of compound mouldproof antibacterial agent, 0.2-2.0% of lubricating agent, 3-15% of toughening agent, 1.0-8.0% of coupling agent, 0.0-5.0% of moisture absorbing agent and 0.1-5.5% of other auxiliaries. According to the mouldproof antibacterial wood plastic composite provided by the invention, ratio of the crop straw powder is far higher than 50% under the condition that the comprehensive mechanical performances are well maintained, the mouldproof antibacterial wood plastic composite provided by the invention can be used for producing a product with complex structure and large area by virtue of injection moulding, has natural flavour of timber and high strength, can be coloured as required, is low in cost and simple and convenient to process, meets low-carbon requirement, also has mouldproof and antibacterial functions and is especially preponderant when applied to outdoor, damp and biological contact products.

Owner:KECHUANG POLYMER SUZHOU

Color anti-skid ultrathin wearing layer capable of degrading automobile exhaust and preparation method thereof

The invention relates to a color anti-skid ultrathin wearing layer capable of degrading automobile exhaust and a preparation method thereof. The wearing layer consists of the raw materials as follows: epoxy resin, modified epoxy resin, a composite photocatalyst, amine-terminated polyether, a curing agent, a curing accelerator and aggregates. The wearing layer also can be prepared from the raw materials as follows: double-component polyurethane, a composite photocatalyst, a curing agent, a curing accelerator and aggregates. Before the wearing layer is laid, the original road surface needs to be treated, then paying-off and edge protection are performed, binders are mixed, color anti-wear aggregates capable of degrading exhaust gas are scattered uniformly, non-bonded aggregates are recovered, and finally maintenance of the wearing layer, traffic control and opening are performed. The wearing layer has performances of degrading the automobile exhaust and purifying air, can increase the road friction so as to enable the road surface to maintain excellent water mist-proof and anti-skid pavement performance, achieves effects of traffic warning and environment beautifying visually, and has excellent environmental benefit and social benefit.

Owner:TONGJI UNIV

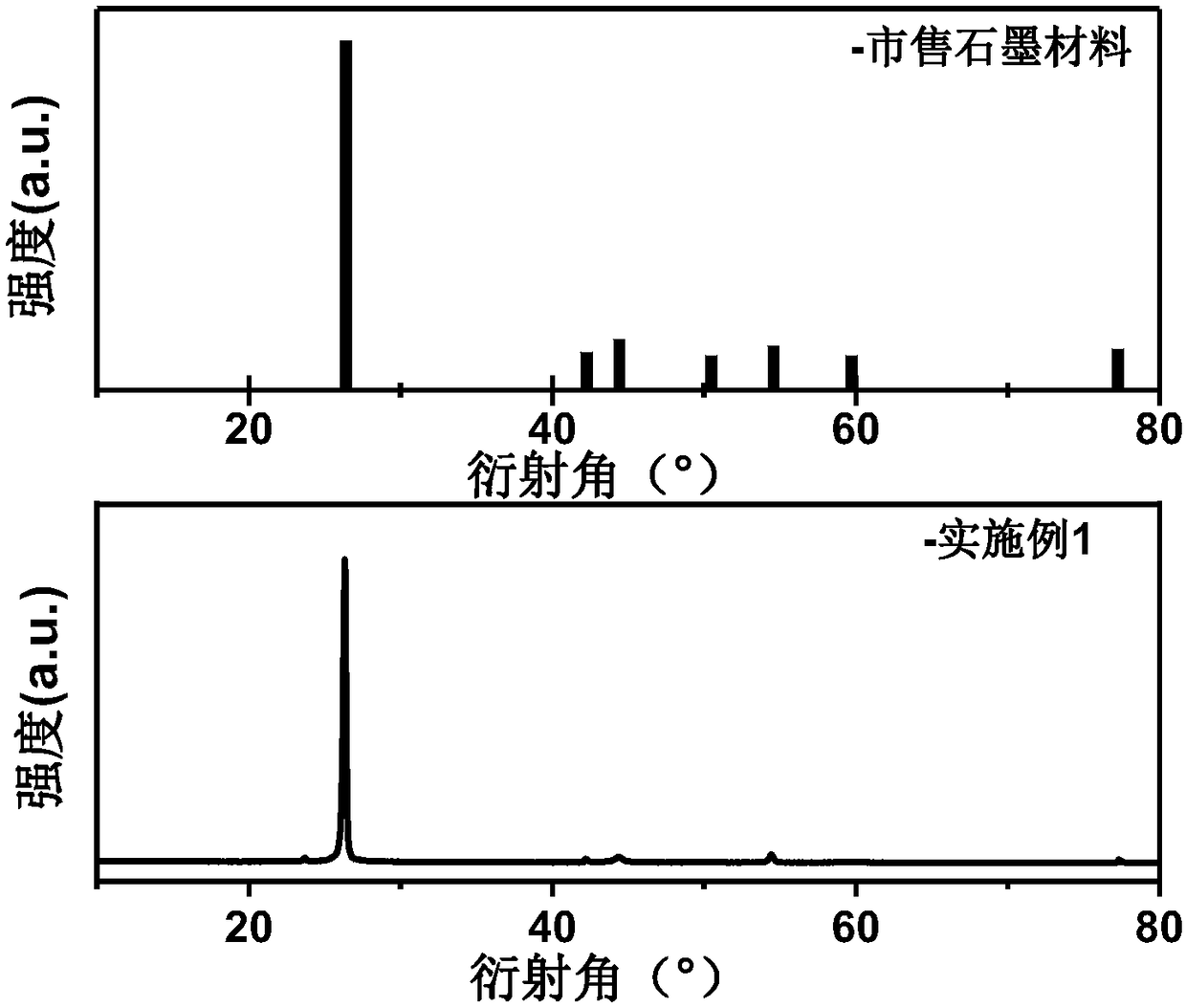

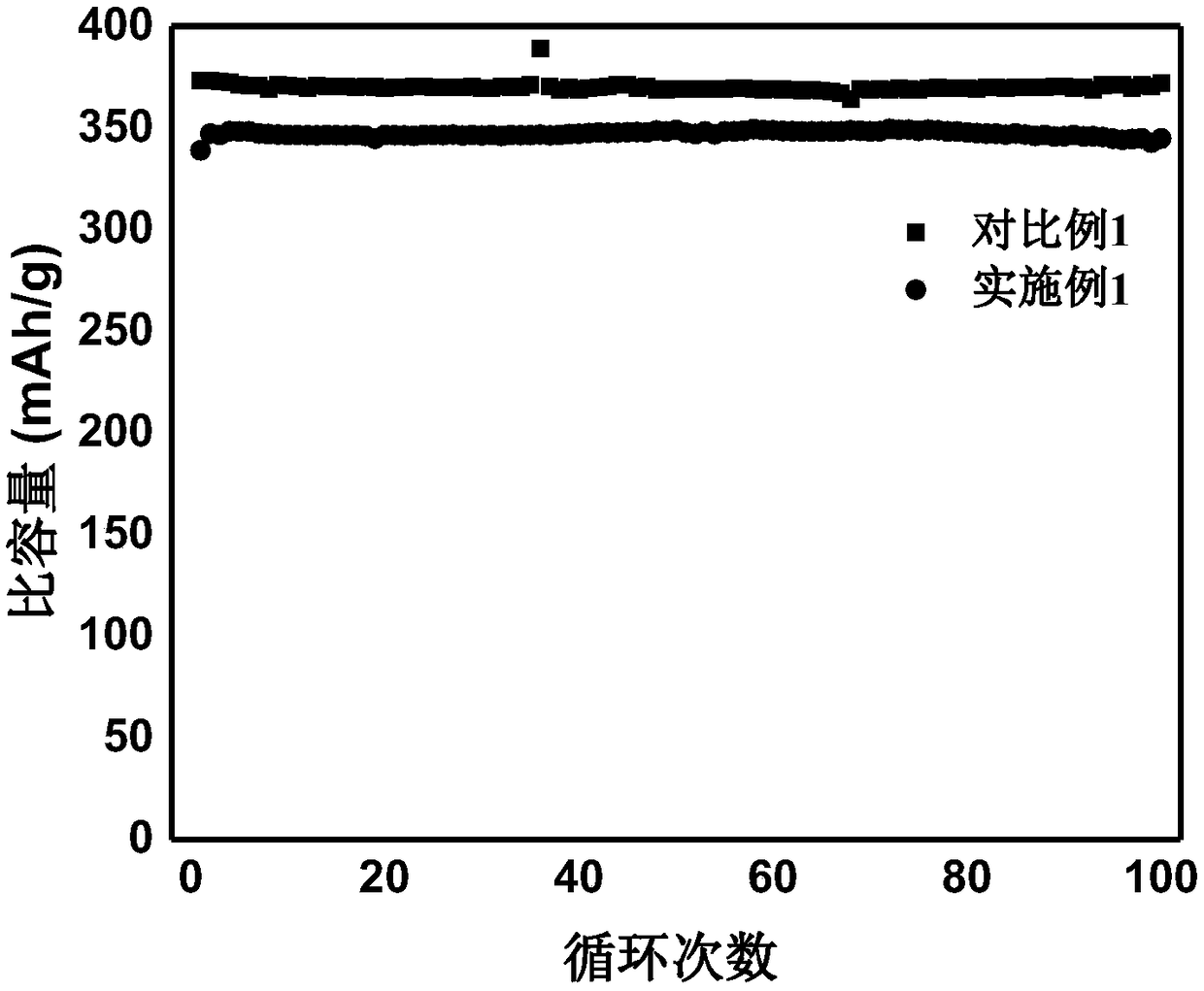

Method for directly recycling graphite anode material

InactiveCN108565521AReduce energy consumptionLow carbonWaste accumulators reclaimingBattery recyclingPower batteryCopper foil

The invention belongs to the technical field of recycling and utilization of an electrode material of a lithium ion power battery, and in particular relates to a method for directly recycling a graphite anode material. The method comprises the following steps: removing an anode electrode piece from a waste lithium ion battery, soaking the anode electrode piece in water, simply separating a graphite anode from a copper foil current collector, and then filtering, drying, grinding and sieving by meshes after changing water for multiple times, so as to obtain the recycled graphite anode material.The method disclosed by the invention is simple and high-efficient, and the obtained electrode material is good in lithium storage performance, excellent in cycle stability, and favorable for recycling the electrode material of the power battery in the industry at a low cost and with low pollution.

Owner:SOUTH CHINA NORMAL UNIVERSITY +1

Baking-free ecological brick made of waste subway engineering mud and making method of baking-free ecological brick

ActiveCN110183202ASolve problems that cannot meet usage standardsCompliant with application standardsSolid waste managementBrickMixed materials

The embodiment of the invention provides a baking-free ecological brick made of waste subway engineering mud and a making method of the baking-free ecological brick and aims to solve the problem thatin the prior art a baking-free brick made of waste subway engineering mud cannot meet use standards because of a too high water content. The baking-free ecological brick comprises the following components in parts by weight: 60-80 parts of waste subway engineering mud, 7.5-20 parts of a dewatering agent, 12-25 parts of a monopotassium phosphate solution and 0.5-2.0 parts of borox. The making method comprises the following steps: putting a dewatering agent with overburnt magnesium oxide into the waste subway engineering mud, and carrying out uniform stirring so as to obtain a mixed material A;putting a monopotassium phosphate solution and borox into the mixed material A, and carrying out uniform mixing so as to obtain a mixed material B, wherein the water content of the mixed material B is22-30%; carrying out coextrusion on the mixed material B so as to obtain a primary brick block; and maintaining the primary brick block for days in an environment of which the temperature is 18-22 DEG C and the RH (relative humidity) is greater than or equal to 65%, so as to obtain the baking-free ecological brick.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

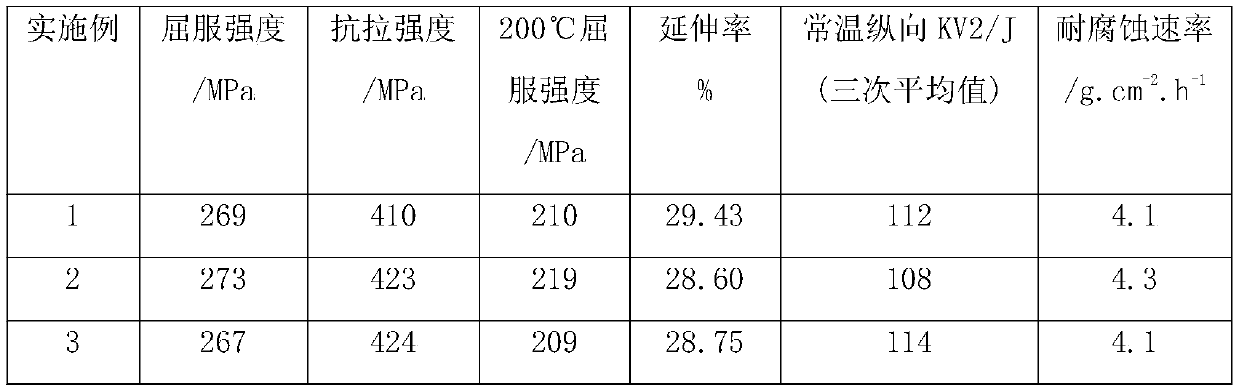

Preparation method of low-cost sulfuric-acid-corrosion-resistant 09CrCuSbRE hot-rolled round steel

InactiveCN111560556ACorrosion loss mass reductionReduce corrosion rateFurnace typesHeat treatment furnacesSteelmakingHeat conservation

The invention discloses a preparation method of low-cost sulfuric-acid-corrosion-resistant 09CrCuSbRE hot-rolled round steel. A steelmaking technological process of the preparation method comprises the steps of converter smelting, external refining, VD vacuum treatment and continuous casting. A steel rolling technological process comprises the steps of casting blank heating, high-pressure water dephosphorization, phi 850 mm cogging mill treatment, phi 700 mm*3+phi 550 mm*4 continuous rolling unit rolling, saw cutting, slow cooling, nondestructive testing, stacking, checking, trimming, bundling, warehousing and delivery. The technical parameters controlled in the rolling process are as follows: the heating temperature is 1150 to 1200 DEG C, and the heat preservation time is more than or equal to 3 hours; the initial rolling temperature is lower than or equal to 1100 DEG C; the final rolling temperature is lower than or equal to 780 DEG C; the slow cooling time is longer than or equal to48 hours; and a rolled tissue is a ferrite and pearlite tissue. Through delivery in a hot-rolled state, a complex heat treatment process is not needed, and a wide process window is realized.

Owner:BAOTOU IRON & STEEL GRP

Process for manufacturing paper pulp by active method and with fresh bamboo as raw material

InactiveCN109811570AIntegrity guaranteedNo pollution in the processNon-woody plant/crop pulpFiberUltra high pressure

The invention provides a process for manufacturing paper pulp by an active method and with fresh bamboo as a raw material. The process comprises the steps that bamboo cutting is performed; slicing isperformed; ultra-high pressure grading rolling is performed, specifically, bamboo chips are placed in a rolling roll for grading rolling, wherein grading rolling includes four to six grades of rolling, and the rolling pressure of each grade is gradually increased; thread rolling is performed; primary filtration extrusion is performed to obtain initially filtered bamboo pulp; secondary filtration extrusion is performed, specifically, water is added to the initially filtered bamboo pulp and then heating and stirring are performed, then physical filtration and secondary extrusion are sequentiallyperformed to obtain re-filtered bamboo pulp, and the total time is not more than 72h from the beginning of raw bamboo cutting to secondary filtration extrusion; and a biological enzyme is softened and released. The process rapidly separates lignin, amino acid, flavone, proteins and the like from bamboo fiber when lignin, amino acid, flavone, proteins and the like are still in a liquid state, is conducive to maintaining the integrity of the bamboo fiber to the utmost extent, is simple in operation and low in cost, is energy-saving, environmentally friendly and low-carbon, and is worth popularizing and applying.

Owner:樊士英

Thermal transfer ribbon and preparation method thereof

InactiveCN110370834ARaw materials are simpleWide variety of sourcesInk ribbonsThermographyEngineering

The invention provides a thermal transfer ribbon and a preparation method thereof. The ribbon consists of a substrate, a back coating and an oil ink layer, wherein the back coating and the oil ink layer are separately coated with the two sides of the substrate. The preparation method adopts a coating process. According to the thermal transfer ribbon and the preparation method thereof disclosed bythe invention, raw materials are simple, sources of the raw materials are wide, a low-carbon and environment-protection concept can be conformed, and expansion of the ribbon application fields is facilitated.

Owner:湖南鼎一致远科技发展股份有限公司

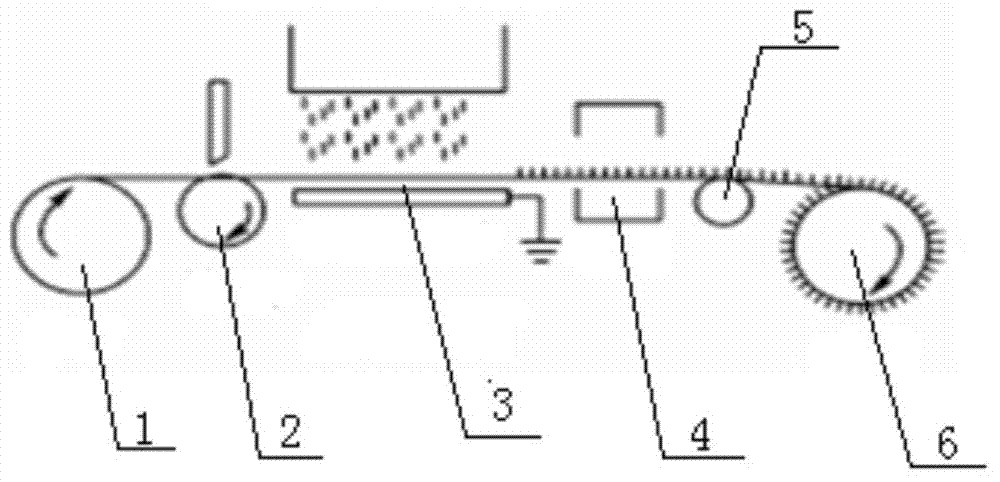

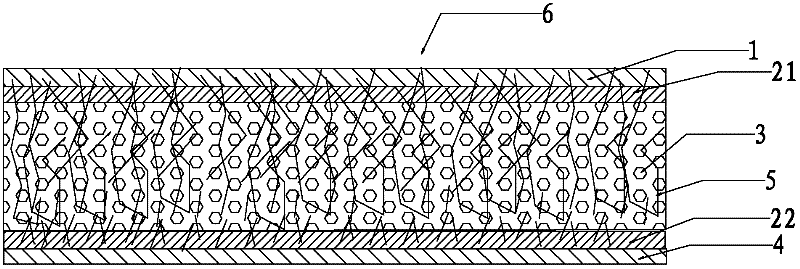

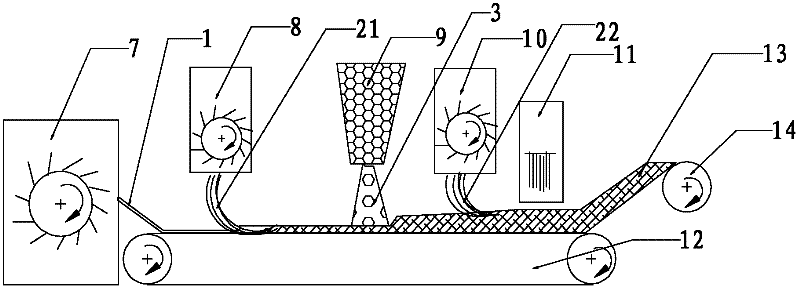

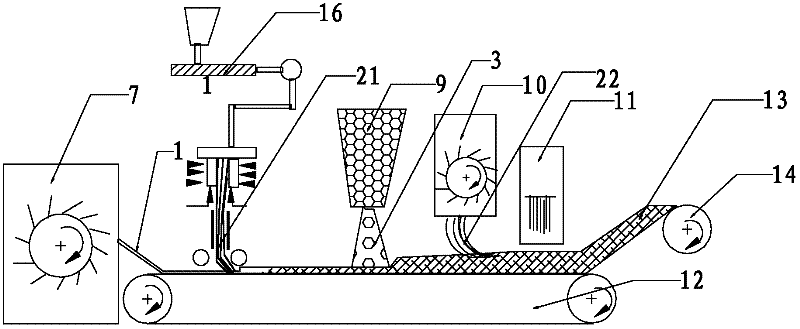

Manufacturing method for disposable sanitary base material and production line thereof

InactiveCN102555367AReduce production capacityReduce process linksSynthetic resin layered productsLaminationProduction lineEnvironmental resistance

The invention discloses a manufacturing method for a disposable sanitary base material and a production line for the manufacturing method. In the manufacturing method, a surface layer is formed on a net strip through net forming by first net-forming equipment; a first wrapping layer is formed on the surface layer through a net formed by second net-forming equipment; paving equipment is used for paving a water-absorbing material on the first wrapping layer to form an absorbing layer; a second wrapping layer is formed on the absorbing layer through a net formed by third net-forming equipment; and curing equipment is used for curing all the stacked layers to form the disposable sanitary base material. For the manufacturing method, on one production line, the surface layer, the wrapping layers and the absorbing layer are subjected to on-line production, and are stacked and cured together, so that the disposable sanitary base material is formed, the production steps and the production links for upstream suppliers are greatly reduced, for example, production links such as winding, unwinding, slitting and packaging for the surface layer and the wrapping layers are reduced, the rejection rate is reduced, the using amount of glue is reduced, the transportation amount is reduced, so that the cost is greatly reduced, and the function of low carbon and environmental production is achieved; and with the reduction of the using amount of glue, the product is more friendly and safer to the human bodies.

Owner:SHANDONG JUNFU NONWOVEN MATERIALS

Phase-change energy storage ceramsite and preparation method thereof

The invention discloses phase-change energy storage ceramsite and a preparation method thereof, relating to the technical field of phase-change energy storage materials. The phase-change energy storage ceramsite contains the following raw materials in parts by weight: 50-70 parts of diatom plate polishing waste, 3-5 parts of quick lime, 20-50 parts of gel materials, 20-30 parts of solid-liquid organic phase-change energy storage materials and 15-40 parts of water. The preparation method comprises the steps of mixing the raw materials in a formula ratio, and carrying out granulation and room-temperature maintenance, so as to obtain the ceramsite. According to the phase-change energy storage ceramsite, the diatom plate polishing waste and the quick lime are taken as the raw materials, the solid-liquid organic phase-change energy storage materials are taken as an energy storage material, the raw materials and the energy storage material are matched with the gel materials so as to generatethe light and high-strength phase-change energy storage ceramsite, so that the application defect of fusion leakage of an organic phase-change material is remedied by virtue of the microstructure advantages and relatively high adsorption capacity of diatom plate polishing powder, and the high-added value functional utilization of the diatom plate polishing waste is realized. By utilizing fire-free and steam-free manners, the pretreatment of the raw materials is omitted, so that the preparation method has the advantages of simple preparation process, low cost, energy saving and environmental protection and the like.

Owner:江苏古德乐环保科技有限公司 +1

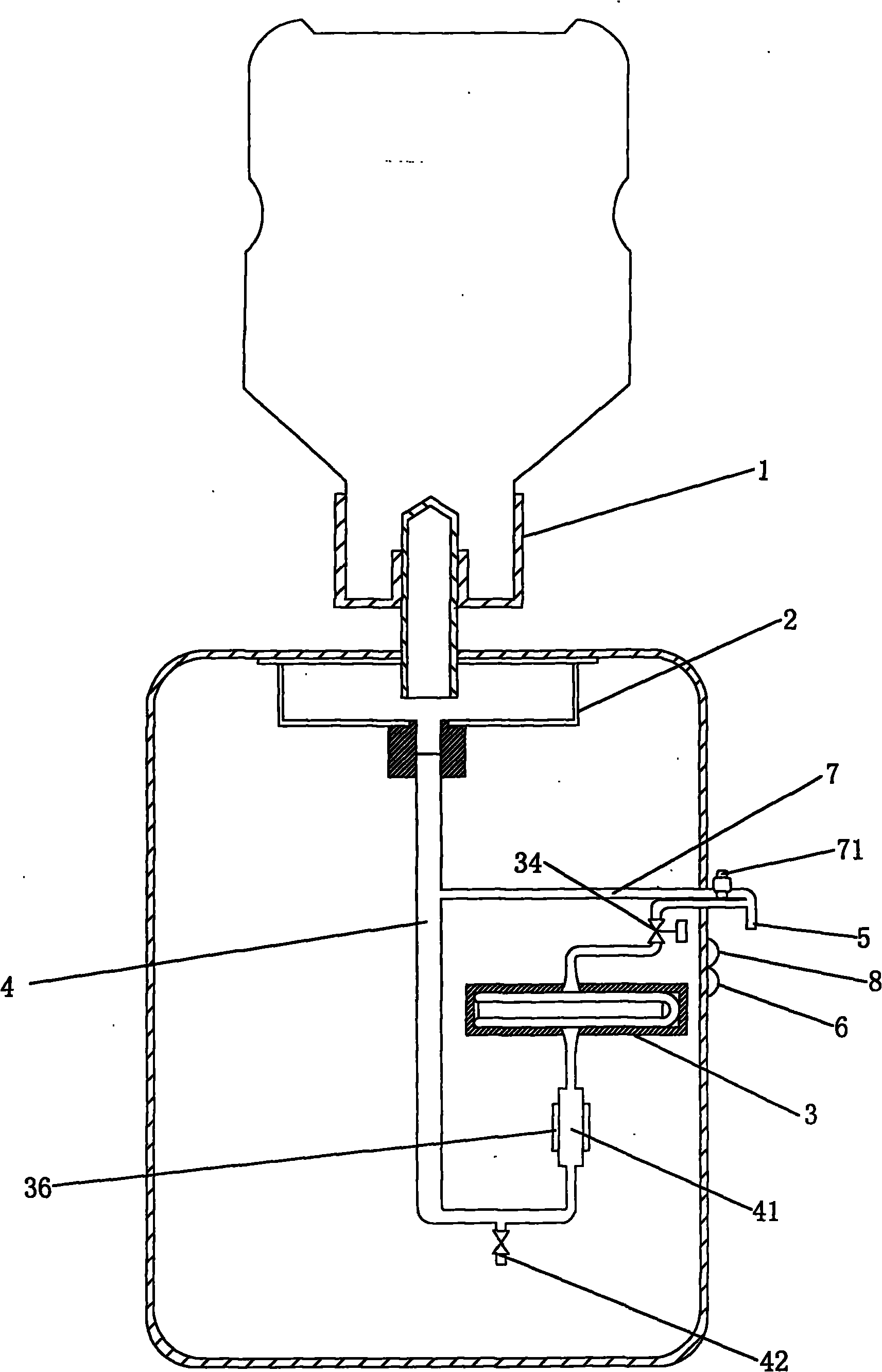

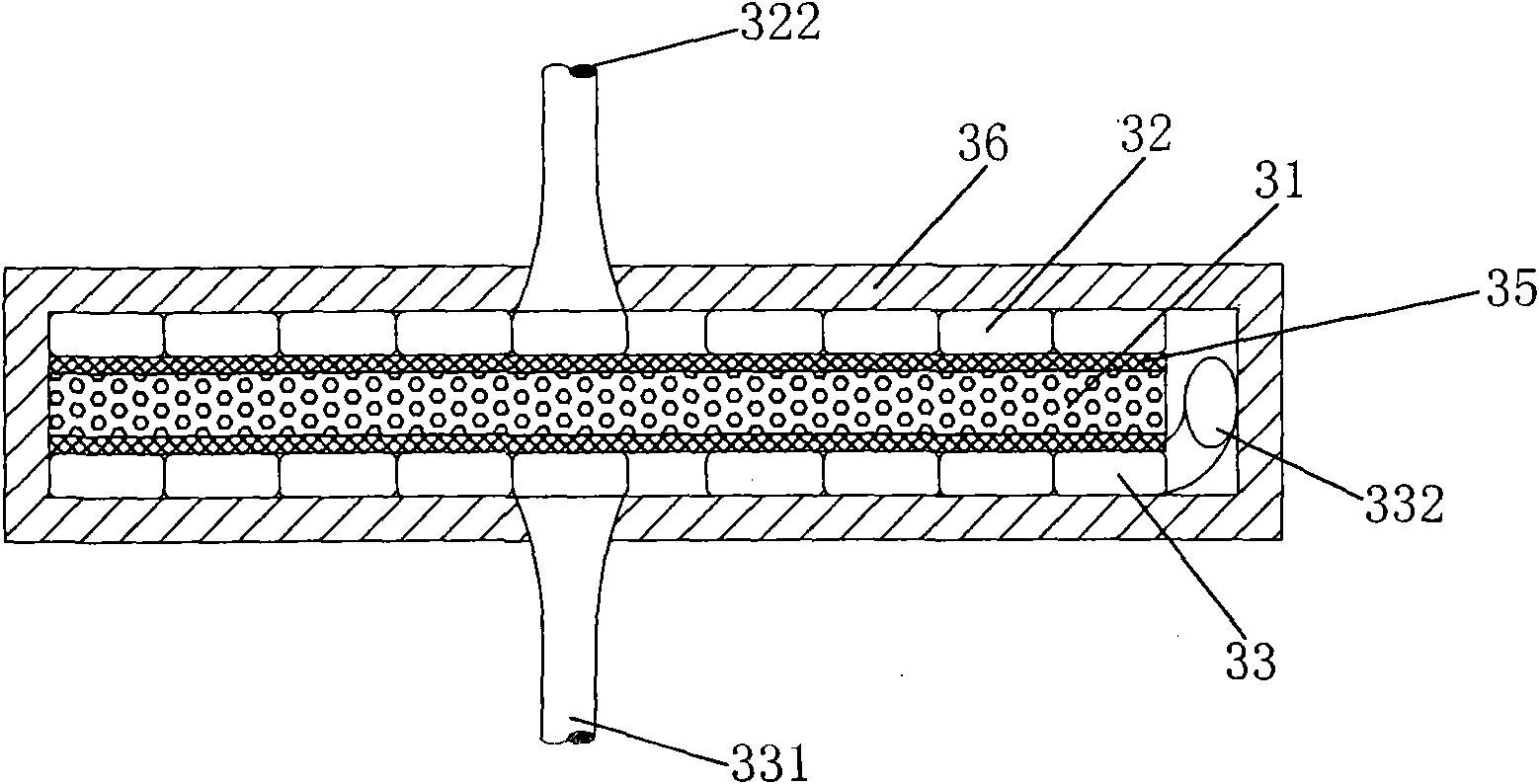

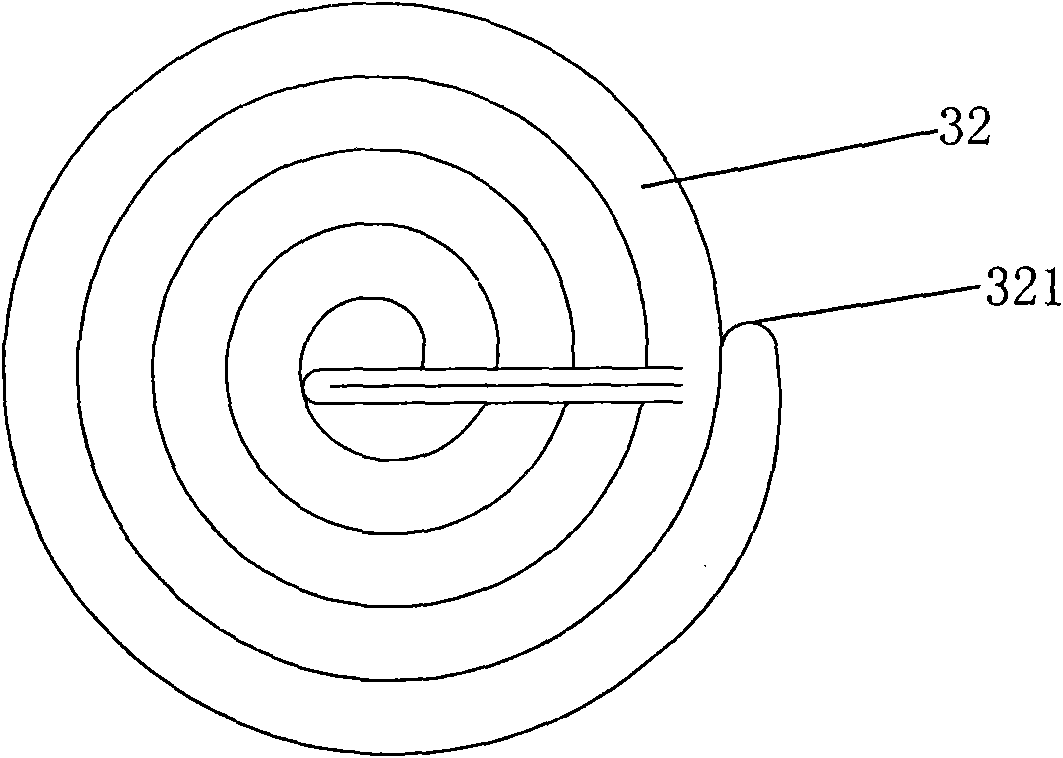

Electromagnetic instant heat drinking water machine

The invention provides an electromagnetic instant heat drinking water machine which supplies required hot water for drinking instantly by utilizing electromagnetic induction. The drinking water machine comprises a shell, a bottle holder, a bucket and a heating body; the heating body comprises a high-frequency induction coil panel as well as an upper metal coil pipe and a lower metal coil pipe which are arranged at the upper side and the lower side of the coil panel, the metal panel is flat, the length of the short side of the section of the inner cavity of the metal panel is 3.0-4.0 mm, and the length of the long side of the section of the inner cavity of the metal panel is 15-30mm; the water feeding end of the lower metal coil pipe is connected with the bucket at the bottom of the bottleholder through a passage water pipe, the water discharging end of the lower metal coil pipe is connected with the water feeding end of the upper metal coil pipe, and the water discharging end of the upper metal coil pipe is connected with a water outlet arranged outside the shell through an electromagnetic valve; the surface of the shell is provided with an electrified switch of the heating body,and the electrified switch is connected with the electromagnetic valve. The drinking water machine provided by the invention has the advantages of rapid rise of temperature, reasonable structure, simple manufacture process and particularly high thermal efficiency, can obtain hot water according with the drinking requirement in short time, and is a novel drinking water machine which can be completely implemented and popularized and accord with the development tread of endowment protection and energy saving.

Owner:王承辉

Processing method of quick flock printing of clothing

InactiveCN106149430AMeet individual needsSmall batchTextile decorationPulp and paper industryEnergy conservation

The invention discloses a processing method for rapid flocking printing of garments, which comprises the following steps: producing flocking paper in a flocking factory - printing paste on garments - laminating the suede surface of the flocking paper with garments - pressing - cooling - go to paper. The invention is a new production process of electrostatic flocking, which can produce small batches and multiple varieties, even one piece of clothing can be produced. The production is convenient, the delivery is fast, and there is no need to go to the flocking factory, which saves energy and ensures quality. It meets the requirements of green, environmental protection, low carbon and health of textiles, and lays a good foundation for the diversification of clothing and the development of flocking printing.

Owner:IANGSU COLLEGE OF ENG & TECH

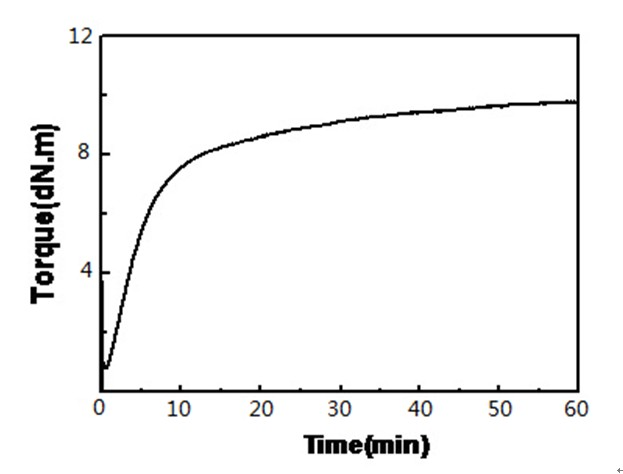

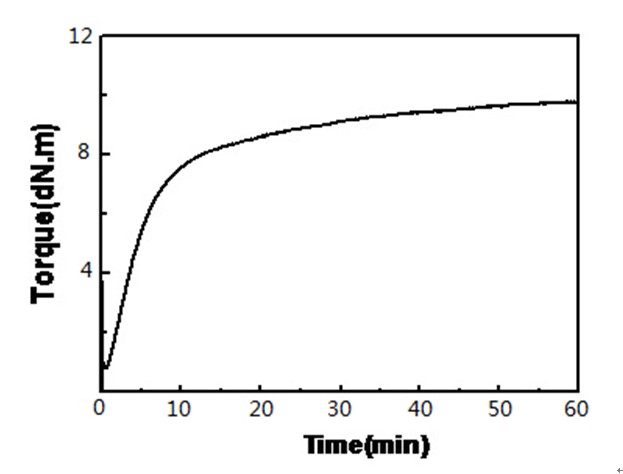

Method for vulcanizing nitrile elastomer

The invention relates to a method for vulcanizing a nitrile elastomer. The method is characterized by comprising the following steps: adding 100 parts by mass of nitrile rubber resin and 5-55 parts by mass of vulcanized cross-linking agent, and mixing at 20-50 DEG C to obtain a composite sizing material; feeding the composite sizing material into reacting equipment at 130-200 DEG C for vulcanization reaction; and discharging after 5-6 minutes and cooling to obtain the nitrile elastomer, wherein the vulcanized cross-linking agent is tartaric acid, malic acid or lactic acid or mixed hydroxy carboxylic acid of two or three of the above hydroxy carboxylic acids mixed at any ratio; and the nitrile rubber resin is chemigum resin, butadiene rubber resin, powdered nitrile rubber, carboxy terminated nitrile rubber resin or liquid carboxy terminated nitrile rubber resin, or the mixed nitrile rubber resin of two or three nitrile resins mixed at any ratio. The method has the advantage of simple vulcanization system, and the cross-linking agent is non-toxic, thereby meeting the requirement of low-carbon and environment-friendly chemical industry development and having wide application prospects.

Owner:FUJIAN NORMAL UNIV

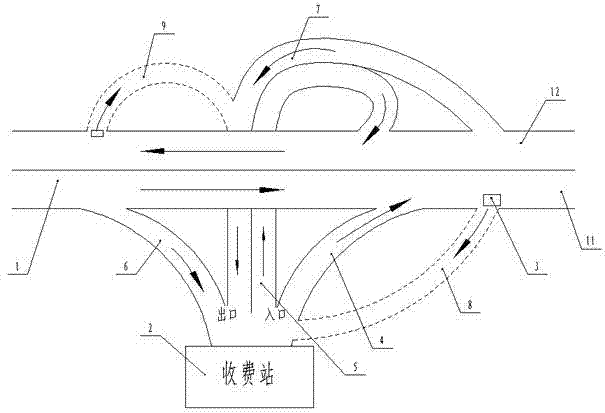

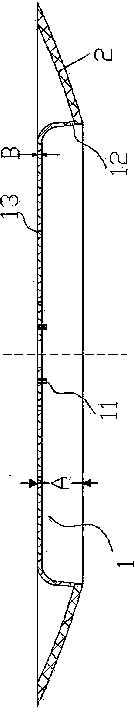

Expressway with error correcting road

The invention belongs to the field of expressway construction, and particularly discloses an expressway with an error correcting road. The expressway with the error correcting road is simple in structure, and convenient to use, and can quickly correct a car moving direction. The expressway comprises a main stem, wherein the main stem comprises a right ramp and a left ramp; a highway toll station is arranged at one side of the main stem; two access channels and two dispatch channels are arranged between the toll station and the main stem; the first access channel is communicated with the right ramp; the second access channel is communicated with the left ramp; the first dispatch channel is communicated with the right ramp; the second dispatch channel is communicated with the left ramp; a first error correcting channel and a second error correcting channel are also arranged between the toll station and the main stem; the first error correcting channel is arranged at the right side of the first access channel and communicated with the right ramp; the second error correcting channel is arranged at the left side of the second dispatch channel; the second error correcting channel is communicated with the left ramp through a culvert below the main stem.

Owner:李朝

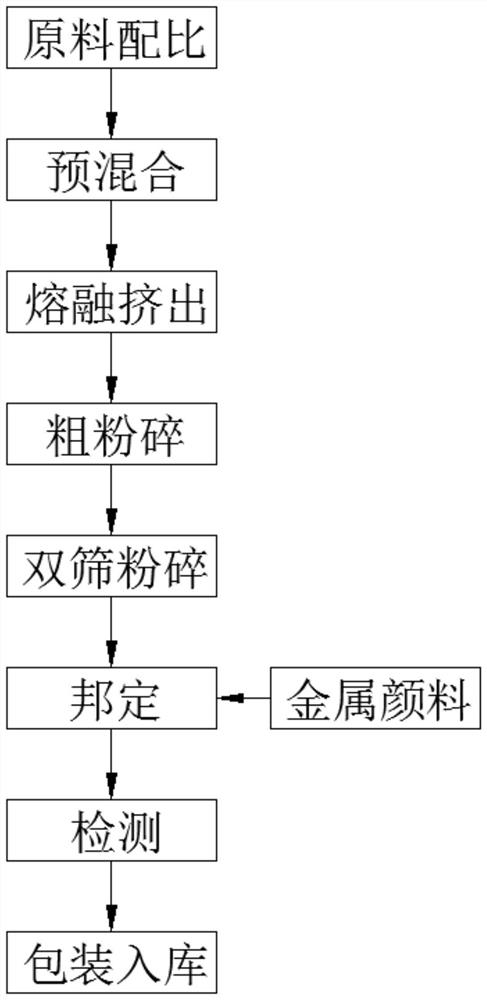

Novel high-grade powder coating and preparation method thereof

InactiveCN111635691AHigh impact strengthAcid resistantPowdery paintsGrain treatmentsCoated surfaceWeather resistance

The invention discloses a novel high-grade powder coating and a preparation method thereof. The problems that the existing powder coating is poor in impact strength and acid and alkali resistance, thelubricity of the powder coating cannot meet the use requirements, in addition, in the powder coating production process, the problem of oxidative decomposition of body resin is easily caused due to the problems of an agent discharging method, the quality of the powder coating is further influenced are solved. The matching of the powder coating and the synthesis method of the powder coating are improved and optimized, so the powder coating has high impact strength, strong acid resistance, alkali resistance, salt spray resistance and weather resistance, and flat and smooth coating surface, thecuring time can be shortened, the purposes of energy conservation, low carbon and environmental protection are achieved, and the use performance of the powder coating is improved; and matrix resin oxygenolysis can be avoided by adopting a deep thread low-temperature extrusion method in the production process of the powder coating. Double-screening fine grinding is adopted to guarantee that matrixresin particles are small and uniform, so thin coating can be conducted, and the coating effect is better.

Owner:ANHUI MEIJIA NEW MATERIAL

Low-carbon environment-friendly material for injection moulding

The invention discloses a low-carbon environment-friendly material for injection moulding. The low-carbon environment-friendly material is prepared from the following raw materials in percentage by weight: 20%-45% of polypropylene, 53%-70% of wood powder (or bamboo powder), 0.2%-2.0% of lubricating agents, 11%-30% of silane coupling agents, 0.5-3% of preservative agents, 1%-3% of antioxidants, 0.1%-2.0% of antibacterial agents, 0.1%-15% of abrasion-resistant agents, 0.1%-8.0% of coupling agents, 1.0%-5.0% of moisture absorbents, 0.1%-2.0% of antistatic agents and 0.1%-5.5% of other auxiliary agents. The low-carbon environment-friendly material disclosed by the invention can be subjected to color blending as required, is mildewproof and antibacterial, can prevent the dust from being electrostatically adsorbed, adopts renewable recycling raw materials, is low in cost and easy and convenient to process, facilitates batch production and popularization, accords with low-carbon, economic, green and environment-friendly characteristics and has very good significance through substitution for plastic raw materials and woods.

Owner:QINGDAO JUNZE SHENGTAI INTELLIGENT TECH

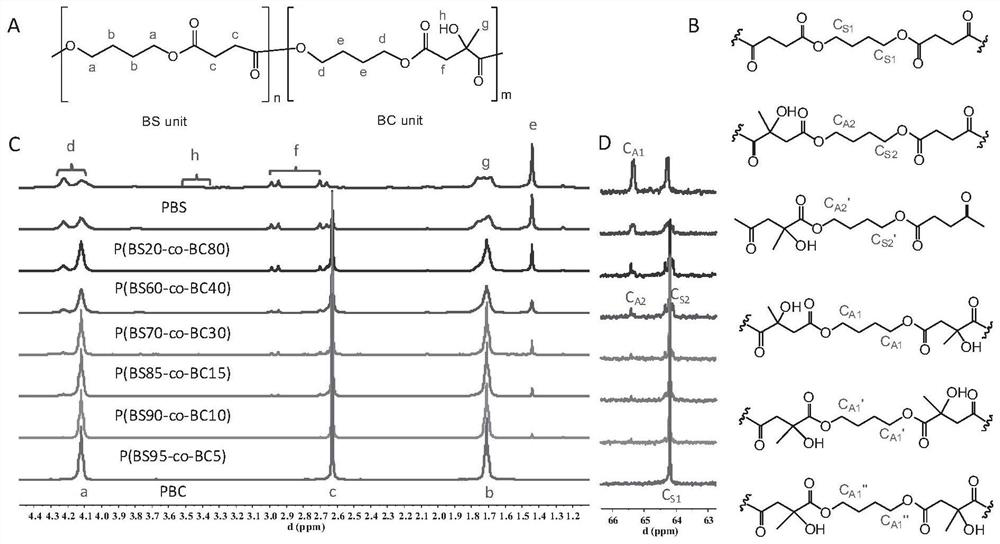

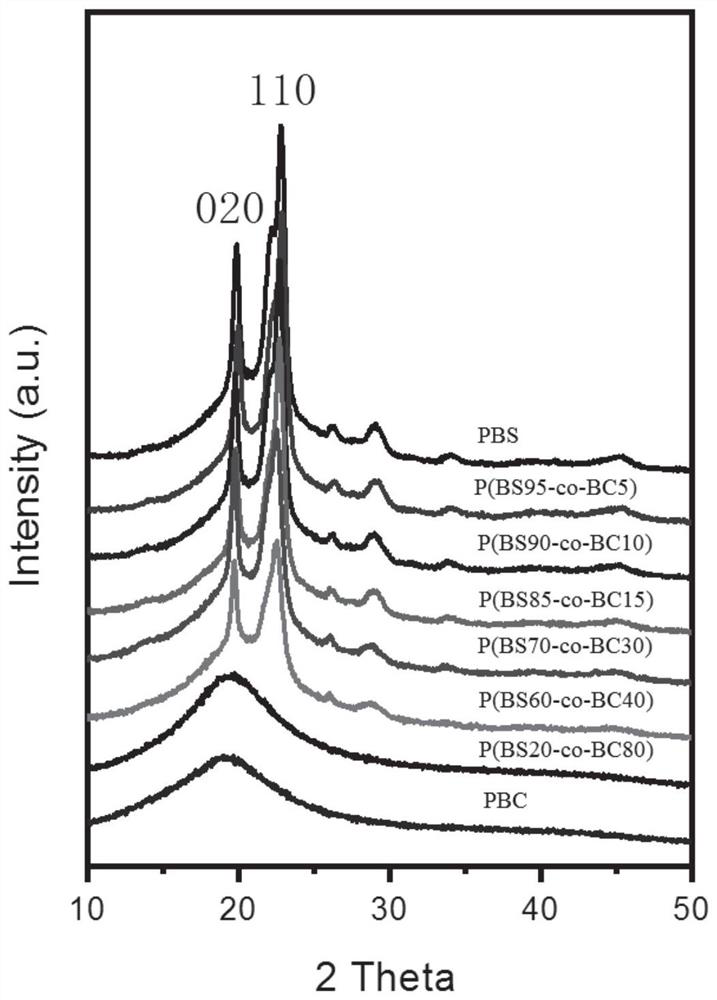

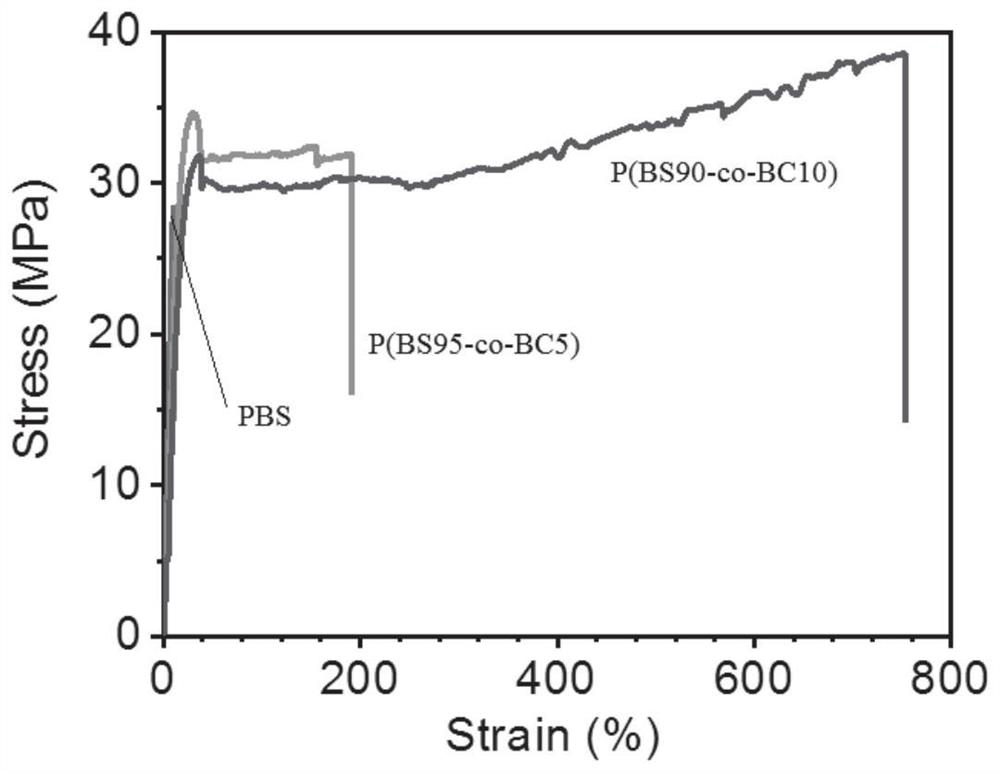

Copolyester and preparation method thereof

The invention relates to citramalic acid-based polyester and a preparation method thereof, in particular to a method for obtaining copolyester with excellent performance through polycondensation of dicarboxylic acid compounds citramalic acid, succinic acid and saturated straight-chain dihydroxy compounds such as butanediol. The copolyester is synthesized under the conditions that the melt polycondensation temperature is 180-230 DEG C, the polycondensation time is 0.5-5 hours and the polycondensation vacuum degree is 100-2000 Pa. Compared with polybutylene succinate (PBS) without citramalic acid, the synthesized polyester has excellent properties such as high toughness, high barrier property and rapid degradability, and has the remarkable advantages of good practicability, good application prospect and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Plastic ceiling lamp base

InactiveCN104075282AReduce manufacturing costBeautiful and chicLighting support devicesLight fasteningsEngineeringInjection moulding

The invention discloses a plastic ceiling lamp base which is closely matched with a transparent decorative cover to form an integral energy-saving ceiling lamp casing, is prepared by injection moulding by adopting PP plastic, and is characterized in that a high point at the radial outer part of the lamp base and the bottom face of the lamp base form an arc surface; a cavity is manufactured in the middle of the lamp base; a screw hole and a positioning hole are manufactured in the cavity; three equally-divided notches are manufactured at the junction part of the arc surface and the cavity, and are matched with a salient pole of the decorative lamp cover; pins of a 2D tube can be fixed in the screw hole inside the cavity; the positioning hole can be used for fixing the lamp seat of a ring-shaped pipe and LED decorative lamp reflectors.

Owner:任金瑞

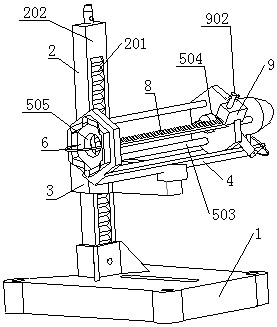

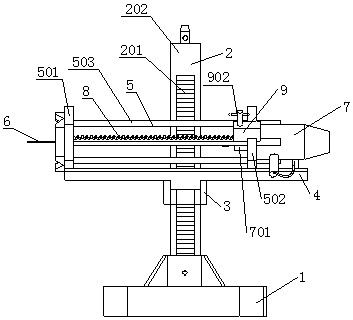

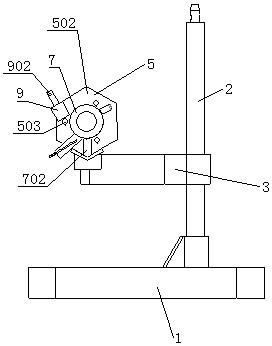

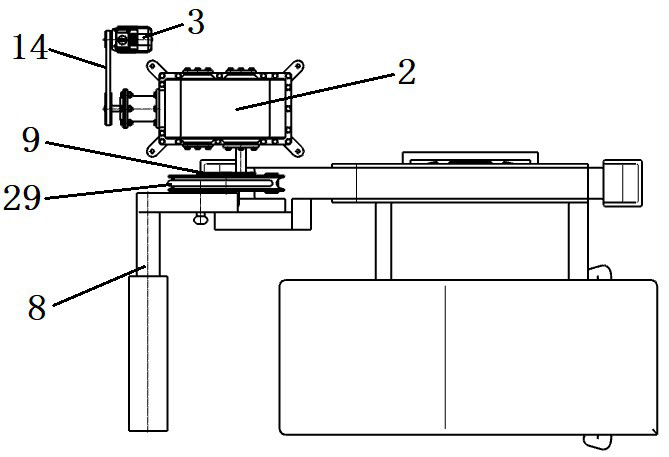

Transverse drilling mechanical device for vertical columns of corrugated beam steel guardrail

ActiveCN111644653AExcellent StraightnessAvoid wastingLarge fixed membersBoring/drilling machinesClassical mechanicsStructural engineering

The invention provides a transverse drilling mechanical device for vertical columns of a corrugated beam steel guardrail. The transverse drilling mechanical device comprises a base, a lifting platformis fixedly connected to the base and connected with a longitudinal pipeline lift which can move up and down on the lifting platform, a transverse V-shaped support is fixedly connected to the longitudinal pipeline lift, a guiding frame is fixedly connected to the support and comprises a fixed disc and a movable disc, a drilling machine is fixedly connected to the movable disc, a second through hole is formed in the movable disc, the drilling machine penetrates through the second through hole to be fixedly connected with the movable disc, the end with a chuck of the drilling machine faces the fixed disc, and the center of the chuck and the center of a first through hole are located on the same straight line. The transverse drilling mechanical device can drill the constructed usable guardrail directly without dismantling the guardrail for machining, and it can be ensured that the line shape and straightness of the drilled guardrail reach optimal.

Owner:SHANDONG LUZHIFENG

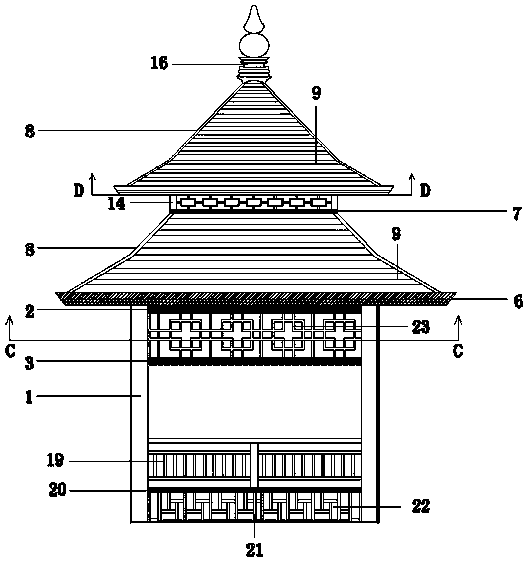

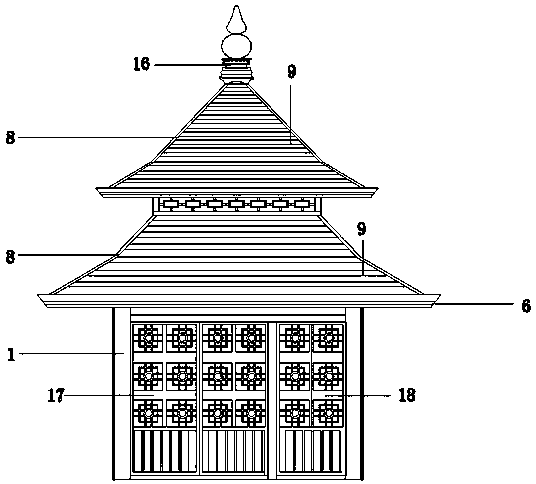

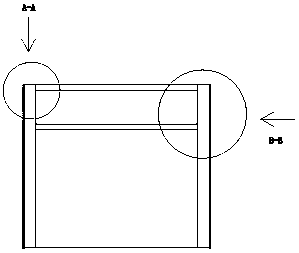

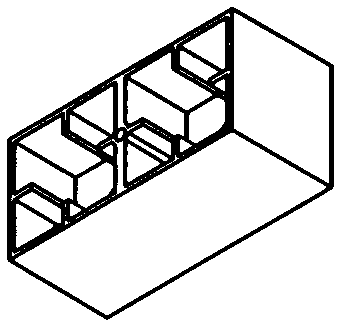

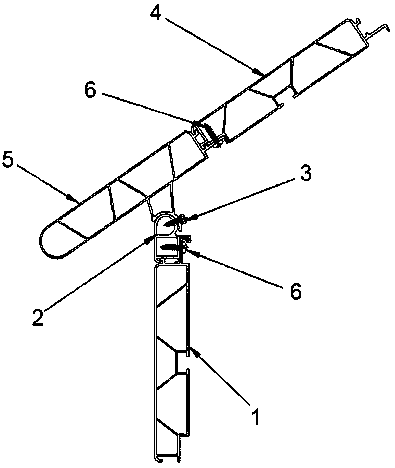

Dual-stage-ceiling Chinese style structure framework room prepared from aluminum profile

PendingCN109057007ATo satisfy the market's needsConform to energy savingBuilding constructionsEnvironmental resistanceDual stage

The invention provides a dual-stage-ceiling Chinese style structure framework room prepared from an aluminum profile, and relates to the technical field of building construction. The framework room comprises a frame supporting mechanism, a first-stage ceiling mechanism, a second-stage ceiling mechanism, a frame door mechanism and an antiquing window mechanism. Through structural optimization, theredundant modificability of a traditional wood structure connecting mechanism is removed, and the industrial squeeze-forming and manufacturing is better facilitated; light-weight design is implemented, and raw materials are saved on the premise of ensuring the connecting strength; by means of the characteristic that the aluminum alloy profile can be infinitely lengthened when machined, the preparation of assembling units with any length or height can be realized, the defect that a traditional wood structure building is greatly limited by materials is eliminated, the traditional dual-layer-ceiling structure assembly room is finally prepared from the aluminum profile, the antiquing degree is high, the ancient building market requirements are met, and the regulations on energy conservation, environment protection, low carbon emission and carbon emission reduction of building projects in China are met.

Owner:YUNNAN YUXI HONGTA ALUMINUM FACTORY

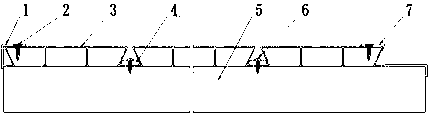

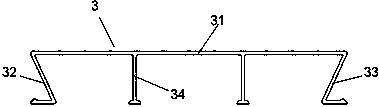

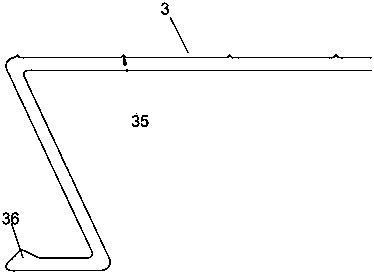

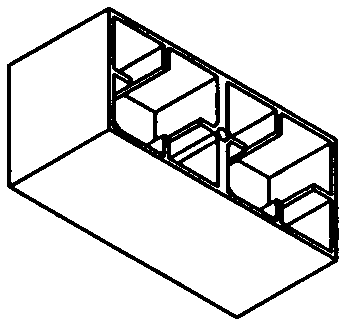

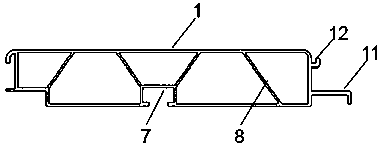

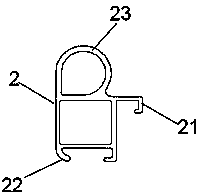

Hydrophobic aluminum alloy floor structure

The invention relates to a hydrophobic aluminum alloy floor structure. The hydrophobic aluminum alloy floor structure includes a plurality of hydrophobic aluminum alloy floor components, pressing blocks, edge sealing corner aluminum, and edge sealing aluminum folding plates; each hydrophobic aluminum alloy floor component is composed of a flat plate strip, a left inner inclined bracket and a right inner inclined bracket which are arranged at the left end and right end of the flat plate strip, and a plurality of support feet arranged on the bottom surface of the flat plate stripe; both sides of the pressing blocks are pressing block inclined sides, screw positioning concave points are arranged in the middle of pressing block planes, and pressing block fixing grooves are formed in both sides of the bottom surfaces of the pressing blocks; and the pressing blocks are installed between every two mutually connected hydrophobic aluminum alloy floor components, the pressing blocks are fixed to a frame cross beam or the concrete ground through round head self-turning and tapping screws, edge sealing corner aluminum is installed at one ends of the hydrophobic aluminum alloy floor components, and fastened through countersunk head self-turning and tapping screws, the other ends of the hydrophobic aluminum alloy floor components are provided with the edge sealing aluminum folding plates, and when a platform is made, the whole structure has high bearing capacity, compression resistance is high, firmness and durability are provided, and water resistance, fire protection and safety characteristics are achieved.

Owner:ALUHOUSE TECHGD CO LTD

Multifunctional building material and preparation method thereof

The invention relates to the technical field of building materials, in particular to a multifunctional building material and a preparation method thereof. The multifunctional building material provided by the invention comprises, by mass, 10-50% of an inorganic gel material, 20-60% of a lightweight porous material, 1-10% of inorganic powder, 1-5% of an olefin polymer, 3-10% of an ethylene-vinyl acetate copolymer, 5-35% of a polymer binder and 0.1-1.5% of a release agent. The prepared multifunctional building material has good heat resistance and mechanical strength at high temperature; the weight of the material per unit volume is further reduced while the mechanical strength of the building material is not affected; and the multifunctional building material further has good waterproof performance and heat preservation and heat insulation performance, and is an energy-saving, low-carbon and environment-friendly multifunctional building material.

Owner:深圳田十科技有限公司

Building block type wood-plastic brick

The invention provides a building block type wood-plastic brick. The building block type wood-plastic brick is composed of a brick body, upper protrusions disposed at the upper surface of the brick body; lower grooves disposed inside the lower surface of the brick body and fixing structures distributed around the lower grooves. The depth of the lower grooves is not less than that of the upper protrusions. The shapes of the lower grooves are corresponding to those of the upper protrusions. The lower grooves and the upper protrusions can be engaged together through the fixing structures. The problems of environment pollution, inconvenience for use and the like in a conventional technology are overcome, and the building block type wood-plastic brick which is convenient for use and has high cost performance is provided.

Owner:苏州工业园区科创橡塑有限公司

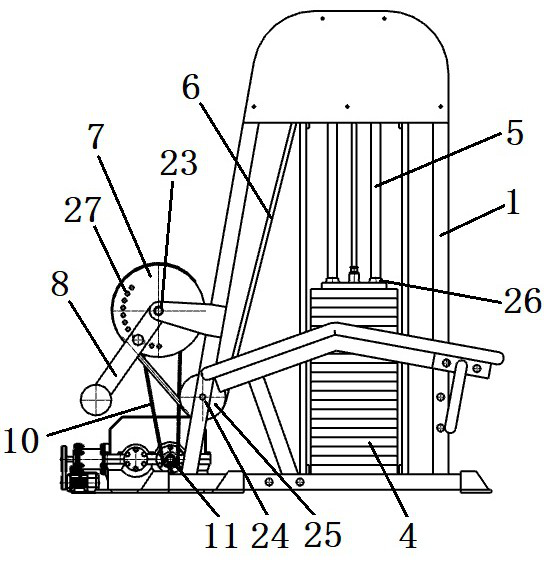

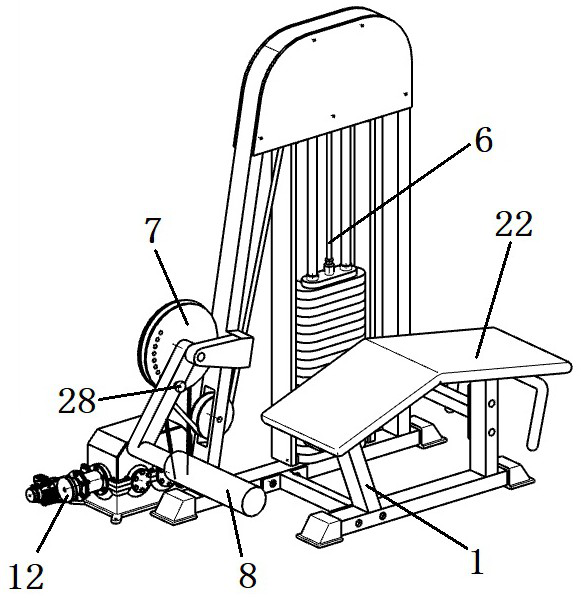

Self-power-generation sitting type leg bending trainer device

PendingCN113856137ALow carbonProtect the environmentFrom muscle energyMachines/enginesPhysical medicine and rehabilitationEngineering

A self-power-generation sitting type leg bending trainer device comprises a rack, a power input device, a transmission device and a power generation device, and the power input device comprises an adjusting disc, a power arm, a rope and a balance weight; the power generation device is a generator based on the law of electromagnetic induction; the power input device is installed on the rack, power is input by manpower through the power arm, the power is converted into gravitational potential energy of the balance weight, and when the manpower stops inputting the power, the gravitational potential energy released by return of the balance weight passes through the transmission device and reaches the power generation device to generate electric power. The self-power-generation sitting type leg bending trainer device not only can be used for body building, but also can be used for converting physical energy of a human body into electric energy; and the self-power-generation sitting type leg bending trainer device has the advantages of being accurate in transmission, low in noise, low in vibration and the like, can be installed on occasions such as gymnasiums and rehabilitation centers, and is effective equipment for people to practice energy-saving and environment-friendly concepts and exercise and fitness.

Owner:SHANDONG JIAOTONG UNIV

Angle adjustment-free connection structure for aluminum roof panels and aluminum wall boards

PendingCN109025021AImprove bending abilityImprove torsion resistanceBuilding roofsFree rotationEngineering

Owner:ALUHOUSE TECHGD CO LTD

Copper-intermediate silver contact for relay

The invention discloses a copper-intermediate silver contact for a relay, and the contact provided by the invention consists of contacts, tail ends and intermediates, wherein the contacts and the tail ends are made of a silver material; and the intermediates are made of a copper material. The copper-intermediate silver contact for the relay disclosed by the invention has the characteristics of low cost, saved precious metal and the like while maintaining the original characteristics of high conductivity, low resistance, good contact and efficient conductance, thereby according with the requirements of low carbon, high efficiency and sustainable development to an industrial product nowadays.

Owner:SANYOU CORP LTD

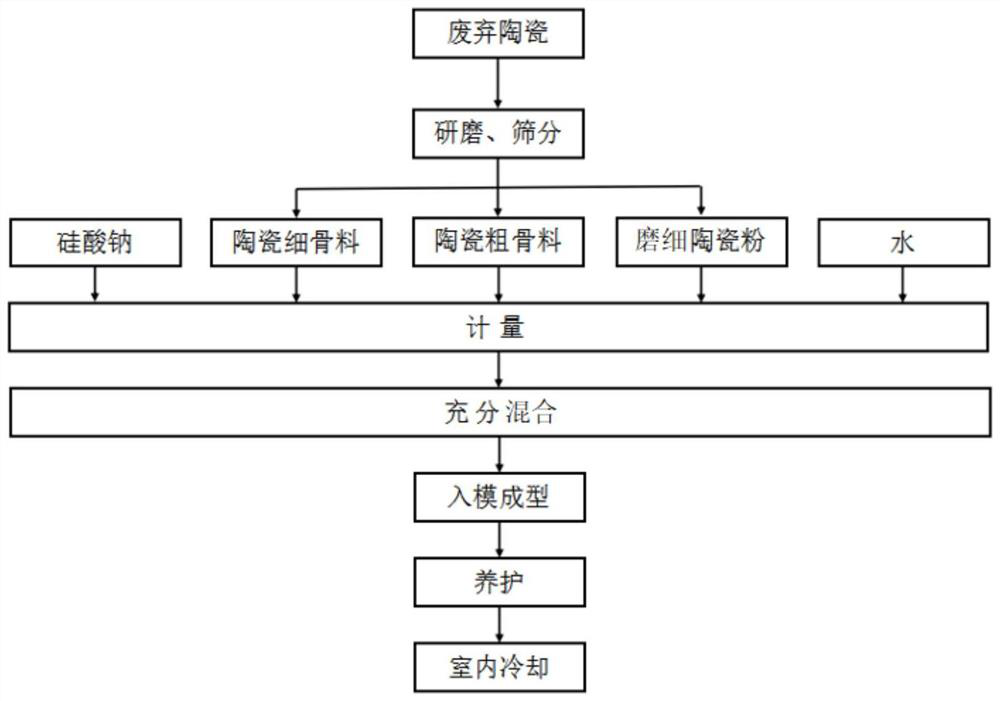

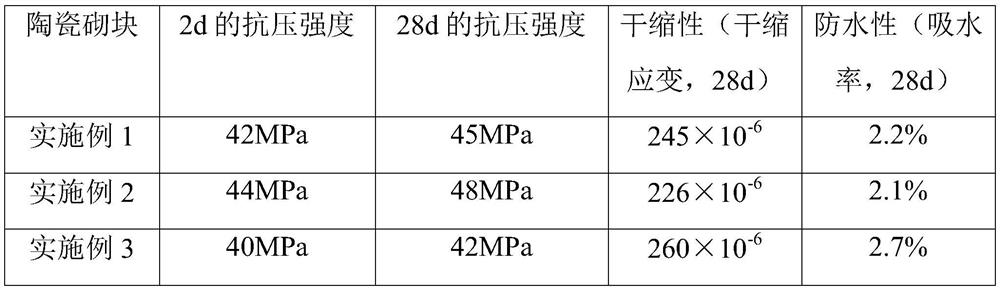

Ceramic building block and preparation method thereof

The invention relates to the technical field of building materials, and particularly discloses a ceramic building block and a preparation method thereof. The ceramic building block comprises the following components in parts by mass: 45-65 parts of ceramic coarse aggregate, 45-58 parts of ceramic fine aggregate, 20-25 parts of ground ceramic powder, 20-25 parts of sodium silicate and 8-12 parts of water. According to the ceramic building block provided by the invention, ceramic is used as a main raw material, under the condition that traditional components such as cement, sand and lime are not added, only three ceramic raw materials with different particle sizes and proportions are compatible, and a conventional curing process is performed under the action of sodium silicate, so that relatively high use strength can be achieved, and addition of cement is omitted; and the manufacturing cost of the building block is effectively reduced.

Owner:CHINA ACAD OF BUILDING RES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com